SPENCE D50 User manual

Instruction Manual

VCIMD-16110

www.SpenceValve.comwww.SpenceValve.com

Type D50 Pressure Regulator

▲ WARNING

Failure to follow these instructions or

to properly install and maintain this

equipment could result property damage

and personal injury or death.

Type D50 pressure regulator must be

installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations and

Emerson instructions.

If the valve vents gas or a leak develops

in the system, service to the unit may be

required. Failure to correct issue could

result in a hazardous condition.

Installation, operation and maintenance

procedures performed by unqualified

personnel may result in improper

adjustment and unsafe operation. Either

condition may result in equipment

damage or personal injury. Only a

qualified person shall install or service

the Type D50 pressure regulator.

Introduction

Scope of the Manual

This manual provides instructions for the installation,

troubleshooting, maintenance and parts ordering for

Type D50 pressure regulator.

Product Description

The Type D50 Pressure Regulator is a direct-operated

valve normally closed, single seat design featuring

packless construction, balanced metal, diaphragms

and protected main spring.

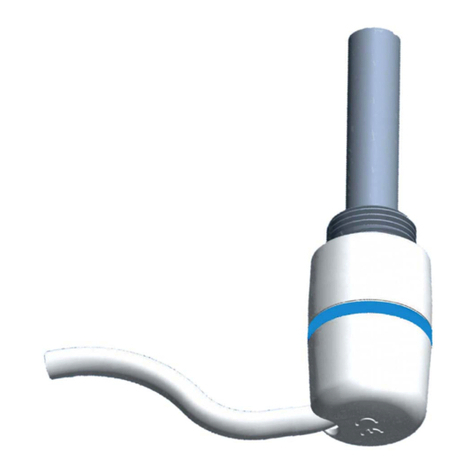

Figure 1. Types D50 Pressure Regulator

Type D50

April 2022

Specications

This section lists the specications for the Type D50 pressure regulator. Factory specications are stamped on the

nameplate fastened on the regulator at the factory.

Valve Temperature Rating(1)

Stainless steel Disk

Cast iron: 400°F / 204°C

Teflon®Disk

Cast iron: 300°F / 149°C

Main Valve Material

Cast iron

Approximate Weight

3.6 to 13.6 lbs / 8 to 30 kg

Valve Sizes

NPS 1/2, 3/4, 1, 1-1/4, 1-1/2 and 2 /

DN 15, 20, 25, 32, 40 and 50

End Connection Styles

NPT and BSPT

Valve Pressure Rating(1)

Stainless steel Disk

Cast iron: 200 psig / 13.8 bar

Teflon®Disk

Cast iron: 300 psig / 21.0 bar

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

Principle of Operation

The Type D50 is a direct-operated regulator.

Downstream pressure is registered through the control

ports to the under side of the diaphragm. As the

pressure on diaphragm approaches a balance with the

force exerted by the adjusting spring, disk is throttled

to a position where just enough uid ows to maintain

the set delivery pressure.

Intended Purpose

The Type D50 Direct Acting Pressure Regulator

is a compact, moderately priced steam, water or

gas regulator intended to satisfy most fundamental

requirements for pressure reduction.

Teon®is a mark owned by E.I. du Pont de Nemours and Co.

Installation

▲ WARNING

Personal injury or system damage

may result if this regulator is installed,

without appropriate overpressure

protection, where service conditions

could exceed the limits given in

the Specications section and/or

regulator nameplate.

Additionally, physical damage to the

regulator may result in personal injury

or property damage due to escaping of

accumulated gas. To avoid such injury

and damage, install the regulator in a

safe location.

Under enclosed conditions or indoors,

escaping gas may accumulate and be an

explosion hazard. In this case, the vent

should be piped outdoors.

For regulator constructions with a

spring case vent, the vent should be

kept open to permit free ow of gas

to the atmosphere. Protect openings

against entrance of rain, snow, insects

or any other foreign material that may

plug the spring case vent or vent line.

All pressure equipment should be

installed in a non-seismic area;

should not be exposed to re; and

should be protected from thunderbolt

(lightning) strikes.

2

Type D50

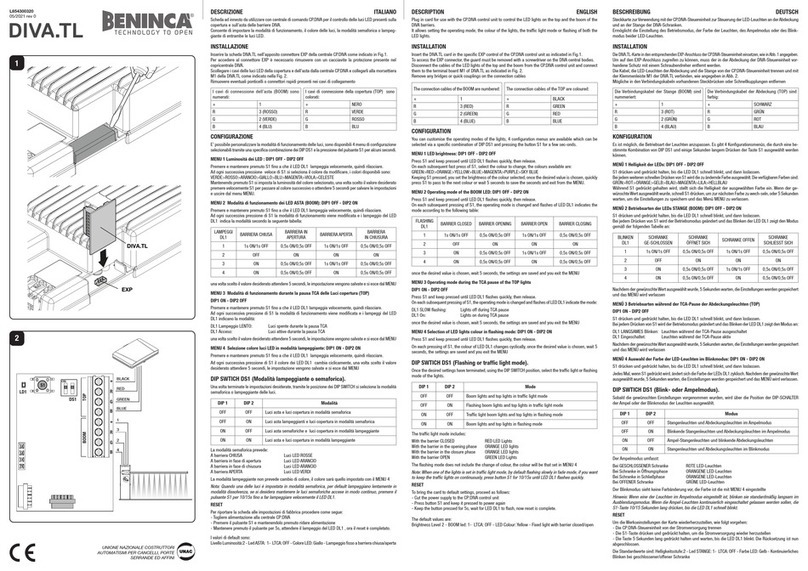

SPRING BUTTON

ADJUSTING SPRING

DIAPHRAGM(1)

DIAPHRAGM GASKET(1)

STEM BUSHING ASSEMBLY(1)

SEAT RING(1)

SEAT RING(2)

OPTIONAL TEFLON®

DISK FOR LIQUID

AND GAS SERVICE

TEFLON®DISK ASSEMBLY(2)

DISK(1)

BOTTOM PLUG GASKET(1)

The above parts are all that are available.

1. Parts contained in repair kit.

2. Parts substituted in Teon®repair kit.

Figure 2. Type D50 Operational Schematic

Teon®is a mark owned by E.I. du Pont de Nemours and Co.

3

Type D50

Planning the Installation

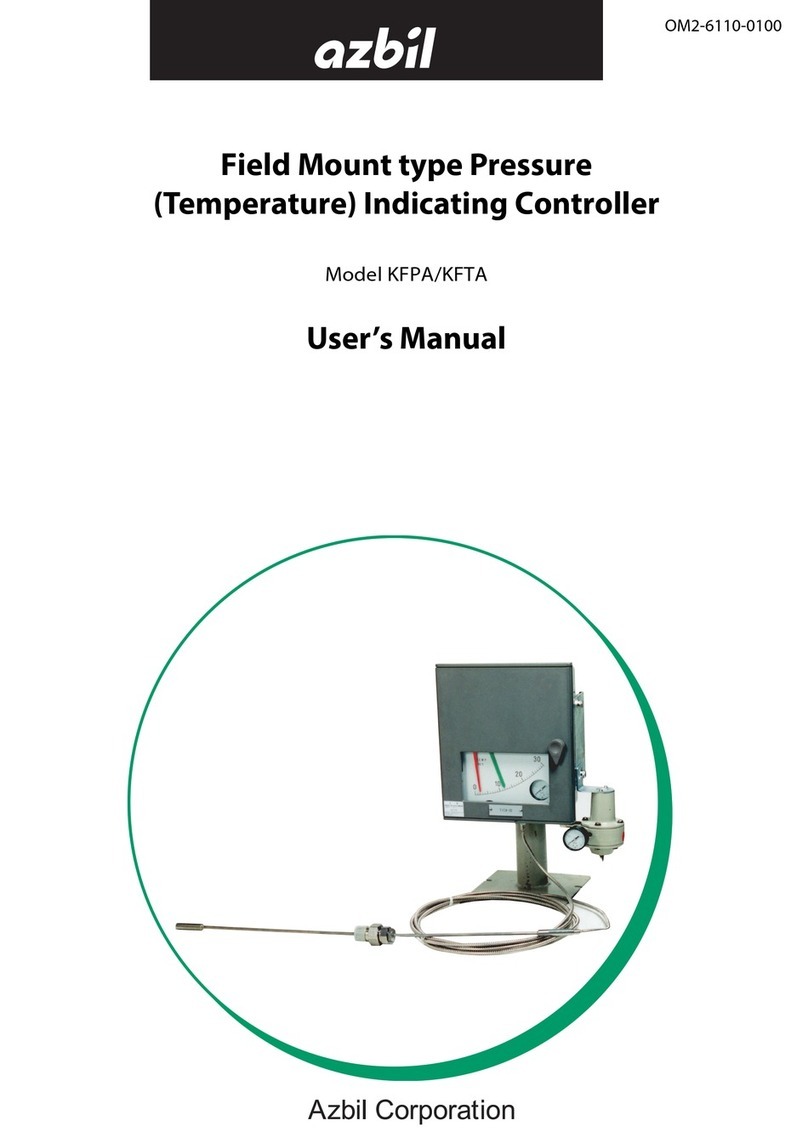

1. Locate the pressure regulator in a straight run of

horizontal pipe. See Figure 4.

2. Allow access room above and below the valve for

inspection and maintenance.

3. For steam service, in order to prevent

water hammer and erratic operation, install

properly sized traps to provide proper

drainage of condensate before and after the

pressure regulator.

4. Avoid the damaging effects of scale and dirt in

pipe lines by installing a Y-Type Strainer as shown

in Figure 4.

5. Provide a 3-valve by-pass to facilitate inspection

and maintenance without interrupting service.

6. If the pressure rating of the downstream piping

or connected equipment is less than the initial

pressure, install a safety valve as shown in

Figure 4.

7. Install initial and delivery pressure gauges to

indicate performance. When long runs of piping

Installing the Valve

1. Flush the piping system thoroughly to clear it of

any debris.

2. Mount the valve between unions with the arrows

under the diaphragm flange pointing in the

direction of the flow.

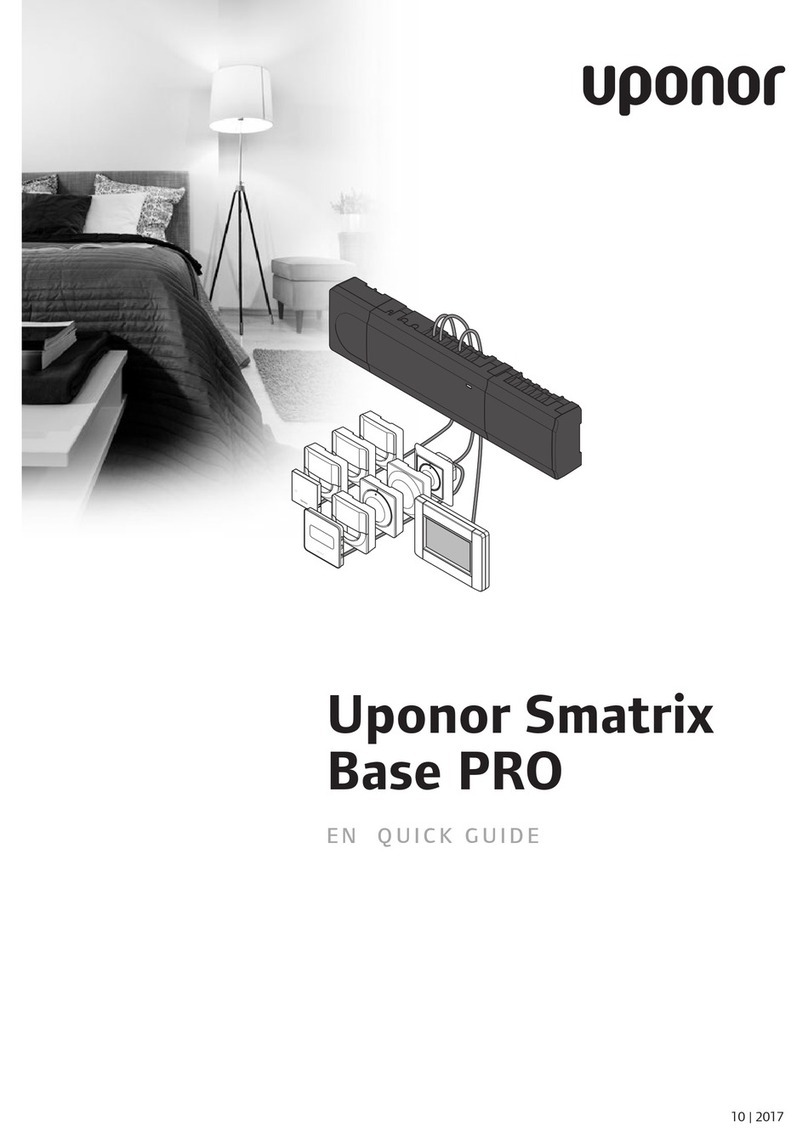

Figure 3. Aspirator Location Mark

NORMAL POSITION

ASPIRATOR LOCATION MARK

ADJUSTED POSITION

are involved, the delivery pressure gauge should

be located as close to the process or equipment

controlled as is practical.

8. To eliminate excessive noise and enhance stability

with steam and other compressible fluids:

a. Avoid single pressure reduction in excess of

5 to 1 ratio.

b. Enlarge the delivery pipe size to effect a

reasonable flow velocity at the reduced

pressure. A concentric tapered transition

is recommended.

c. Avoid sharp turns close to the regulator outlet

as well as bull-headed tee connections to low

pressure mains.

4

Type D50

D1 D2

Adjusting the Delivery Pressure

1. When received, the Type D50 Pressure Regulator

is preset to the delivery pressure listed on the

box label.

To change the delivery pressure:

a. Loosen the lock nut on the adjusting screw.

b. Turn adjusting screw clockwise to increase the

delivery pressure; (or)

c. Turn the adjusting screw counterclockwise to

decrease the delivery.

d. Retighten the lock nut.

2. Mount the valve between unions with the arrows

under the diaphragm flange pointing in the

direction of the flow.

Troubleshooting

1. Failure to open or excessive delivery pressure

fall-off:

a. Adjusting spring, key 6, may have been

tampered with, or broken.

b. Initial pressure may be down due to partially

closed supply valve, clogged strainer, or

other obstruction.

Figure 4. Type D50 Installation

GLOBE VALVE

DRIP AND TRAP

GATE VALVE

STRAINER ASPIRATOR

ADJUSTMENT

GATE VALVE

DRIP AND TRAP AHEAD OF RISE IN PIPING

SECONDARY PRV OR CONTROL VALVE

AVOID BULL-HEADED

CONNECTION TO LOW PRESSURE

STEAM MAIN WHEN REDUCTION

IN NOISE LEVEL IS IMPORTANT

AT LEAST 10 PIPE DIAMETERS (D1)

STRAIGHT RUN, FULL SIZE

AT LEAST 20 PIPE DIAMETERS (D2)

TO FIRST TURN SECONDARY PRV

OR CONTROL VALVE

SAFETY VALVE

LONG

RADIUS

ELBOW

TYPE D50

REGULATOR

2. Failure to close or over-riding delivery pressure:

a. Adjusting spring, key 6, may have been

tampered with.

b. Bypass valve may be leaking or open.

c. Valve diaphragm may be broken.

d. Valve may be held open by foreign matter.

3. Valve chatter or noise.

Certain critical flow conditions may create valve

chatter as evidenced by a humming noise as

the valve closes. Readjustment of the Aspirator

Adjustment feature of the Type D50 pressure

regulator permits the user to desensitize the valve

in order to reduce or eliminate valve chatter.

When received, the Aspirator Adjustment is in the

vertical position. If adjusting is necessary, looses

the locking nut and turn the adjusting screw slowly

within the range shown in Figure 3, until the valve

chatter is eliminated or minimized.

Do not over-adjust.

Note

When replacing the Aspirator Assembly,

key 14, the Aspirator Location Mark,

Figure 3, should face the valve outlet

when completed.

5

Type D50

Parts Ordering

When corresponding with your local Sales Oce about

this equipment, always reference the service and

serial number. Also specify voltage and frequency.

Parts List

Key Name

1 Adjusting Screw

2 Lock Nut

3 Nameplate

4 Spring Chamber

5 Spring Button

6 Adjusting Spring

7 Pressure Plate

8 Flange Screw

9 Lock Washer

10 Body

11 Gasket

12 Diaphragm

13 Pusher Plate

14 Aspirator Assembly

15 Stem

16 Seat Ring

17 Integral Disk

18 End Cap

19 Valve Spring

20 Gasket

21 Screen

22 Guide Bushing

23 Composition Disk

24 Disk Holder

Maintenance

1. Under normal operating conditions,

complete dismantling at regular intervals is

not recommended.

2. Before inspection, cleaning or replacement of

worn or broken parts, make certain that the

pressure regulator has been isolated from the

initial and delivery pressures. Make sure also

that any internal pressure in the regulator has

been relieved.

If a hot or otherwise hazardous fluid is handled by

the valve, appropriate precaution should be taken

prior to disassembling the valve or removing it

from the line.

3. When disassembling the valve, first remove the

compression from the adjusting spring.

4. Minor damage to the seat ring and disk may be

repaired by light grinding with 400 grit or finer

lapping compound.

5. Before reassembling the valve, the old gasket

material and sealing compound should be

removed. Metal to metal joints should be sealed

with Copalite, Permatex or equal plastic gasket

compound compatible with service of the valve.

6. When ordering replacement parts, refer to the

parts list (Table 1). Order parts by part name,

valve size and include the item number from the

Nameplate (key 3, Figure 5).

VALVE SIZE

MATERIAL DELIVERY

PRESSURE RANGE

ADJUSTING SPRING

PART NUMBER

SPRING BUTTON

PART NUMBER

REPAIR/CONVERSION KIT

NPS DN Stainless steel Teon®Seat

1/2 15

Cast iron

3 to 15

10 to 30

25 to 80

75 to 140

WAL05-13105-0

WAL05-13106-0

WAL05-13107-0

WAL05-13108-0 WAL05-13098-0

WAL17082 WAL17086

3/4 20 WAL17083 WAL17087

1 and 1-1/4 25 and 32 Cast iron

3 to 15

10 to 30

25 to 80

75 to 140

WAL05-13106-0

WAL05-13112-0

WAL05-13115-00 WAL17084 WAL17088

WAL05-13116-00 WAL05-13101-0

1-1/2 and 2 40 and 50 Cast iron

3 to 15

10 to 30

WAL05-13117-0

WAL05-13118-0 WAL05-13102-0

WAL17085 WAL17089

30 to 100 WAL05-131119-0 WAL05-13103-0

Table 1. Type D50 and Parts List

6

Type D50

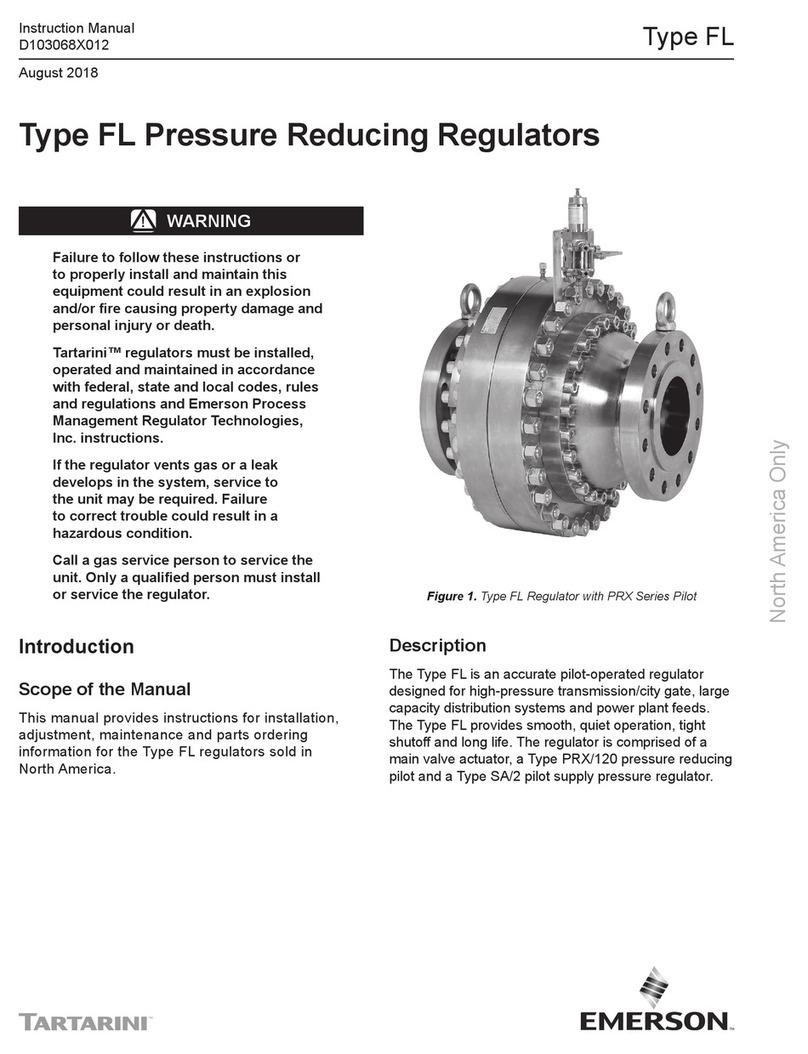

1

2

3

4

5

6

7

8

9

10

11

12

22

13

14

15

16

17

23

24

21

20

19

18

Figure 5. Type D50 Assembly

7

Type D50

VCIMD-16110 © 2022 Emerson Electric Co. All rights reserved. 04/22

Spence is a mark owned by one of the companies in the Emerson Automation

Solutions business unit of Emerson Electric Co. The Emerson logo is a

trademark and service mark of Emerson Electric Co. All other marks are

property of their prospective owners.

The contents of this publication are presented for informational purposes only,

and while every eort has been made to ensure their accuracy, they are not to

be construed as warranties or guarantees, express or implied, regarding the

products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We

reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Electric Co. does not assume responsibility for the selection, use

or maintenance of any product. Responsibility for proper selection, use

and maintenance of any Emerson Electric Co. product remains solely with

the purchaser.

Type D50

Emerson Automation Solutions

SpenceValve.com

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

SIOI136

Table of contents

Other SPENCE Controllers manuals

Popular Controllers manuals by other brands

FIBER SENSYS

FIBER SENSYS Fiber Defender FD508 user manual

Azbil

Azbil KFPA user manual

Mitsubishi

Mitsubishi D700 VFD installation guide

Emerson

Emerson TARTARINI FL Series instruction manual

ACC

ACC RC-85 owner's manual

Sistemes Electrònics Progrés s.a.

Sistemes Electrònics Progrés s.a. AGRONIC 2500 instruction manual

Xantrex

Xantrex Trace C35 Installation and operation guide

ZyXEL Communications

ZyXEL Communications NXC Series user guide

THOMSON

THOMSON MEC 310 - APLLICATION NOTES EXTERNAL I-O... quick start guide

Mitsubishi Electric

Mitsubishi Electric Q170MSCPU user manual

YASKAWA

YASKAWA Z1000U Series quick start guide

Selmo

Selmo PAD quick start guide