SPE DFG460-5 User manual

DFG460-5

Diamond Floor Grinder

Operating Manual

This manual is provided to persons purchasing an

SPE machine and may not be reproduced in part or full

without written permission of

SPE International Ltd.

This manual provides the basic information required

and is only to be used as a guideline.

The SPE machines are manufactured and covered by

SPE design registrations granted and pending.

SPE International Ltd reserves the right to alter the

equipment design and specification as required

without notice.

The SPE product range is subject to amendment and

improvement as a result of on going research

Honeyholes Lane, Dunholme, Lincoln LN2 3SU, England

Tel: +44 (0) 1673 860709 Fax: +44 (0) 1673 861119

Email: sales@spe-int.com

DFG460-5

Operating Manual

DFG460 Triple Head

Floor Grinder

OPERATING MANUAL

This manual covers to the best of our knowledge the operation and maintenance of the

DFG460-5 diamond floor grinder. Before operation of the equipment the manual should be

read and understood by the operator. The safety regulations must be followed at all times.

Service of electrical components should be carried out by authorised personnel.

WARNING

Failure to follow these instructions may result in serious personal injury ordeath. SPEdisclaims

all responsibility for damage to persons or objects arising as a consequence of incorrect

handling of the machine and failure to inspect the machine for damage or other faults that may

influence the operation prior to starting work.

DFG460-5

Operating Manual

INDEX

Page No

1 Starting Work

2 DFG460 Tooling

3 Maintenance

4 Safety

5 Spare Parts Breakdowns

6-7 Main Gearbox Assembly

8-9 Main Drive Assembly

10-11 Pivot Frame Assembly

12-13 Axle Frame Assembly

14-15 Adjustable Strut Assembly

16-17 Handle Assembly

18-19 Drive Gear Assembly

20-21 Intermediate Gear Assembly

22-23 Driven Gear Assembly

24 Electrical Components

25 Specification Sheet

26 Warranty

27 Declaration of Conformity

28 Conditions of Sale

DFG460-5

Operating Manual

STARTING WORK

1. BEFORE STARTING WORK ENSURE THAT THE GRINDING HEADS HAVE BEEN

FITTED, SEE PAGE 3

2. Ensure the power supply is correct for DFG460-5 - This should be a 110V 32 amp supply

from the mains or generated with a minimum of 8 kVA on 50 cycles. See Page 2 for further

details.

3. Connect a vacuum to the port at the rear of the machine to control the dust.

4. The height of the operating handle can be adjusted by using the hand-wheel at the rear of

the machine. Turning the hand-wheel anti-clockwise will raise the handle and clockwise will

lower the handle.

The grinding head of the machine can pivot and the movement can be altered by adjusting

the two grinding head stops at the front and rear of the frame.

5. Turn on the vacuum.

6. Start the machine by turning the switch on the panel to the start position. Hold for 2-3

seconds for the motor to start and then release. The switch will return to its run position.

7. To stop the machine, turn the switch to the off position.

The machine can be disassembled to enable it to fit into a small vehicle. Unplug the motor

lead from the electrical panel then take out the pins in the yokes at the base of the main

handle and also the one at the bottom of the height adjustment tube, lift the handle assembly

from the frame of the machine.

1

DFG460-5

Operating Manual

DFG460 TOOLING

The DFG460 is fitted with three drive plates that use a quick release tooling system. These

are fitted to the machine with three countersunk screws per plate. Ensure that these plates

are securely fastened to the machine prior to fitting any tools.

METAL GRINDING TOOLS

1. Disconnect the machine from the power supply.

2. Tip the DFG460 backwards onto the operator handle. The machine must be secured and

supported.

3. Fit the metal tools into the drive plates by locating the dovetail on the back of the tool into

the chamfered slot in the drive plate and slide outwards. Give the tool a tap outwards to lock

into position.

4. Repeat the above process to fit the other eight tools into the drive plates.

5. Removal of existing tools is the reverse of the above. Tap the tool inwards to unlock and

slide out of the slot in the drive plate.

6. After fitting the tools, gently lower the machine back onto the floor surface.

RESIN POLISHING TOOLS

The resin tools are fitted as a two piece system. Fitting will require a set of resin tool holders

(part no 5495 (x9)) with the Velcro backing that will accept most standard 60mm diameter

Velcro backed resin tools.

1. Disconnect the machine from the power supply.

2. Tip the DFG460 backwards onto the operator handle, the machine must be secured and

supported.

3. Fit the resin tool holders into the drive plates by locating the dovetail on the back of the

tool holder into the chamfered slot in the drive plate and slide outwards, give the tool a tap

outwards to lock into position.

4. Repeat the above process to fit the other eight tool holders into the drive plates.

5. Once all the tool holders are in place, press on the required resin tools onto the velcro

backing.

6. Changing resin tools only involves removing from the tool holder and replacing.

To remove the tool holders, tap inwards to unlock and slide out of the slot in the drive plate.

7. After fitting of the tools, gently lower the machine back onto the floor surface.

NOTE: Always use the same type and bond of tool on each of the three heads, equally worn

tools must be fitted as a set.

To ensure the correct tool is being used, check wear rates after quarter of an hour and again

at half hourly intervals, this will give an indication of total wear rates and cost per square

metres.

2

DFG460-5

Operating Manual

MAINTENANCE

AFTER USE:

Clean the machine to remove all build up of dust and surface residue. If using a hose pipe or

pressure washer, take care that water is not directed onto electrical components and switches.

(Note: Motors and switches are not waterproof)

Ensure the height adjustment thread is cleaned and then lightly oiled. Periodically it should be

removed and the female threaded section cleaned out and oiled regularly to maintain a light,

smooth height adjustment.

The flexible couplings that support the drive plates should be checked on a weekly basis, the

couplings should be firm without excessive movement.

The planetary gear case is sealed and should not require any maintenance, the internal gears

are lubricated with Lithium EPO grease.

All components should be checked daily for tightness.

All plugs, sockets and electrical leads should be checked for condition and damage.

Periodically check the oil level in the drive gearbox. Ensure that the machine is level and

remove the top blanking plug from the gearbox at the front of the machine. If oil comes out of

the hole when the plug is removed then the gearbox contains sufficient oil, if not then top up the

gear box using a SY320 grade gear oil.

3

DFG460-5

Operating Manual

SAFETY

Only trained operatives should be allowed to work the DFG460 range of floor grinders.

Note: It is possible that the noise level produced by the Diamond Floor Grinder could exceed

90dbA. Appropriate PPE must be worn and the equipment must be used in line with

guidelines laid down by the Health & Safety Executive.

Always ensure that all power leads and hoses are disconnected before attempting to service

the machine. Never tip the machine backwards until the grinding plates have stopped

rotating and the machine has been isolated at the main supply.

Noise and vibration will occur at various levels dependent on the grindingattachmentsand work

being completed. It is recommended that tests are taken on site to provide the operator with

accurate information on using the equipment within the guidelines laid down by the Health &

Safety Executive.

NOTE:

1. NEVER OPERATE THE DFG460 FLOOR GRINDER OUTDOORS IN WET CONDITIONS AS

THE ELECTRICAL COMPONENTS ARE NOT WATERPROOF

2. NEVER OPERATE THE DFG460 WITH THE HEADS RAISED FROM THE FLOOR

3. THE SERVICE OF ELECTRICAL COMPONENTS SHOULD BE CARRIED OUT BY

AUTHORISED PERSONNEL ONLY.

4

DFG460-5

Operating Manual

5

[

6HH1RWH

6HH1RWH

%RWK6LGHV

6HH1RWH

%RWK6LGHV

[

[

[

3ODQ(OHYDWLRQ2I*HDUER[

:LWK7RS3ODWH5HPRYHG

2Q$VVHPEO\*HDUV7R0HVK

6PRRWKO\$QG5XQ7RJHWKHU

:LWKRXW%LQGLQJ

,PSRUWDQW)LOO:LWKJ

2I(322/LWKLXP

*UHDVH2Q$VVHPEO\

5HPRYH6KDUS(GJHV&RUQHUV

$OO0DFKLQHG6XUIDFHV7R%H6TXDUH3DUDOOHO

1RWH6HDO*HDUER[2Q$VVHPEO\:LWK*DVWLWH0XOWL3XUSRVH6LOLFRQH6HDODQW&OHDU

5(9,6,216

5(9

'(6&5,37,21

'$7(

$33529('

,1,7,$/5(/($6(

%-

'21276&$/(

/LVWRI3DUWVDQG0DWHULDOV

$

'5$:,1*1R

7,7/(

')*0DLQ*HDUER[$VVHPEO\

')*

'$7(

*(1(5$/72/(5$1&(

0081/(66

27+(5:,6(67$7('

$//',0(16,216

,10081/(66

27+(5:,6(67$7('

7+,5'$1*/(

),1,6+

0$7(5,$/

47<

6&$/(

'5$:1%<

'5$:,1*1R

7,7/(

')*0DLQ*HDUER[$VVHPEO\

')*

7+,6'2&80(17,635,9$7($1'

&21),'(17,$/$1'7+(3523(57<

2)63(,17(51$7,21$//WG,70867

127%(&23,('2568%0,77('72

$1<7+,5'3$57<:,7+2877+(

&216(172)63(,17(51$7,21$//WG

685)$&(35(3$5$7,21(48,30(17

63(,QWHUQDWLRQDO/WG

+RQH\KROHV/DQH

'XQKROPH

/LQFROQVKLUH

/168

(QJODQG

7HO

)D[

:HE6LWHKWWSZZZVSHLQWFRP

(PDLOLQIR#VSHLQWFRP

*'&

DFG460-5

Operating Manual

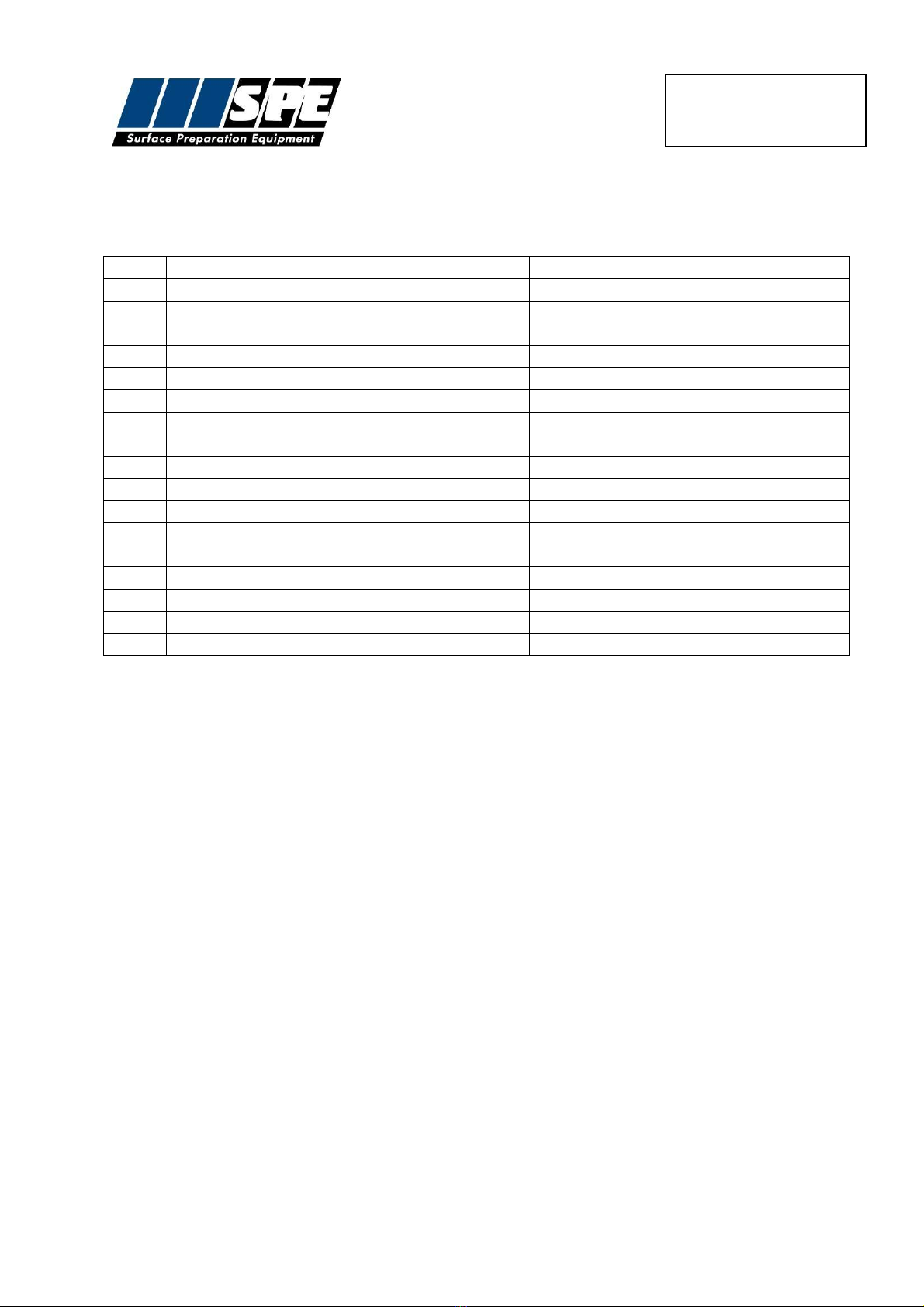

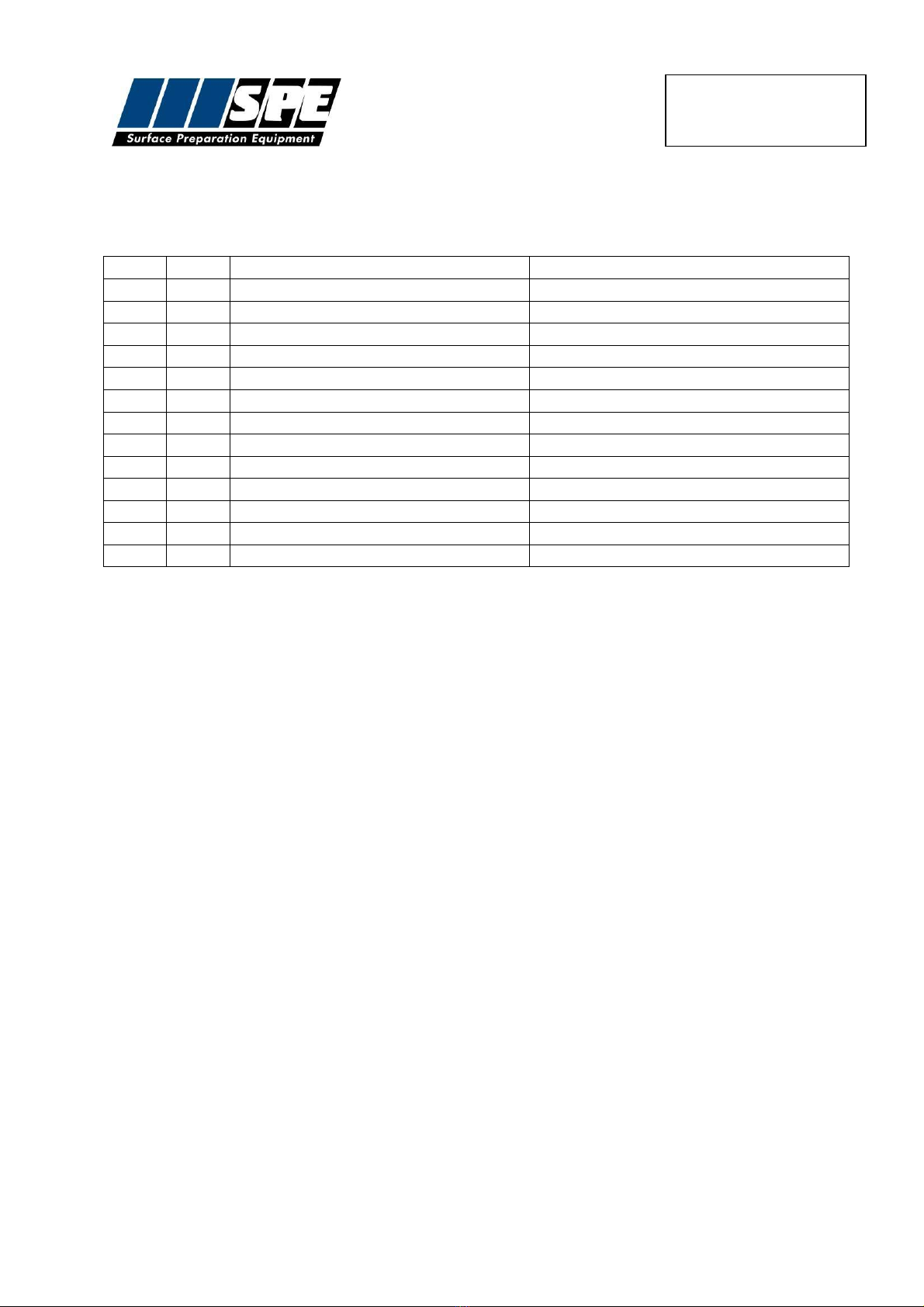

MAIN GEARBOX ASSEMBLY

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

5504

Upper Gear Plate

2

-

See drawing no. DFG-460-0066-1

Page 18-19

3

-

See drawing no. DFG-460-0067-1

Page 20-21

4

-

See drawing no. DFG-460-0068-1

Page 22-23

5

1

5525

Main Hub

6

1

5505

Upper Gear Ring

7

1

5506

Lower Gear Ring

8

1

5507

Lower Gear Plate

9

1

7424

Lip Seal

10

6

BOLT246

M8 x 16 Cap HD Skt Screw

11

6

WASHER004

M8 Flat Washer

12

6

WASHER024

M8 Spring Washer

13

6

BOLT226

M6 x 45 Cap HD Skt Screw

14

12

BOLT225

M6 x 40 Cap HD Skt Screw

15

6

BOLT224

M6 x 12 Cap HD Skt Screw

16

18

NUT043

M6 Nyloc Nut

17

24

WASHER003

M6 Flat Washer

7

1RWH$OO)DVWHQHUV7R%H6HFXUHG:LWK/RFNWLWH2Q$VVHPEO\

5(9,6,216

5(9

'(6&5,37,21

'$7(

$33529('

92/7$*(83'$7(

%-

'21276&$/(

/LVWRI3DUWVDQG0DWHULDOV

$

'5$:,1*1R

7,7/(

')*0DLQ'LYH$VVHPEO\

96LQJOH6SHHG

')*

'$7(

*(1(5$/72/(5$1&(

0081/(66

27+(5:,6(67$7('

$//',0(16,216

,10081/(66

27+(5:,6(67$7('

7+,5'$1*/(

),1,6+

0$7(5,$/

47<

6&$/(

'5$:1%<

'5$:,1*1R

7,7/(

7+,6'2&80(17,635,9$7($1'

&21),'(17,$/$1'7+(3523(57<

2)63(,17(51$7,21$//WG,70867

127%(&23,('2568%0,77('72

$1<7+,5'3$57<:,7+2877+(

&216(172)63(,17(51$7,21$//WG

685)$&(35(3$5$7,21(48,30(17

63(,QWHUQDWLRQDO/WG

+RQH\KROHV/DQH

'XQKROPH

/LQFROQVKLUH

/168

(QJODQG

7HO

)D[

:HE6LWHKWWSZZZVSHLQWFRP

(PDLOLQIR#VSHLQWFRP

*'&

DFG460-5

Operating Manual

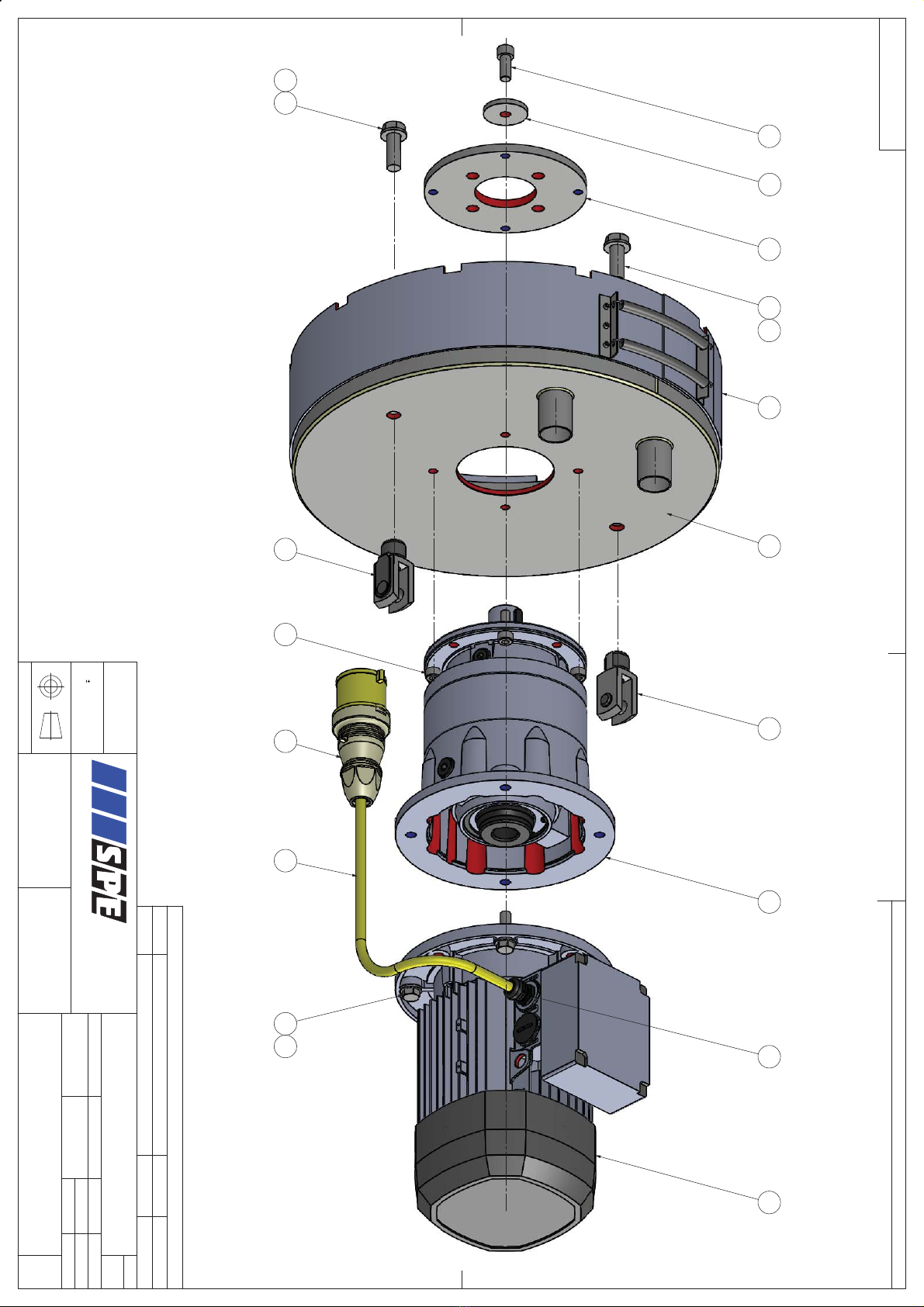

MAIN DRIVE ASSEMBLY

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

5520

Gearbox Retaining Plate

2

1

5539

Gearbox Lock Washer

3

2

5513

Yoke & Clevis Pin

4

1

5511

Gearbox

5

1

7017

Electric Motor

6

1

5512

Dust Skirt

2

7331

Dust Skirt Spring

7

1

5503

Cowl

8

1

SPCG/LNM20

Cable Gland

9

1

SP230-404

32A 4Pin Trailing Plug

10

1

7513

4.0mm² Arctic Yellow Cable

11

2

BOLT094

M16 x 45 Set Screw

12

2

WASHER008

M16 Flat Washer

13

4

BOLT082

M12 x 40 Set Screw

14

1

BOLT282

M12 x 30 Cap HD Skt Screw

15

4

WASHER006

M12 Flat Washer

16

4

BOLT263

M10 x 30 Cap HD Skt Screw

9

5HPRYH6KDUS(GJHV&RUQHUV

$OO0DFKLQHG6XUIDFHV7R%H6TXDUH3DUDOOHO

1RWH$OO)DVWHQHUV7R%H6HFXUHG:LWK/RFNWLWH2Q$VVHPEO\

5(9,6,216

5(9

'(6&5,37,21

'$7(

$33529('

,1,7,$/5(/($6(

%-

'21276&$/(

/LVWRI3DUWVDQG0DWHULDOV

$

'5$:,1*1R

7,7/(

')*3LYRW)UDPH$VVHPEO\

')*

'$7(

*(1(5$/72/(5$1&(

0081/(66

27+(5:,6(67$7('

$//',0(16,216

,10081/(66

27+(5:,6(67$7('

7+,5'$1*/(

),1,6+

0$7(5,$/

47<

6&$/(

'5$:1%<

'5$:,1*1R

7,7/(

176

')*

7+,6'2&80(17,635,9$7($1'

&21),'(17,$/$1'7+(3523(57<

2)63(,17(51$7,21$//WG,70867

127%(&23,('2568%0,77('72

$1<7+,5'3$57<:,7+2877+(

&216(172)63(,17(51$7,21$//WG

685)$&(35(3$5$7,21(48,30(17

63(,QWHUQDWLRQDO/WG

+RQH\KROHV/DQH

'XQKROPH

/LQFROQVKLUH

/168

(QJODQG

7HO

)D[

:HE6LWHKWWSZZZVSHLQWFRP

(PDLOLQIR#VSHLQWFRP

*'&

DFG460-5

Operating Manual

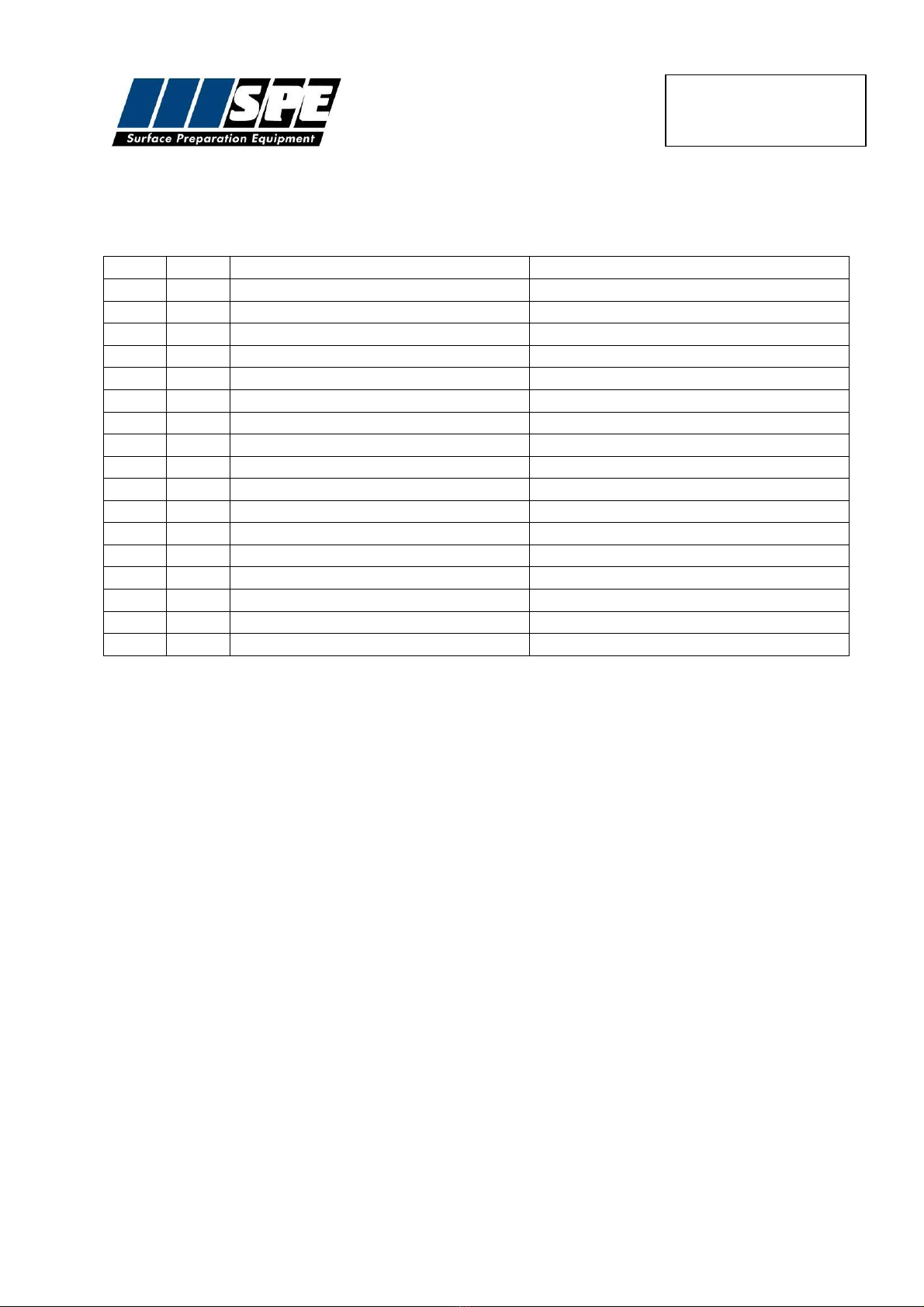

PIVOT FRAME ASSEMBLY

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

5501

Frame

2

1

5540

Frame Lock Washer

3

1

5508

Cover Plate

4

3

5515

Thumb Screw

5

2

BOLT064

M10 x 40 Set Screw

6

1

BOLT062

M10 x 30 Set Screw

7

2

NUT005

M10 Nut

11

2YHUDOO

5HI

5HI

5HI

5HI

1RWH$OO)DVWHQHUV7R%H6HFXUHG:LWK/RFNWLWH2Q$VVHPEO\

5(9,6,216

5(9

'(6&5,37,21

'$7(

$33529('

,1,7,$/5(/($6(

%-

'21276&$/(

/LVWRI3DUWVDQG0DWHULDOV

$

'5$:,1*1R

7,7/(

')*$[OH)UDPH$VVHPEO\

')*

'$7(

*(1(5$/72/(5$1&(

0081/(66

27+(5:,6(67$7('

$//',0(16,216

,10081/(66

27+(5:,6(67$7('

7+,5'$1*/(

),1,6+

0$7(5,$/

47<

6&$/(

'5$:1%<

'5$:,1*1R

7,7/(

176

')*$[OH)UDPH$VVHPEO\

')*

7+,6'2&80(17,635,9$7($1'

&21),'(17,$/$1'7+(3523(57<

2)63(,17(51$7,21$//WG,70867

127%(&23,('2568%0,77('72

$1<7+,5'3$57<:,7+2877+(

&216(172)63(,17(51$7,21$//WG

685)$&(35(3$5$7,21(48,30(17

63(,QWHUQDWLRQDO/WG

+RQH\KROHV/DQH

'XQKROPH

/LQFROQVKLUH

/168

(QJODQG

7HO

)D[

:HE6LWHKWWSZZZVSHLQWFRP

(PDLOLQIR#VSHLQWFRP

*'&

DFG460-5

Operating Manual

AXLE FRAME ASSEMBLY

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

5541

Axle Assembly

2

14

WASHER009

M20 Flat Washer

3

2

2013

Rear Wheel

4

1

5031

Oilite Bush

5

2

BOLT042

M8 x 20 Set Screw

6

2

WASHER053

M8 x 40 Repair Washer

13

$OWHUQDWLYHO\)LW

6SULQJ3LQ2Q$VVHPEO\

5HPRYH6KDUS(GJHV&RUQHUV

$OO0DFKLQHG6XUIDFHV7R%H6TXDUH3DUDOOHO

5(9,6,216

5(9

'(6&5,37,21

'$7(

$33529('

,1,7,$/5(/($6(

%-

'21276&$/(

/LVWRI3DUWVDQG0DWHULDOV

')*

')*$GMXVWDEOH6WUXW$VVHPEO\

7,7/(

'5$:,1*1R

$

7+,5'$1*/(

*'&

7HO

)D[

:HE6LWHKWWSZZZVSHLQWFRP

(PDLOLQIR#VSHLQWFRP

63(,QWHUQDWLRQDO/WG

+RQH\KROHV/DQH

'XQKROPH

/LQFROQVKLUH

/168

(QJODQG

7+,6'2&80(17,635,9$7($1'

&21),'(17,$/$1'7+(3523(57<

2)63(,17(51$7,21$//WG,70867

127%(&23,('2568%0,77('72

$1<7+,5'3$57<:,7+2877+(

&216(172)63(,17(51$7,21$//WG

')*

7,7/(

'5$:,1*1R

$

'5$:1%<

6&$/(

47<

0$7(5,$/

),1,6+

7+,5'$1*/(

'$7(

685)$&(35(3$5$7,21(48,30(17

$//',0(16,216

,10081/(66

27+(5:,6(67$7('

*(1(5$/72/(5$1&(

0081/(66

27+(5:,6(67$7('

176

DFG460-5

Operating Manual

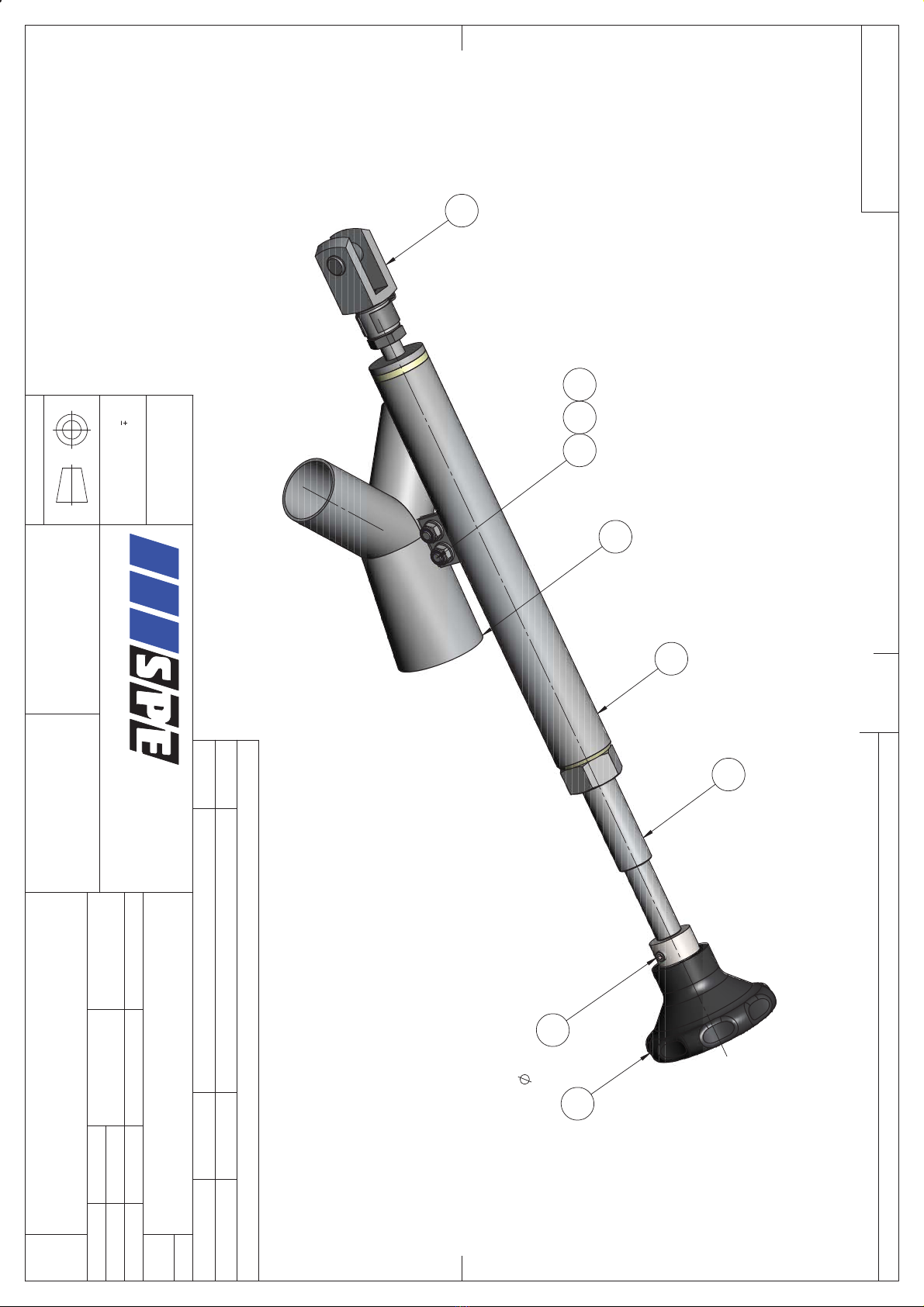

ADJUSTABLE STRUT ASSEMBLY

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

5509

Height Rod

2

1

5510

Hose Y Piece

3

1

5518

Height Screw

4

1

9122

Yoke & Clevis Pin

5

1

5519

Handwheel

6

2

BOLT227

M6 x 16 Cap HD Skt Screw

7

2

NUT043

M6 Nyloc Nut

8

2

WASHER003

M6 Flat Washer

9

1

BOLT302

M6 Grub Screw

15

5HI

5HI

1RWH$OO)DVWHQHUV7R%H6HFXUHG:LWK/RFNWLWH2Q$VVHPEO\

5(9,6,216

5(9

'(6&5,37,21

'$7(

$33529('

,1,7,$/5(/($6(

%-

'21276&$/(

/LVWRI3DUWVDQG0DWHULDOV

$

'5$:,1*1R

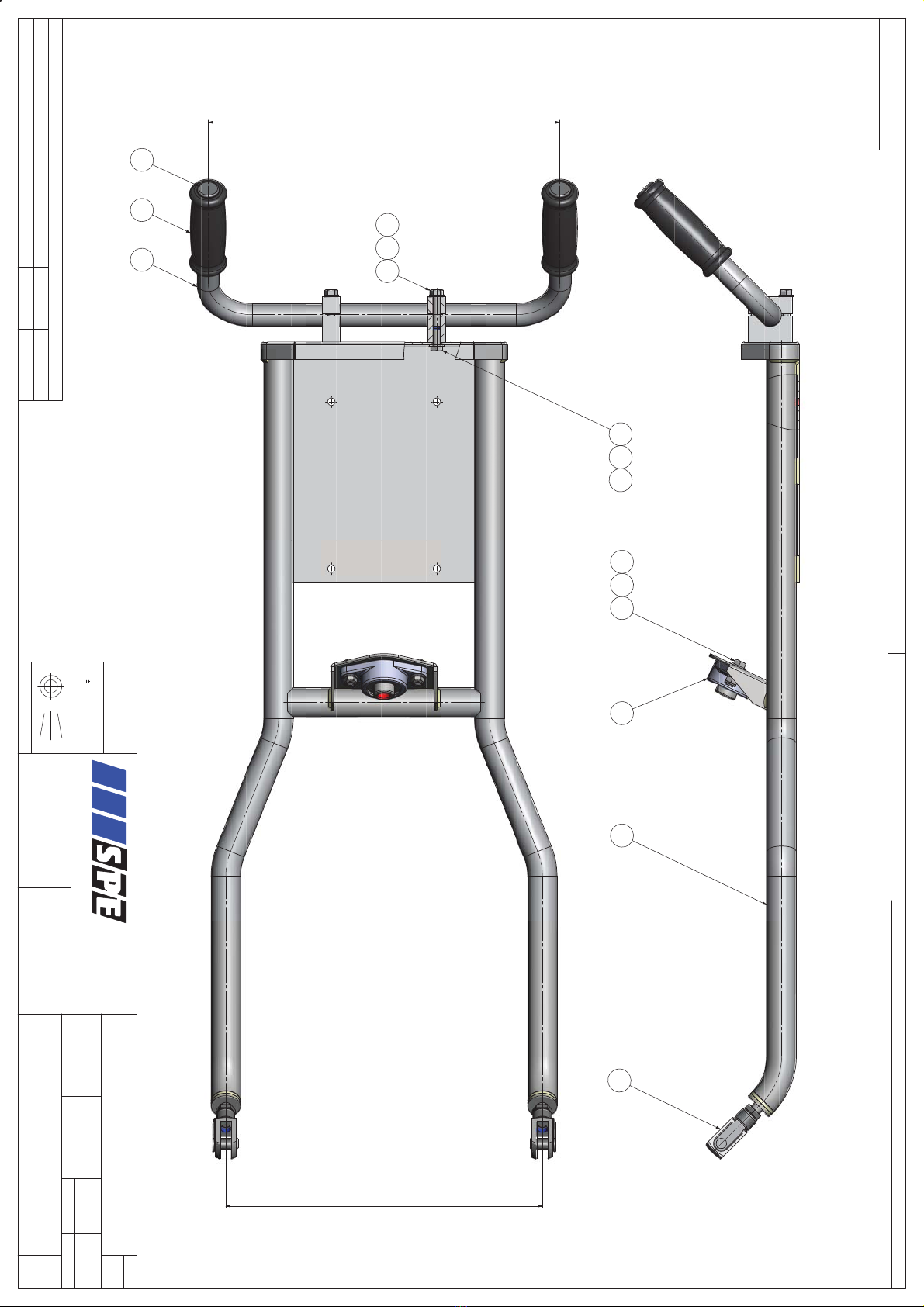

7,7/(

')*+DQGOH$VVHPEO\

')*

'$7(

*(1(5$/72/(5$1&(

0081/(66

27+(5:,6(67$7('

$//',0(16,216

,10081/(66

27+(5:,6(67$7('

7+,5'$1*/(

),1,6+

0$7(5,$/

47<

6&$/(

'5$:1%<

'5$:,1*1R

7,7/(

')*+DQGOH$VVHPEO\

')*

7+,6'2&80(17,635,9$7($1'

&21),'(17,$/$1'7+(3523(57<

2)63(,17(51$7,21$//WG,70867

127%(&23,('2568%0,77('72

$1<7+,5'3$57<:,7+2877+(

&216(172)63(,17(51$7,21$//WG

685)$&(35(3$5$7,21(48,30(17

63(,QWHUQDWLRQDO/WG

+RQH\KROHV/DQH

'XQKROPH

/LQFROQVKLUH

/168

(QJODQG

7HO

)D[

:HE6LWHKWWSZZZVSHLQWFRP

(PDLOLQIR#VSHLQWFRP

*'&

DFG460-5

Operating Manual

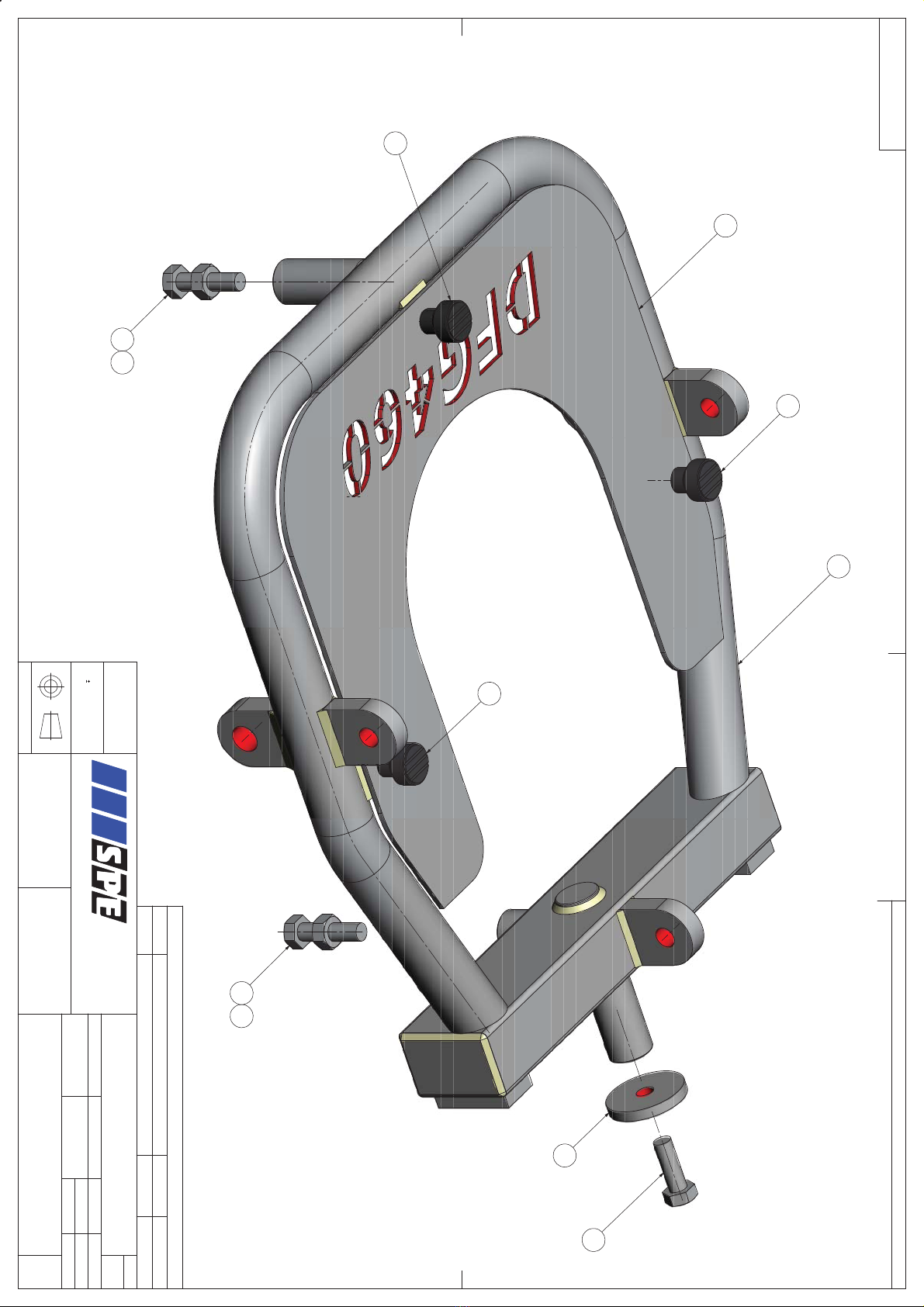

HANDLE ASSEMBLY

ITEM

QTY

PART NUMBER

DESCRIPTION

1

2

9122

Yoke & Clevis Pin

2

1

5502

Handle Assembly

3

2

5516

Handle Clamp

4

2

5516

Handle Clamp

5

1

5517

Handle Bar

6

1

9134

Bearing

7

2

9104

Hand Grip

8

2

TI/011

Tube End

9

4

BOLT045

M8 x 35 Set Screw

10

2

BOLT043

M8 x 25 Set Screw

11

4

BOLT042

M8 x 20 Set Screw

12

2

NUT044

M8 Nyloc Nut

13

12

WASHER004

M8 Flat Washer

17

This manual suits for next models

1

Table of contents

Other SPE Floor Machine manuals