Prebena 11-L64 Installation instructions

PREBENA

Wilfried Bornemann GmbH & Co. KG

FASTENING TECHNOLOGY

Wilfried Bornemann GmbH & Co. KG Telefax: +49(0)6044 / 9601-820 www.prebena.de

Seestraße 20-26, D-63679 Schotten

Original operating manual

for stationary, compressed air-operated

industrial staplers

MODULE 11-L64

97556903

Page 2of 30

Introduction

This instruction manual will help you to use the pneumatic MODULE 11-L64 industrial stapler in a

•proper,

•safe and

•economic

manner.

In these operating manual. the MODULE 11-L64 industrial stapler is simply referred to as the stapler.

We assume that every user of the stapler has knowledge of the handling of compressed air-operated

devices and the utilised materials. Persons without this knowledge must be instructed in the

operation of the stapler by an experienced user.

This instruction manual is intended for use by the following persons:

•Persons operating this stapler,

•persons who clean or use this stapler, or

•persons disposing of this stapler.

Each of these persons must have read and understood the contents of this instruction manual.

This instruction manual is an integral component of the product. It must always be kept at the

stapler. Hand over the instruction manual together with the stapler if you sell it or otherwise pass it

on.

Page 3of 30

Contents

Design features........................................................................................................................................5

General design features .......................................................................................................................5

Characteristics of the hazard warnings ................................................................................................5

Characteristics of the notes on damage to property or the environment...........................................5

Safety .......................................................................................................................................................6

Intended use.........................................................................................................................................6

Improper use ........................................................................................................................................6

Avoiding risk of fatal injuries................................................................................................................6

Avoiding risk of explosion.....................................................................................................................6

Avoiding damage to the stapler ...........................................................................................................6

Description...............................................................................................................................................7

Information on the type plate..............................................................................................................8

Preparing the stapler...............................................................................................................................9

Unpacking the stapler...........................................................................................................................9

Checking the condition.........................................................................................................................9

Assembly instructions........................................................................................................................... 10

Assembling the stapler...................................................................................................................... 10

Connecting the stapler to the compressed air supply....................................................................... 10

Connecting the stapler to the control line ........................................................................................ 12

Changing the magazine ..................................................................................................................... 13

Removing the magazine .................................................................................................................... 13

Installing the magazine...................................................................................................................... 14

Operating the stapler ........................................................................................................................... 15

Regulating the stapler with the operating pressure ......................................................................... 15

Servicing the stapler ............................................................................................................................. 16

Cleaning the housing and outer surface............................................................................................ 16

Oiling the stapler ............................................................................................................................... 17

Malfunctions......................................................................................................................................... 18

Malfunction overview ....................................................................................................................... 18

Other malfunctions............................................................................................................................ 19

Page 4of 30

Ordering accessories............................................................................................................................. 20

Fasteners ........................................................................................................................................... 20

Disposing of the stapler........................................................................................................................ 21

Technical details ................................................................................................................................... 22

Manufacturer's address........................................................................................................................ 23

Warranty............................................................................................................................................... 24

Circuit diagrams.................................................................................................................................... 25

Pneumatics diagram.......................................................................................................................... 25

Electrical diagram.............................................................................................................................. 26

Declaration of Incorporation in accordance with 2006/42/EC ........................................................... 27

Appendix to the Declaration of Incorporation .................................................................................... 28

Spare parts list ...................................................................................................................................... 30

Page 5of 30

Design features

General design characteristics

Various elements of the instruction manual are marked with defined design characteristics. These

enable you to easily differentiate between

normal text,

•lists or

➢action steps.

Tips contain additional information such as specific details about using the stapler in an economic

manner.

Characteristics of the hazard warnings

All the hazard warnings in this instruction manual have the same layout. On the left is a symbol

indicating the type of danger. On the right, is another symbol and a signal word describing the source

of the danger and notes on how to avoid it.

DANGER

Notes with the word DANGER warn about hazards that will directly result

in serious or fatal injury.

WARNING

Notes with the word WARNING warn about hazards that could result in

serious or fatal injury.

CAUTION

Warnings with the word CAUTION warn about hazards that could result in

minor to moderate injury.

Characteristics of the notes on damage to property or the environment

IMPORTANT

These notes warn about hazards that could result in damage to property or the environment.

Page 6of 30

Safety

When using the stapler, observe and follow all warnings and instructions in this instruction manual

and on the stapler itself.

Intended use

When using the stapler, observe and follow all warnings and instructions in this instruction manual

and on the stapler itself.

The MODULE 11-L64 stationary stapler is used for driving staples into wooden materials, insulating

material and plasterboard. Use with other materials is only permitted after consultation with the

manufacturer. Intended use also includes compliance with accident prevention regulations and the

statutory regulations and standards applicable at the place of use. Any other use is considered

improper use and may result in material damage or even personal injury.

Improper use

In particular, improper use is considered to be if the stapler is operated

•by persons who are not familiar with the use of staplers and the utilised materials,

•with a bridged circuit breaker,

•after it has been modified by the operator without authorisation,

•using fasteners that do not originate from PREBENA, see page 24.

PREBENA WILFRIED BORNEMANN GMBH & CO. KG will not accept any liability for damage caused as

the result of improper use.

Avoiding risk of fatal injuries

•Connecting the stapler to the regulating and compressed air network is prohibited as long as

the stapler is not connected to the production system in the intended direction of

installation.

•Never point the stapler at people, animals or their body parts.

•Do not allow children to play with packaging film - danger of suffocation.

Avoiding risk of explosion

•Do not use the stapler in potentially explosive environments.

•Never operate the stapler with oxygen or with other ignitable gases or gas mixtures.

•Do not expose the compressor to temperatures above 100 °C.

Avoiding damage to the stapler

•Never open the stapler housing. Always leave repair work to a qualified technician.

•Do not use the stapler if it has been dropped or damaged. Have the stapler checked by a

qualified technician before putting it back into operation.

Page 7of 30

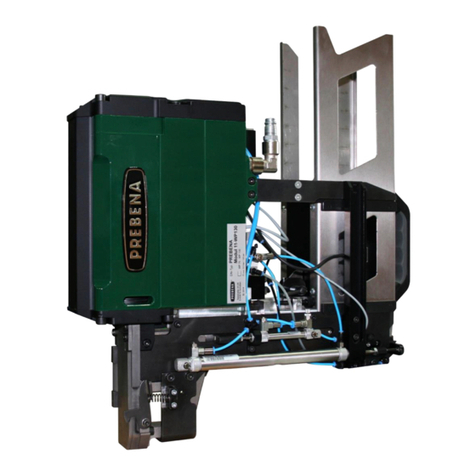

Description

Page 8of 30

No.

Explanation

1

Fastening screw with nut

2

Interchangeable magazine

3

Retaining pawl

4

Sensor; magazine fill level

5

Sensor; feed monitoring

6

Barb; staple reloading channel

7

Barb; staple infeed

8

Venting hole

9

Regulator connection socket

10

Clamping nut

11

Bump stop

12

NW10 compressed air connection

13

Driver

Information on the type plate

The type plate is affixed to the left-hand side of the housing. It contains the following information:

•Company name and country of origin,

•type designation of the stapler,

•type designation of the fasteners to be used.

Page 9of 30

Preparing the stapler

Unpacking the stapler

➢Take the stapler out of its packaging.

➢Remove all packaging material such as plastic film and padding material.

WARNING

Risk of suffocation for children when playing with packaging film.

➢Do not allow children to play with packaging film.

➢Keep packaging material out of the reach of children.

➢Keep the packaging material for future use.

➢Keep the transport case for transporting the stapler.

The stapler may only be transported in the transport case.

Checking the condition

WARNING

Risk of injury when operating a damaged stapler or if the accessories are

not attached properly.

➢Check the condition of the stapler every time before using it.

➢Make sure that the stapler is in a flawless condition.

➢In particular, check the following points:

•The hose line must be undamaged.

•All parts of the stapler and all accessories must be securely fastened.

•The safety mechanisms must not be blocked or otherwise impaired in their

functionality.

•No parts of the stapler or its accessories may display external damage such as

scratches or dents.

Scratches in the paintwork of the housing or magazine are not considered to be

damage.

➢Do not connect a damaged stapler to a compressed air supply.

➢Have a damaged stapler repaired by a qualified technician before putting it into operation.

Page 10 of 30

Assembly Instructions

Assembling the stapler

The assembly procedure can vary on account of the differences in production systems.

CAUTION

When assembling the drive stapler, body parts could get clamped and

crushed between the stapler and the production plant.

➢Have the installation tool ready at hand (ring/open-ended wrench SW24)

➢Place the stapler in the designated assembly position and secure it with the fastening nut and

tool.

➢Tighten the fastening nut to 210 Nm.

➢The height is adjusted on the plant.

Connecting the stapler to the compressed air supply

Only connect the stapler to the compressed air supply after it has been attached to

the production system as described in the installation instructions.

The stapler can be connected to a compressor or a compressed air system.

Page 11 of 30

The stapler may only be operated with a compressor or a compressed air system under the

following conditions:

•The operating pressure of the compressor or compressed air system must not exceed the

maximum operating pressure for the stapler by more than 10%. Information about the

operating pressure for the stapler can be found in this chapter.

•In the case of compressed air systems with a higher pressure, a pressure control valve

(pressure reducer) with a downstream pressure relief valve must be fitted in the

compressed air line.

•The compressed air must be filtered, dry and oiled with PREBENA special nailer oil.

•A compressed air conditioner must be mounted on the coupling side at the outlets for

the compressed air line to the stapler. This should comprise

- a filter,

- a water separator and

- an oiler.

•If an oiler is not installed, the length of the air line to the stapler must not exceed 10m.

Otherwise, two to five drops of PREBENA special nailer oil need to be poured directly

into the air inlet of the stapler every day before putting it into operation.

•The compressed air system must be capable of maintaining the operating pressure even

with the desired air extraction.

•The inside diameter of the air line must be at least 13 mm.

•The connection for the stapler must be fitted with a quick coupling with NW 10 and an

inside diameter of at least 10 mm.

CAUTION

Operating the stapler with compressed air systems that do not meet the

above requirements may cause damage to it.

➢Only operate the stapler with suitable compressed air systems.

➢Only use the stapler if it is in a flawless condition.

➢Check the condition of the stapler.

➢Check the compressed air hose connection for foreign bodies and dirt and clean as necessary.

➢Set the operating pressure at the compressor pressure regulator to 4.5 - 7.5 bar.

WARNING

Unintentionally activating the stapler when connecting it to the

compressed air supply can result in serious or fatal injury.

➢Do not point the stapler at people or animals.

➢Empty the magazine before connecting the stapler.

CAUTION

Damaged hose lines can burst, and the escaping compressed air could

cause material damage.

➢Check the compressed air system and the stapler for material

damage before connecting them.

➢Only connect the stapler to a functioning compressed air system.

Page 12 of 30

Important

Damaged hose lines can burst, and the escaping compressed air could cause material damage.

➢Check the compressed air system and the stapler for damage before connecting them.

➢Only connect the stapler to a functioning compressed air system.

➢Push the quick-release lock (1) of the compressed air hose onto the connection (2) until it

audibly engages.

➢Check the operating pressure indicated on the compressor pressure gauge.

Connecting the stapler to the control line

Only connect the stapler to the compressed air supply after it has been attached to the

production system as described in installation instruction 2.

A 6-pin XLR type connector plug must be used. The pin assignment is described in the chapter

"Circuit diagrams".

WARNING

Defective cable connections and exposed contacts can result in personal

injury and material damage.

➢Check the cable connection for possible damage.

➢Only attach the stapler to a flawless cable connection.

➢Push the connecting cable (1) onto the connection socket (2) until it audibly engages.

Page 13 of 30

Changing the magazine

The magazine is designed as an interchangeable magazine and is not loaded when it is installed on

the stapler. The magazine is detached from the device for reloading so that it can be conveniently

filled with staples at an external station.

The staples are delivered in an industrial packaging for quick and easy charging of the magazines.

Removing the magazine

Turn the retaining pawl (4) in the direction of the arrow and pull the magazine (1) backwards off the

stapler.

Page 14 of 30

Installing the magazine

Attach the magazine in the reverse manner to removing it. Make sure that the guide rails do not

twist when inserting the magazine. Also make sure that the retaining pawl (4) is fully engaged by the

spring force. Push the magazine up to the stop buffer by exerting slight pressure on it. If this does not

work, loosen the lock nut (3) and readjust the position of the stop buffer with the thread. Then

tighten the nut again.

The procedure for changing the magazine is the same for all magazine types.

Which magazines can be used are shown in the overview below:

Magazine design

PREBENA staples

Type L35

L35

Type L38

L38

Type L40

L40

Type L44

L44

Type L50

L50

Type L55

L55

Type L63

L63

Page 15 of 30

Operating the stapler

Regulating the stapler with the operating pressure

You can set the penetration depth of the stapler into the material by regulating the operating

pressure. At a higher operating pressure, the fasteners are driven deeper into the material; setting a

lower operating pressure reduces the penetration depth.

Set the operating pressure to achieve the required penetration depth. This has the

following benefits:

•You save energy (compressed air),

•you reduce the noise level, and

•you reduce the wear of the stapler.

Proceed as follows to set the operating pressure:

➢Adjust the pressure at the pressure valve of the compressor or compressed air system.

➢Observe the pressure reading.

Checking the penetration depth

➢Shoot a staple into a sample workpiece with the same characteristics as the processing

material.

➢Repeat these steps until you have set the required penetration depth.

Page 16 of 30

Servicing the stapler

The stapler may only be serviced by persons who have the necessary knowledge, skills and

experience. Any work not described here may only be performed by the manufacturer's customer

service team or by the manufacturer.

During all servicing work, the compressed air connection and the control line between

the stapler and the production system must be disconnected.

WARNING

Unintentionally activating the stapler when emptying the magazine can

result in serious or fatal injury.

➢Disconnect the stapler from the compressed air supply before

cleaning it.

➢Remove the magazine and all staples from the feed channel and

on feed bridge.

Cleaning the housing and outer surface

Important

The stapler or accessories can be damaged by using unsuitable cleaning agents.

➢Only use a dry, slightly moistened cloth or a cloth moistened with mild soapy water for

cleaning the stapler.

Light soiling

➢Wipe the stapler housing clean with a dry cloth.

Severe soiling

➢Wipe the stapler housing clean with a cloth lightly moistened with mild soapy water.

➢Then wipe the housing with a cloth slightly moistened with tap water.

➢Rub down with a dry, soft cloth.

Soiling in the discharge channel/feed bridge

The discharge channel and feed bridge should be cleaned at regular intervals depending

on the discharge intensity.

Use of the staples can cause adhesive residue to accumulate in the discharge channel and on the

feed bridge.

➢Remove this residue using a compressed air gun and a fine cleaning brush.

Page 17 of 30

Oiling the stapler

Important

Inadequate lubrication or using incorrect lubricants can cause damage to the stapler.

➢Only use PREBENA special nailer oil.

If an oiler is not fitted and the length of the air line to the stapler exceeds 10 m, adequate

lubrication cannot be assured.

➢In this case, pour two to five drops of PREBENA special nailer oil directly into the connection

for the compressed air source every day before putting the stapler into operation.

Page 18 of 30

Malfunctions

WARNING

Operating a damaged or malfunctioning stapler can result in serious or

fatal injury.

➢In the event of a malfunction, immediately disconnect the stapler

from the compressed air supply.

➢Remove the magazine and all staples from the feed channel and

on feed bridge.

➢Do not use the stapler until the malfunction has been remedied.

Important

The stapler can be damaged by repairs undertaken by unauthorised persons.

➢Make sure that the stapler is only repaired by the manufacturer.

Malfunction overview

Possible malfunctions and the necessary measures are listed in the overview below.

Symptom

Possible cause

Remedy

Stapler is losing

air.

Fastening screws have

become loose.

Notify customer service.

A seal is defective.

Notify customer service.

Operating

pressure too high.

Valve defective.

Immediately disconnect the stapler from

the compressed air supply.

Notify customer service.

Operating pressure set too

high or stapler damaged.

Reduce operating pressure.

If the problem persists:

Immediately disconnect the stapler from

the compressed air hose.

Notify customer service.

Fasteners are not

being fully driven

in.

The operating pressure is too

low.

Increase operating pressure.

The driver tip on the stapler is

worn/broken

Notify customer service.

Staples cannot be

discharged.

The operating pressure is too

low.

Increase the operating pressure of the

compressed air system to the maximum

permissible level.

The moving parts are stuck

together with lubricant after

long storage.

Clean stapler.

Set maximum operating pressure.

Perform test discharges.

When staples are discharged,

set the required operating pressure.

Otherwise notify customer service.

Discharge is

triggered without

Feed bridge/channel is soiled.

Clean feed bridge/channel.

Incorrect fasteners have been

loaded.

Remove fasteners.

Fill stapler with PREBENA fasteners.

Page 19 of 30

a fastener being

driven in.

The stapler is not adequately

lubricated.

Fill PREBENA special nailer oil into the used

compressed air connection.

Fire a test discharge.

The operating pressure is too

low.

Increase operating pressure.

The piston with the driver

does not return to the home

position after the driving-in

action.

Notify customer service.

The triggering action is not

completed.

Notify customer service.

The driver is bent.

Notify customer service.

The reloading

cycle is

interrupted.

Passage of the throttle valves

has changed.

Notify customer service.

Fastener has become wedged

during reloading.

Disconnect stapler from the compressed air

supply.

Remove fasteners from reloading opening.

Load new fasteners and fire a test

discharge.

Other malfunctions

If other malfunctions of the stapler have occurred which cannot be remedied by oiling and cleaning

it, you must notify the PREBENA service team.

➢Do not carry out any repair work on the stapler.

➢Make sure that all malfunctions of the stapler are remedied by the PREBENA service team.

Page 20 of 30

Ordering accessories

Accessories can be ordered from the manufacturer. Only use original PREBENA accessories, or

accessories that have been approved by PREBENA, to operate the stapler.

Product no.

Accessories

Z200.10

Special oil for compressed air nailers 1/2 litre

Z200.00

Small mist oiler

62151004

Interchangeable magazine for HK type L35

62152402

Interchangeable magazine for HK type L38

62152203

Interchangeable magazine for HK type L44

62151105

Interchangeable magazine for HK type L50

62151204

Interchangeable magazine for HK type L55

62152501

Interchangeable magazine for HK type L63

62752602

Spare part set (listing see attachment)

Ordering additional fasteners

The stapler may only be used with the respective PREBENA staples shown on the type plate.

Type

Length

Wire size

Spine width

L35 CNKHA

CSVHA-ETA

CRFHA-ETA

35 mm

1.39 x 1.58 mm

10.7 mm

L38 CNKHA

CSVHA-ETA

CRFHA-ETA

38 mm

1.39 x 1.58 mm

10.7 mm

L40 CNKHA

CSVHA-ETA

CRFHA-ETA

40 mm

1.39 x 1.58 mm

10.7 mm

L44 CNKHA

CSVHA-ETA

CRFHA-ETA

44 mm

1.39 x 1.58 mm

10.7 mm

L50 CNKHA

CSVHA-ETA

CRFHA-ETA

50 mm

1.39 x 1.58 mm

10.7 mm

L55 CNKHA

CSVHA-ETA

CRFHA-ETA

55 mm

1.39 x 1.58 mm

10.7 mm

L63 CNKHA

CSVHA-ETA

CRFHA-ETA

63 mm

1.39 x 1.58 mm

10.7 mm

Table of contents

Other Prebena Power Tools manuals

Prebena

Prebena KTVH-B19D User manual

Prebena

Prebena 1A-AZ16BNH User manual

Prebena

Prebena KTVH-B19D User manual

Prebena

Prebena SLIDER 4C-Z50 User manual

Prebena

Prebena 3X-CNW50 User manual

Prebena

Prebena PKT-7-RK90 Installation instructions

Prebena

Prebena 11-WP130 User manual

Prebena

Prebena 1A-AZ16BNH Quick start guide

Prebena

Prebena SLIDER 4C-Z50 Quick start guide

Prebena

Prebena 1GP-ALK35 User manual