INSTRUCTIONS FOR MODELS

92-SE-4300-07

For additional assistance or service please contact:

SPEAKMAN®Company

400 Anchor Mill Road

New Castle, DE 19720

800-537-2107

www.speakman.com

SE-4300

GRAVITYFLO™

Portable Eyewash

with Drench Hose

HELPFUL TOOLS & SUPPLIES:

TOOLS AND SUPPLIES

Flat Tip

Screwdriver

Adjustable

Wrench

Socket

Wrench Phillips

Screwdriver

Pencil Level Drill Drill Bit

x/xx”

Measuring

Tape

Safety

Glasses

Slip Joint

Wrench

3 Year Limited Warranty

Additional warranty information can be found at:

www.speakman.com

WARRANTY

MAINTENANCE

Be sure to wear eye protection.

SAFETY TIPS

Occasional cleaning and disinfection is recommended.

To clean the inside of the unit, add 1/2 cup (4 fluid

oz.) of Clorox (liquid bleach) to a full tank of potable

water. Allow the mixture to penetrate for 15 minutes.

Drain tank, and rinse thoroughly several times with

potable water. Take care to not overtighten drain cap

as damage may occur. For further information about

Clorox, call toll-free at 1-800-292-2200. Follow

refilling instructions in this manual and place the tank

back in service. Should any repair part be required,

use only genuine SPEAKMAN parts for repair or

replacement. See available replacement parts in this

document, to order parts call 1-800-537-2107.

IMPORTANT

ANSI Z358.1 requires that all self-contained eyewash

shall be visually inspected weekly, unless the product

is placed in environments with extreme conditions that

may affect the form, fit, or function of the unit

(temperature, dirt, etc.). If this is the case, then the

inspection should be conducted more often as the end

user deems necessary. Speakman Company furnishes

a testing record tag (91-0635) with each unit. On this

tag, the date of inspection and the inspectors’ initials

should be noted. ANSI Z358.1 specifies that the

height of the spray heads is to be between 33” - 45”

from the floor. The SE-4300 unit weighs approximately

185 lbs filled. Ensure the mounting surface (wall, etc.)

and mounting hardware can safely hold a minimum

vertical load of 300 lbs. Be sure to read instructions

thoroughly before beginning installation. Do not

overtighten any connections or damage may occur.

The unit should be full at all times, to achieve the

minimum 15 minute run time as stated by ANSI, in

case of an emergency. Refill the tank to a full level

after each activation. Before refilling tank dry and

clean outside of spray heads, and inside of pull strap

to remove debris, and to assure proper sealing.

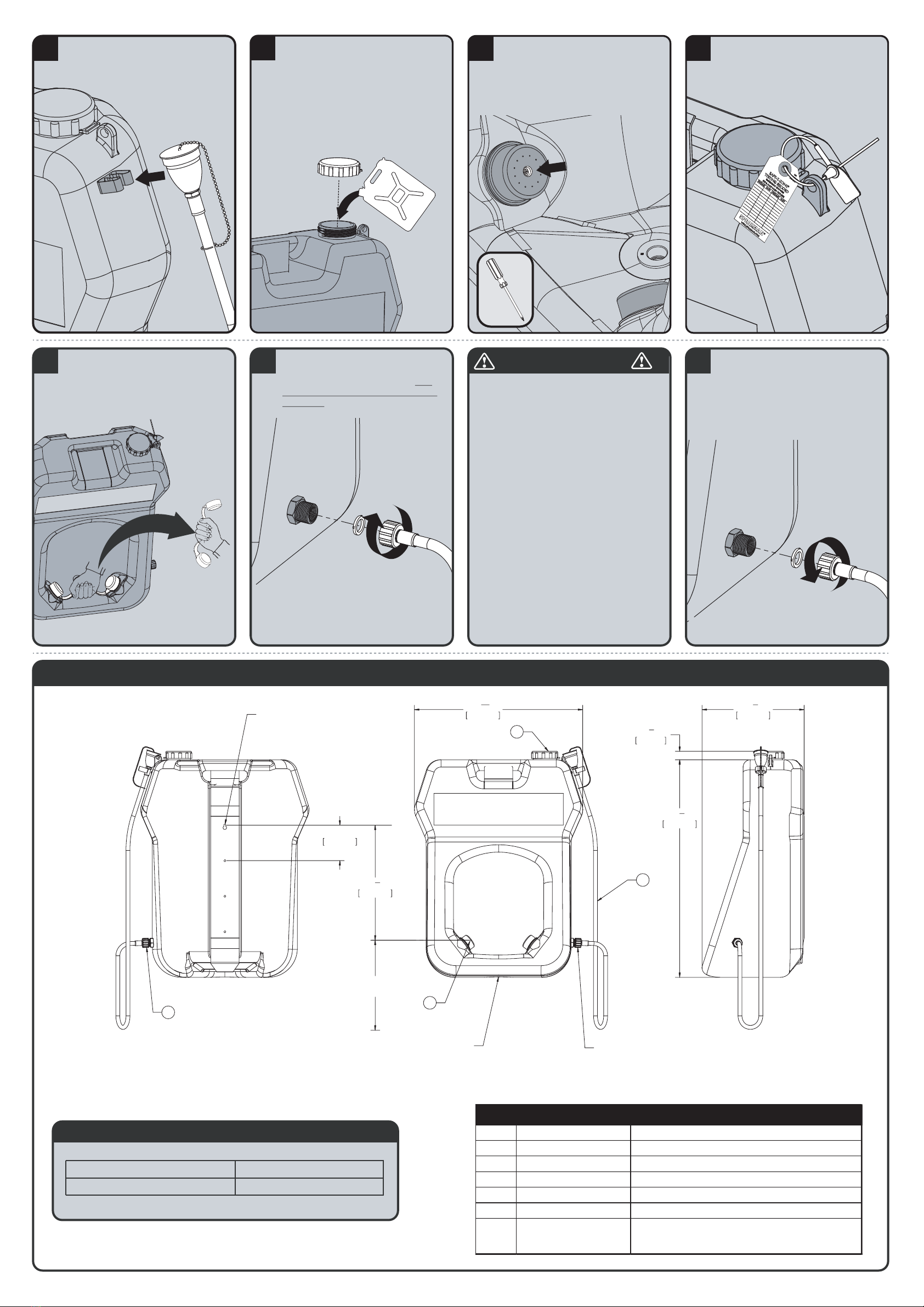

1Using a screwdriver, remove the lower

portion of the Wall Bracket from the

recess on the Tank. Remove the Tank from

the Wall Bracket completely.

2Select a suitable location for the SE-4300. The

location should protect the unit from freezing

and potential scalding conditions. After

confirming the Spray Head height, refer to the

rough-in diagram for Wall Bracket height

measurements to determine mounting hole

locations for the bracket. Making sure the

bracket is level, mark and drill holes in the

mounting structure.

Note: Mounting hardware not included. Ensure

the mounting surface (wall, etc.) and mounting

hardware can safely hold a minimum vertical

load of 300 lbs.

3Mount the Wall Bracket using appropriate

hardware, making sure to torque to

manufacturer’s specifications, if applicable.

Note: Mounting hardware not included. Ensure

the mounting surface (wall, etc.) and mounting

hardware can safely hold a minimum vertical

load of 300 lbs.

4Install empty Tank to Wall Bracket by first

inserting “hook” on the top of the bracket

into the handle of the Tank (1). Lower the

Tank until the Wall Bracket snaps into the

recess at the bottom of the Tank (2).

5

Retrieve drain parts from accessory bag. Insert Drain Fitting (1) through openings in the Tank and

Wall Bracket. Drain Washer (2) can now be positioned over the threading, followed by wrench

tightening Drain Nut (3). Be sure not to over tighten Drain Nut.

6Retrieve the Pull Strap from the accessory

bag. Slide the cups over the Spray Heads

individually, pressing firmly until they are

fully seated. Make sure handle portion of

the Pull Strap is oriented so the word “PULL”

is easily seen in an upright position.

7Remove the drain plug and washer from

the same side of the tank.

8Attach drench hose to 3/4" GHT male

thread outlet on the right-side of the

eyewash tank, making sure it is snug

enough to compress rubber sealing washer

for proper sealing. Do not over-tighten or

damage to outlet on tank or coupling nut

could occur.

9Attach the hose clip with self-tapping screw

1-1/2” from the front and top of tank. The

hose assembly can be positioned on either

the right or left side of the tank depending

on customer preference.

1½”