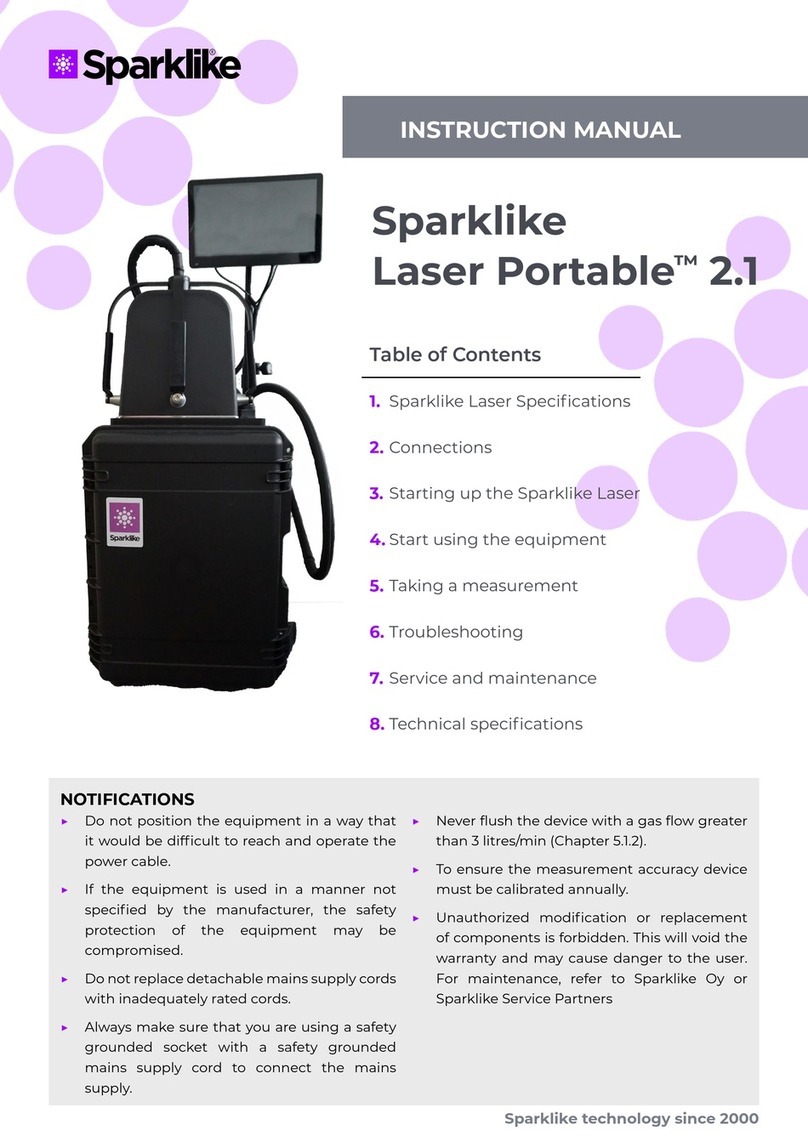

sparklike Laser Portable 2.0 User manual

Sparklike

Laser Portable™2.0

Sparklike technology since 2000

Your IG Quality Assurance

INSTRUCTION MANUAL

Table of Contents

1. Sparklike Laser Specications

2. Starting up the Sparklike LASER

3. Start using the equipment

4. Taking a measurement

5. Troubleshooting

6. Service and maintenance

7. Connections

8. Technical specications

ÎDo not position the equipment in a way that it would be

difcult to reach and operate the power cable.

ÎIf the equipment is used in a manner not specied by the

manufacturer, the safety protection of the equipment

may be compromised.

ÎDo not replace detachable mains supply cords with

inadequately rated cords.

ÎAlways make sure that you are using a safety grounded

socket with a safety grounded mains supply cord to

connect the mains supply.

ÎNever ush the device with a gas ow greater than 3 litres/

min (Chapter 3.2).

ÎTo ensure the measurement accuracy device must be

calibrated annually.

ÎUnauthorized modication or replacement of components

is forbidden. This will void the warranty and may cause

danger to the user. For maintenance, refer to Sparklike Oy or

Sparklike Service Partners.

NOTIFICATIONS:

1. SPARKLIKE LASER SPECIFICATIONS

Laser Classication

Sparklike Laser device uses a

semiconductor laser as a light source.

According to the regulations, the laser

is tested by a third party as class 1

laser product (SGS-CSTC Standards

Technical Services Co. Ltd., test report

GZES150500576331)

Class 1 Laser product

Cannot emit laser radiation at known hazard levels.

Users of Class 1 laser products are generally exempt

from radiation hazard controls during operations and

maintenance. Class 1 laser is eye-safe under normal

operating conditions.

Laser Specications

Wavelength: 760 nm

Maximum optical output power: 3 mW

Maximum single mode output power: 0.6 mW

Classication: Class 3B

Visibility: NIR (Near Infrared)

Standards & Regulations

IEC 60825-1: 2014 (Third edition)

2. STARTING UP THE SPARKLIKE LASER

After connecting all the cables, turn on the device

from the power switch on the main unit. A blue light

will light up around the power switch. Windows will

start and “Start” buttons led on the measuring device’s

handles will light up. After Windows has started, start

Laser Software by Sparklike.

When starting the Laser software, the lights at the

joint of the handles should turn on.

NOTE: When the device is turned on, start the software

and let the device warm-up for 15-30 min.

Place the measuring head to the holder at the top of

the device. Remember to lock the measuring head in

place with a locking knob.

Red light continuous Battery voltage too low but

Sparklike application is on

Green light continuous Sparklike application is on

☀Blue light blinking Device in stand by

☀Red light blinking Laser driver temperature too

high

☀

☀

Red and blue lights

blinking alternately

Laser driver temperature too

low (sensor error)

No light at all Battery switched off

The power switch has an indicator light:

Locking the knob and

Indicator leds on the handles

Power switch on the

main unit

2

3. START USING THE EQUIPMENT

3.1 Starting up the device

Remove the protective lm from the measurement

head window. Leaving the lm will interfere

measurement.

3.2 Software functionality and pages

The following chapters will discuss each page of the

software – Main Page, Settings Page, and Test Page –

and their functions.

“Measure” button on the Main Page will start the meas-

urement. It is also possible to start the measurement

directly by pressing any of the buttons on the measur-

ing head handles. For more information on taking the

measurement, read Chapter 4.

3.2.1 Software – Main Page

The Main Page of the software entails the following

functions: A place to add user comments, the choice

between measuring double or triple glazed units and

showing obtained results.

1. In the box labelled “User Comment” you can

write text to be added with your measurement

result using the on-screen keyboard found in the

Windows Taskbar. This information is saved to the

le together with your results. This box can be lled

automatically using the barcode reader.

2. Double glass measurement is set as a default for

Sparklike Laser analyser, this can be observed

from the “Double IG” indicator being green. It is

possible to measure also triple glazed products. To

measure triple glazed units, slide down the button

on the left-hand side of the Main Page. Once this is

done, the “Triple IG” indicator lights up. The default

settings can be found in the image representing the

Main Page with the default setting.

3. Pressing the “Measure” button will initiate the

measurement. During the measurement, the

“Measuring” indicator is blinking. After the

measurement has been completed, the “Ready”

indicator is lit, and you will see your measurement

results on the right-hand side of the screen.

4. In the middle of the page, you will also be able to

observe the results on the thickness of the glass and

the space between the glasses as well as the total

thickness of the IGU. You will get this reading whilst

your gas concentration measurement is measured.

5. To return all the values back to default values,

press the “Reset” button or change the values back

manually. When pressing the “Reset” button it

takes a few seconds to return all the values back to

default.

The results are displayed once the measurement is

nished. When the gas measurement results are over

the high limit value, the green indicator will light up on

the Main Page next to the measured gas concentration

results. The limits for color indicators can be dened

on the Setting Page and the indicators, green, yellow,

or red, will light up accordingly (instructions in the

following chapter labelled Software - Settings Page).

Main page

1.

4.

2.

3. 5.

3

3.2.2 User interface – Settings Page

The Settings Page of the software entails the following

functions: dening glass and spacer thicknesses (pre-

set), setting measurement time, setting the device for

multiple sequential measurements, setting the meas-

urement result indicator limits, measurement head in-

ner oxygen concentration check, and opening the daily

measurement results.

Adding (1) pre-set values with “Glass” and “Spacer” drop-

down boxes assists the software to identify the correct

glass and spacer thickness values and to enable the

measurement of glass and spacer thicknesses outside

the software default values. It is recommended to use

pre-set values if it seems that the glass thicknesses are

measured wrong. This may happen, e.g., in the case

of certain coated or laminated glasses. As a default

software identies glass thicknesses between 2 and

13 mm and spacer thicknesses from 6 to 25 mm. The

device operator can set glass thicknesses from 2 to 23

mm and spacer thicknesses from 4 to 40 mm. When

using the pre-set values via the drop-down boxes, the

software identies the glass and cavities thicknesses in

the ±1 mm range from each given value. The glass and

spacer closest to the measurement device are “Glass

1” and “Spacer 1”, the further glasses and spacer being

sequentially “Glass 2”, “Spacer 2”, and “Glass 3”.

“Measurement time” (2) drop-down box indicates the

time to collect data from one cavity. This can be adjust-

ed between 2–5 seconds. The default time is 5 seconds.

Longer measurement time is advised for greater accu-

racy.

“Enable counter” and “Meas. count” (3) refer to settings

for making multiple measurements (discussed below in

Section 4.3.1).

“High limit” and “Low limit” (4) refer to the desired result

range. For easy interpretation of the results, there are

three indicator lights next to the results, featured on the

Main Page of the software. To suit their local require-

ments, the user can set these values via the Setting

Page by adjusting the “High limit” and “Low limit” values

by clicking up or down or by using the on-screen key-

board to type the desired value. i) when the gas meas-

urement results are over the high limit value, the green

indicator will light up, ii) if the result is between high

and low limit, the yellow indicator is lit, iii) and if the

result is below the low limit, the red indicator turns on.

To access the daily measurement results, click on the

Results “Open” button (5).

NOTE: Measurement results are shown on the screen,

but are simultaneously saved on your device, and can

be accessed at Windows Explorer: Computer\Local

Disc(C:)\Temp\Results

“Gas ll”, “Self check”, “O2 concentration”, and

“Test passed” (6) refer to purging oxygen from the

measurement head (discussed below in Section 4.1.2).

“O2 concentration” tells the measured O2 concentration

inside the measurement head in percent. “Test passed”

shows the last date the self-check has been passed.

Settings page

1.

2.

4.

3.

5.

4

3.2.3 Software – Test Page

The Test Page of the software provides the laser

temperature and current check function. The laser

component needs to be operated at the correct

Test page

temperature to yield highly accurate measurement

results. Incorrect temperature adjustment may crash

the software. This is discussed below in Section 4.1.1.

4. TAKING A MEASUREMENT

4.1 Daily operations for temperature check

and gas ll

AT EVERY STARTUP: The operator should check for

temperature and oxygen concentration. This ensures

the correct operation of Sparklike Laser. To ensure the

quality of the measurements it is recommendable that

the operator checks the oxygen concentration every

two hours.

4.1.1Temperature check

The laser component needs to be operated at the cor-

rect temperature to yield highly accurate measurement

results. Let the device warm-up with software running

for 15-30 min. Incorrect temperature adjustment might

result in incorrect measurement results or unexpected

functions. Take the following actions to test the temper-

ature adjustment whenever starting up the device.

Choose the “Test” page from the upper left corner of

the software. Press the “Laser I&R” button (the indicator

below the button starts blinking) and see the following:

ΓLaser I (mA)” should be 1,7–5,9 mA and “Laser R

(kOhm)” should be 5–17 kOhm). The values are

specic for each device, depending on the laser

source.

ÎFigures on the graph should be equally spaced and

with approximately 50 points spacing. See test

menu picture.

If these are correct, press STOP. The indicator below the

“Laser I&R” button stops blinking. If these do not apply,

see the troubleshooting section in Chapter 5.6.

NOTE: remember always to press STOP before starting

to use the laser or checking the oxygen level in the

measuring head.

5

4.1.2Oxygen concentration check

Sparklike Laser is a gas ll analyser; however, it meas-

ures the oxygen absorption from the insulating glass

unit. For correct readings, oxygen inside the measuring

head needs to be removed as well as possible. This is

done by ushing the measuring head with e.g., argon,

or nitrogen. These gases are later referred as ushing

gases.

NOTE: Separate ushing gas cylinder, gas hose, regula-

tor and owmeter are needed in order to complete the

oxygen concentration check. These equipment do not

come with the device.

On the Settings Page, press “Self check” button. The

indicator below the button starts blinking and the

indicator light on the measurement head turns yellow.

The self-check will measure the oxygen concentration

inside the measuring head and show the result on the

box below the button. The operator can begin to use

the device if the result is below 0.1 %. If the oxygen con-

centration is higher than this, the software gives a “Low

inner gas concentration! Fill the device!” and the indica-

tor light on the measurement head turns red.

The date for the last successful self-check can be found

in the “Test passed” box on the Settings Page.

If the result is over 0.1%, there is too much oxygen inside

the measuring head, and you should ush the device.

Flushing the oxygen from the measurement head

ÎPlace the measuring head facing down on the

holder on the top of the case.

ÎThe gas ll inlet is next to the power switch. Attach

the connector for the ushing gas hose to the main

unit. Join the ushing gas hose (6x4mm).

ÎApply dry and pure (> 99.9%) ushing gas ow of 1–3

l/min (maximum 3 l/min!) to the hose.

ÎPress the “Gas ll” button on the software (light on

the button will turn on). This will open the internal

valves and guide the ushing gas ow through

the measuring head. During the lling, press “Self

check” button to check the concentration. On

each check, you should see the concentration

to decrease. Continue lling as long as the

concentration does not go any lower, and the self-

check result is < 0,1 %. The device can be used while

the measuring head is being ushed with a ushing

gas. After you have successfully removed the oxygen

from the measuring head by replacing it with a

ushing gas, press the “Gas ll” button again to

close the valves (indicator turns off), and disconnect

the gas ow.

NOTE: Internal oxygen concentration can be tested

anytime via Settings Page by pressing the “Self check”

button. It is recommended to do this check every two

hours, or every time when suspecting incorrect read-

ings.For any problems, see the troubleshooting section

in Chapter 5.7.

4.2Basic measurement

Choose “Double IG” or “Triple IG” from the Main Page

depending on which type of IGU you are going to meas-

ure.

Place the measuring head front cushion rmly against

the window. It is possible to start the device in two

alternative ways:

ÎPress the “Start” button directly on any of the

handles of the measuring head (see picture below).

Connector for the ushing

gas hose and the hose

Start button on

the handle

6

ÎPress the “Measure” button on the Main Page of the

software. Use only when the device is resting on a

horizontal surface (see picture: Main page).

The vacuum pump evacuates the oxygen between the

measuring head and the glass to attach them lightly

together. If the vacuum is poor, the software will give a

warning message. The “Measuring” led starts to blink on

the software. The indicator leds on the measuring head

will turn blue. Keep your hands on the handles (if the

device is not used on a horizontal surface).

The measurement takes about 18–28 seconds depend-

ing on the settings and the window to be measured.

Once the measurement is ready, the vacuum pump

stops, and the measuring head is released from the

glass. “Ready” led turns green and the results are dis-

played on the Main Page.

4.3Advanced measurement

4.3.1 Enable Counter

If you have enabled counter (Settings Page), signal how

many measurements you would like to take in a row.

First, select a number for the “Meas. count” box by click-

ing up or down arrows, or by typing a value with the on-

screen keyboard. Use of “Meas. count” is recommended

only if measuring is made on horizontal surfaces.

Then, if you press the “Enable counter” button, multiple

measurements are done in a sequence. A green indica-

tor is switched on.

NOTE: If the user has changed any of the following de-

fault values: i) glass or spacer thickness ii) measurement

time or iii) counter state, the “Pre-set Active” indica-

tor on the Main Page turns red when measuring. This

reminds the user that the measurement settings are

different from the default values. To return all the values

back to default values, press the “Reset” button on the

Main Page or change the values back manually. When

pressing the “Reset” button it takes a few seconds to

return all the values back to default.

4.3.2Editing the default settings

You can edit the default values with normal Windows

editing applications such as Notepad.

1. Open the c:\temp\Settings.ini le

2. Change the corresponding values. Do this with

discretion to not interfere with the operation of the

device. Safe values to edit are, e.g. High_limit and

Low_limit for the indicator lights on the Main page

of Sparklike Application. It is not recommended

to edit other values without consulting Sparklike

product support.

3. Save and close the le

4. Stop and restart the Sparklike Application to use

the new settings values.

4.4 Understanding the results

For triple glass units, the device measures rst the

overall value of both cavities, then the 1st cavity, and

then based on these measured results, calculates the

gas content of the 2nd cavity. Therefore, the results of

the 2nd cavity can be considered as indicative of what

complements the information of each cavity.

ÎSee the insulating gas (such as argon, krypton, or

xenon) concentration on the result boxes on the

Main Page.

Purple light continuous Device in stand by

Blue light continuous Measuring

☀Blue light blinking Vacuum missing

Green Measurement about to end/

done

Blue Self-check in progress

Yellow Gas ll valves open

Red Error

Measuring head indicator lights:

7

ÎFor a double glazed unit, only the “Cavity 1”

result is shown.

ÎFor a triple glazed unit, all three results are

shown.

ΓCavity 1” is measured, and “Cavity 2” is a

calculated

ΓCavity 1&2 avg” is the overall gas ll and it

considers the thicknesses of both cavities

(weighted average).

ÎThe measurement accuracy is dened in

Technical Specications at the end of this

manual.

Main page with sample

measurement results for

triple glass

Check that the glass and cavity dimensions are what

they should be. If they are not, see the troubleshooting

section in Chapter 5.8.

REMINDER: Measurement results are shown on the

screen, but are simultaneously saved on your device:

Disc (C:)\Temp\Results

5. TROUBLESHOOTING

5.1 Restarting the program

When starting the system, if the indicator leds on the

handles of the measuring head do not light up (Chapter

2), restart the program by closing the window from the

upper right corner.

Start the program by double-clicking the Laser software

icon on your desktop.

If the Windows freezes and you are unable to shut

down the device, press the power switch for a few

seconds to force shut down the device. If this does not

help, open the trolley case and disconnect the battery

from the switch inside the case, see picture.

5.2 DAQ identication error message

Check that Windows has a connection to the DAQ:

From Windows desktop press the “Start” icon >> Win-

dows System >> Control Panel >> Device Manager. There

should be Data Acquisition Devices >> USB DAQ.

Battery switch

inside the case

Press “Start” icon on

Windows desktop

8

1. If the USB DAQ is found (This device is working

properly): Run the ResetNICong at C:\Program Files

(x86)\National Instruments\Shared\Reset NI Cong.

After running ResetNICong it will ask you to restart

the computer, select No and turn off the computer

from the windows operation system and then turn

it on from the power switch.

2. If the USB DAQ is not found: the device is inactive.

Check that the DAQ led on the connector panel

inside the case is on.

2.1 If DAQ led is on: the USB connection is working.

Then shut down windows and after that, restart

the device. If this does not solve the problem,

contact the product support at Sparklike for

instructions.

2.2 If DAQ led is off, contact the product support at

Sparklike for instructions.

5.3 Laser temp or current out of range

Check from the connector panel that the green-la-

belled circular multipin connector is rmly connected

to the connector panel. Shut down the Windows, wait

20 seconds before restarting the device.

5.4 Drive error

Check from the connector panel that all the circular

multipin connectors are rmly attached. Shut down the

Windows, wait 20 seconds before restarting the device.

Connector panel, cable

connections and indicator

leds inside the case

5.5 Glass detection error message

If the “Glass Detection Error” message appears, check

that the pre-set glass and spacer values are correct, the

device is rmly against the glass, and the device is not

tilted. In these cases, the device window may need to

be cleaned. If that does not help, shut down the Win-

dows, and wait 20 seconds before restarting the device.

If the above-mentioned actions do not work error

message is caused by the lack of the laser signal on the

detector. This is due to insufcient amount of laser light

passing the surfaces 1 or 2 on the IGU due to coatings.

Try measuring from anther side.

5.6 Adjusting the laser temperature

If the parameters and the graph on the daily operations

(Chapter 3.2) are incorrect, please try the following

actions:

ÎLet the device warm up for 15 minutes.

ÎPress the “Stop” button and then “Laser I&R” button

on the Test page again to restart the test process

(see picture Test Page, Chapter 3.2.3.). If the readings

or the graph are still incorrect, restart the program

(see Chapter 5.1. Restarting the program) and press

“Laser I&R” button again. See picture A for reference.

ÎIf this does not help, and the graph is still not

correct (about 50 dots equal spacing), it means that

the laser temperature is incorrect and needs to be

adjusted: Try the self check function on Settings

Page. You will have an info screen about laser

temperature adjustment. See the picture Peaks

equally for the reference.

If the temperature of the laser has changed so much

that one cannot see the peaks in the Test page “Laser

I&R” test, one can ne-tune the temperature as follows

(Sparklike technical support can help you on this).

50 pts

Peaks equally

9

1. Open the c:\temp\Settings.ini le with Windows

Notepad.

2. Change the value of the “T_ne_tune” variable.

Changing the value from 0 to 0,01 will move the

peaks to about 5 data points. Using a negative value

(-0,01) will move the peaks to the opposite direction.

3. Save and close the le.

4. Open the laser software and run the “Laser I&R” test

from the “Test” page. The peaks should have moved

according to the value you’ve set to the variable.

Test page with Laser I&R

function, STOP and

distribution of peaks

5. Increase the value as much as needed and try to

nd a value where the peak spacing is close to 50

data points.

6. Check that the nal “Laser R” value is close

(inside couple of hundred Ohms) to the “Rvalue”

mentioned in the “Settings.ini” -le. If not, there

could be another oxygen peak closer to the original

value but to the “other direction” (negative or

positive adjustment value).

5.7Internal oxygen concentration problems

Sparklike Laser is a gas ll analyser that works by meas-

uring the oxygen inside the glazing unit. To ensure cor-

rect readings, oxygen needs to be removed from inside

the measuring head by replacing it with argon or other

ushing gas such as xenon or nitrogen.

Internal oxygen concentration is tested from the

Settings Page on the software by pressing the “Self

check” button. When testing the internal oxygen level

or making the argon ll, the operator might run into the

following situations:

Internal oxygen concentration result does not go below

0.1 %, as required. Normally the internal oxygen con-

centration level should drop below 0.1% within about

20 min of ushing time. If the oxygen level settles to a

value over 0.1% and does not go any lower, please check

that:

Îthe used ushing gas is pure (>99.9 % argon)

Îthere is pressure and the ow rate is 1–3 l/min

(maximum 3 l/min!)

Îgas ll button is enabled on the software’s Settings

Page

Îturn the measuring head slowly upside down a few

times to help remove oxygen (otherwise keep the

measuring head vertically on the holder)

ÎIf all of these are OK, but the problem persists,

please contact sparklik[email protected]om for further

assistance.

10

Internal oxygen concentration result drops below 0.1%,

but there is considerable variation in “Self check” results.

Once the result is very low, around 0.01–0.05%, the op-

erator might see some variation in the “Self check” read-

ings so that some readings might be even > 0.1%. This is

Settings page after

Self check isperformed

normal, as the concentration is so low, that sometimes

the measurement noise can cause variation. Important

thing is that most of the “Self check” measurements are

< 0.1%, as required.

5.8Measurement problems

If unexpected inconsistent readings are received, please

check the following things:

ÎLaser temperature

ÎInternal oxygen concentration

ÎVacuum suction holds the measuring head tightly

against the insulating glass to be measured

ÎGlass and spacer thicknesses are approximately

according to the correct expected thicknesses

ÎTry to measure close to the spacer.

ÎDo several measurements on the same IGU and

compare the results. If most of the measurements

are consistent but there are exceptional results,

repeat the measurement. The exceptional results

might be measurement errors.

ÎIf there is a special reective coating (e.g., Low-E), try

measuring from the non-coated side to get a better

signal to the sensor and more accurate results.

ÎIf the vacuum does not hold the measuring head

tightly against the glass, make sure that the IG

surface is not too bent to avoid proper contact.

You can try to help the vacuum by pressing the

measuring head against the glass rmly once the

measurement has started.

ÎIf glass or spacer thicknesses are shown incorrectly,

the measurement is taken from the incorrect

location and the results are not correct. The device

operator can try to help the analysis by providing

the pre-set values to the drop-down menus for glass

and spacer thicknesses on the Settings Page. When

the operator provides this information, the software

can locate the correct measurement locations more

easily.

If the problems persist, please contact

sparklik[email protected]om. Also, please be prepared to

have the IG structure information, coating characteris-

tics available, and the measurements data le.

11

6.SERVICE AND MAINTENANCE

6.1Calibration

To ensure the measurement accuracy Sparklike Laser

Portable 2.0 must be calibrated and maintenanced

annually.

To request calibration and/or maintenance, please

contact Sparklike Service Center

sparklike.com/en/care-and-maintenance/calibration.

6.2 Technical support using remote

connection

Sparklike can offer remote technical support using

TeamViewer application. Connect your device to the In-

ternet using an Ethernet cable. The Ethernet connector

is located in the connector panel inside the trolley case.

Please contact Sparklike sparklik[email protected]om to

open the remote connection for technical support.

6.3 Packing and shipping

Sparklike Laser Portable 2.0 is sensitive measuring

device and the device must be packed appropriately to

ensure safe shipping. Go to sparklike.com/guidance/lp

to get instructions how to pack the device for transpor-

tation.

The window of the measurement head is sensitive to

scratches. If the window of the measurement head

requires cleaning, use materials and solvents made

for delicate optical instruments.

Ethernet connector location

in the connector panel

inside the trolley

The device pack on a pallet.

7. CONNECTIONS

The measuring head is connected with 4 signal cables

to the matching sockets on the main unit and with a

ushing hose to the ushing gas inlet connector. The

signal cables and matching sockets are distinguished

by the color and text-markings. The display is connected

with an HDMI connector, USB connector, and power

cord to the main unit. For connecting or disconnecting

the cables, refer to sparklike.com/guidance/lp.

Connector panel:

Connections

12

8. TECHNICAL SPECIFICATION

Overall dimensions Main unit 410 x 290 x 560 mm (without wheels)

Measuring head 310 x 190 x 330 mm

Device in operation 440 x 390 x 1200 mm (with wheels)

Supply voltage and frequency

(refer to product label on mains

connector)

USA 120 V / 60 Hz ± 10 %

Europe 220‒240 V / 50‒60 Hz ± 10 %

Asia 100 V 50/60 Hz ± 10%

Korea 220-240 V / 50-60 HZ ± 10 %

Power consumption Max 100 W

Connecting cable 2 or 5 m

Weight Main unit 19.5 kg

Measuring head 6.5 kg

Operating conditions +5 – +40 °C, indoor use only

Humidity 20–80%

Altitude up to 2000 m

Thickness measurement

accuracy

± 50 μm *

Repeatability of the gas

measurements

± 2 % *,**

Measurement time 18–28 s (depends on the settings and IG structure)

Maximum IG thickness 51 mm (from surface 1 to surface 3 with DGU, from surface 1 to 5 with TGU)

Minimum panel thickness 2 mm

Connectors 4x circular multipin connector, RJ-45, 2x USB 2.0, VAC Power (C14)

Display 10.1” Touch Screen with Pen

Software Windows 10, Laser Software by Sparklike (all included)

Data logging capability SSD Storage (15 GB), USB/Network transfer

* Typical construction of the insulating glass unit

** At least 30 measurements are needed that 95 % condence interval is valid

13

Other manuals for Laser Portable 2.0

1

Other sparklike Measuring Instrument manuals

sparklike

sparklike Laser Portable 2.1 User manual

sparklike

sparklike GasGlass User manual

sparklike

sparklike Handheld 3.0 User manual

sparklike

sparklike Handheld User manual

sparklike

sparklike Laser Portable 2.1 User manual

sparklike

sparklike Gasglass handheld User manual

sparklike

sparklike GASGLASS HANDHELD V2 User manual

sparklike

sparklike Handheld 3.0 User manual

sparklike

sparklike Handheld 3.0 User manual

sparklike

sparklike Laser Portable 2.0 User manual