Soyer SRM EcoWeld BMK-20i User manual

Operating Instructions

Stud Welding Device

BMK-20i

GB: English Version

Read these operating instructions before starting any work!

Doc.ID: P00265

Date of issue: 06.2021

www.soyer.com

Operating instructions BMK-20i | Soyer Bolzenschweißtechnik 3

Device numbers

We recommend entering your device numbers here so that they can be

accessed quickly if servicing is required.

Device

Type

Serial number

Stud welding device

BMK-20i

Stud welding gun

PH-3N SRM

Stud welding gun

PH-2L

Stud welding gun

PH-4L

Operating Instructions

Document no.: P00265, 06-2021, translation of the original German manual

(German: P00165)

All information contained in this document is the property of Heinz Soyer

Bolzenschweißtechnik GmbH.

Revision status

Document

created / modified

Editor

Date

Original

Created

MS/IS

June 08th, 2021

4 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

CONTENTS

1General information.............................................................................................................. 6

1.1 Validity of the operating instructions ...................................................................................... 6

1.2 Registered trademarks........................................................................................................... 6

1.3 Abbreviations and definitions................................................................................................. 7

1.4 Declaration of conformity ....................................................................................................... 7

1.5 Manufacturer.......................................................................................................................... 9

1.6 Instruction, training................................................................................................................. 9

1.7 Standards and directives........................................................................................................ 9

2Important safety instructions............................................................................................. 10

2.1 Warning signs used.............................................................................................................. 10

2.2 General safety instructions................................................................................................... 11

2.3 Safety instructions for the working method.......................................................................... 14

2.4 Personal protective equipment ............................................................................................ 15

2.5 Intended use of the stud welding device.............................................................................. 16

Incorrect use.................................................................................................................... 16

2.6 Intended use of the stud welding guns ................................................................................ 16

Incorrect use.................................................................................................................... 17

2.7 Requirements on the part of the operator............................................................................ 17

Prerequisites for personnel.............................................................................................. 17

3Transport.............................................................................................................................. 18

4Storage, shutdown.............................................................................................................. 18

5Disposal ............................................................................................................................... 18

6Description of the BMK-20i stud welding device............................................................. 19

6.1 Type designation.................................................................................................................. 19

6.2 Working method................................................................................................................... 19

Stud welding with SRM Technology®.............................................................................. 20

Drawn arc stud welding technology using inert gas ........................................................ 21

Drawn arc stud welding technology with ceramic ferrules............................................... 22

6.3 Overview of the controls and connecting elements ............................................................. 23

Display and setting area .................................................................................................. 25

6.4 Technical data of the BMK-20i stud welding device ............................................................ 26

6.5 Permitted welding guns........................................................................................................ 27

6.6 Cleaning the stud welding system ....................................................................................... 28

7Description of stud chuck.................................................................................................. 29

7.1 SRM®stud chuck ................................................................................................................. 29

Setting the SRM®stud chuck........................................................................................... 29

7.2 Drawn arc stud chucks......................................................................................................... 31

8Description of the PH-3N SRM stud welding gun............................................................ 32

8.1 Technical data of the PH-3N SRM stud welding gun........................................................... 33

8.2 Installing the SRM®stud chuck in the PH-3N SRM welding gun......................................... 34

8.3 Cleaning the welding gun..................................................................................................... 36

9Description of the PH-2L and PH-4L stud welding guns ................................................ 37

9.1 Description of the PH-2L stud welding gun.......................................................................... 37

Technical data of the PH-2L stud welding gun................................................................ 38

Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik 5

Adjusting the speed of immersion (damping) for PH-2L.................................................. 39

9.2 Description of the PH-4L stud welding gun.......................................................................... 40

Technical data of the PH-4L stud welding gun................................................................ 41

Adjusting the speed of immersion (damping) for PH-4L.................................................. 42

9.3 PH-2L and PH-4L stud welding guns with SRM Technology®............................................. 43

How to retrofit the PH-2L and PH-4L stud welding guns to SRM Technology®.............. 45

9.4 PH-2L and PH-4L stud welding guns with drawn arc & inert gas ........................................ 47

How to retrofit the PH-2L and PH-4L stud welding guns to drawn arc welding with inert gas

......................................................................................................................................... 48

9.5 PH-2L and PH-4L stud welding guns with drawn arc & ceramic ferrule.............................. 50

How to retrofit the PH-2L and PH-4L stud welding guns to drawn arc welding with ceramic

ferrule ......................................................................................................................................... 51

9.6 Cleaning the welding gun..................................................................................................... 54

10 Setup and connection......................................................................................................... 55

10.1 Requirements for the installation site................................................................................... 55

10.2 Connection of the stud welding device and the stud welding guns ..................................... 56

Mains connection......................................................................................................... 56

Connecting the earth cable ......................................................................................... 56

Connecting the stud welding gun ................................................................................ 57

Connecting the inert gas supply.................................................................................. 57

11 Settings ................................................................................................................................ 61

11.1 Setting welding parameters.................................................................................................. 61

Support tables for device settings ............................................................................... 62

Setting the welding current and the welding time........................................................ 64

Setting/deactivating the SRM®current........................................................................ 65

Setting the gas preflow time (gas test)........................................................................ 66

Setting the lift height (drop time) in the "Setup" mode ................................................ 67

12 Welding operation............................................................................................................... 69

12.1 Carrying out welding ............................................................................................................ 69

12.2 Notes on checking the quality of the weld............................................................................ 71

Visual inspection.......................................................................................................... 71

12.3 Switching off the device ....................................................................................................... 72

12.4 Welding defects and their causes........................................................................................ 73

13 Maintenance and repair...................................................................................................... 77

14 Service.................................................................................................................................. 77

15 Spare and conversion parts............................................................................................... 78

15.1 Spare and conversion parts for drawn arc welding with ceramic ferrules ........................... 78

16 Warranty conditions ........................................................................................................... 79

6 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

1 General information

These operating instructions contain important information and rules for the operation

of the devices. Keep the operating instructions in a readily accessible location close to

the devices.

The term 'Devices' in the operating instructions refers to the stud welding device and

the stud welding gun.

Carefully read the operating instructions and any other documents contained in the

technical documentation. Pay particular attention to the safety instructions which are

intended to help you recognise any possible residual risks and prevent hazards.

The drawings and diagrams in these operating instructions are for illustration purposes

and may vary slightly from the actual equipment.

The manufacturer reserves the right to make technical changes.

1.1 Validity of the operating instructions

These operating instructions apply to the following devices:

Stud welding device BMK-20i

Stud welding gun PH-3N SRM

PH-2L

PH-4L

1.2 Registered trademarks

The following terms in these instructions are used with registered trademarks:

SRM®:

SRM Technology®

SRM stands for magnetic field stud welding and refers to

welding or stud welding in a radially symmetrical magnetic

field.

SOYER®:

Developments/technologies of Soyer GmbH.

Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik 7

1.3 Abbreviations and definitions

Essential abbreviations or designations in this manual:

HZ-1 threaded studs: SOYER®universal weld studs with centring tip

MF threaded studs: SOYER®threaded studs with a reduced flange

diameter (MF stands for mini flange).

PT threaded stud Capacitor discharge welding studs with thread

IT tapped studs Capacitor discharge tapped studs

RD threaded studs Drawn arc welding studs with thread

1.4 Declaration of conformity

The devices are designed and constructed in accordance with the generally accepted

codes of practice.

Please note that significant changes to the device will cause the declaration of

conformity to become void.

Furthermore, the manufacturer's warranty may be rendered invalid.

8 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

Stud welding device

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

CE Declaration of Conformity

We herewith declare that the machine described in the following and the version available on the

market correspond in design and construction to the safety and health requirements of the listed

guidelines and standards. Any unauthorised modification to this machine automatically annuls this

declaration.

Designation of machine : Stud welding device

Machine type : BMK-20i

Machine no. : ______________________

Applicable EU directives : RoHS Directive (2011/65/EU)

Low Voltage Directive (2014/35/EU)

EMC Directive (2014/30/EU)

Applied harmonised : EN 60 974-1:2018 + A1:2019

standards, in particular EN 60 974-10:2016

Applied national standards : DGUV Regulation 1

Date : 01 February 2021

Producer’s signature : ____________________

Signer’s function : Managing Director

Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik 9

1.5 Manufacturer

The manufacturer of the devices is:

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

Phone: 0049-8153-885-0

Fax: 0049-8153-8030

Web: www.soyer.de, www.soyer.com

1.6 Instruction, training

SOYER®offers optional and individual instruction in the operation of the devices.

Moreover, SOYER®offers training for customer-specific use of the devices.

Information on the scope and costs of instruction and training can be obtained

from Soyer GmbH.

1.7 Standards and directives

The following standards, inter alia, must be observed for carrying out stud welding

work and for the qualification of personnel:

DIN EN ISO 14555 Welding - Arc stud welding of metallic materials

DIN EN ISO 14732 Welding personnel - Qualification testing of welding operators and

weld setters for mechanised and automatic welding of metallic materials

DIN EN IEC 60974-9 Arc welding equipment - Installation and use

Technical Bulletin DVS 0904 Instruction for practice - Arc stud welding

10 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

2 Important safety instructions

Read the following chapters carefully and follow the safety instructions. If you are

uncertain or if an instruction cannot be followed, please contact the manufacturer.

The devices have been constructed according to the generally accepted codes of

practice and in compliance with, and application of, the recognised safety requirements.

To achieve the greatest possible safety, it is essential that all of the safety instructions

in these operating instructions are heeded and followed.

2.1 Warning signs used

Warning signs are used in this document, depending on the potential danger of the

situation.

Safety and information symbols used in this manual

Imminent danger leading to severe injuries or death.

Potentially dangerous situation that may lead to severe

injuries or death.

Potentially dangerous situation that may lead to minor

injuries.

Without the warning triangle, this warning sign is also

used in the event of danger of material damage.

Additional information indicating danger from electric

current. The additional sign is used in conjunction with

a warning sign.

Additional sign indicating the danger of burns. The

additional sign is used in connection with a warning

sign.

Do not touch the surface or the housing: Risk of electric

shock.

Do not touch or open, danger to unauthorised persons.

Danger to persons with medical implants such as

pacemakers.

The information sign is not a warning sign. It indicates

important and useful information on the subject.

Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik 11

Safety instructions on the devices

As an additional warning of danger, warning labels can be found on the devices.

Warning labels are affixed by the manufacturer and must not be removed. If a warning

label is damaged and thus illegible, a new warning label must be affixed immediately.

Warning labels must be obtained from the manufacturer.

2.2 General safety instructions

Danger from electric current, general information

When working on live components, there is a danger to life from electric current.

Work on electric or electronic components may only be performed by trained

electrotechnical personnel in accordance with currently applicable

electrotechnical regulations.

Protective devices must not be manipulated or disabled. Protective devices

include, for example, housing and housing cover, fuses or power switches.

If protective devices have to be removed for maintenance work, the device

may only be switched on again when all protective devices are installed and

their functionality has been checked.

Starting the device with faulty protective devices is not permitted. Faulty

protective devices must be repaired or replaced immediately. Unintentional

operation by third parties must be prevented.

12 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

Danger from electric current during maintenance and repair

When working on live components, there is a danger to life from electric current.

Work on electric or electronic components must only be carried out by trained

electrotechnical personnel of Soyer Bolzenschweißtechnik.

Before performing any work on the stud welding device, the mains switch of

the device must be switched off and the mains plug of the stud welding

device must be disconnected.

Before performing any work on the stud welding gun, the supply cables to

the stud welding device must be disconnected.

If protective devices have to be removed for maintenance work, the device

must only be switched on again when all protective devices are installed and

their functionality has been checked.

Danger from magnetic fields

In the area surrounding the device, strong magnetic fields occur during the welding

process. These may influence medical auxiliary aids and can therefore result in

danger to life.

Persons with electrical medical aids (such as pacemakers) must keep away

from the devices.

The operating personnel must ensure that persons with medical aids keep

away from the devices.

Danger of explosion from an inappropriate installation site in explosive

atmospheres

The device is not designed for use in potentially explosive zones.

The device must not be installed and operated in potentially explosive

atmospheres.

Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik 13

Risk of burns due to hot surfaces

During the welding process, the workpieces and some parts of the welding gun get

so hot that touching them may cause burns.

Always use personal protective equipment.

Before working on hot parts of the device, check that they have cooled down.

Do not hold the gun in the welding area.

Risk of burns from hot welding spatter

Dangerous welding spatter can occur during the welding process.

Always use personal protective equipment.

Fire hazard from hot welding spatter

Welding spatter or hot workpieces produced during the welding process can result in

fire hazard.

Do not store combustible or highly inflammable materials in the welding area.

14 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

2.3 Safety instructions for the working method

Hazards due to incorrect working method

Hazards for operators and third parties can arise due to an incorrect working method.

Ensure sufficient stability and a dry installation location for the device.

Make sure you do not knock over the device or pull it down from its position

with the gun cables.

Make sure, especially with mobile use, of your own good stability during

welding.

Do not hold the workpiece in your hands during welding. The workpiece must

be securely fixed during the welding process.

Never wrap the gun lines around parts of your body (e.g. arm) as electric

fields can occur.

If the gun is not positioned properly or the gun settings are incorrect, a flash

can occur during welding. Do not look directly into the flash.

The gun carries out lifting movements during the welding process. Do not

hold the gun tight in the area of moving parts.

Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik 15

2.4 Personal protective equipment

It is recommended to wear personal protective equipment when working with the stud

welding device.

Danger due to a lack of or incorrect PPE

During stud welding, there is a risk of burns, especially due to hot welding spatter.

The formation of strong electric arcs can also cause a glare hazard.

Always wear suitable, closed protective clothing.

Type and extent of the protective equipment depends on the respective

occurrence and intensity of welding spatter, arcs and/or noise. This varies

depending on the basic material, stud material, stud size and required

welding performance.

Please observe the following instructions for protective equipment.

Recommended personal protection equipment

Protective goggles

During welding, welding spatters and a flash of light

occur. Wear appropriate safety goggles with side

protection and a filter protector, if necessary.

Protective gloves

During welding, the workpieces and parts of the welding

gun get hot and welding spatters occur. Wear

appropriate, non-combustible, heat-resistant protective

gloves.

Protective clothing

Welding spatters occur during the welding process.

Wear appropriate, non-combustible and, if necessary,

heat-resistant, protective clothing.

Safety shoes

Welding spatters occur during the welding process.

Wear appropriate, non-combustible, heat-resistant

safety footwear.

Hearing protection

Depending on the welding device and the welding

application, relatively loud welding noises may occur.

Wear appropriate hearing protection.

16 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

2.5 Intended use of the stud welding device

Pins and threaded studs from M3 - M16 made of steel and stainless steel can be welded

using the SOYER®BMK-20i stud welding device (M16 preferred with SOYER®HZ-1

weld studs and SRM Technology®).

Special studs or diameters on request.

The stud welding device must only be operated with the welding guns described in

chapter “6.5 Permitted welding guns” on page 27.

The stud welding device must be operated within the technical specifications.

Only welding studs according to DIN EN ISO 13918 and SOYER®standard may be

welded.

The stud welding device supports the following welding processes:

SRM® welding (stud welding in a radially symmetrical magnetic field)

Drawn arc stud welding with inert gas

Drawn arc stud welding with ceramic ferrules

Incorrect use

Any use of the device deviating from the intended use is considered improper use.

Improper use, unauthorised modification or manipulation of the device will void the

declaration of conformity and all warranty claims against the manufacturer.

2.6 Intended use of the stud welding guns

With the SOYER®stud welding guns described in these operating instructions, pins and

threaded studs from M3 to M16 as well as many different weld fasteners made of steel

and stainless steel can be welded according to the DIN EN ISO 13918 and SOYER®

standards.

The maximum diameter and type of weldable studs can be limited by the

performance capacity of the stud welding device on which the gun is operated.

Special studs or diameters on request.

The operation of welding guns is only permitted with the stud welding devices described

in the technical data of the gun.

The stud welding gun must be operated within the technical specifications.

Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik 17

Incorrect use

Any use of the welding gun deviating from the intended use is considered improper

use.

Non-intended use, unauthorised modification or manipulation of the device will void the

declaration of conformity as well as all warranty claims against the manufacturer.

Misuse of the welding gun as a tool, e.g. as a hammer for checking the weld quality, is

not permitted.

2.7 Requirements on the part of the operator

The operator of the device must ensure that the preconditions described in this

operating manual regarding safe operation of the device are met.

These include, for example, the conditions at the installation location, regulatory

requirements for a safe workplace, training of the operating personnel and qualified

personnel in using the device, if applicable, compliance with required maintenance work

as well as monitoring the intended use of the device.

These operating instructions must be stored in the vicinity of the stud welding device.

The operator of the device must ensure that all protective devices are present, active

and intact before the stud welding device is used.

Please observe the DIN EN IEC 60974-9 standard (arc welding equipment - part 9:

Installation and operation) in the currently valid version.

Prerequisites for personnel

Operating personnel

The persons authorised to operate the device must be familiar with the stud welding

device and trained accordingly. They must have read and understood these operating

instructions. When working with the stud welding device, they must also be able to avert

possible residual danger to themselves and third parties or minimise them as far as

possible.

To maintain the qualification, safety training must be carried out at least once a year. In

the event of malfunction or for maintenance, specially trained personnel or the

manufacturer must be consulted, if necessary.

Operators of stud welding equipment must have technical expertise for operating and

adjusting the devices properly as well as for properly carrying out weldings.

If welding personnel have to be qualified for certification of welding, the DIN EN ISO

14555 and DIN EN ISO 14732 standards are to be observed.

18 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

Trained electrotechnical personnel

In general: Work on live elements may only be performed by authorised electricians.

This work must be performed in line with the applicable technical rules for

electrotechnical devices.

All devices of Soyer Bolzenschweißtechnik GmbH must only be opened by

SOYER®personnel or personnel authorised by SOYER®.

3 Transport

When transporting the device, make sure it cannot be damaged. Use appropriate

packaging to protect the device against weathering effects, especially moisture.

Danger during transport

The device is equipped with a handle and carrying strap on the top. The handle and

carrying strap are intended exclusively for transport by hand. Never pull ropes

through the handle or carrying strap to lift the stud welding device by means of a

crane to the installation site. The welding device would become instable and might

tilt from its original position. As a result the handle or carrying strap could rip and the

unit could fall to the ground.

4 Storage, shutdown

During storage or shutdown, make sure to protect the device against dirt and humidity.

Protect the stud welding device against unauthorised access by third parties.

5 Disposal

Local environmental directives must be observed when disposing of the device.

Water-endangering as well as environmentally hazardous substances are to be

disposed of in accordance with legal regulations.

If applicable, materials must be separated according to regulations.

Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik 19

6 Description of the BMK-20i stud welding device

The main elements of the stud welding device and their function are shown and

described in the following.

6.1 Type designation

Designation

Order number

Feature

BMK-20i

P01347

Mains voltage

3 x 400 V, 50/60 Hz, 32 AT

6.2 Working method

With the SOYER®BMK-20i stud welding device, pins and threaded studs from M3 to

M16 or Ø 2 - 16 mm (M16 preferred with SOYER® HZ-1 weld studs & SRM Technology®)

made of steel and stainless steel can be welded.

Only welding studs from SOYER®(preferably HZ-1 and MF types) may be welded.

Fasteners from other manufacturers must be approved by SOYER®.

The BMK-20i stud welding device operating with SRM Technology® was specially

developed for mobile use. Thanks to SRM®, it enables problem-free welding, even

under difficult conditions.

The BMK-20i stud welding device operates on the basis of a compact inverter power

source and provides a constant welding current from 100 A to 1200 A at welding times

from 20 ms to 500 ms. The rectified mains voltage is converted into high frequency

voltage with a frequency of 75 kHz by an Insulated Gate Bipolar Transistor-based

(IGBT-based) inverter. The energy is transferred by a high frequency transformer and

rectified on the output side. As a result of the high control speed in combination with the

integrated SRM®welding process of the BMK-20i, the reproducibility of the welds is

increased and the quality of the welds considerably improved.

20 Operating instructions BMK-20i | Heinz Soyer Bolzenschweißtechnik

Stud welding with SRM Technology®

The welding procedure recommended by SOYER®for operating the BMK-20i is the

patented SRM®welding procedure (patent no.: 10 2004 051 389) in conjunction with

the HZ-1 universal weld stud with a plane end face and centring tip (patent no.: 10 2006

016 553).

SRM®stands for stud welding in a radially symmetric magnetic field. This innovative

welding technology allows for welding in a ratio of 1:10 of the sheet metal thickness to

the stud diameter (previously 1:4) where the use of ceramic ferrules can be dispensed

with.

The various advantages of the SRM®procedure open up completely new possible

applications in the entire stud welding sector.

Functional principle

The stud tip touches the

workpiece and is lifted.

The arc is initiated.

The ignited arc is guided

by a magnetic field and

melts both joint parts

fully.

The stud immerses in the

very flat weld penetration

zone and is solidly

connected.

The advantages of the SRM®welding process are:

No bothersome weld bead

Welding from constrained positions now also without ceramic ferrule

Reduced weld penetration in the plate

Lower energy consumption and reduced welding time

No welding spatter

For stud welding with SRM Technology®, a gas mixture is used as an aid.

Following inert gas mixtures are recommended:

82% argon and 18% CO2(standard inert gas)

90% argon and 10% CO2 (preferably with Ø ≥ 12 mm)

85% argon and 15% CO2

Table of contents

Other Soyer Welding System manuals

Soyer

Soyer BMK-10i User manual

Soyer

Soyer BMS-4 ACCU-DUO User manual

Soyer

Soyer BMK-12 W User manual

Soyer

Soyer BMK-8i User manual

Soyer

Soyer HesoMatic-9 User manual

Soyer

Soyer BMK-16i User manual

Soyer

Soyer BMH-22i User manual

Soyer

Soyer BMS-10N User manual

Soyer

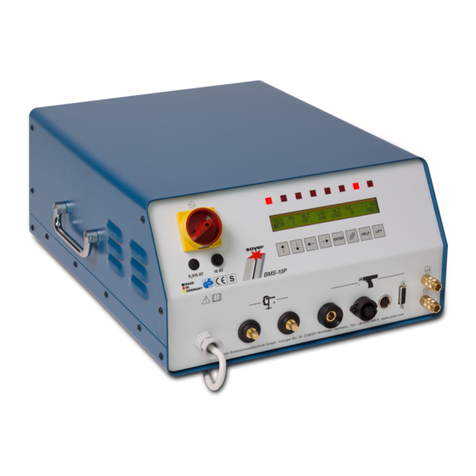

Soyer BMS-10P User manual

Soyer

Soyer BMK-12i User manual

Soyer

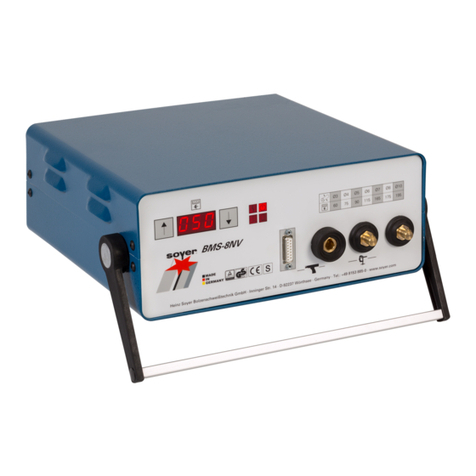

Soyer BMS-8N User manual

Soyer

Soyer BMS-8N User manual

Soyer

Soyer BMK-16i User manual

Soyer

Soyer BMS-4 Akkumat User manual

Soyer

Soyer BMS-9 ACCU User manual

Soyer

Soyer PH-9 SRM12 User manual

Soyer

Soyer BMK-12 W User manual

Soyer

Soyer BMS-9 ACCU User manual

Soyer

Soyer BMK-8 U User manual

Soyer

Soyer BMS-9 ACCU User manual