SPE DFG500-2 User manual

DFG500-2

Twin Speed

Diamond Floor Grinder

Operating Manual

This manual is provided to persons purchasing an

SPE machine and may not be reproduced in part or full

without written permission of

SPE International Ltd.

This manual provides the basic information required

and is only to be used as a guideline.

The SPE machines are manufactured and covered by

SPE design registrations granted and pending.

SPE International Ltd reserves the right to alter the

equipment design and specification as required

without notice.

The SPE product range is subject to amendment and

improvement as a result of on going research

Honeyholes Lane, Dunholme, Lincoln LN2 3SU, England

Tel: +44 (0) 1673 860709 Fax: +44 (0) 1673 861119

Email: sales@spe-int.com

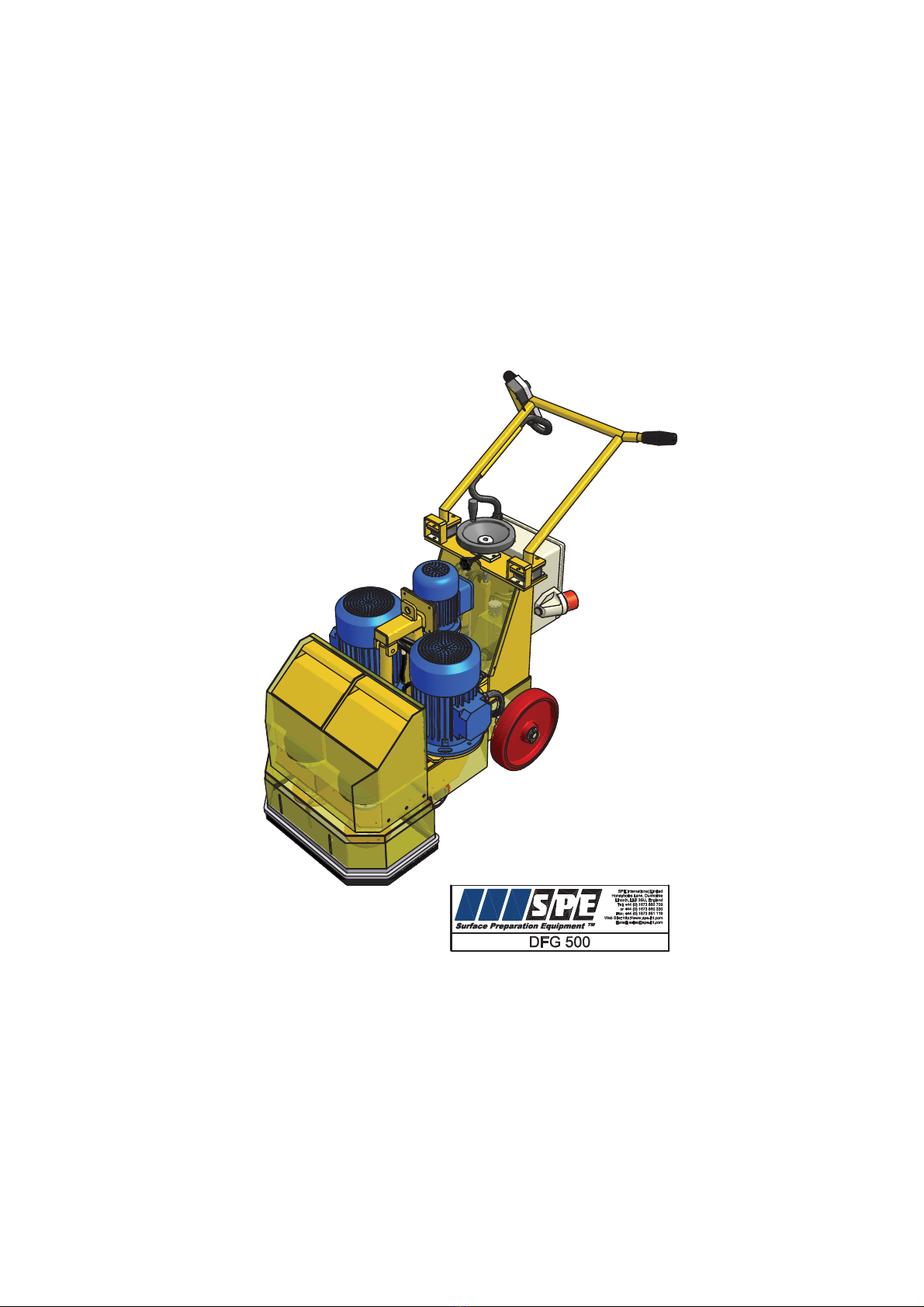

DFG500 - 2

Operating Manual

DFG500 Twin Speed

Diamond Floor Grinder

OPERATING MANUAL

This manual covers to the best of our knowledge the operation and maintenance of the

DFG 500 - 2 diamond floor grinder. Before operation of the equipment the manual should be

read and understood by the operator. The safety regulations must be followed at all times.

Service of electrical and hydraulic components should be carried out by authorised personnel.

Failure to follow these instructions could result in damage to the machine and/or serious

personal injury or death.

WARNING

Failure to follow these instructions may result in serious personal injury or death. SPE

disclaims all responsibility for damage to persons or objects arising as a consequence of

incorrect handling of the machine and failure to inspect the machine for damage or other faults

that may influence the operation prior to starting work.

DFG500 - 2

Operating Manual

INDEX

Page No

1 Starting Work

2 Changing Grinding Plates

Wet Grinding

Weights

3 Maintenance

4 Safety

5-6 Reversing Phases

Twin Speed Operation

7-8 Accessories

9 Spare Parts Breakdown

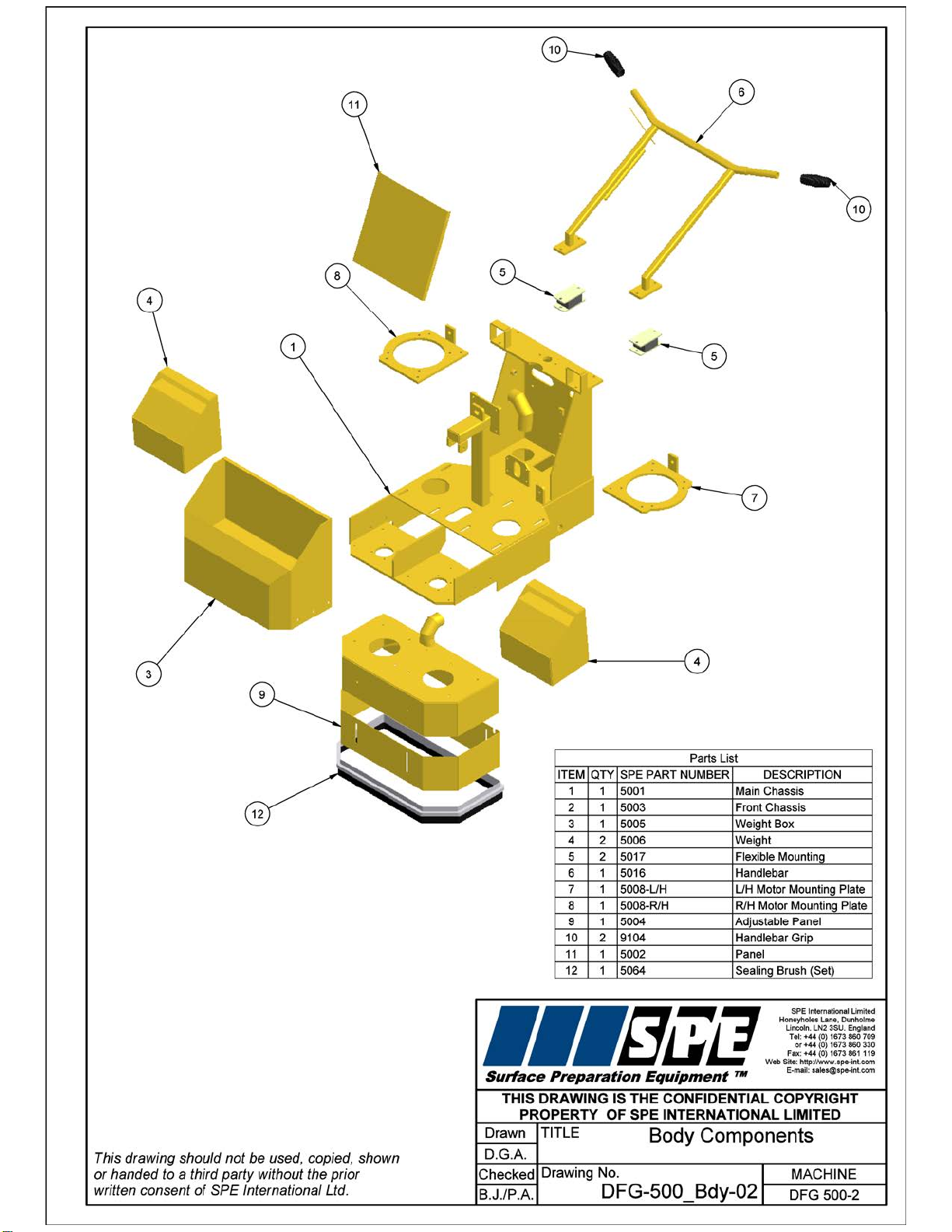

10 Body Components

11 Drive Components

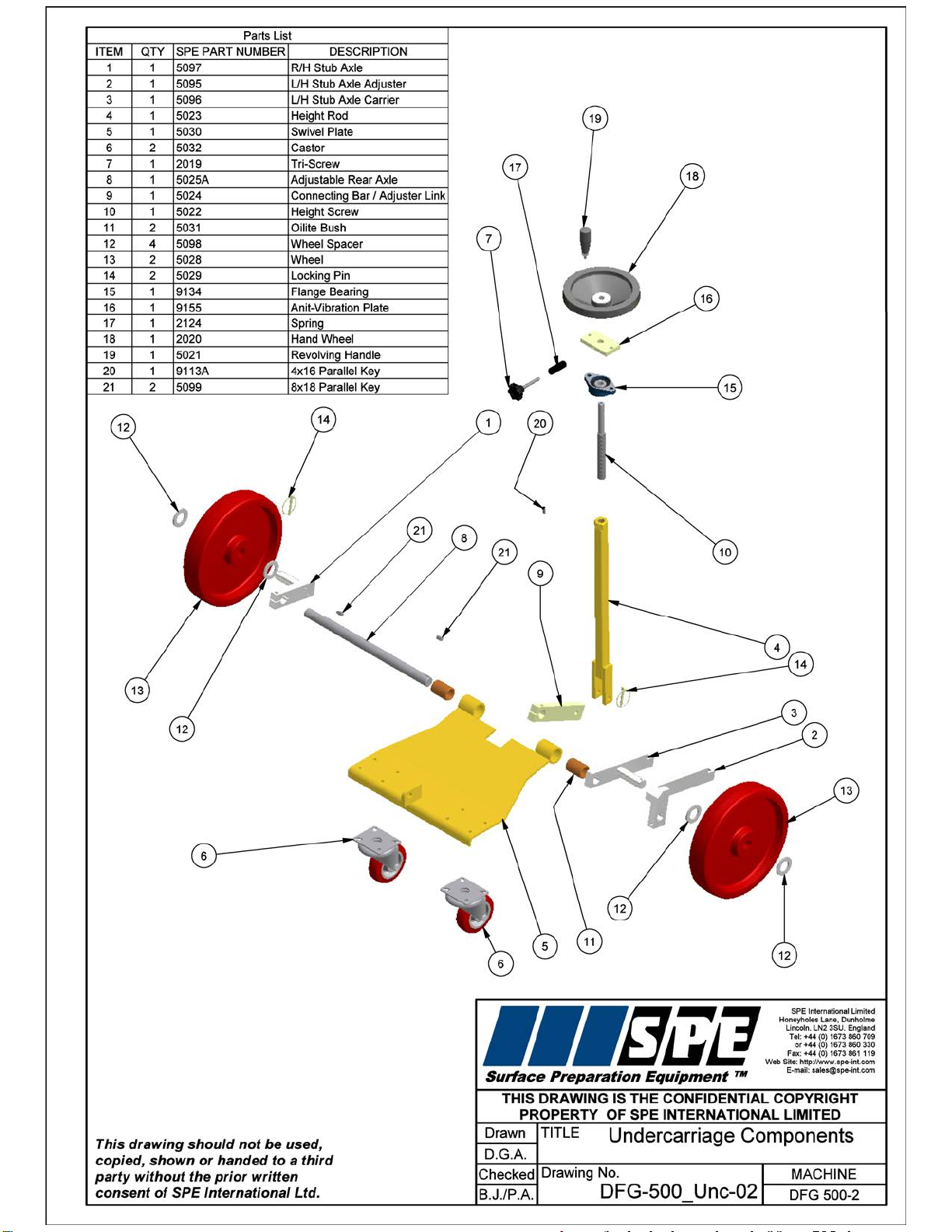

12 Undercarriage Components

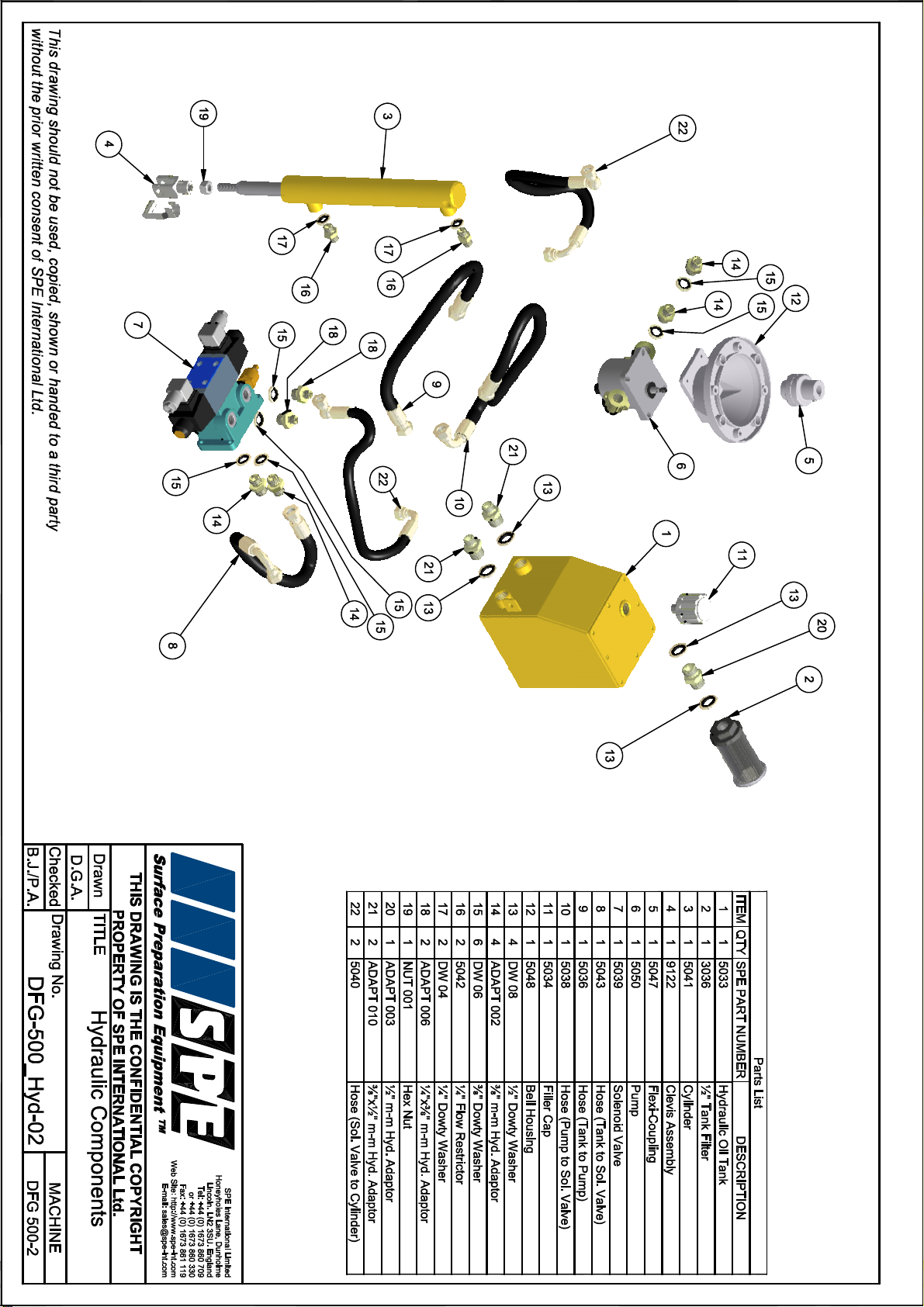

13 Hydraulic Components

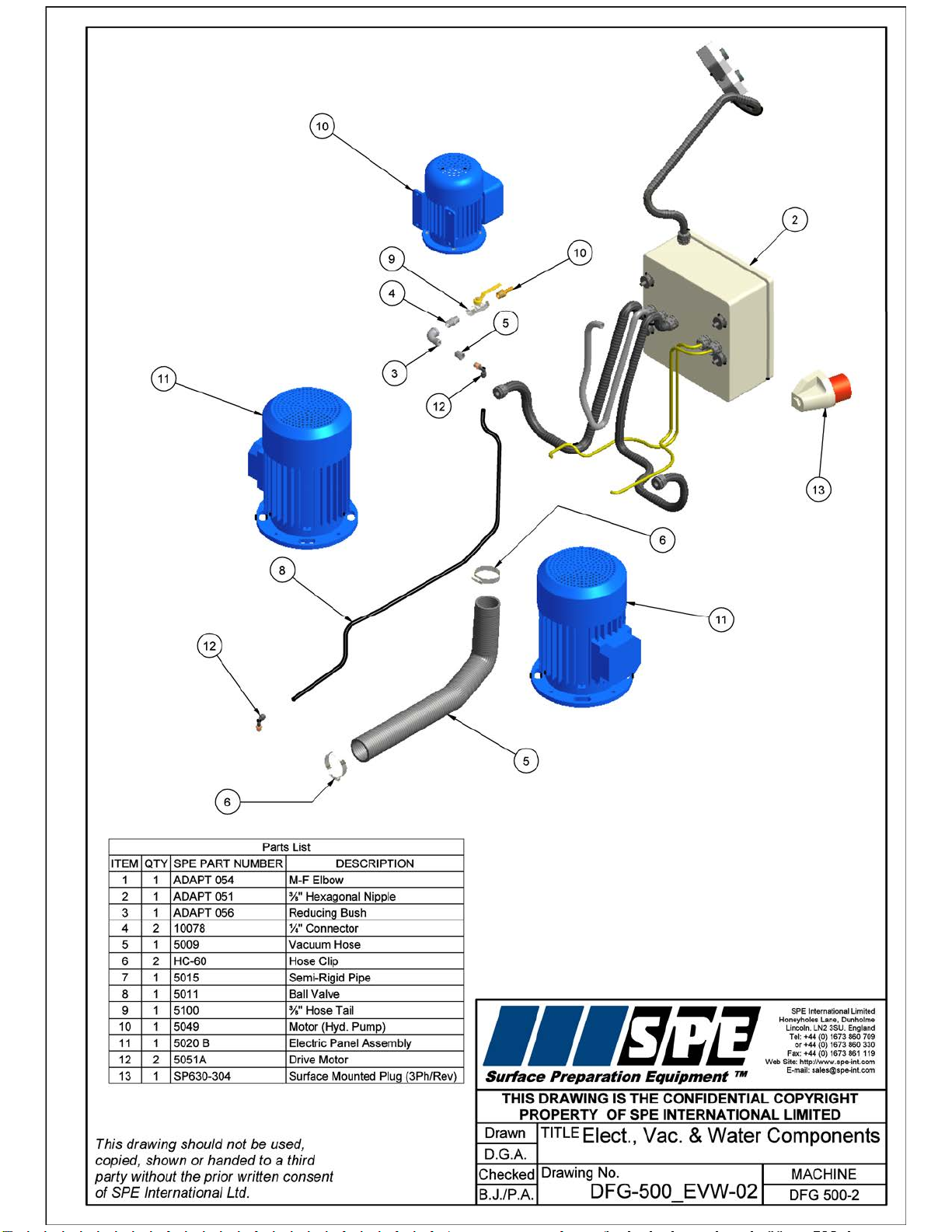

14 Electric, Vacuum & Water Components

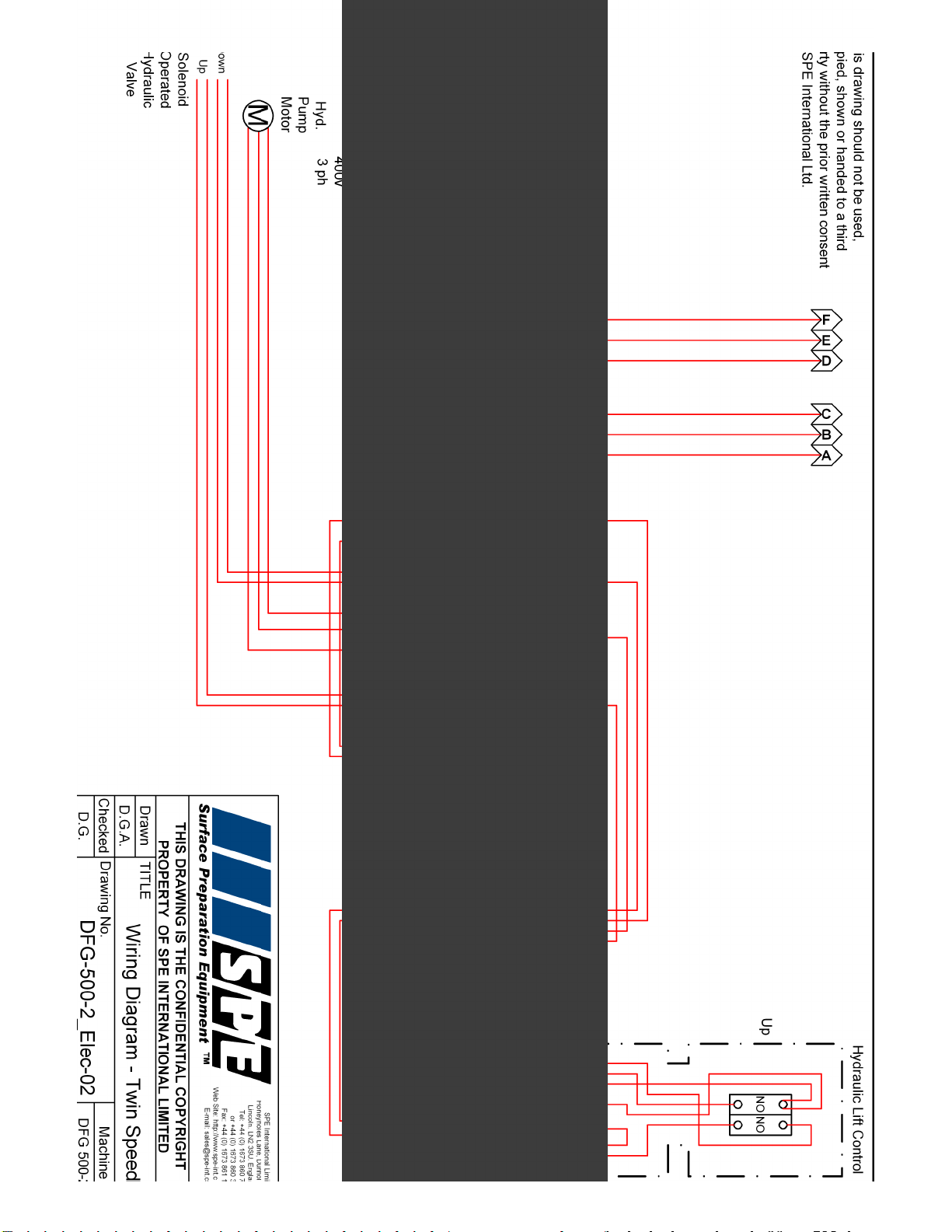

15-16 Wiring Diagram

17 Electrical Components

18 Specifications

19 Noise/Vibration Assessment

20 Warranty

21 Declaration of Conformity

22 Conditions of Sale

DFG500 - 2

Operating Manual

STARTING WORK

BEFORE STARTING WORK CHECK SET UP OF THE MACHINE AND GRINDING

PLATES HAS BEEN COMPLETED.

1. Ensure the power supply is correct.

DFG 500 - this should be a 380/415v 32 amp supply from the mains or generated with a

minimum of 20 kva on 50 cycles.

2. DFG 500 - the plug on the machine is a 380/415v 32 amp red plug.

3. After connecting the machine to the power supply, turn the red isolator switch to the On

position red light will illuminate on the electric panel. To check that the 3 phase power

supply is phased to suit the machine, press the raise and lower buttons on the handle bar.

If the machine works correctly on the buttons the supply is phased to suit the machine. If

not 2 of the 3 phases must be reversed – see page 5.

4. Raise the machine high enough to gain access to the dust skirt, slacken the screws thus

ensuring the skirt is free to move up and down as required.

5. Lower the machine on to the grinding plates and make sure the jockey wheels are free

moving and off the floor surface.

6. It is vital that the machine should grind the floor along the same plane (Incorrect set-

up will result in uneven diamond wear, deep grinding marks, vibration and damage

to flexible couplings that support the heads).

7. Set the machine down on the floor to be prepared and check the level of the floor with a

spirit level. Place the spirit level on the front side of the machine and adjust the rear wheel

height using the black hand wheel until the level of the machine is the same as the level of

the floor. Then lock the hand wheel.

8. Fit the dust skirt to the correct height, approx 0.5mm clear of the floor and tighten up set

screws.

9. Lift the floor grinder up on to the jockey wheels using the raise button on handlebar.

Examine grinding plates for any damage and check allen screws bolts are tight – see page

2 changing grinding plate for torque settings. Connect vacuum hose or water supply to

control dust. WARNING – DO NOT ALLOW WATER TO MAKE CONTACT WITH ANY

ELECTRICAL COMPONENTS. The floor grinder is now ready to commence work.

10. Start both motors up by pressing the start buttons one at a time and allow the machine

to run for approximately 30 seconds.

11. Lower the machine on to the floor whilst moving the machine either forwards or

backwards. Try to grind the surface in a figure of eight pattern for best finish.

12. When lifting machine to cease grinding the heads should be lifted off the floor slowly

with the dust extraction still operating in order to allow the dust to clear from the work area.

13. If the operator has any difficulty whilst operating the machine press the red stop button

located at the back of the machine.

NEVER ALLOW THE MACHINE TO REMAIN STATIONARY WHILST THE PLATES ARE

ROTATING AND IN CONTACT WITH THE SURFACE.

NEVER CHANGE SPEED SETTING WHILST MACHINE IS IN USE – SEE PAGE 5

1

DFG500 - 2

Operating Manual

CHANGING GRINDING PLATES

1. Make sure heads have stopped rotating, lift the DFG off the floor to its maximum height.

2. Disconnect from power supply.

3. Tilt the machine backwards on to its handles. The machine must be secured and

supported.

4. Make sure the grinding plate is cool to the touch.

5. Use an 8mm Allen key to undo the countersunk screws securing the diamond plate to

the flexible couplings.

6. Remove grinding plate and replace.

7. Ensure grinding plates are seated to coupling correctly prior to tightening counter sunk

screws diagonally to a maximum torque of 75Nm.

8. Lower the machine back to an upright position.

9. Reconnect to the power supply.

10. Two equally worn heads must be fitted as a pair.

11. Set the machine level to floor, see starting work.

CHECK FOR CORRECT WEAR RATE AFTER QUARTER OF AN HOUR AND AGAIN AT

HALF AN HOUR INTERVAL. - THIS WILL GIVE AN IDEA OF WEAR RATE

SEE SPECIFICATION SHEET FOR AVAILABLE PLATES – SEE PAGES 7-8

12. Adjust machine level as the plate reduces through wear.

WET GRINDING

When grinding wet a hose is connected to the water tap on the side of the machine where

an adjustment handle for the water supply is mounted. The water is ejected forward under

the grinding plate.

When grinding wet the machine should still not be allowed to stop moving whilst the plates

are in contact with the surface

WARNING: DO NOT ALLOW WATER TO MAKE CONTACT WITH ANY ELECTRICAL

COMPONENTS

WEIGHTS

It is recommended that the ballast weights are removed at the commencement of grinding

and ONLY ADDED if an increased pressure is needed on the surface.

2

DFG500 - 2

Operating Manual

MAINTENANCE

AFTER USE:

- Clean the machine to remove all build up of dust and surface residue. If using a hose

pipe or pressure washer take care that water is not directed onto electrical components

and switches.

(Note: Motors and switches are not waterproof)

- Ensure the height adjustment thread is cleaned and then lightly oiled. Periodically it

should be removed and the female, threaded section cleaned out and oiled to maintain a

light, smooth height adjustment.

- The drive belts will give a long and trouble free operating life if basic procedures are

followed. The drive belts are tensioned by sliding the motor along the adjusting slots. It is

important that the drive belt is not over tensioned. Serious damage could be caused to

the drive shaft, drive shaft bearings and drive motor if the belt is excessively tight.

- All components should be checked daily for tightness and the drive belts for tension

weekly.

- The flexible drive couplings that support the grinding heads should be checked on a

weekly basis, the couplings should be firm without excessive movement.

- Any excess vibration due to uneven headwear should result in the heads being changed

to eliminate damage to couplings and bearing assembly support units.

3

DFG500 - 2

Operating Manual

SAFETY

Only trained operatives should be allowed to work the DFG500 range of floor grinders.

Note: It is possible that the noise level produced by the Diamond Floor Grinder could

exceed 90dbA. Appropriate PPE must be worn and the equipment must be used in line

with guidelines laid down by the Health & Safety Executive.

Never leave the DFG500 unattended whilst in use. Always stop the motors and lift the

heads of the machine prior to leaving the machine.

Always ensure that all power leads and hoses are disconnected before attempting to

service the machine. Never tip the machine backwards until the grinding plates have

stopped rotating and the machine has been isolated at main supply.

Noise and vibration will occur at various levels dependent on the attachments and work being

completed. SPE have assessments conducted under test conditions detailed in the operating

manual, see page 19. However, it is recommended that additional tests are taken on site to

provide the operator with accurate information on using the equipment within the guidelines

laid down by the Health & Safety Executive.

NOTE:

1. NEVER OPERATE THE DIAMOND FLOOR GRINDER WITHOUT BELT GUARDS

FITTED

2. NEVER OPERATE THE DIAMOND FLOOR GRINDER OUTDOORS IN WET

CONDITIONS AS THE ELECTRICAL COMPONENTS ARE NOT WATERPROOF

4

DFG500 - 2

Operating Manual

REVERSING PHASES

If the machine does not raise or lower correctly on the buttons on the handle bar, the power

supply is phased incorrectly for the machine. Disconnect power cable and reverse phases

as shown on page overleaf.

Reconnect power cable and retest. If the phases have not reversed and machine does not

work correctly, seek advice of qualified electrician.

TWIN SPEED OPERATION

The DFG500-2 is fitted with a switch located on the electric panel allowing a high and low

speed grinding option. The high speed setting is recommended for the majority of

applications such as concrete grinding and coating/adhesive removal. The slow speed

setting is recommended for polishing applications using the polymer diamond system.

The speed setting must be selected prior to starting the grinding heads.

DO NOT CHANGE SPEED SETTING DURING USE AS THIS MAY CAUSE SERIOUS

DAMAGE TO ELECTRICAL COMPONENTS.

5

DFG500 - 2

Operating Manual

Part No

Description

Application

6401

Economy grade 250mm

10 segment (blue)

Economical removal of most types of

adhesives and surface contaminants.

Excellent for using on rougher surfaces as a

first grind. Can be used wet or dry.

6402

Super Agressive 250mm

10 segment (red)

Designed for the removal of S/L and epoxy

coatings in a commercially viable way. Can

be used for the majority of aggressive

grinding applications and will give extended

wear on heads.

Can be used wet or dry.

6403

Standard Grade 250mm

16 segment (blue)

Removal and grinding of most types of

concrete floor in preparing for follow on

coatings. General all purpose head for most

grinding works.

Can be used wet or day.

6404

High performance 250mm

20 segment (blue)

Fast removal and grinding of most types of

plain and painted concrete floors. Will key

floors for coatings, removal of high spots, lip

edges etc. Suitable for first and second

stage grinding to terrazzo and aggregated

seamless floors.

Can be used wet or dry.

6405

Button head 250mm

16 segment (blue)

For the removal of the thicker adhesive on

sand / cement screed whether open or

closed. Will cope with large volume areas in

a cost effective manner. To be used with

softer elastomeric and thin film coatings.

6408

Polymer diamond backing plate

Backing drive plate for the polymer diamond

system.

Takes 16 polymer button inserts.

7

Accessories

DFG500 - 2

Operating Manual

6420

6409

6410

6411

6412

6413

6414

GREEN ULTRA COARSE 16no

BLACK EXTRA COARSE 16no

BROWN COARSE 16no

RED MEDIUM 16no

YELLOW FINE 16no

WHITE EXTRA FINE 16no

BLUE ULTRA FINE 16no

Polymer diamond system to be used only on

the DFG 500 twin speed (slow speed option)

for second stage grinding and polishing of

terrazzo, stone and marble etc. The buttons

fit securely into the aluminium backing plate.

Wet use only.

6422

6423

COARSE STEEL POLYMER

16No

MEDIUM STEEL POLYMER

16No

Steel polymer diamond system to be used

on DFG 500 twin speed (slow speed option).

For second stage grinding and finishing of

cementitious, polyurethane and epoxy

based terrazzo, terrazzo tiles and concrete

flooring. Provides rapid action and long life.

Wet use only.

6403C

Fine grit 250mm 16 segment (purple)

Finishing and polishing of cementitious

polyurathane, epoxy based terrazzo,

terrazzo tiles and decorative aggregated

concrete flooring.

Can be used wet or dry.

6415

Carborundum grinding and wire brush

block holder drive plate.

Drive plate for the carborundum grinding

blocks and wire brush blocks.

6416

6417

6418

Carborundum grinding blocks

Fine

Medium

Coarse

For economical polishing and grinding

removal of high spots, over watered slabs,

rain damaged slabs, lip edges etc.

6419

6421

16 gauge round wire block

Spring steel block

General scarifying, removal of rubber carpet

backing, grease and oil build-up without

damage to substrate.

8

DFG500 - 2

Operating Manual

9

DFG500 - 2

Operating Manual

DFG500 TWIN SPEED

ELECTRICAL COMPONENTS

QTY

DESCRIPTION

SPE PART NO

1

Panel

SP58017

1

Back Panel

SP55817

7

Contactor

-

1

Aux Switch

SPLADN40

2

Overload

SPLRD12

2

Overload

SPLRD16

1

Stop Switch

SPZB4BZ102

2

Start Switch

SPZB4BZ101

2

Start Button

SPZB4BA3

1

Stop Button

SPZB4BS44

1

Lens

SPZB4BV04

1

Panel Lamp

SPZB4BV5

2

Switch Box

SPXALBO1

4

Contact Switches

SPXENL1111

2

Start Button

SPZA2BA3

2

Trip

SPC60HD316

1

Trip

SPC60HD304

1

Trip

SPC60HC202

2

Glands

-

3

Brass Bushes

-

1

Coupler

-

4

Glands

9258/200

1

Glands

-

1

Isolator

SPFWA4/3C

1

Transformer

5020A

1

32amp 5Pin Phase Rev.

surface Plug

SP630PH

4

Bobbins

9245/500

1

700/400 R.P.M. Sticker

-

2

Conversion Kit

-

1

Two Speed Switch

-

1

N/O X N/C Contact Block

-

1

N/O Contact

-

1

N/C Contact

-

17

Table of contents

Other SPE Floor Machine manuals

Popular Floor Machine manuals by other brands

Windsor

Windsor Dri-Matic user manual

Nilfisk-Advance

Nilfisk-Advance SW5500 B Service manual

Schwamborn

Schwamborn ES 330 Translation of the original operating manual

KENT

KENT 20 Specifications

Nilfisk-Advance

Nilfisk-Advance Hydro-Retriever 2052 CR 1300 Instructions for use

Bona

Bona FlexiSand AMO310000 Manual and safety instructions

Pacific

Pacific TRIUMPH 1190 Parts manual,operating & maintenance instructions

American-Lincoln

American-Lincoln 3366 Operator's manual & parts list

Kärcher

Kärcher BD 45/40 Service manual

Advance acoustic

Advance acoustic Reel Cleaner 56108050 Operator's manual

Tornado

Tornado BR Vario II manual

Chariot

Chariot Chariot 86037880 parts list