SPACEMAKER RGB88ONEU Use and care manual

This manual suits for next models

1

Other SPACEMAKER Outdoor Storage manuals

SPACEMAKER

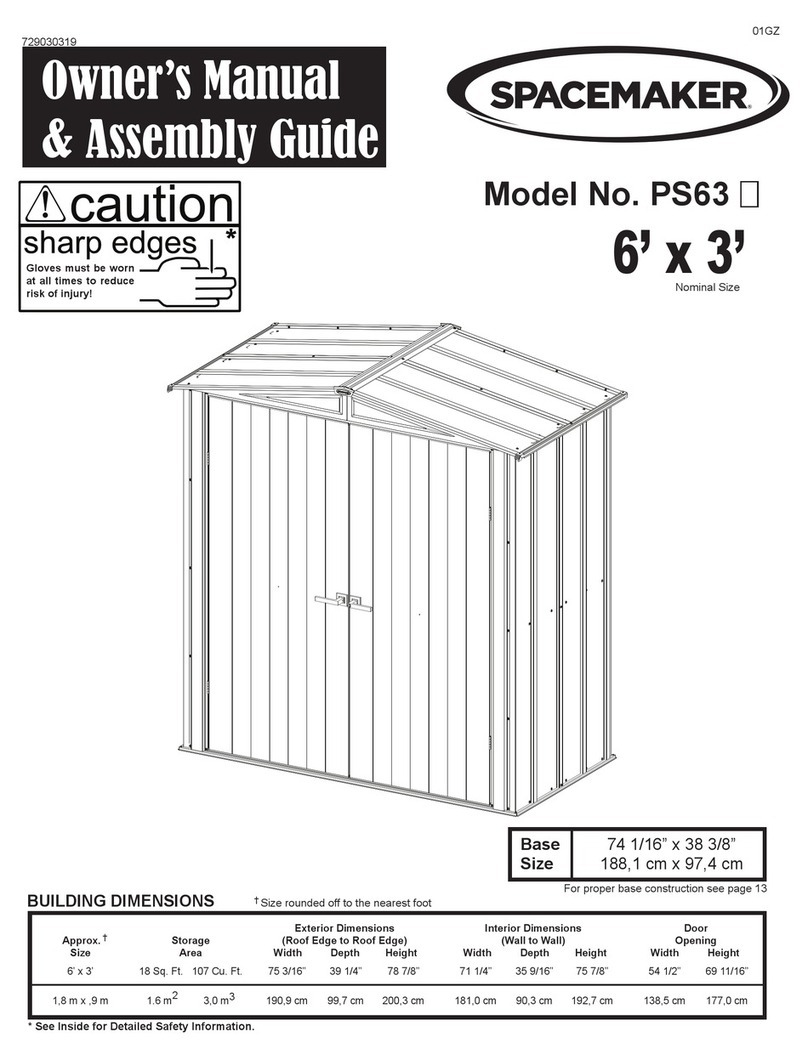

SPACEMAKER PS63 Instructions for use

SPACEMAKER

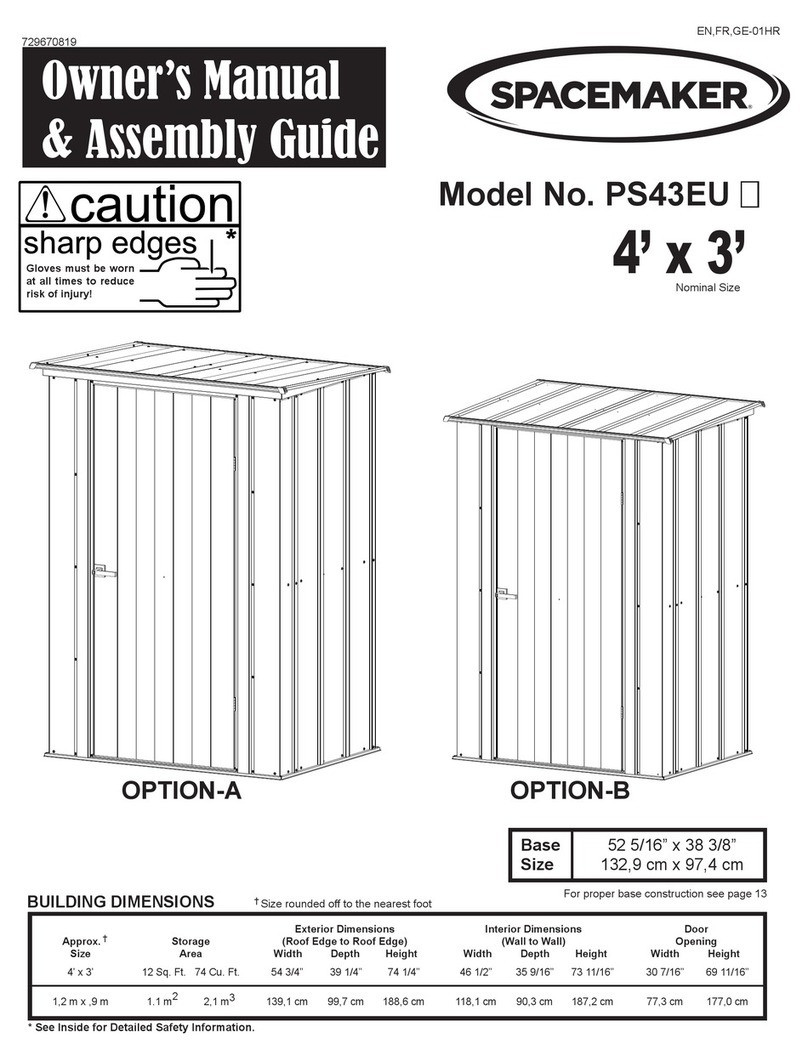

SPACEMAKER PS43EU Series Instructions for use

SPACEMAKER

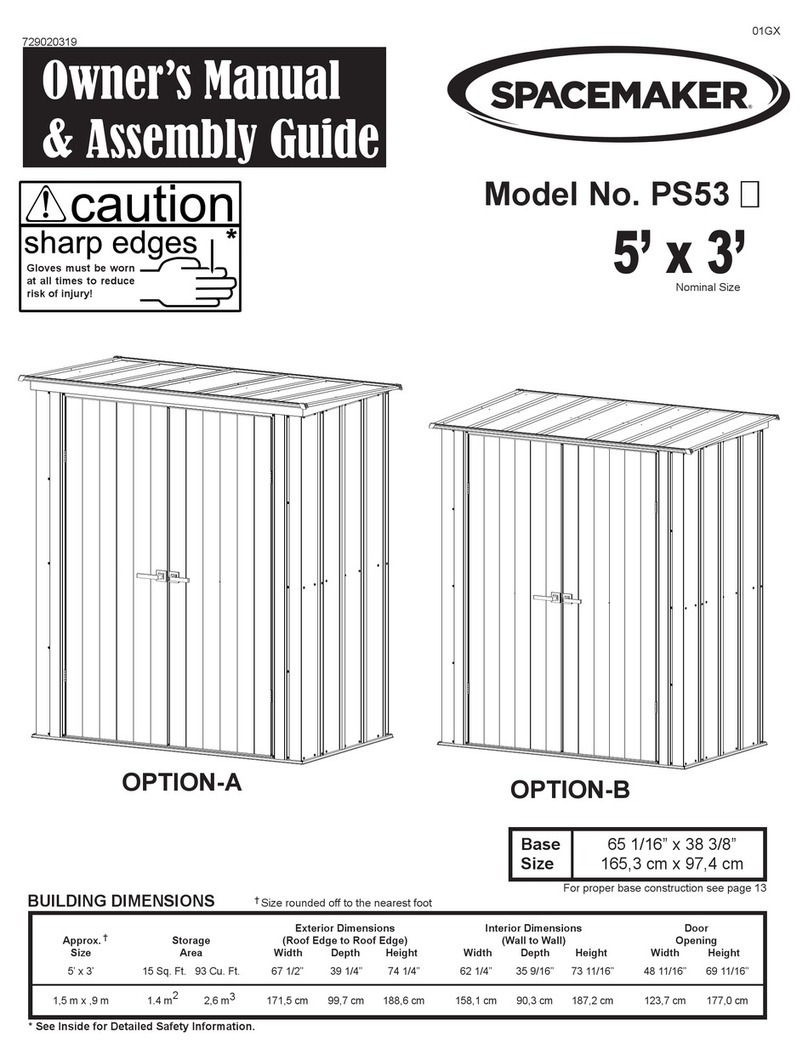

SPACEMAKER PS53 Instructions for use

SPACEMAKER

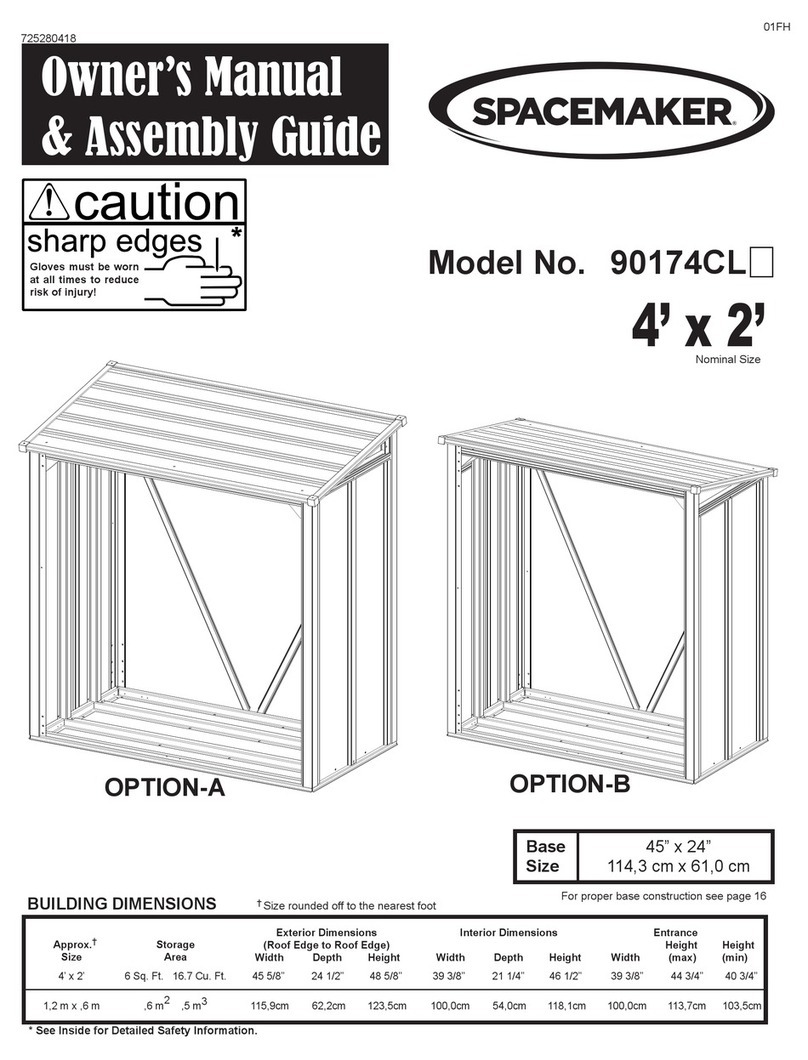

SPACEMAKER 90174CL Series Instructions for use

SPACEMAKER

SPACEMAKER VERSA-SHED EVRS53 Series Instructions for use

SPACEMAKER

SPACEMAKER EL64 User manual

SPACEMAKER

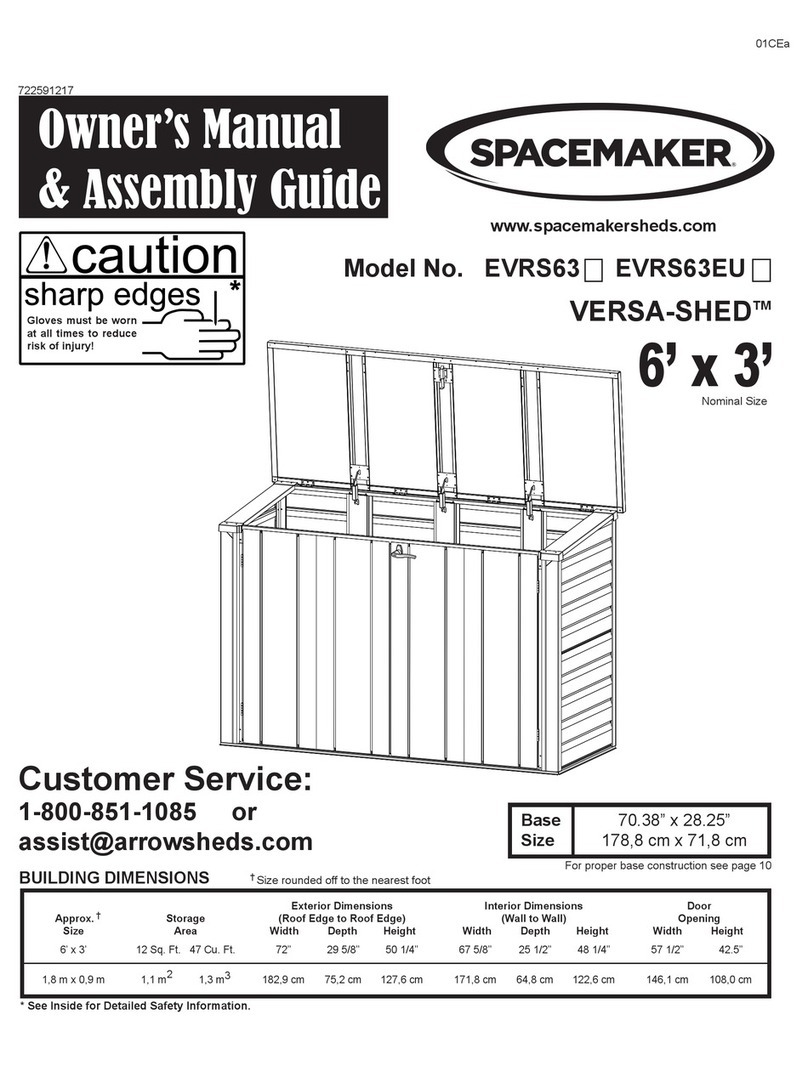

SPACEMAKER VERSA-SHED EVRS63 Instructions for use

SPACEMAKER

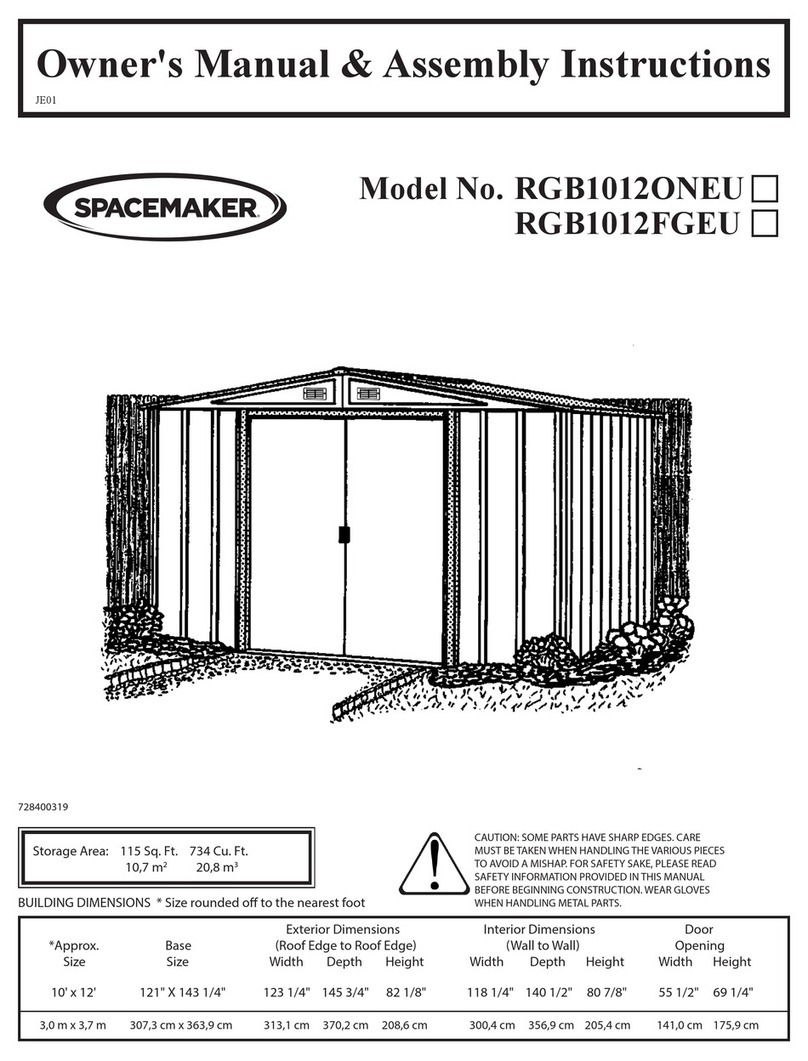

SPACEMAKER RGB1012ONEU Use and care manual

SPACEMAKER

SPACEMAKER RGB108ONEU Use and care manual

SPACEMAKER

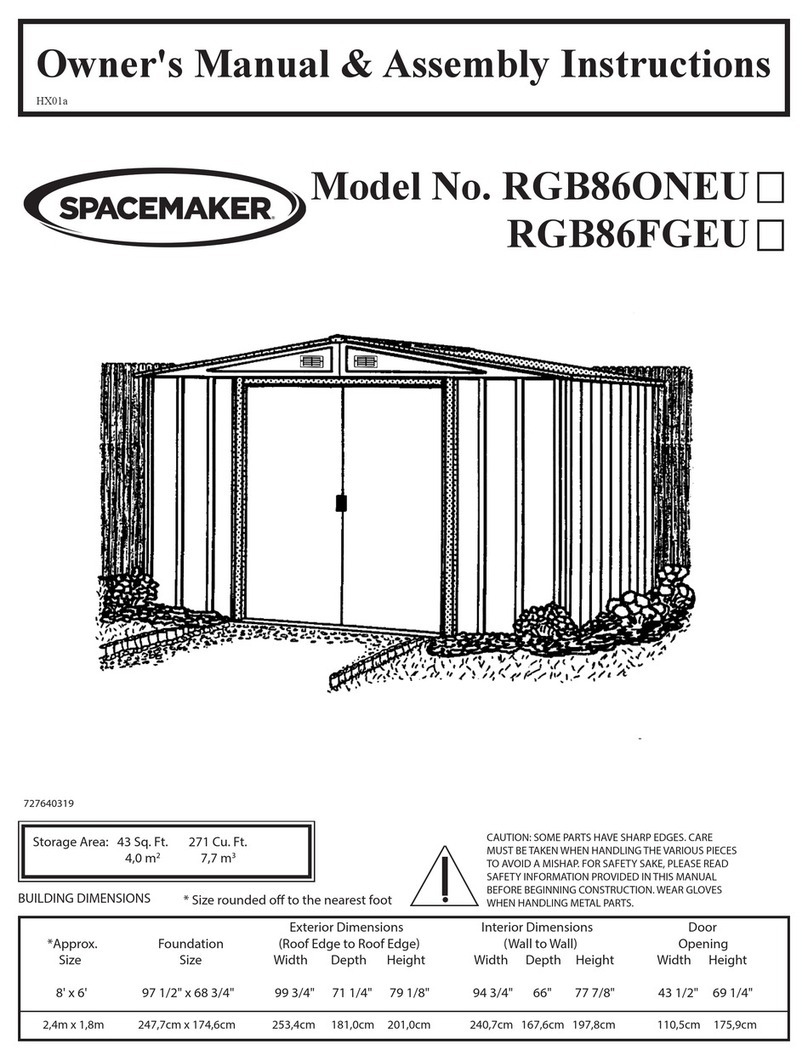

SPACEMAKER RGB86ONEU Use and care manual

Popular Outdoor Storage manuals by other brands

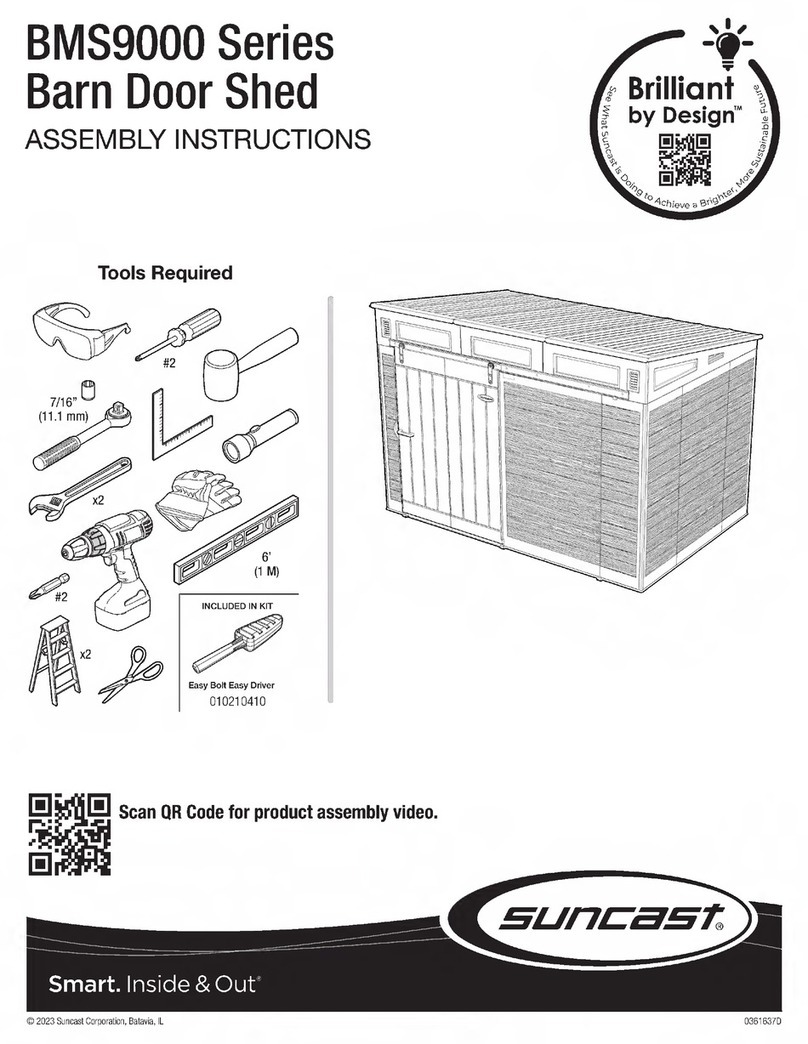

Suncast

Suncast Brilliant by Design BMS9000 Series Assembly instructions

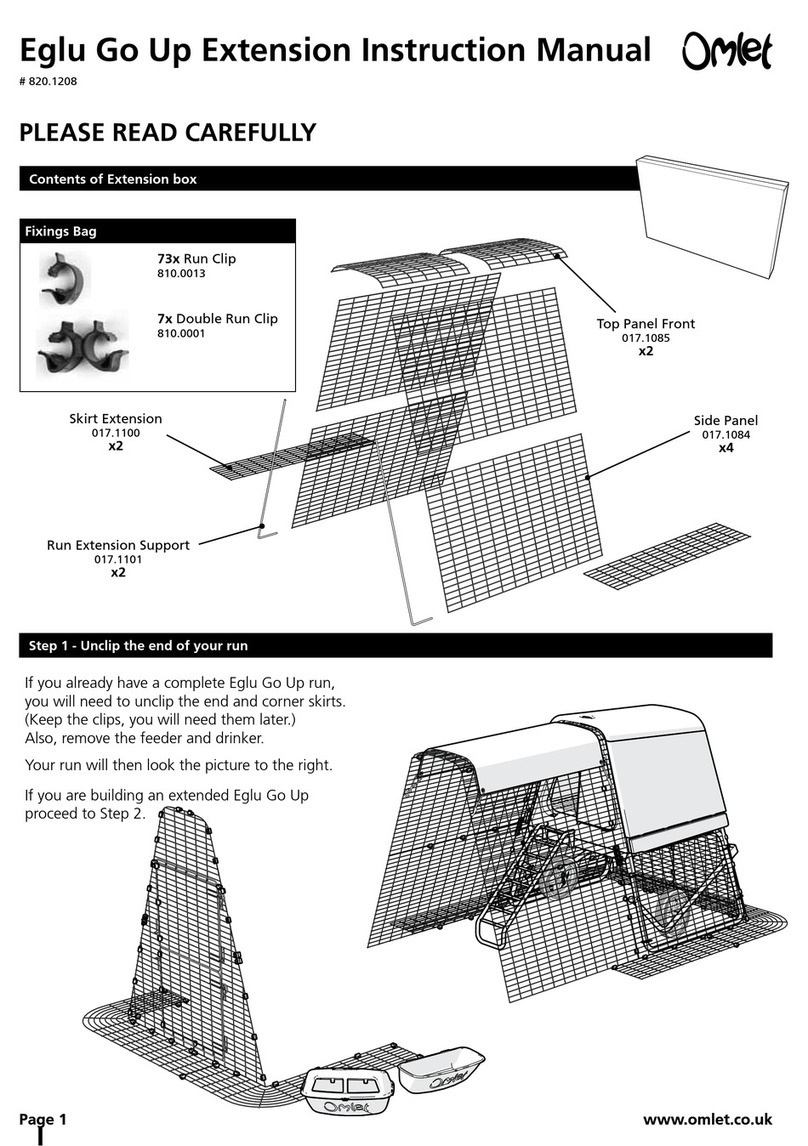

Omlet

Omlet Eglu Go Up instruction manual

Alice's Garden

Alice's Garden LYS manual

Weka

Weka 607.0602.00.00 ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

Arrow

Arrow CM1014-A1 Owner's manual & assembly instructions

ABSCO SHEDS

ABSCO SHEDS 30152GK Assembly instructions

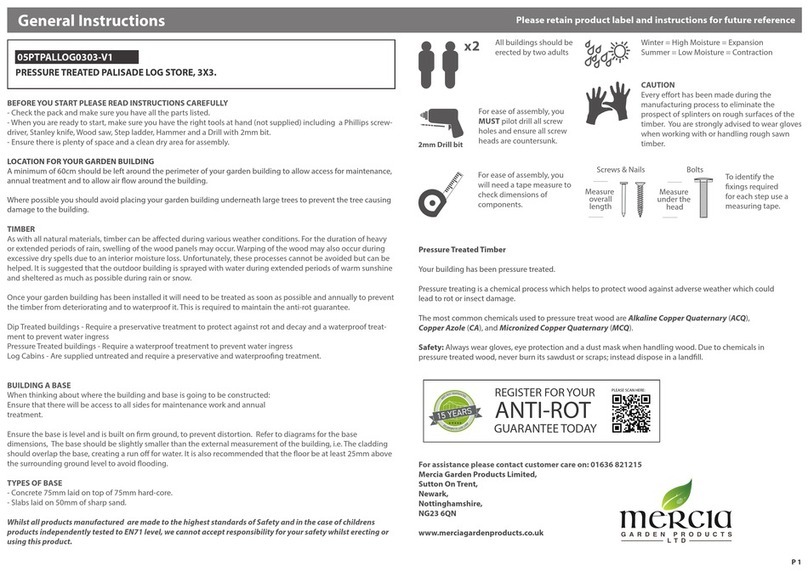

Mercia Garden Products

Mercia Garden Products 05PTPALLOG0303-V1 General instructions

Riverlea

Riverlea Duratuf KIWI SHEDS MK4A Assembly instructions

Arrow

Arrow FDN54 Owner's manual & assembly instructions

Handy Home Products

Handy Home Products 16616 Building instructions

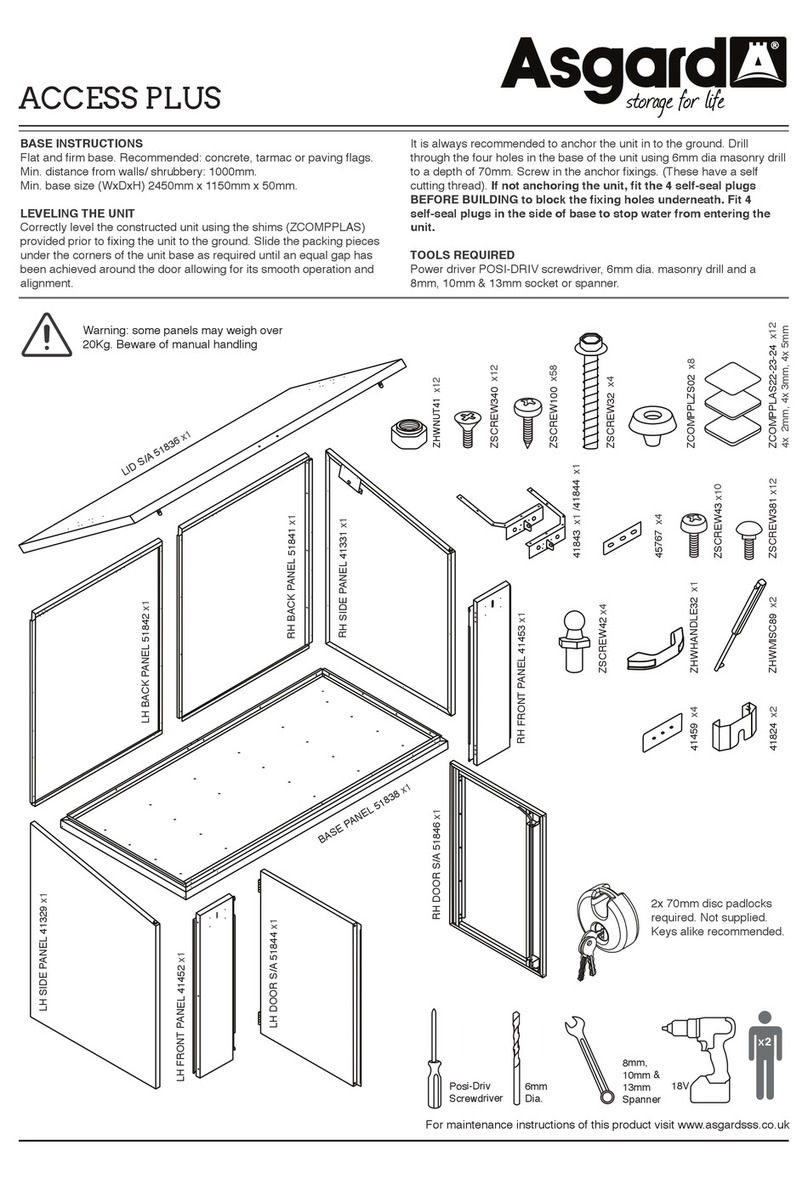

Asgard

Asgard ACCESS PLUS quick start guide

Riverlea

Riverlea Duratuf Garrison Sheds PL36 Assembly instructions

ABSCO SHEDS

ABSCO SHEDS J15231FK Assembly instruction

Riverlea

Riverlea Duratuf SS2010 Assembly instructions

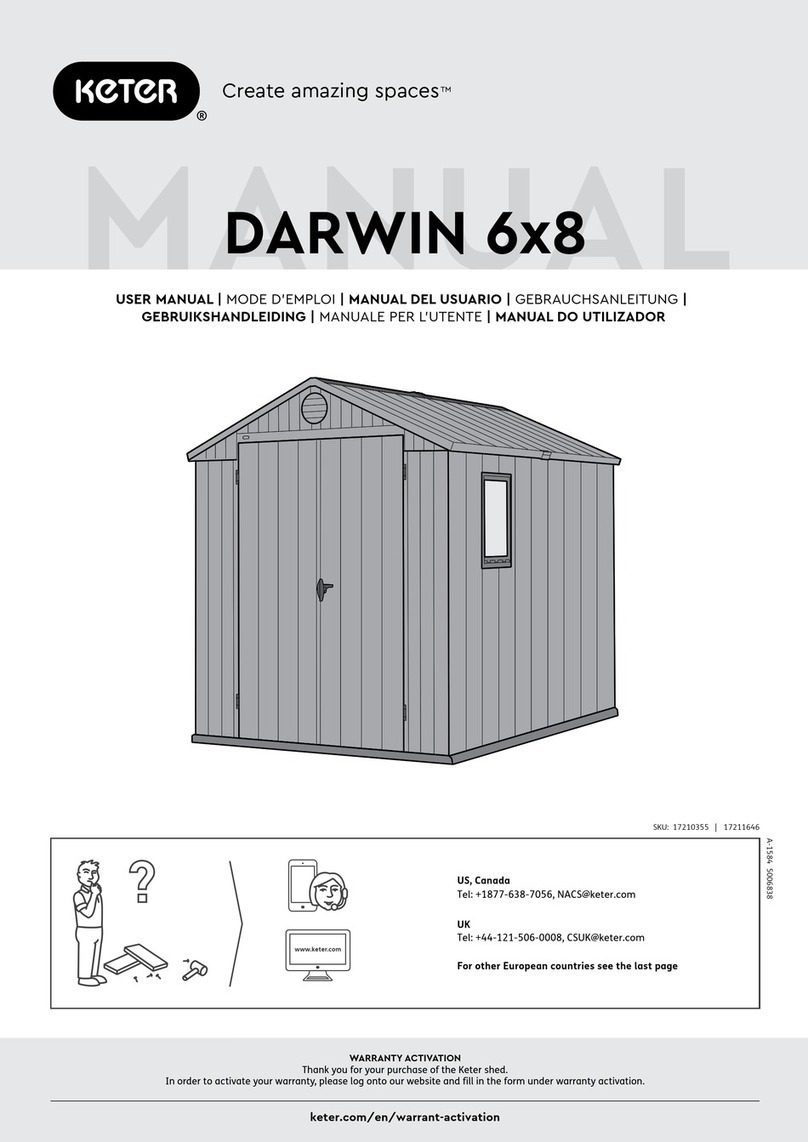

Keter

Keter MANOR 6x5DD user manual

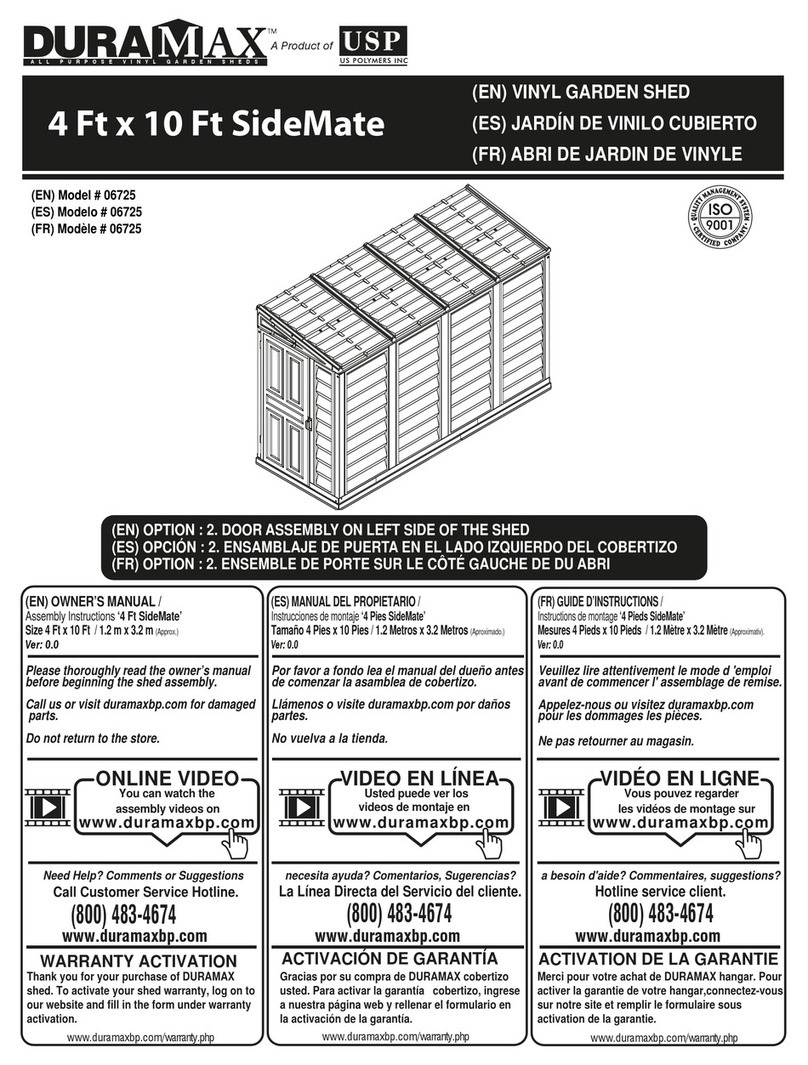

USP

USP DURAMAX 4 Ft x 10 Ft SideMate manual

Keter

Keter DARWIN 6x8 user manual

Arrow Storage Products

Arrow Storage Products EZEE SHED EZ10872HVCREU Owner's manual & assembly guide