BMK-16 W

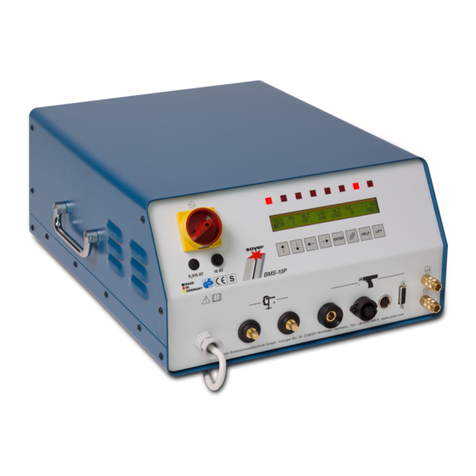

5.1.1 Operating elements...................................................................................................... 31

5.1.2 Display elements.......................................................................................................... 32

5.1.3 • LED display................................................................................................................ 33

5.1.4 Connecting elements ................................................................................................... 34

5.1.5 Symbols ....................................................................................................................... 35

5.1.6 Fuses (items 1 and 3, chapter 5.1) .............................................................................. 36

5.2 Preparation for start-up................................................................................................ 36

5.2.1 Earth connection .......................................................................................................... 36

5.2.2 Connection of stud welding gun................................................................................... 38

5.2.3 Gas supply ................................................................................................................... 38

5.2.4 Power supply ............................................................................................................... 38

5.3 Adjustment of operating modes................................................................................... 39

5.3.1 Starting the stud welder ............................................................................................... 39

5.3.2 Operating modes / parameters .................................................................................... 39

5.4 Special functions.......................................................................................................... 43

5.4.1 Special function "Erasing the working storage" ........................................................... 43

5.4.2 Special function " Display of operating counter".......................................................... 43

5.4.3 Special function "Setting the type of feeder and its functions". ................................... 44

5.4.4 Special function "Selection of language. Display of software version number"........... 45

5.4.5 Special function "Setting the feeder operation" ........................................................... 46

6Operation........................................................................................................... 47

6.1 Standard operation ...................................................................................................... 47

6.1.1 Setting welding parameters for standard welding operation........................................ 47

6.1.2 Welding parameters for welding operation .................................................................. 50

6.1.3 Minimum sheet thickness when welding with drawn arc operation ............................. 50

6.2 Welding operation with shielding gas .......................................................................... 51

6.2.1 Preparation of gas supply ............................................................................................ 51

6.2.2 Instructions for welding with shielding gas .................................................................. 52

6.3 Welding operation with ceramic ferrules...................................................................... 52

6.3.1 Instructions for welding with ceramic ferrules.............................................................. 53

6.4 Stopping the stud welder ............................................................................................. 53

7Quality control .................................................................................................. 54

7.1 General........................................................................................................................54

7.2 Demands on the company........................................................................................... 54

7.3 Test execution.............................................................................................................. 55

7.3.1 Production of samples ................................................................................................. 55

7.3.2 Visual inspection .......................................................................................................... 55

7.3.3 Bend test...................................................................................................................... 56

7.3.4 Tensile test................................................................................................................... 57

8Maintenance...................................................................................................... 58

8.1 Stud welder.................................................................................................................. 58

8.2 Cleaning.......................................................................................................................58

8.2.1 Detergents ................................................................................................................... 58

8.3 Replacement of components....................................................................................... 59

9Spare parts list for BMK-16 W......................................................................... 60

9.1 Spare parts for BMK-16 W........................................................................................... 60

10 Troubleshooting ............................................................................................... 61

10.1 Malfunctions................................................................................................................. 62

11 Transport and storage...................................................................................... 65

12 Terms of warranty............................................................................................. 65

13 List of standards and guidelines .................................................................... 66

10