SP Scientific FTS Systems BioCool 80 User manual

LOW-TEMPERATURE BATH OPERATOR’S MANUAL

FTS

S

YSTEMS

B

IO

C

OOL

™

80

Controlled Rate Freezing Bath

Rev 002, 08/12 i

© SP Scientific 2012

Copyright © 2012 SP Scientific. All marks herein are used under license.

All brand or product names mentioned may be trademarks or registered trademarks of their respective

companies.

Part Number 100006071

Rev 002, 08/12

Original Instructions

The U.S. English version of this document is the original instructions.

All other languages are a translation of the original instructions.

SP Scientific

3538 Main Street

935 Mearns Road

815 State Route 208

Stone Ridge, NY 12484

USA

Warminster, PA 18974

USA

Gardiner, NY 12525

USA

(800) 251-1531

(800) 523-2327

(800) 431-8232

(845) 687-0071

(215) 672-7800

(845) 255-5000

SP Service

(877) 548-4666

SP Service Fax

(845) 687-0024

Website

http://www.spscientific.com/

This Low-Temperature Bath Operator’s Manual contains confidential and proprietary information of SP

Scientific and may be used only by a recipient designated by and for purposes specified by SP Scientific.

Reproduction of, dissemination of, modifications to, or the creation of derivative works from this Low-

Temperature Bath Operator’s Manual, by any means and in any form or manner, is expressly prohibited,

except with the prior written permission of SP Scientific. Permitted copies of this document must retain all

proprietary notices contained in the original.

The information in this document is subject to change without prior notice. Always confirm with SP

Scientific that you are using the most current version of this document. SP Scientific is free to modify any

of its products and services, in any manner and at any time, notwithstanding the information contained in

this document.

THE CONTENTS OF THIS DOCUMENT SHALL NOT CONSTITUTE ANY WARRANTY OF ANY KIND,

EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE OR GIVE RISE TO ANY

LIABILITY OF SP SCIENTIFIC, ITS AFFILIATES OR ITS SUPPLIERS.

The terms and conditions governing the use of this Low-Temperature Bath Operator’s Manual shall

consist of those set forth in written agreements with SP Scientific.

ii Rev 002, 08/12

© SP Scientific 2012

Important Symbols

WARNING! INJURY OR EVEN

DEATH MAY RESULT IF A

RECOMMENDATION MARKED

WITH THIS SYMBOL IS NOT

HEEDED.

CRUSH HAZARD. KEEP HANDS

CLEAR WHEN OPERATING DOOR.

ELECTRIC SHOCK DANGER!

USE APPROPRIATE CAUTION

TO AVOID INJURY OR DEATH.

CORROSIVE CHEMICAL. WEAR

SUITABLE GLOVES, SAFETY

GLASSES, AND PROTECTIVE

CLOTHING.

BURN DANGER! POTENTIALLY

HOT SURFACE. USE

APPROPRIATE CAUTION.

PROPERTY CAUTION! TO PREVENT

DAMAGE TO CHAMBER EQUIP-

MENT AND/OR LOAD, ADHERE TO

PROCEDURES MARKED BY THIS

SYMBOL.

DO NOT STORE FLAMMABLE

MATERIALS IN CHAMBER.

PRACTICAL OPERATING TIP.

THESE RECOMMENDATIONS

STREAMLINE UNIT OPERATION

AND PREVENT COMMON

OPERATOR ERRORS.

WEAR SAFETY GLASSES.

EXPLOSIVE MATERIALS HAZARD!

KEEP OBJECTS AWAY FROM HEAT.

Safety Warnings

Always transport the unit with care. Sudden jolts or drops may damage the refrigeration system.

Always observe all warning labels.

Always turn off the unit and disconnect the line cord from the available power source prior to performing any

service or maintenance procedures.

Always turn off the unit and disconnect the line cord from the available power source prior to moving the unit.

Always empty the reservoir / bath chamber prior to moving the unit.

Never operate equipment with damaged line cords.

Never operate the unit without cooling fluid in the reservoir.

Never remove warning labels.

Never operate damaged or leaking equipment.

Rev 002, 08/12 iii

© SP Scientific 2012

Warranty Information

FTS Systems BioCool™ 80 low temperature baths are warranted by SP Scientific to be free of defects in material and

workmanship when operated under normal conditions as specified in the instructions provided in this manual. Please

take this opportunity to locate the serial tag on your new FTS Systems BioCool™ 80 and record the information below

for future reference. SP Scientific also recommends that you complete and return your unit’s warranty registration card.

Model Number

Serial Number

Part Number

Limited Warranty

SP Scientific (the “Company”) shall warrant each of its products against defects in material or workmanship for a period

of 12 months from the date of shipment provided that the product is used in a reasonable manner under appropriate

conditions and consistent with the applicable operating instructions.

The obligation of the Company shall be, at its option, to repair or replace, without charge any parts that prove to be

defective within the warranty period, if the purchaser notifies the Company promptly in writing of such defect. No

product shall be returned to the Company without prior approval of the Company.

This limited warranty shall cover the costs of parts and labor to repair or replace all defective product(s) at the Seller’s

factory. For all products installed by the Company and located within the Company service travel areas, this warranty

shall cover transportation charges to ship the product to and from the Company’s factory and/or the costs of travel,

room and board if the Company’s employees conduct repair at the Buyer’s location. In lieu of repair or replacement at

the Company’s factory, the Company may, in its discretion, authorize a third party to perform the repair or replacement

at the Buyer’s location, and at the Company’s sole expense.

The Company shall not be responsible for labor charges payable with respect to persons other than Company

employees. Replacement or repair of parts pursuant to this warranty shall not in any way extend the original warranty

period. The Company shall not be responsible for any unauthorized repairs, replacements or product modifications, nor

will it be responsible for any product failures resulting from such unauthorized repairs, replacements or product

modifications negligently or otherwise made by persons other than Company employees or authorized representatives

of the Company. The buyer shall assume transportation charges to ship the product to and from the Company’s factory

and the costs of travel, room and board if the Company’s employees conduct repair at the Buyer’s location within the

warranty period if the product was not installed by the Company’s and/or is not located within the Company’s service

travel areas.

THE COMPA

NY DOES NOT MAKE AND EXPRESSLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, WITH

RESPECT TO THE SALE, INSTALLATION, DESIGN OR USE OF ITS PRODUCTS. ADDITIONALLY, THE

COMPANY SHALL

NOT BE LIABLE FOR ANY CONSEQUENTIAL DAMAGES RESULTING FROM THE USE OF OR

ANY DEFECTS IN ITS PRODUCTS.

The Company’s employees are available to provide general advice to customers concerning the use of the Company’s

products; however, oral representations are not warranties with respect to particular products or their uses and may not

be relied upon if they are inconsistent with the relevant product specifications for the items set forth herein.

Notwithstanding the above, the terms and conditions set forth in the Company’s formal sales contracts shall be

controlling and supersede any inconsistent terms contained herein, and any changes to such contracts must be made

in writing and signed by an authorized executive of the Company.

WARNING! THE DISPOSAL AND/OR EMISSION OF SUBSTANCES USED IN CONNECTION WITH

THIS EQUIPMENT MAY BE GOVERNED BY VARIOUS FEDERAL, STATE OR LOCAL

REGULATIONS. ALL USERS OF THIS EQUIPMENT ARE URGED TO BECOME FAMILIAR WITH

ANY REGULATIONS THAT APPLY IN THE USERS AREA CONCERNING THE DUMPING OF

WASTE MATERIALS IN OR UPON WATER, LAND OR AIR AND TO COMPLY WITH SUCH

REGULATIONS.

iv Rev 002, 08/12

© SP Scientific 2012

Rev 002, 08/12 v

© SP Scientific 2012

Contents

Important Symbols ............................................................................................................................................... ii

Safety Warnings................................................................................................................................................... ii

Warranty Information .......................................................................................................................................... iii

Introduction ................................................................................................................. 1

Overview ..............................................................................................................................................................1

Key Features ...................................................................................................................................................1

Maximum Cooling Rates .................................................................................................................................2

BioCool™ 80 Overview........................................................................................................................................2

Buzzer .............................................................................................................................................................3

Installation................................................................................................................... 5

Initial Inspection ...................................................................................................................................................5

Installation............................................................................................................................................................6

Air Flow Considerations...................................................................................................................................6

Ambient Conditions .........................................................................................................................................6

Services and Utilities .......................................................................................................................................6

Installing the Magnetic Stirrer and Vortex Breaker ..........................................................................................7

Operation .................................................................................................................... 9

Overview ..............................................................................................................................................................9

Operation .............................................................................................................................................................9

Powering On....................................................................................................................................................9

The Solo Controller .......................................................................................................................................10

Display and Indicators ...................................................................................................................................10

Adjusting Bath Temperature..........................................................................................................................10

Ramp / Soak Patterns ...................................................................................................................................11

Magnetic Stirrer .............................................................................................................................................15

Powering Off..................................................................................................................................................15

Restarting...........................................................................................................................................................15

Fluid .......................................................................................................................... 17

Recommended Fluid and Selected Properties...................................................................................................17

Fluid Filling.........................................................................................................................................................17

Magnetic Stirrer .............................................................................................................................................18

Maintenance ............................................................................................................. 19

Cleaning.............................................................................................................................................................19

Contents

FTS Systems BioCool™ 80

vi Rev 002, 08/12

© SP Scientific 2012

Condenser.....................................................................................................................................................19

Bath System ..................................................................................................................................................19

Compressor Safeties .........................................................................................................................................20

Refrigerant Types and Properties..................................................................................................................20

Refrigeration System.....................................................................................................................................20

Voltage ..........................................................................................................................................................20

Accessories............................................................................................................... 21

Straw Rack (Model SR-36) ................................................................................................................................21

Ampule Rack (Model SR-12) .............................................................................................................................21

Ampule Rack (Model SR-15) .............................................................................................................................22

Appendix A: Temperature Calibration ....................................................................... 23

Appendix B: Troubleshooting .................................................................................... 25

Rev 002, 08/12 1

© SP Scientific 2012

Chapter

1

Introduction

Overview

The FTS Systems BioCool™ 80 delivers controlled rate freezing capabilities, as well

as continuous operation at temperatures as low as -80 °C. Built to provide you with

years of smooth, quiet and reliable operation, the FTS Systems BioCool™ 80 packs

both performance and innovation into a compact, bench-top design.

Utilizing a liquid medium, the FTS Systems BioCool™ 80 controls the rate of freezing

samples without the use of expendables such as dry ice or liquid nitrogen (N2(liq)).

The FTS Systems BioCool™ 80 comes standard with temperature control and also

includes a variable speed-controlled magnetic stirrer to provide more accurate

temperature control and uniformity. Each configuration features an air-cooled

refrigeration system and stainless steel reservoir.

THE FLUID AND INNER WALLS OF THE RESERVOIR CAN REACH

TEMPERATURES BELOW -90 °C (-130 °F). EXTREMELY LOW TEMPERATURES

CAN CAUSE SERIOUS AND IMMEDIATE DAMAGE TO SKIN. THE ABSENCE OF

FROST IN UNITS EQUIPPED WITH THE FROST ISOLATING WARMING LOOP

SHOULD NOT BE MISTAKEN AS AN INDICATION OF WARM TEMPERATURE.

DESPITE THE ABSENCE OF FROST, THE TEMPERATURE OF THE RESERVIOR

FLUID AND WALLS MAY BE DANGEROUSLY LOW.

THE FTS SYSTEMS BIOCOOL™ 80 IS NOT INTENDED FOR USE WITH

EXTREMELY FLAMMABLE FLUIDS SUCH AS ISOPENTANE (C5H12).

Key Features

Specimen chamber is 5 inches (12.7 cm) in diameter and 6 inches (15.2 cm)•

deep.

Magnetic stirrer and vortex breaker allow for constant agitation of bath.•

Optional racks allow for the use of straws or ampules.•

Introduction

FTS Systems BioCool™ 80

2 Rev 002, 08/12

© SP Scientific 2012

Maximum Cooling Rates

The following cooling rates are achieved with ambient conditions of 22 ºC (72 ºF)

using clean methanol as the bath fluid. Some deviation from these rates may occur if

the ambient temperature is significantly higher or lower than 22 ºC (72 ºF), if the

methanol bath fluid is contaminated by water or if a different bath fluid is used.

Temperature Range Cooling Rate

20 to -60 ºC 2.5 ºC/minute

-60 to -80 ºC 1.3 ºC/minute

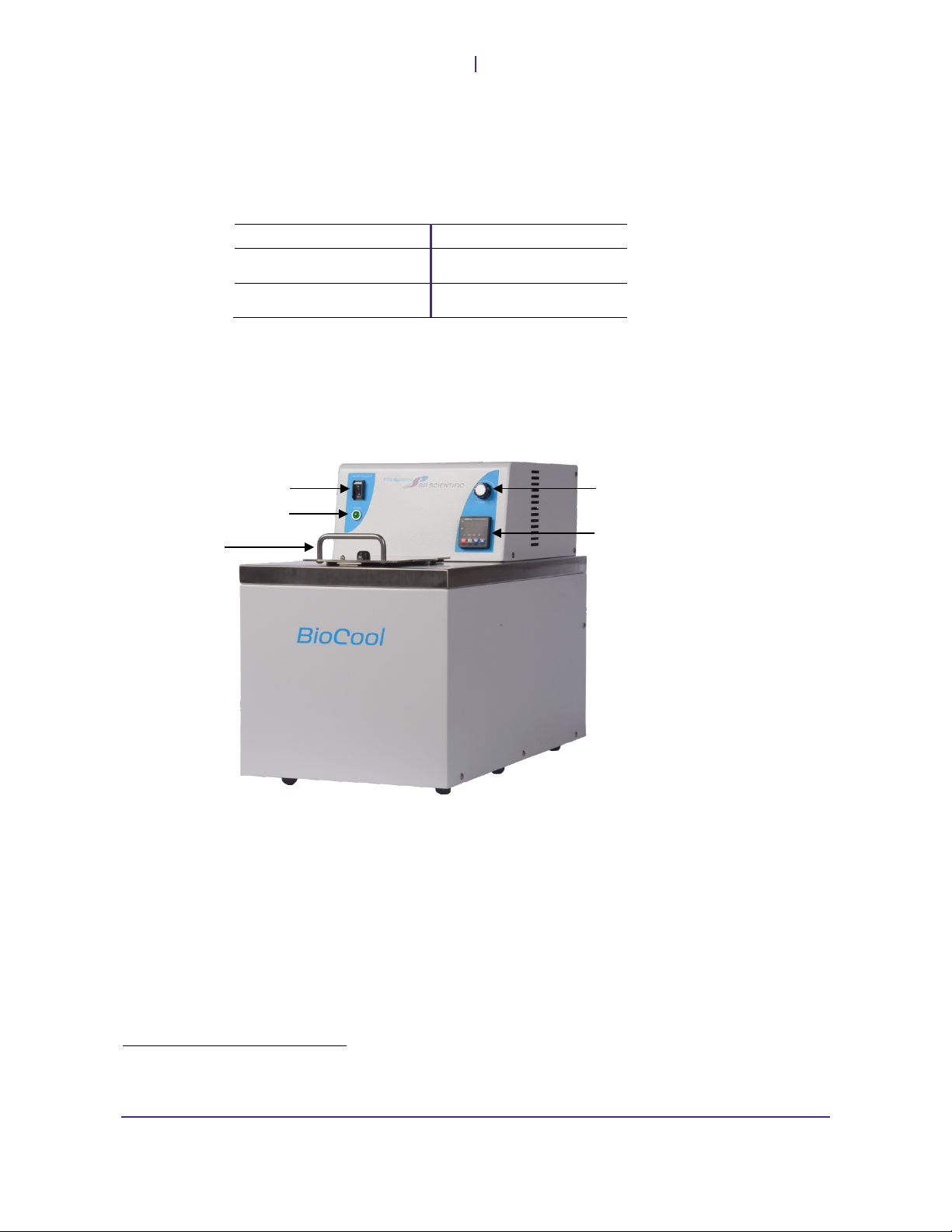

BioCool™ 80 Overview

The FTS BioCool™ 80 is designed for general freezing applications. This unit includes

a cascade refrigeration system and an on/off breaker switch. The BioCool™ also

features the Solo microprocessor controller, which provides precise temperature

control within ± 0.1 °C across the temperature control range of -80 °C to 20 °C. 1

When powered on, the BioCool™ 80’s refrigeration system will activate. After

approximately two (2) minutes, the green Chill light illuminates to indicate that the

second stage compressor is active.

The FTS BioCool™ 80 is also equipped with a solid-state variable speed-controlled

magnetic stirrer to provide more accurate temperature control and uniformity.

1The FTS Systems BioCool™ 80 offers continuous operation at temperatures as low as -80 °C. Lowest possible temperatures

may be dependent upon the selected bath fluid, as well as ambient conditions and airflow.

Breaker Switch

Chill Indicator LED

Hinged, Stainless

Steel Insulated

Reservoir Lid

Fluid Stir Control Dial

Solo Microprocessor Controller

FTS Systems BioCool™ 80

Introduction

Rev 002, 08/12 3

© SP Scientific 2012

Buzzer

The FTS BioCool™ 80 comes equipped with a buzzer, which is located on the back of

the unit. The buzzer will sound at the end of a program run, notifying the operator that

the run has completed.

Note: For additional information about the buzzer, including how to program a run and silence

the buzzer, please see SP Scientific’s Solo Controller operator’s manual.

Buzzer

Introduction

FTS Systems BioCool™ 80

4 Rev 002, 08/12

© SP Scientific 2012

Rev 002, 08/12 5

© SP Scientific 2012

Chapter

2

Installation

Initial Inspection

Your FTS Systems BioCool™ 80 low-temperature bath was carefully packed and

thoroughly inspected before leaving the SP Scientific factory. However, in the unlikely

event that shipping damage has occurred, retain all packing material and contact your

freight carrier immediately.

DO NOT ACCEPT DAMAGED SHIPMENTS FROM A CARRIER WITHOUT A

SIGNED NOTIFICATION OF DAMAGES.

Upon receiving your shipment, inspect all contents of your equipment for damage.

Uncrate and/or unwrap the unit. Carefully remove all packing material from the unit

and inspect for visible damage. Check packing material for small accessory items and

retain shipping carton and packing material if possible. Inspect the inside of the unit

and related parts for visible damage and leaks. Check for visible liquid at or near the

base of the unit. The reservoir should be clean and dry.

If concealed damage or loss is discovered, contact the freight carrier immediately.2

Keep all contents, packing material and related paperwork intact until a written report

is obtained.

Note: SP Scientific will cooperate in the matter of collecting your claim, but is not responsible

for the collection or free replacement of the material. When possible, replacement parts will be

shipped and invoiced to you, making them a part of your claim.

2“Concealed damage or loss” refers to damage or loss that does not become apparent until the merchandise has been

unpacked and inspected. Should damage or loss be discovered, you may make a written request for inspection by the carrier's

agent within 15 days of the delivery date. You may then file a claim with the freight carrier or SP Scientific, depending on the

terms of your shipment. If your shipment was “FOB Destination” file your claim with SP Scientific and include the inspection

report and any other supporting documents. If your shipment was “FOB Shipping Point” file your claim with the freight carrier

and include the inspection report and any other supporting documents.

Installation

FTS Systems BioCool™ 80

6 Rev 002, 08/12

© SP Scientific 2012

Installation

The FTS Systems BioCool™ 80 is designed for bench-top installation in a laboratory

environment. The unit should be installed on a firm, level surface in a location that is

convenient for both operation and service.

NEVER PLACE THE UNIT IN AN AREA WHERE EXCESSIVE HEAT, MOISTURE OR

CORROSIVE MATERIALS ARE PRESENT.

Air Flow Considerations

The FTS Systems BioCool™ 80 is equipped with an air-cooled refrigeration system.

Air is pulled from the left side of the unit to cool the refrigeration system components

and then exits the rear panel. When positioning your system, ensure that it is located

on a firm, level surface in an area that provides adequate air circulation.

Inadequate airflow will degrade the unit’s cooling capacity and in extreme cases may

result in compressor failure. A minimum of four (4) inches of clearance on all sides of

the unit is required to ensure proper airflow and avoid damage to the refrigeration

system.

Ambient Conditions

For best low-temperature operation, consider that the ideal ambient temperature for

your FTS Systems BioCool™ 80 is approximately 22 °C (72 °F). Higher ambient

temperatures will interfere in the system’s ability to achieve its ultimate low

temperature.

NEVER OPERATE THE FTS SYSTEMS BIOCOOL™ 80 IN AN AREA WITH AN

AMBIENT TEMPERATURE ABOVE 32°C (90°F).

Services and Utilities

The FTS Systems BioCool™ 80’s serial tag, which is located on the unit’s back panel,

provides the unit’s serial number and electrical requirements. Ensure that the voltage,

phase, frequency and amperage listed on the serial tag match your facility’s available

power supply (e.g., as a minimum the power outlet you intend to use must meet the

requirements listed on the serial tag).

CAUTION! IF YOU ARE UNSURE ABOUT THE AVAILABLE ELECTRICAL VOLTAGE

SUPPLY IN YOUR FACILITY, CONSULT A QUALIFIED ELECTRICIAN.

Prior to connecting your FTS Systems BioCool™ 80 to the available electrical supply,

ensure that the Main Power switch is in the Off position. You may connect the unit to

the available electrical supply at this time.

FTS Systems BioCool™ 80

Installation

Rev 002, 08/12 7

© SP Scientific 2012

Installing the Magnetic Stirrer and Vortex Breaker

The FTS BioCool™ 80 is equipped with a solid-state variable speed-controlled

magnetic stirrer and a vortex breaker to provide more accurate temperature control

and uniformity. To install the magnetic stirrer and vortex breaker:

Remove the packaging washers from the inside of the stainless steel1.

reservoir and from the bottom of the magnetic stirrer. These washers are

placed on the magnetic components of the unit for shipping purposes only

and are intended to be removed prior to operation.

Place the magnetic stirrer, magnet side down, into the center of the reservoir.2.

(Pushing the edges of the stirring mechanism beyond the black gasket at the

top of the reservoir may require some force.) As you lower the magnetic

stirrer into place, be careful not to bend or tweak the metal temperature probe

that hangs inside the reservoir.

Note: The screws on top of the magnetic stirrer should not come in contact with the

sides of the bath as you place the magnetic stirrer into the reservoir. If they do, retract

them using your fingers or a screwdriver.

Packaging Washer in Reservoir

Packaging Washer on Bottom

of Magnetic Stirrer

Temperature Probe

Reservoir (Top View)

Magnetic Stirrer (Bottom View)

Installation

FTS Systems BioCool™ 80

8 Rev 002, 08/12

© SP Scientific 2012

Once the stirrer assembly is in place, adjust the four holding screws by hand3.

so that each screw lightly touches the side of the reservoir. Then, use a

screwdriver to further extend each screw so that the stirrer is held snugly in

place in the center of the reservoir. Be sure that all screws are extended to

the same length; this will keep the stirrer assembly centered in the bath.

Hold the vortex breaker by its metal handle (a small tab, bent 90° at the tip)4.

and place it into the reservoir so that it rests evenly on top of the magnetic

stirrer. (Pushing the edges of the vortex breaker beyond the black gasket at

the top of the reservoir may require some force.)

Magnetic Stirrer In

Holding Screws

Holding Screws

Temperature Probe

Reservoir (Top View)

Reservoir (Top View)

Magnetic Stirrer and Vortex Breaker

Assembled in Reservoir

Vortex Breaker Handle

Temperature Probe

Rev 002, 08/12 9

© SP Scientific 2012

Chapter

3

Operation

Overview

The FTS BioCool™ 80 offers a continuous display of temperatures in 0.1 degree

increments and is capable of controlling temperatures within ± 0.1 °C across the

equipment’s full operating temperature range.

Operation

Powering On

Note: Before powering on and cooling, install the magnetic stirrer and vortex breaker (as

described in Chapter 2: Installation) and fill the reservoir with fluid (as described in Chapter 4:

Fluid).

To activate the refrigeration system:

Toggle the on/off breaker switch to the On position.1.

Main Breaker

Operation

FTS Systems BioCool™ 80

10 Rev 002, 08/12

© SP Scientific 2012

The Solo Controller

The BioCool™ 80 includes a proportional-integral-derivative (PID) microprocessor

controller. The Solo controller features a bright, two-line, two-color, seven segment

LED readout.

Display and Indicators

Process Value (PV) Display

Displays the current fluid temperature in the bath.

Set Value (SV) Display

Displays the desired fluid temperature.

Adjusting Bath Temperature

Press the Up and/or Down buttons to increase and decrease the fluid1.

temperature shown on the SV Display.

Press the Set button to select the displayed value.2.

Note: For more detailed information on operating the Solo controller, including how to

connect your Solo controller to a PC for ease of operation, see SP Scientific’s Solo

Controller operator’s manual.

Status Indicator Area

Down Button

Up Button

Rotate Button

Set Button

Process Value (PV)

Display

Set Value (SV)

Display

FTS Systems BioCool™ 80

Operation

Rev 002, 08/12 11

© SP Scientific 2012

Ramp / Soak Patterns

The FTS BioCool™ 80 is preprogrammed with three sample ramp/soak patterns.

These patterns can be viewed using either the Solo keypad or the Solo configuration

software. After becoming familiar with the ramp/soak functionality as demonstrated via

the three sample patterns, create new patterns to suit your individual process

requirements using either the Solo keypad or the Solo configuration software. For

more information, refer to SP Scientific’s Solo Controller operator’s manual.

THE THREE SAMPLE PATTERNS THAT COME LOADED ON YOUR BIOCOOL™ 80

WERE DESIGNED FOR DEMONSTRATION PURPOSES. SP SCIENTIFIC DOES NOT

RECOMMEND USING THESE PATTERNS FOR FREEZING TISSUE OR OTHER

PRODUCT-RELATED APPLICATIONS.

When viewed using the Solo software Ramp/Soak Pattern Editor, the three sample

patterns (Pattern 0, Pattern1 and Pattern 2) appear as follows:

Note: Please refer to SP Scientific’s Solo Controller operator’s manual for complete details on

how to operate Ramp/Soak on your FTS BioCool™ 80 and how to download and install the

Solo software on a PC.

Calculating Ramp Rate

The ramp rate can be calculated using the following equation:

Ramp Rate =

Change in Temp

Change in Time

Operation

FTS Systems BioCool™ 80

12 Rev 002, 08/12

© SP Scientific 2012

Sample Pattern 0

Step

Parameter

Value

Step 0

Temp.

22 °C

Time.

10 minutes

Step 1

Temp.

-6 °C

Time.

15 minutes

Step 2

Temp.

-6 °C

Time. 15 minutes

Step 3

Temp.

-40 °C

Time.

1 Hour, 43 minutes

Step 4

Temp.

-40 °C

Time.

10 minutes

Step 5

Temp.

0 °C

Time.

0 minutes

Step 6

Temp.

0 °C

Time.

0 minutes

Step 7 Temp. 0 °C

Time.

0 minutes

Last Step Number

4

Additional Cycles

0

Next Pattern Number

Program End

Sample Pattern 0 Description

The program starts at 22 °C and holds (soaks) at that temperature for 10 minutes. The

temperature then ramps from 22 °C to -6 °C in 15 minutes. This results in a ramp rate

of 1.9 °C/m. A temperature of -6 °C is then held (soaked) for 15 minutes. The

temperature then ramps from -6 °C to -40 °C over the period of 1 hour and 43

minutes. This results in a ramp rate of .33 °C/m. The temperature is then held at

-40 °C for 10 minutes.

Note: The system has been factory programmed to sound an alarm when the programmed

pattern ends.

Sample Pattern 1

Step

Parameter

Value

Step 0

Temp.

22 °C

Time.

10 minutes

Step 1

Temp.

-7 °C

Time.

12 minutes

Step 2

Temp.

-7 °C

Time.

30 minutes

Step 3

Temp.

-33 °C

Time.

52 minutes

Step 4

Temp.

-33 °C

Time.

0 minutes

Table of contents

Other SP Scientific Laboratory Equipment manuals