Speedaire 5YAR9 Instructions for use

E

N

G

L

I

S

H

E

S

P

A

Ñ

O

L

F

R

A

N

Ç

A

I

S

Speedaire®4"

Reversible Angle Grinder

Operating Instructions & Parts Manual 5YAR9

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Form 5S6624 Printed in China

04634

Version 0

KKU373

08/10

#628

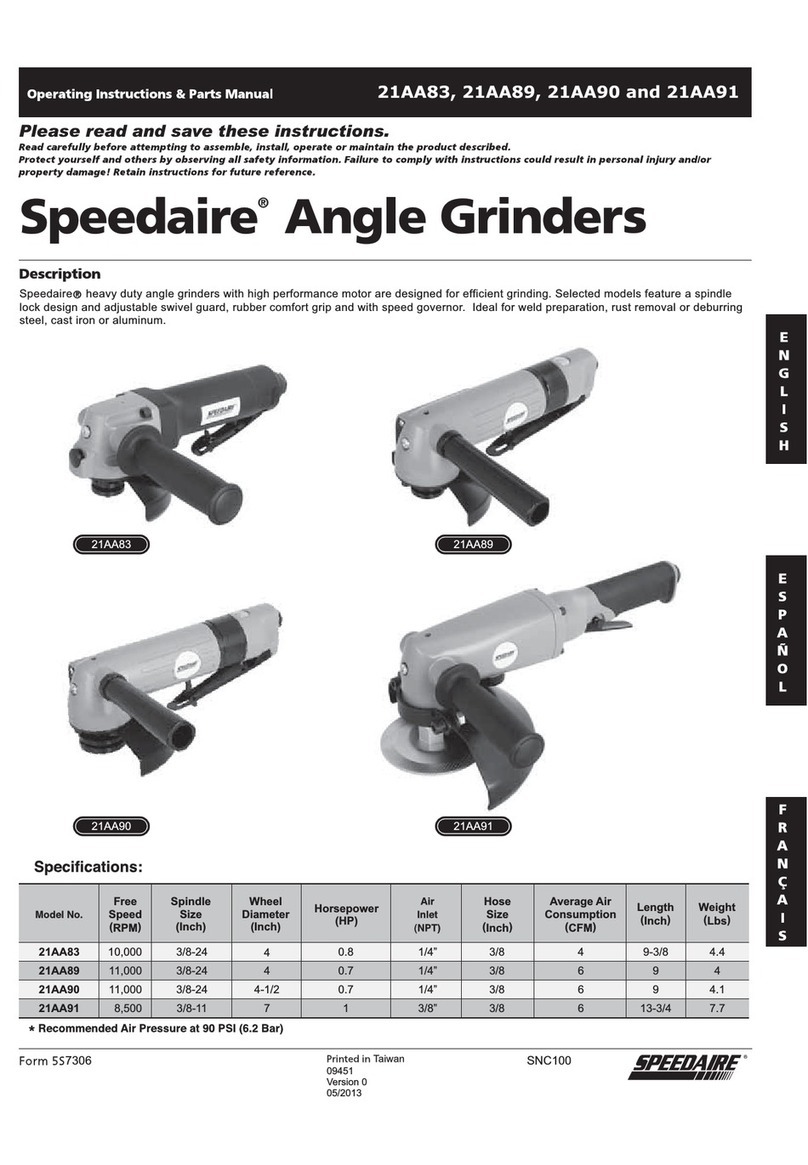

Description

Speedaire This heavy duty reversible angle grinder with energy efficient 0.9 hp motor is

provided plenty of power for rust adn material removal. REversible option to direct sparks

and debris away from the user and sensitive work surfaces.

Includes:

1 - 4" Reversible Angle Grinder

1 - Wrench

1 - Hex Wrench

Figure 1

Unpacking

When unpacking the unit, carefully look for

any damage that may have occurred during

transit. Check for loose, missing or damaged

parts.

Specifications

Free Speed (No load) ....................12,000 RPM

HP................................................................. 0.9

Exhaust ......................................................Rear

Length................................................... 9-3/16"

Wheel Diameter........................................... 4"

Spindle Size ............................................... 5/8"

Average Air Consumption

@ 15 Second Run Time...................... 3.35 CFM

Minimum Hose Size ............................3/8" I.D.

Air Inlet...............................................1/4" NPT

Maximum Air Pressure............................90 PSI

Weight ...................................................2.4 lbs.

General Safety Information

1. For Additional Safety

Information Consult:

Your employer, union, and/or trade

association. US Department of Labor

(OSHA); www.osha.gov. “Safety Code

For Portable Air Tools” (B186.1)

2. Wheel Guard Usage

Always use the recommended wheel

guard to prevent injury from broken

grinding wheel parts.

If a guard has withstood a wheel

breakage do not continue to use it. It may

be damaged.

Position the guard between the grinding

wheel and the operator.

Use barriers to protect others from wheel

fragments and grinding sparks.

3. Projectile Hazards

Always wear impact-resistant eye and

face protection when involved with or

near the operation, repair or

maintenance of the tool or changing

accessories on the tool.

Be sure all others in the area are wearing

impact-resistant eye and face protection.

Even small projectiles can cause eye

injuries and blindness.

A grinding wheel that bursts can cause

very serious injury.

Daily measure the air grinder speed with

a tachometer to make sure it is not

greater than the RPM marked on the

grinding wheel.

Never use a grinding wheel marked with

a speed lower than the air grinder speed.

4. Grinding Wheel Mounting Hazards

Correct grinding wheel mounting is

necessary to prevent injury from broken

wheels.

Do not use chipped or cracked grinding

wheels.

Grinding wheels should be a free fit on

the spindle to prevent stress at the hole.

Use only wheel collars that come with the

grinder for mounting the grinding wheel.

Flat washers or other adapters may over

stress the wheel. Always use heavy paper

blotter discs between the wheel collars

and the grinding wheel.

Tighten the wheel on the spindle to

prevent spin off when the air grinder is

turned off.

Before grinding, test grinding wheel by

briefly running tool at full throttle. Be

sure to use a barrier (such as under a

heavy work table) to stop any possible

broken wheel parts.

5. Workplace Hazards

Slip/Trip/Fall is a major cause of

serious injury or death. Beware of

excess hose left on the walking or

work surface.

High sound levels can cause

permanent hearing loss. Use hearing

protection as recommended by your

employer or OSHA regulation (see 29

CFR part 1910).

Maintain a balanced body position

and secure footing.

Repetitive work motions, awkward

positions and exposure to vibration

can be harmful to hands and arms.

If numbness, tingling, pain or

whitening of the skin occurs, stop

using tool and consult a physician.

Avoid inhaling dust or handling debris

from the work process which can be

harmful to your health. Use dust

extraction and wear respiratory protective

2

E

N

G

L

I

S

H

Speedaire®4" Reversible

Angle Grinder

5YAR9

Speedaire® Operating Instructions and Parts Manual

General Safety Information

(continued):

5. Workplace Hazards (continued)

which produce airborne particles.

This tool is not intended for use in

explosive atmospheres and is not

insulated for contact with electric

power sources.

Potentially explosive atmospheres can

be caused by dust and fumes resulting

from sanding or grinding.

Use dust extraction or suppression system

which is suitable for the material being

processed.

Some dust created by power sanding,

sawing, grinding, drilling and other

construction activities contains chemicals

known to the State of California to

cause cancer and birth defects or other

reproductive harm.

Some examples of these chemicals

are:

– Lead from lead based paints

– Crystalline silica bricks

and cement and other masonry

products

– And Arsenic and chromium

from chemically-treated rubber

Your risk from these exposures

varies, depending on how often

you do this type of work. To reduce

your exposure to these chemicals:

work in a well ventilated area, and

work with approved safety

equipment, such as dust masks that

are specially designed to filter out

microscopic particles.

For professional use only.

Installation

Designed to operate on 90 PSI, lower

pressure (below 90 PSI) will reduce

performance of the tool while higher air

pressure over 90 PSI raise the performance of

the tool beyond its rated capacity and could

cause serious damage to tool and user.

Always use clean dry air. Excessive moisture

and dirt will greatly reduce the life of any air

motor. We recommend the installation of an

in-line filter-regulator-lubricator as close to

the tool as possible.

Pre-Operation

Before the tool is connected to the air

supply, clean the air hose of accumulated

dust and moisture. Before removing a tool

for service or changing accessories, make

sure the air line is shut off and drained of air.

This will prevent the tool from operating if

the throttle is accidentally engaged.

Operation

1. Supply tool with 90 PSI of clean, dry air.

Higher pressure drastically reduces tool

life. Connect tool to air line using pipe,

hose, and fitting sizes shown in Figure 2.

Do not install a quick coupler directly into

the grinder throttle handle.

2. Air Supply and Connection

Hazards.

Air under pressure can cause severe

injury.

Always shut off air supply, drain hose of

air pressure and disconnect tool from air

supply when not in use, before changing

accessories or when making repairs.

Never direct air at yourself or

anyone else.

Whipping hoses can cause serious injury.

Always check for damaged or loose hoses

and fittings.

Do not use quick disconnect couplings at

tool. See Figure 2 for correct set up.

Whenever universal twist couplings

are used, lock pins must be installed.

Do not exceed maximum air pressure of

90 PSI or as stated on tool nameplate.

Maintenance

Lubrication

Use an air line lubricator with Mobil Almo

525 air tool oil (model 4ZF22), adjusted

to two (2) drops per minute. If an air line

lubricator cannot be used, add air motor

oil to the inlet once a day.

Figure 2 - Air Diagram

3

E

N

G

L

I

S

H

For Repair Parts, call 1-800-323-0620

24 hours a day – 365 days a year

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Speedaire® Operating Instructions and Parts Manual 5YAR9

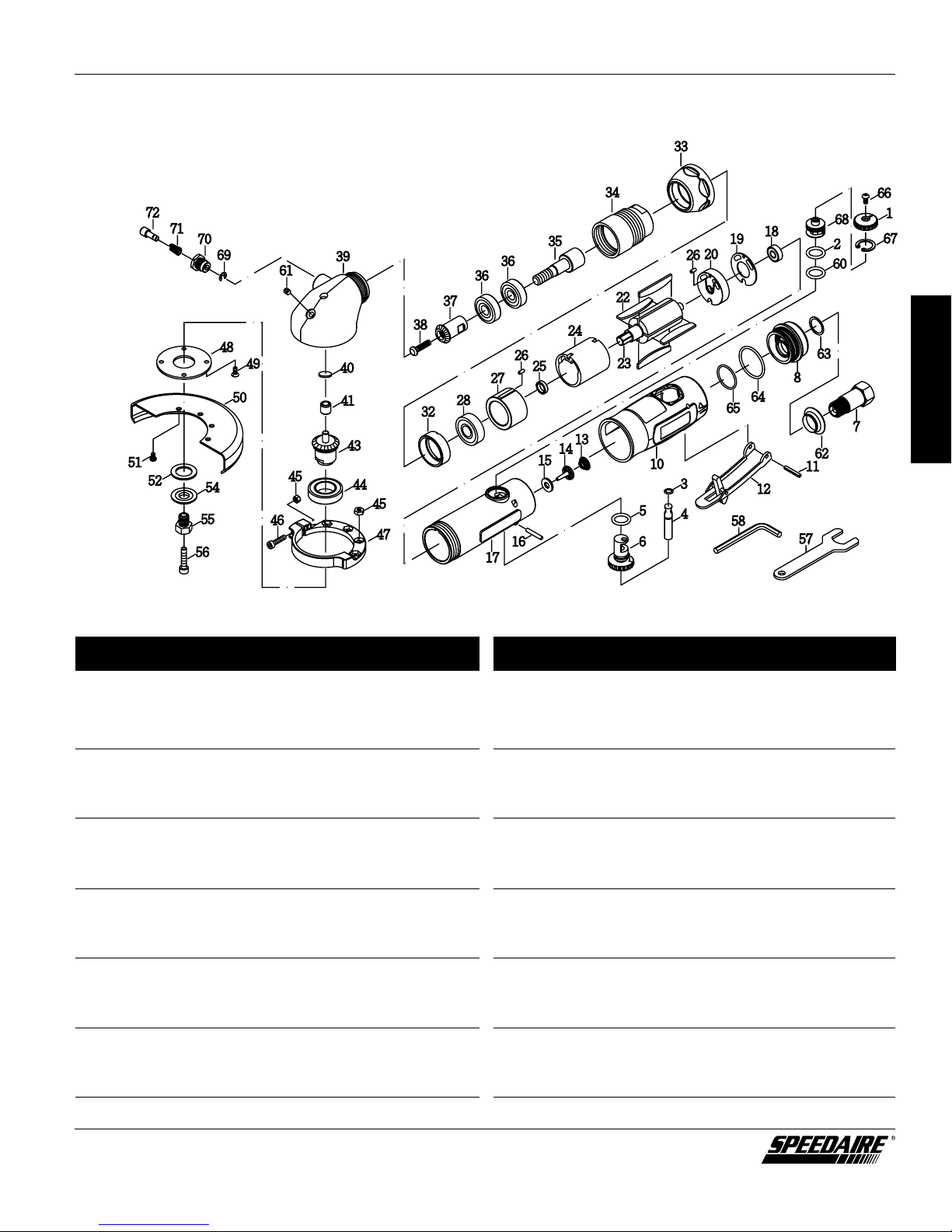

Figure 3 – Repair Parts Illustration for Speedaire® 4" Reversible Angle Grinder

Repair Parts List for Speedaire® 4" Reversible Angle Grinder

1 Regulator TTST25101A2G 1

2 O-Ring (AS015) TTST25102G 1

3 O-Ring (3.5*1.4) TTOB04G 1

4 Valve Stem TTOB05G 1

5 O-Ring (P10) TTOB02G 1

6 Regulator TTST25106G 1

7 Air Inlet TTST25107AG 1

8 Exhaust Sleeve TTST25108AG 1

10 Protecting Rubber TTST250R1010G 1

11 Pin TT120121G 1

12 Lever TTST25112G 1

13 Spring TTST288314G 1

14 Valve TTST288315G 1

15 Washer (6*13.8*1.6T) TTST288316G 1

16 Pin (2.8*25.8L) TTST25116AG 1

17 Housing TTST251171G 1

18 Bearing (626) TTST22536AG 1

19 Washer (17*33.2*0.8t) TTST25119G 1

20 Rear Plate TTST25120G 1

22 Rotor Blade TTST25122G 4

23 Rotor TTST25523G 1

24 Cylinder TTST21315G 1

25 Bearing Spacer TTST25125G 1

26 Pin (2.5*6L) TT70018G 2

27 Front Plate TTST25127G 1

28 Bearing (6000ZZ) TT70048AG 1

32 Nut TTST25432G 1

33 Clamp Nut TTST25433G 1

34 Spindle Housing TTST25534G 1

35 Spindle TTST25535G 1

36 Bearing (609) TTST288734G 2

37 Pinion Gear (14T) TTST25437G 1

38 Screw (M4*20) TTST25538G 1

39 Angle Housing TTST25439G 1

40 Washer TTST25440G 1

41 Bearing (HKU609) TTST25441G 1

43 Pinion Gear (21T) TTST25443G 1

44 Bearing (6904) TTST25444G 1

45 Nut TTST25446G 5

46 Screw (M4*20) TTST25446G 1

47 HANDLE LLINK TTST25447G 1

48 Face Plate TTST25448G 1

49 Screw (M4*10) TTST81317G 4

50 Disc Cover TTST25550G 1

51 Screw (M4*6) TTST288542G 4

52 Nut TTST25452G 1

54 Washer TTST25454G 1

55 Nut TTST25555G 1

56 Screw TTST25456G 1

57 Stop Spanner (14mm) TTBT25457G 1

58 Hex (4mm) TT26045G 1

60 O-Ring (S16) TTST25150G 1

61 Oil Cup TT21029G 1

62 Muffler Body TTST20036G 1

63 Washer TTLDB250R43G 1

64 O-Ring (AS125) TTLDB250R45G 1

65 O-Ring (S30) TTLDB250R46G 1

66 Screw (M4*8) TT81447G 1

67 Snap ring (RTW-18) TTST25148G 1

68 Regulator TTST25404A1G 1

69 Snap ring (ETW-4) TTST10015G 1

70 Nut TTST254B64G 1

71 Spring TTST254B62G 1

72 Pin TTST254B63G 1

Ref. Part

No. Description No. Qty.

Ref. Part

No. Description No. Qty.

Manufactured for Dayton Electric Mfg. Co.

Niles, Illinois 60714 U.S.A.

E

N

G

L

I

S

H

5YAR9

Speedaire® Operating Instructions and Parts Manual

LIMITED WARRANTY

DAYTON ONE-YEAR LIMITED WARRANY. SPEEDAIRE®REVERSIBLE ANGLE GRINDER MODELS COVERED IN THIS MANUAL,

ARE WARRANTED BY DAYTON ELECTRIC MFG. CO. (DAYTON) TO THE ORIGINAL USER AGAINST DEFECTS IN WORKMANSHIP

OR MATERIALS UNDER NORMAL USE FOR ONE YEAR AFTER DATE OF PURCHASE. ANY PART WHICH IS DETERMINED TO

BE DEFECTIVE IN MATERIAL OR WORKMANSHIP AND RETURNED TO AN AUTHORIZED SERVICE LOCATION, AS DAYTON

DESIGNATES, SHIPPING COSTS PREPAID, WILL BE, AS THE EXCLUSIVE REMEDY, REPAIRED OR REPLACED AT DAYTON’S

OPTION. FOR LIMITED WARRANTY CLAIM PROCEDURES, SEE “PROMPT DISPOSITION” BELOW. THIS LIMITED WARRANTY

GIVES PURCHASERS SPECIFIC LEGAL RIGHTS WHICH VARY FROM JURISDICTION TO JURISDICTION.

LIMITATION OF LIABILITY. TO THE EXTENT ALLOWABLE UNDER APPLICABLE LAW, DAYTON’S LIABILITY FOR CONSEQUENTIAL

AND INCIDENTAL DAMAGES IS EXPRESSLY DISCLAIMED. DAYTON’S LIABILITY IN ALL EVENTS IS LIMITED TO AND SHALL NOT

EXCEED THE PURCHASE PRICE PAID.

WARRANTY DISCLAIMER. A DILIGENT EFFORT HAS BEEN MADE TO PROVIDE PRODUCT INFORMATION AND ILLUSTRATE

THE PRODUCTS IN THIS LITERATURE ACCURATELY; HOWEVER, SUCH INFORMATION AND ILLUSTRATIONS ARE FOR THE SOLE

PURPOSE OF IDENTIFICATION, AND DO NOT EXPRESS OR IMPLY A WARRANTY THAT THE PRODUCTS ARE MERCHANTABLE,

OR FIT FOR A PARTICULAR PURPOSE, OR THAT THE PRODUCTS WILL NECESSARILY CONFORM TO THE ILLUSTRATIONS OR

DESCRIPTIONS. EXCEPT AS PROVIDED BELOW, NO WARRANTY OR AFFIRMATION OF FACT, EXPRESSED OR IMPLIED, OTHER

THAN AS STATED IN THE “LIMITED WARRANTY” ABOVE IS MADE OR AUTHORIZED BY DAYTON.

Technical Advice and Recommendations, Disclaimer. Notwithstanding any past practice or dealings or trade custom,

sales shall not include the furnishing of technical advice or assistance or system design. Dayton assumes no obligations

or liability on account of any unauthorized recommendations, opinions or advice as to the choice, installation or use of

products.

Product Suitability. Many jurisdictions have codes and regulations governing sales, construction, installation, and/or

use of products for certain purposes, which may vary from those in neighboring areas. While attempts are made to assure

that Dayton products comply with such codes, Dayton cannot guarantee compliance, and cannot be responsible for how

the product is installed or used. Before purchase and use of a product, review the product applications, and all applicable

national and local codes and regulations, and be sure that the product, installation, and use will comply with them.

Certain aspects of disclaimers are not applicable to consumer products; e.g., (a) some jurisdictions do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you; (b) also,

some jurisdictions do not allow a limitation on how long an implied warranty lasts, consequently the above limitation

may not apply to you; and (c) by law, during the period of this Limited Warranty, any implied warranties of implied

merchantability or fitness for a particular purpose applicable to consumer products purchased by consumers, may not be

excluded or otherwise disclaimed.

Prompt Disposition. A good faith effort will be made for prompt correction or other adjustment with respect to any

product which proves to be defective within limited warranty. For any product believed to be defective within limited

warranty, first write or call dealer from whom the product was purchased. Dealer will give additional directions. If unable to

resolve satisfactorily, write to Dayton at address below, giving dealer’s name, address, date, and number of dealer’s invoice,

and describing the nature of the defect. Title and risk of loss pass to buyer on delivery to common carrier. If product was

damaged in transit to you, file claim with carrier.

Manufactured for Dayton Electric Mfg. Co., 5959 W. Howard St., Niles, Illinois 60714-4014 U.S.A.

Speedaire®4" Reversible

Angle Grinder

4

Table of contents

Other Speedaire Grinder manuals

Popular Grinder manuals by other brands

Meterk

Meterk S1M-GW20-115 Translation of the original instructions

U.S.SAWS

U.S.SAWS SX65000C operating manual

Parkside

Parkside PWS 230 C3 Translation of the original instructions

SUHNER ABRASIVE

SUHNER ABRASIVE ASC 9 Technical document

PTA

PTA P1322 Operation manual

Craftsman

Craftsman CMCG400 instruction manual