Soyer BMK-8i User manual

Other manuals for BMK-8i

1

This manual suits for next models

3

Table of contents

Other Soyer Welding System manuals

Soyer

Soyer BMK-12 W User manual

Soyer

Soyer BMK-8 U User manual

Soyer

Soyer BMS-4 ACCU-DUO User manual

Soyer

Soyer BMS-8N User manual

Soyer

Soyer BMS-10P User manual

Soyer

Soyer BMS-9 ACCU User manual

Soyer

Soyer BMS-9 ACCU User manual

Soyer

Soyer HesoMatic-9 User manual

Soyer

Soyer BMK-8i User manual

Soyer

Soyer BMS-9 ACCU User manual

Soyer

Soyer BMS-6 User manual

Soyer

Soyer BMS-10N User manual

Soyer

Soyer SRM EcoWeld BMK-20i User manual

Soyer

Soyer UVR-300 User manual

Soyer

Soyer BMH-22i User manual

Soyer

Soyer BMK-16i User manual

Soyer

Soyer BMK-16i User manual

Soyer

Soyer BMK-16 W User manual

Soyer

Soyer BMS-4 Akkumat User manual

Soyer

Soyer BMH-30i User manual

Popular Welding System manuals by other brands

Miller Electric

Miller Electric CST 250 VRD International owner's manual

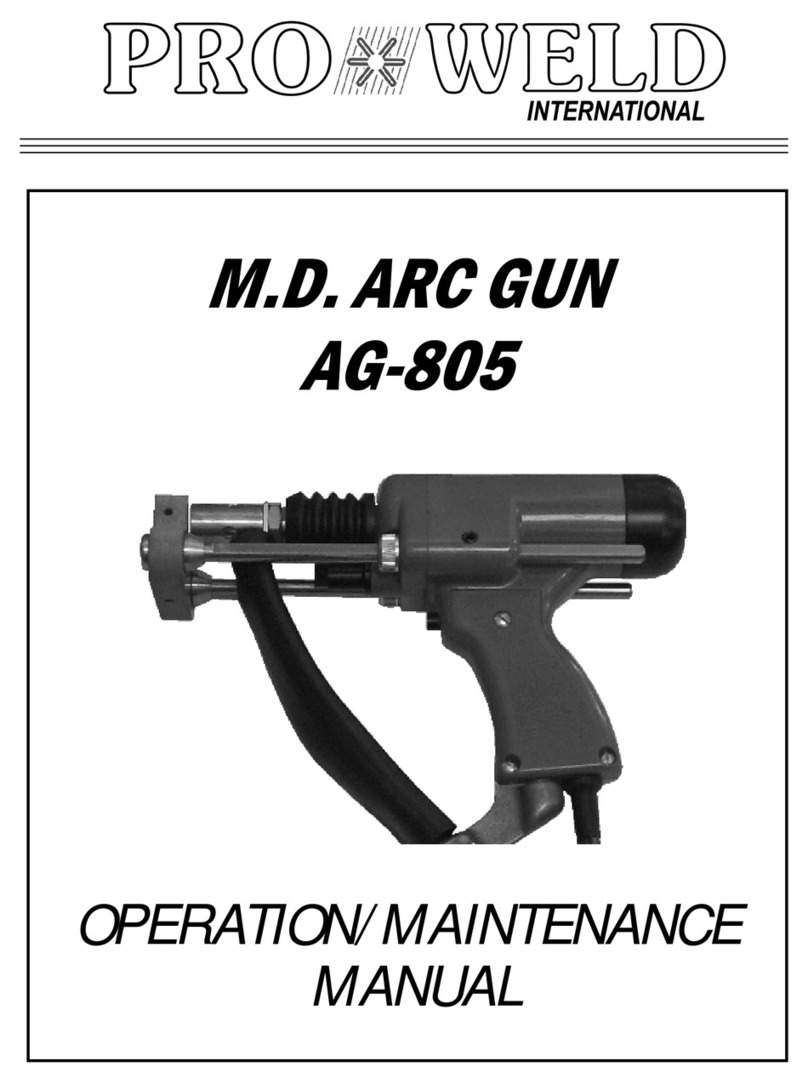

Pro-Weld

Pro-Weld AG-805 Operation and maintenance manual

Lincoln Electric

Lincoln Electric Cool Wave 20S Operator's manual

Hitachi

Hitachi W130 instruction manual

HURNER

HURNER CNC ECO 355 user manual

Powermat

Powermat PM-220L-IMGS user manual