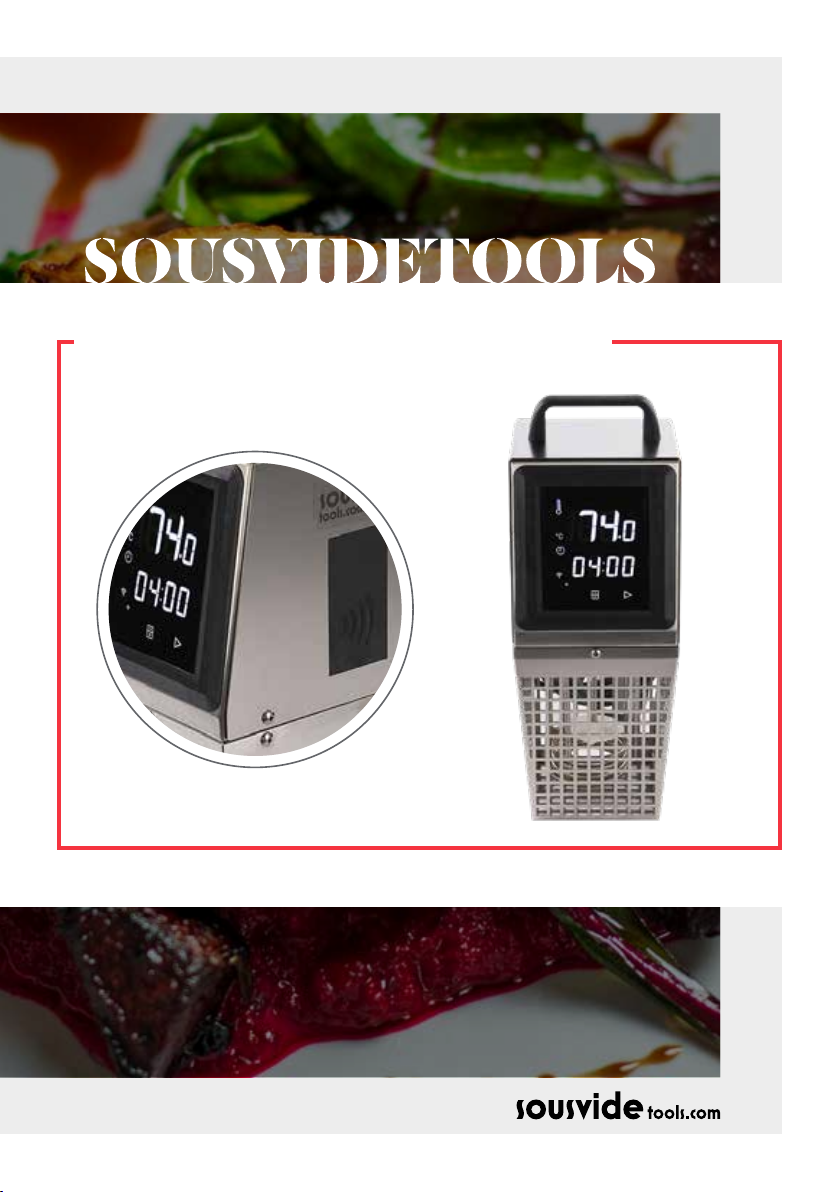

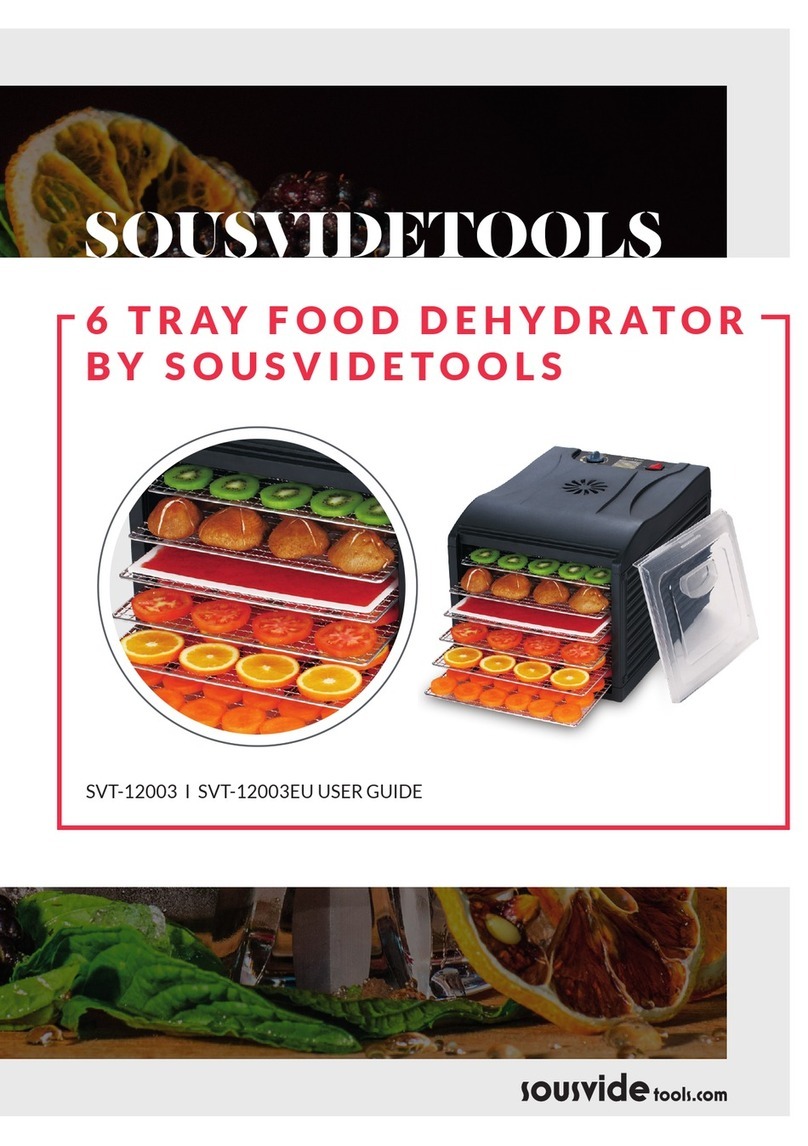

SousVideTools SVT-01008 User manual

PLATINUM 2.0 THERMAL

CIRCULATOR

SVT-01008 I SVT-01008EU USER GUIDE

2

IMPORTANT - READ BEFORE USE

Please read this user manual carefully before using the appliance.

GENERAL PRECAUTIONS

SAFETY EQUIPMENT

• The SousVideTools®Platinum 2.0 Thermal Circulator may be used only by trained staff familiar with the

safety information given in this manual.

• New staff must be trained in the use of the machine before using it.

• Do not touch the machine's heating equipment.

• Before cleaning or servicing the machine, disconnect it from its power supply.

• The residual risks must be assessed when servicing or cleaning the machine with the guards removed.

• When servicing or cleaning the machine, concentrate on the job in hand.

• Periodically check the condition of the power cable; damaged or worn power cables pose a serious

electrical hazard.

• If the machine is malfunctioning, do not use it; contact the Service Centre immediately.

• Never tamper with the machine in any way. Contact the manufacturer if you encounter any anomalies.

• Attempting to disassemble, modify or tamper with any part of the machine by the user or unauthorised

persons immediately void the Declaration of Conformity pursuant to Directive EEC 2006/42, voids the

warranty and relieves the manufacturer of any liability for the consequences of such action.

• The manufacturer is also relieved of all liability for the consequences of:

- improper use or tampering with the machine by improperly trained staff;

- lack of or negligent maintenance;

-useofnon-originalsparepartswhicharenotspeciedforthemodel;

- total or partial failure to follow the instructions given in this manual;

- treating the machine's surfaces with improper products.

The mechanical and electrical safety equipment is conforming with Directives 2014/35, 2006/42. The

SousVideTools®Platinum 2.0 Thermal Circulator is therefore equipped with electrical and mechanical safety

equipment both when operating and when being cleaned or serviced. There are still “RESIDUAL RISKS” which

cannot be completely eliminated, which are highlighted in this manual by the wording “CAUTION“; they are

related to the risks of burning or contusion when loading and unloading the product, and when handling or

cleaning the machine.

3

GENERAL DESCRIPTION

The SousVideTools®Platinum2.0ThermalCirculatorisdesignedandfabricatedspecicallytoguaranteethat:

• all its parts are stable and robustly constructed;

• it is easy to handle with its integral handle, which makes it easy to move and transport;

• the heating is temperature regulated to high precision;

• the impeller ensures excellent mixing of the temperature for loads up to 43L;

• the working temperature is 24 to 99.9 °C / 75.2 - 199.9 °F, with a precision of +/- 0.1.

CONSTRUCTION

The SousVideTools®Platinum 2.0 Thermal Circulator is made in anodized aluminium, to ensure a stable

structure, and also has:

• A large 5” touch screen display, rated IP 67;

• A heating element consisting of two armoured resistances;

• ABS plastic or AISI 304 stainless steel sides;

• A device to shut down the motor when overcurrent or overheating are detected.

INTENDED USE

The SousVideTools®Platinum 2.0 Thermal Circulator is designed for indirectly cooking food packed under

vacuum in bags and immersed in water at a controller temperature (vacuum-packed food). It does not cook

food in any other way or heat liquids other than water. Use the Platinum 2.0 only with the appropriate

Gastronorm tanks equipped with a cover.

If used with other containers, close the container with a suitably shaped cover so as to limit water vapour from

being released into the environment and towards the machine itself.

IMPROPER USE

The SousVideTools®Platinum 2.0 Thermal Circulator has not been designed for cooking food directly, for

growingbacterialculturesorformedicalorscienticresearchingeneral,orforheatingortreatinganyuidin

any manner except for water.

• DO NOT use the machine unless it has been properly installed with all its protective equipment in good

working order and in place, to avoid the risk of damage and injury;

- DO NOT access the machine's electrical equipment;

- DO NOT start the machine if it is malfunctioning;

- DO NOT allow unauthorised persons to work on the machine.

Emergencyresponsetoinjurybyelectricshockconsistsrstofallinbreakingtheinjuredperson'scontactwith

the live equipment (because he has usually lost consciousness). This is highly hazardous. The injured person

is himself an electrical conductor; touching him directly can incur electric shock. It is better to disconnect the

power line contactor, or if this is not possible, move the injured person away with non-conductive material (a

wooden or PVC stick, fabric, leather, etc.). Contact medical staff immediately.

4

TECHNICAL DATA

Citing the "Model", "Serial number" and "year of Manufacture" of the

machine facilitates our technical service in responding to your requests.

A = Product code and name

B = Power supply

C = International Protection

D = Motor frequency

E = Weight

F = Amperage

G = Serial number

H = Manufacturer

PROTECTIVE & SAFETY EQUIPMENT

Before using the machine, make sure it and its safety equipment are properly positioned and in good working order.

Check that everything is present and correct at the start of each shift.

If anything is lacking, report it to the maintenance supervisor.

• Heating element guard (ref. 5 g. 2): prevents contact with the heating element and with the impeller,

which can seriously injure the user.

• Automatic run dry protection (ref. 6 g. 2):ifthelevelofwaterfallsbelowthepermittedminimum(g.5)

the machine stops operating and an error message displays (H2O Low).

• Shut down device (ref. 7 and 12 g. 2): should the temperature sensors reading not agree, due to a fault in

either of them, the machine is shut down and error message displays (PROB).

STRUCTURE OF THE MACHINE

1 Handle

2 Master power switch ON-OFF

3 Fuses

4 Touch screen display with controls

5 Heating element guard

6 Level sensor

7 NTC1 temperature sensor

8 Heating element

9 Impeller

10 Power cable

11 Machine locking knob

12 NTC2 safety sensor

13 NFC reader (only for NFC version)

14 Wireless core probe (optional)

5

TECHNICAL DATA

Fig. no. 3 - Dimensions and clearances

Model Units SVT-01008

Power watt 2000

Power supply 230V/50Hz

Temperature °C / °F 2 4÷99,9 °C / 75,2÷199,9 °F

A x B mm 118 x 120

C x D mm 152 x 176

F / G mm 382 / 215

Max level E mm 151

Min level L mm 52

Noise dB 58

Net weight kg 5

The machine's electrical specications are marked on its name plate, mounted to the rear of the

machine itself; before hooking the machine up electrically, refer to the section “electrical hookup.”

6

DISPOSING OF PACKAGING

The packaging materials (cardboard box, plastic strap and polyurethane foam) can be disposed of as normal

domesticwaste;thereisnodifcultyindisposingofthem.Ifthemachineisinstalledinacountryinwhich

special regulations apply, dispose of the material in a regulatory manner.

ELECTRICAL HOOKUP

The machine has a power cable (3x1.5 mm² x 2.5 m) and a 16A Shuko plug. Connect the 230 V 50 Hz machine

byinstallinga10AΔI=0.03Aresidual-currentdeviceontheline.Alsocheckthattheinformationonthe

machine'snameplatematchthespecicationsgiveninthedeliveryandshippingdocuments,andthatboththe

master switch and cable are easily accessible while the machine is in use.

INSTALLATION

POSITIONING

The SousVideTools®Platinum 2.0 Thermal Circulator has been designed to be used with normal cooking tanks

(1/1or2/1H.200,asshowning.5),andingeneralwithtanksofcapacityupto43litresandamaximum

depth of 200mm.

ThePlatinum2.0mustbesupportedbyaspecialprolemember(ref.1g.5)ontheedgeofthetank,and

securedwiththeknob(ref.2g.5).

Fillthetankwithwater,takingcaretoobservethemaximumandminimumlevelmarkings.Ifthetankislled

to below its minimum level, the Platinum's level sensor will prevent it from starting, the machine will emit

beeps and an error message (H2o Low) will appear on the display.

Follow the instructions to the letter and do not exceed the maximum level marked on the side of

the machine (g 5); avoid splashing when lling the tank or loading it with the bags.

Fig. no 5

7

Fig. no 6

WIRING DIAGRAM

USING THE MACHINE

Itisgoodpracticetorstloadthebagscontainingtheproducttobecookedandonlythencompletellingof

the tank with water, so as to avoid exceeding the maximum allowed level.

Fill the water to no more than the maximum level, and add some vinegar to prevent scale and deposits building

up, to the amount of 1/2 cup per 40 litres of water.

Change the water in the tank at least once a day to prevent deposits, algae etc. forming inside it. The bags must

be completely immersed in the water.

Thebagsshouldnotoccupymorethan30%ofthetank'scapacity,toensurethereissufcientwatertodeliver

heat uniformly to the product. Take care that the bags do not prevent proper circulation of the water and

hence even cooking.

Always use the cooking lid.

Check the water level regularly, since it can evaporate very quickly. If the water falls below the minimum level,

the machine will emit a few beeps and an error message (H2o low) will appear on the display.

Once the cycle has completed, turn the machine off with the STOP button on the display.

Set the master switch (on the side of the machine) to OFF, pull the plug out of the power socket, remove the

machine from the tank, dry it and empty the tank, otherwise the machine will emit a few beeps and an error

message (Rem H2o) will appear on the display.

8

CONTROLS

TOUCH SCREEN DISPLAY: displays the temperature

in °C / °F, the time, the 10 preset programs and

whether the heating element is on or not. All these

values can be edited on the display itself.

START button: hold down for 3 seconds to

startthecookingcycle.Thebuttonashes

during the cycle.

STOP button: hold down for 3 seconds to stop

the cooking cycle.

UP (+) buttons: they are used to set the

temperature and cooking time values, in

addition to the stand-by time.

PROGRAM / CONFIRM button: pressing this

button displays the list of programs, pressing it

repeatedly displays the programs one at a time.

CAUTION:thisbuttonisalsousedtoconrm

changes to the time and/or temperature settings

both within a programme and manually, by

pressing and holding it for 3 seconds.

TEMPERATURE button: press this button

to access the temperature setting and

conrm/quitsettingmode.Duringthe

cycle, pressing this button displays the

temperature setting.

°C / °F button: press one of the 2 buttons to

switch between Celsius and Fahrenheit.

Fig. no 7

TIME button: press this button to set the

cooking program time; during the cycle, it

displays the time remaining to completion.

Whenthemachineisrststartedupor

is in stand-by mode, press it to adjust the

time using the arrows that appear above

the hours, minutes and seconds. Press the

buttonagaintoconrmthesetting.

HEATING ELEMENT led: the led turns

on when a cooking cycle is in progress to

indicate that the heating element is on and

heating the water. When the temperature

setpoint is reached, the led and the heating

element itself both turn off, and then turn

on when required to maintain the water

temperature.

PROGRAM led: the led (dot on the screen)

turns on to indicate that one of the ten

programs is being displayed or is in use for

cooking. If none of the dots on the screen is

on, no program is displayed.

9

PROGRAM TYPES

To access the touch-screen display function, check that the master switch is set to ON, that the desired unit of

measurementforthetemperaturehasbeenset(°Celsiusor°Fahrenheit),andmakesurethatyouhavelledor

added water to the tank up to the maximum level indicated on the sides of the machine.

The Platinum 2.0 operates in two modes:

1manual cooking, with the cooking temperature and time set manually;

2automatic cooking, using one of the ten preset programs.

MANUAL COOKING

In this case, no stored program is in use (no dot on), and the temperature and time must be set manually. Press

the TEMPERATURE button and then use the UP button located above the 3 temperature digits to set the

desiredtemperature;nowpressthePROGRAMMES/CONFIRMbuttontoconrmthesetting.

Subsequently,presstheTIMEbuttontosetthedurationofthecycleandconrmitwiththePROGRAMMES/

CONFIRM button; the cycle will start as soon as the Platinum 2.0 emits a buzzer to signal that the set

temperature has been reached.

You can stop the cycle at any time with the STOP button.

at the end of any cooking process or as soon as the machine is immersed in water, the impeller (ref.

9 Fig. 2) will start working. This condition is entirely normal and only occurs at temperatures >30°C.

AUTOMATIC COOKING

In this case, one of the ten programs has been selected. To display these programs, press PROGRAM and then

use the button to display all the stored cooking cycles. To select one of the programs, press START to run it.

If none of the programs is suitable, you can edit and save an existing program.

Within one of the ten memorised programmes, press the TEMPERATURE button, set the temperature with the

UPbuttonsandconrmitwiththePROGRAMMES/CONFIRMbutton;next,presstheTIMEbuttonanduse

theUPbuttonstochoosethedesiredvaluethenconrmwiththePROGRAMMES/CONFIRMbutton.

The edited program has now been saved and can be used for cooking.

Once the machine has reached the water temperature setpoint, and at the end of each cooking cycle, the

machine emits a beep.

For the NFC model: move the bag with the core probe (ref. 14 Fig. 2) close to the NFC reader located on the

side of the machine ref. 13 Fig. 2. At this point, the display will show some lines and “NFC” to signal that the

machine is communicating with the core probe. Wait 5–6 seconds for the core temperature reading and the

display will then show the measured temperature. Put the bag back into the tank.

once cooking terminates, take the machine out of the tank, otherwise it will emit beeps and show

an error message (Rem H2o) on the display as a reminder.

10

POSSIBLE ERRORS

The Platinum 2.0 can display the following error codes:

H2O Low: the alarm signals that the level of the water in the tank is too low. The machine will emit a buzzer.

TO RESET IT, ADD WATER INTO THE TANK;

POW: the alarm will signal that cooking has been interrupted due to a loss of voltage for more than 2 hours.

The machine will emit a buzzer. TO RESET IT, SWITCH THE MACHINE OFF AND THEN ON AGAIN USING

THE ON/OFF BUTTON;

H2O PROB: the alarm will signal an anomaly in the NTC1 temperature sensor. The machine will emit a buzzer.

TO RESET IT, CONTACT THE SERVICE CENTRE AND REPLACE THE SENSOR;

MOT PROB: the alarm will signal an anomaly in the NTC1 or NTC2 temperature sensors or an overheating

condition. The machine will emit a buzzer. CONTACT THE SERVICE CENTRE TO REPLACE ONE OR BOTH OF

THE SENSORS;

REM H2O: the alarm will signal that the machine is not cooking and has been immersed in water for more than

1 minute. The machine will emit a buzzer. TO RESET IT, TAKE IT OUT OF THE WATER OR START A COOKING

CYCLE.

If the machine does not turn on, check the fuses next to the master switch on the left side of the machine.

CARING FOR THE HEATING ELEMENT

To protect the heating element and all parts immersed in water against scale, we advise adding 1/2 cup of

vinegar per 20/30 litres of water for each cooking cycle.

Change the water every day.

CLEANING

GENERAL INFORMATION

• Since the machine is not in contact with the food but only with the water, it does not require particular

cleaning. check that the machine is not blocked or soiled by broken cooking bags, or algae and other residue

due to degraded cooking water. If it is, contact the service centre.

• In case of need, the immersed part of the machine can be rinsed with water, while its top can be cleaned

with neutral detergent at room temperature, using a soft cloth.

• Do not use pressure cleaners or jets of water to clean the machine.

• Do not use tools, brushes or anything that may damage the machine's surfaces.

• Do not clean any part of the machine in a dishwasher.

• Do not insert brushes or tools into the machine's openings and slots.

Before cleaning the machine, pull its plug out of the power socket to isolate the machine

completely from the rest of the system.

11

SCRAPPING & DISPOSAL

MAINTENANCE

POWER CABLE

Check the condition of the cable regularly and call the SERVICE CENTRE if it needs replacing.

Before servicing the machine, pull its plug out of the power socket to isolate the machine

completely from the rest of the system.

DECOMMISSIONING

If you decide to put the machine out of service for any reason, make sure that it cannot be used by other

persons: disconnect and cut the electrical connections.

DISPOSAL

Once the machine has been decommissioned, it can be disposed of. This should be done by a waste

management company, and its materials sorted for disposal.

WEEE WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT

Directive 2002/95/EC, 2002/96/EC and 2003/108/EC on the restriction of the use of certain

hazardous substances in electrical and electronic equipment, and waste electrical and

electronic equipment .

This symbol, crossed out wheelie bin, on the product or on its packaging indicates that this product must not

be disposed of with your other household waste.

Separate waste collection of this appliance is organised and managed by the manufacturer. It is the user’s

responsibility to contact the manufacturer and follow the waste treatment system the manufacturer has

adopted for separate waste collection.

The separate collection and recycling of your waste equipment at the time of disposal will help to conserve

natural resources and ensure that it is recycled in a manner that protects human health and the environment.

Gastronomy Plus LTD

UK: Central Barn, Claughton Business Park,

Hornby Road, Claughton, Lancaster, LA2 9JX

0800 678 5001

01524 770 060

www.sousvidetools.com

EU: c/o ProductIP BV Authorized

Representative Dept. Galvanistraat 1,

6716 AE Ede, Netherlands

This manual suits for next models

1

Table of contents

Other SousVideTools Kitchen Appliance manuals

SousVideTools

SousVideTools IVIDE WIFI COOKER User manual

SousVideTools

SousVideTools Senses 300 User manual

SousVideTools

SousVideTools IV300 User manual

SousVideTools

SousVideTools IV250 User manual

SousVideTools

SousVideTools SVT-12003 User manual

SousVideTools

SousVideTools VS270-P User manual

SousVideTools

SousVideTools IVIDE CHAMBER User manual

SousVideTools

SousVideTools VS520-P User manual

SousVideTools

SousVideTools iVide Thermal Circulator Wifi User manual