Spaceman 6228AH User manual

SPACEMAN AIR

PUMP SOFT

SERVE TRAINING

*use this training guide for Spaceman USA models:

6228AH, 6235AH, 6236AH, 6250AH, 6260AH, 6338AH, and 6378AH

Spaceman USA Soft Serve Pump Training

rev042219

NOTES AND FUNCTIONS OF YOUR MACHINE

Product is poured into the refrigerated hopper (product should be

below 41°F) where it is kept until flowing into the freezing cylinder via

the air tube.

On the front of your machine is an digital control to regulate and

maintain consistent product quality for each flavor as an analog rocker

switch to power the board on or off.

Inside the freezing cylinder, the beater mixes the product while freezing

and produces a soft serve product.

The machine you have purchased is an air pump soft serve machine.

It is capable of producing a variety of products that include: Soft Serve

Frozen Yogurt, Ice Cream, select custard products, and sorbets.

•Air pump (or pressurized) soft serve machines use pressure to add a higher, controlled

percentage of air to the product mix and maintain pressure in the freezing cylinder so that the

air does not escape. Air pump machines are ideal for customers looking for higher profits,

creamier product, or anyone serving cones.

Spaceman USA Soft Serve Pump Training

rev042219

ROUTINE MAINTENANCE OPERATIONS

Clean and Lubricate Daily

Replace Wearable Parts Every

1 to 3 months*

Internal Cleaning Quarterly**

* Based on machine usage and cleaning

intervals; a Tune-Up Kit is available with

all wearable parts (O-rings, gaskets, etc.)

except scraper blades

** Based on cleanliness of location

and proximity to powder-based

machines

For optimal machine performance and

many years of efficiency and reliability

from your machine, Spaceman USA

recommends cleaning and sanitizing the

machine and its parts daily. The machine

comes equipped with a brush kit

specifically designed to efficiently and

properly clean the machine.

Tune-Up Kit

Spaceman USA Soft Serve Pump Training

rev042219

IMPORTANT:

Cleaning and sanitizing

schedules are governed by state

or local regulatory agencies and

MUST be followed accordingly.

Routine maintenance MUST be

performed a minimum of once

every three days.

CAUTIONS:

Do NOT run the machine without properly lubricating

required parts.

Do NOT clean the machine with abrasive or toxic chemicals

and cleaners. Doing so may cause damage to the stainless

steel material.

ONLY use Spaceman-USA-included cleaning brushes and lubrication.

NEVER use metal objects to clean or operate the machine.

ALWAYS replace wearable parts a minimum of every 3 months.

ALWAYS prime machine prior to operating.

ALWAYS inspect parts for excess wear and damage.

ROUTINE MAINTENANCE OPERATIONS

Spaceman USA Soft Serve Pump Training

rev042219

DRAIN PRODUCT

NOTE CAUTION

To expedite draining, turn off

machine 30 minutes prior to

soften product. To expedite

process, keep a bucket

nearby to temporarily store

removed parts.

NEVER use warm water

when rinsing the machine

to prevent damage.

Spaceman USA Soft Serve Pump Training

rev042219

Press RESET buttons;

press WASH buttons

DRAIN PRODUCT

Remove hopper lids and

agitators

2

Place a bucket or other

container below

dispensing assembly

3

Turn power

switches to ON

41

Spaceman USA Soft Serve Pump Training

rev042219

DRAIN PRODUCT

Fill each hopper with

one gallon of COOL

water

Move draw handles to OPEN

position (DOWN); CLOSE

draw handles (UP) when

product flow slows

significantly

Press RESET buttons to

pause wash cycle

Remove product

and dispose or

refrigerate it

5 6 7 8

Spaceman USA Soft Serve Pump Training

rev042219

DRAIN PRODUCT

OPEN draw handles to

drain water and

remaining product;

CLOSE when finished

Use cool water and the large

brush to scrub the sides and

bottom of the hoppers; be VERY

careful not to damage the low-

mix sensor in the hoppers

Place a bucket or other

container below the

dispensing assembly

Press WASH buttons

10 11 12

Spaceman USA Soft Serve Pump Training

rev042219

9

DRAIN PRODUCT

Use the small brush kit to

clean inside the feed tube at

the bottom of the hoppers

Press RESET to

pause wash cycle

Repeat steps 9 to 15

until water exiting the

draw valves is clear

and free of product

If machine has air pumps:

a. Press RESET buttons

b. OPEN draw handles

(DOWN) for 10 to 15

seconds to relieve

pressure in cylinders

13 14 15 16a

16b

Spaceman USA Soft Serve Pump Training

rev042219

DISASSEMBLE

NOTE CAUTION

Prepare dishwashing area

prior to disassembly, use

bucket to temporarily store

large removed parts and a

small container for O-rings,

and have a towel nearby to

capture excess water.

ALWAYS separate O-rings

and gaskets from metal

parts to prevent damage

while washing.

Spaceman USA Soft Serve Pump Training

rev042219

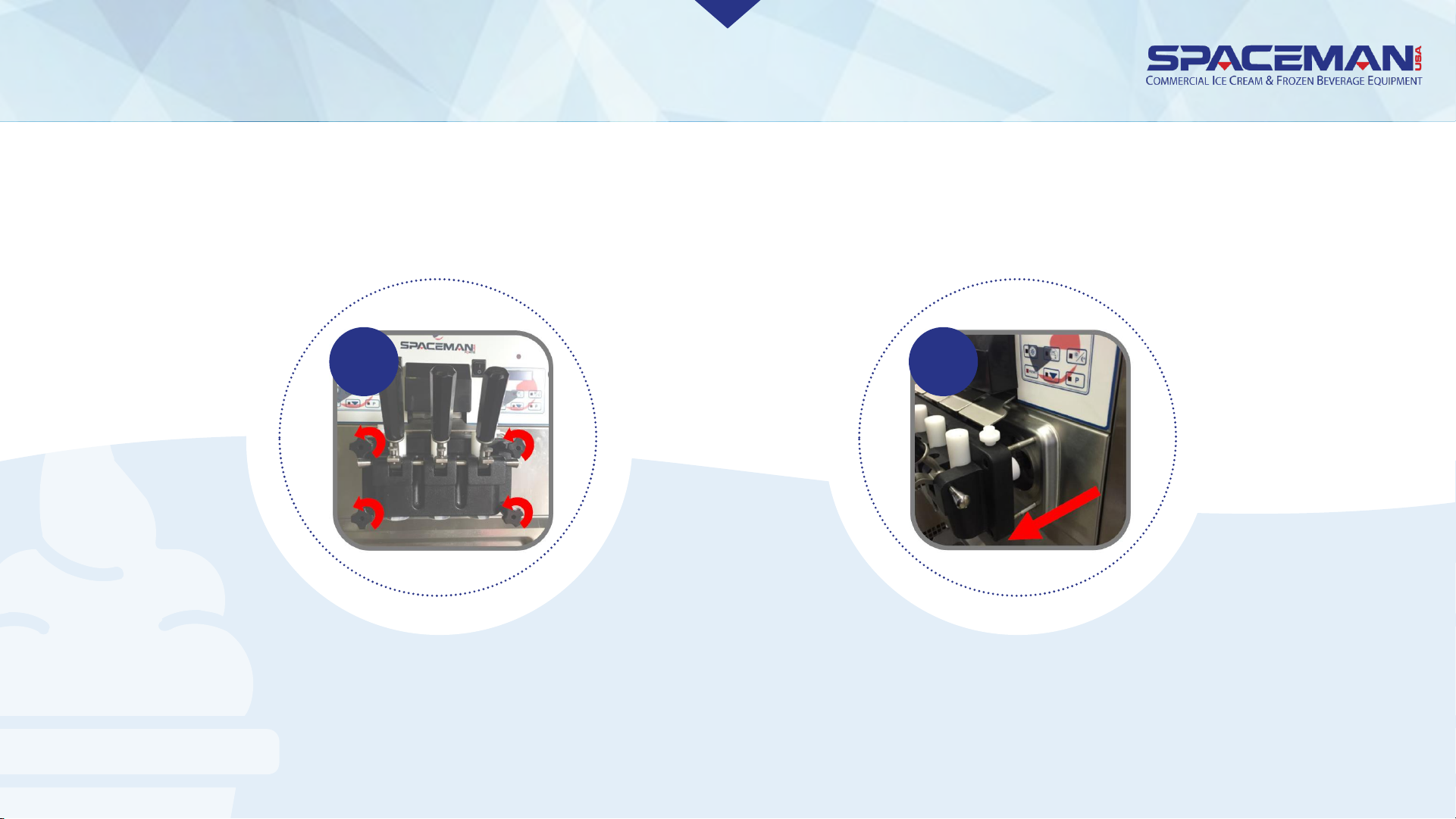

DISASSEMBLE

1. TURN POWER

SWITCHES OFF 2. DISASSEMBLE AIR PUMP

OPEN draw handles

to verify zero

pressure in

cylinders; twist air

tube connectors to

unlock and

disconnect air tubes

Take air tubes apart

completely; each air

tube has O-rings (3),

connectors (2), and

check valve (1)

Push in and rotate air

pumps 1/4 turn clockwise;

pull to remove

12a 2b 2c

Spaceman USA Soft Serve Pump Training

rev042219

DISASSEMBLE

Take suction tubes

apart completely;

each suction tube has

O-ring (1), spring (1),

and stopper (1)

2e

Remove gears and

O-rings from shells

2g

Rotate suction tubes

to unlock and remove

suction tubes, springs,

and stoppers out of air

pumps; watch that

springs don’t fly out

2d

Unscrew bolts on air

pump housings;

separate air pump

covers from shells

2f 2f

2. DISASSEMBLE AIR PUMP

Spaceman USA Soft Serve Pump Training

rev042219

DISASSEMBLE

3. REMOVE DISPENSING DOOR

3a 3b

Remove dispensing-

door hand-screws (4)

Remove dispensing door

assembly from cylinders

Spaceman USA Soft Serve Pump Training

rev042219

DISASSEMBLE

4. Disassemble dispensing door

4a

Remove beater guides (2)

from door assembly;

remove gaskets (2) from

door assembly using O-

ring removal tool

Remove prime plugs (2)

from door assembly;

remove O-rings (4) from

prime plugs using O-ring

removal tool

4b

4b

4c

4c

Unscrew and remove

retention nut; remove

retention pin

Remove draw handles

(3), pushing down first to

pop up draw valves, then

pulling out

4d

Spaceman USA Soft Serve Pump Training

rev042219

DISASSEMBLE

Remove draw valves (3), twisting while

removing to prevent damage

Remove O-rings (4) and H-ring (1) from

draw valves using O-ring removal tool

Rotate star caps (3) so that tabs are

accessible; snap off star caps

4.

Disassemble

dispensing door

4e

4f

4g

Spaceman USA Soft Serve Pump Training

rev042219

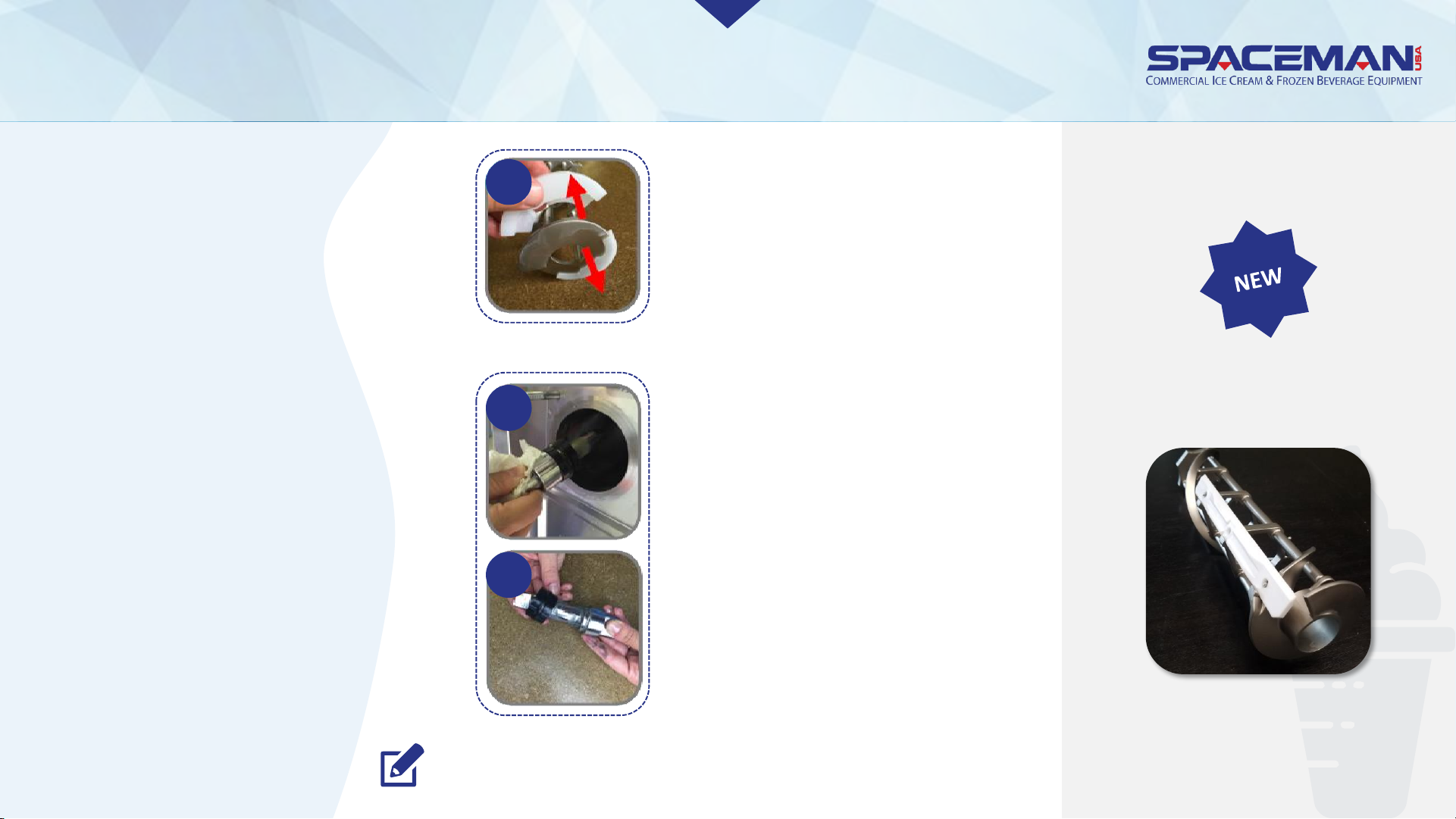

DISASSEMBLY

5.

Disassemble

beater

assembly and

drive shaft

Remove scraper

blades (4) from

beater assemblies;

separate scraper

blade clips (4) from

scraper blades

*some new models

will not have blade

clips

Remove beater

assemblies (2) from

cylinders

5a

5b

5b

“clip-less” blade

NOTE: If you experience assembly difficulty with drive shafts,

Spaceman offers a specialized removal tool for purchase.

Spaceman USA Soft Serve Pump Training

rev042219

DISASSEMBLY

5.

Disassemble

beater

assembly and

drive shaft

Remove drive shafts (2)

from inside cylinders

using a dry towel;

separate gaskets (2) from

drive shafts

Pull off beater shoes (4)

* some new models will

not have beater shoes

“shoe-less” beater

5c

5d

5d

NOTE: If you experience assembly difficulty with drive shafts,

Spaceman offers a specialized removal tool for purchase.

Spaceman USA Soft Serve Pump Training

rev042219

DISASSEMBLE

6.

Remove internal drip

tray and front drip

tray + splash shield

Spaceman USA Soft Serve Pump Training

rev042219

WASH ALL PARTS

Use the large brush and cool

water to thoroughly clean

inside the cylinder; be sure to

scrub the back of the cylinder

and verify the cylinder is free

of ALL product

2

Gently clean and wipe down the

outside of the machine

4

Thoroughly clean and dry the

rear of the cylinder with the

supplied black brushes as

well as a clean, dry towel

3

Verify power switches are

in the OFF position

1

CAUTION:

Never wash parts in a dishwasher. Always hand-wash

components with nontoxic, food-safe cleaners. Spaceman USA Soft Serve Pump Training

rev042219

WASH ALL PARTS

Carefully and thoroughly wash all

parts removed from the machine

using supplied brushes as well as

sponges, and clean towels

if machine has air pumps, be sure

to include all air pump parts in

cleaning

5

Carefully and thoroughly clean all

gaskets and O-rings removed

from the machine; be sure to

wipe gaskets and O-rings to

remove excess lubricant

7

When cleaning the dispensing

door assembly, clean the priming

port with a small brush

6

Verify all parts are clean and free

of all food product prior to re-

assembling machine

8

Spaceman USA Soft Serve Pump Training

rev042219

This manual suits for next models

6

Table of contents

Other Spaceman Ice Cream Maker manuals

Spaceman

Spaceman 6210-60Hz User manual

Spaceman

Spaceman 6210 User manual

Spaceman

Spaceman 6220 Series User manual

Spaceman

Spaceman SM-6228H User manual

Spaceman

Spaceman Gravity Fed Machine User manual

Spaceman

Spaceman 6224 User manual

Spaceman

Spaceman SM-6210 User manual

Spaceman

Spaceman SM-6220 User manual

Spaceman

Spaceman SM-6455H User manual

Spaceman

Spaceman SM-6236H User manual