SPIERINGS AT7 User manual

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 I

Preface

Dear user,

This operating manual provides the user of the Spierings folding crane with information concerning the crane's

construction and operation. You will find detailed technical specifications and maintenance instructions in the

maintenance part of this manual.

© Copyright Spierings Cranes.

All rights reserved.

No part of this publication may be reproduced or published, in any form or in any way, by print, photo print, microfilm or any other means without prior permission from the

manufacturer.

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 II

Liability clause

SECTION 1. OPERATION

1.1 The Spierings truck may only be used for the purpose it was manufactured and designed for and only as

described in the user manual or in the additions to it.

1.2 Any use of the Spierings truck that differs from its design purpose or as described in the use manual or

the additions to it, will cause the product warranty and the manufacturer’s liability, for any direct or

indirect damage, to expire.

1.3 Only qualified, skilled personnel are allowed to operate the truck. The driver should have a special

driving license for driving heavy vehicles. The driver/operator must be in good physical and mental

health, so that he/she is able to carry out the work without restrictions and react with responsibility in all

given situations.

1.4 The driver/operator/user of the Spierings truck should be informed immediately of any additions/changes

to the user manual.

SECTION 2. SAFETY

2.1 For safety reasons the driver/operator/user should carry out all operations as stated in the user manual

or in the additions to it.

2.2 If more stringent safety demands are locally placed on the truck/crane than specified in the Spierings

truck user manual or additions to it, these more stringent requirements must be strictly complied with. If

not, all warranty will expire and the manufacturer will not be liable for any damage or costs.

2.3 The Spierings truck manufacturer points out explicitly, that the driver/operator/user and local personnel

should not enter the cranes/trucks danger zone. If, for any reason or cause, an unexpected situation

occurs during operation one should contact the technical department or Spierings Service department

first before proceeding.

SECTION 3. WARRANTY

3.1 It is prohibited to carry out modifications or welding to the Spierings truck without prior written permission

of the manufacturer of the Spierings truck.

3.2 Frequent maintenance and periodic checks should be carried out in accordance with the user manual, or

in the additions to it. If maintenance or checks are carried out otherwise, or less frequent, without prior

written permission of the manufacturer of the Spierings truck, all warranty will expire and any liability, for

direct or indirect damage, is explicitly excluded.

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 III

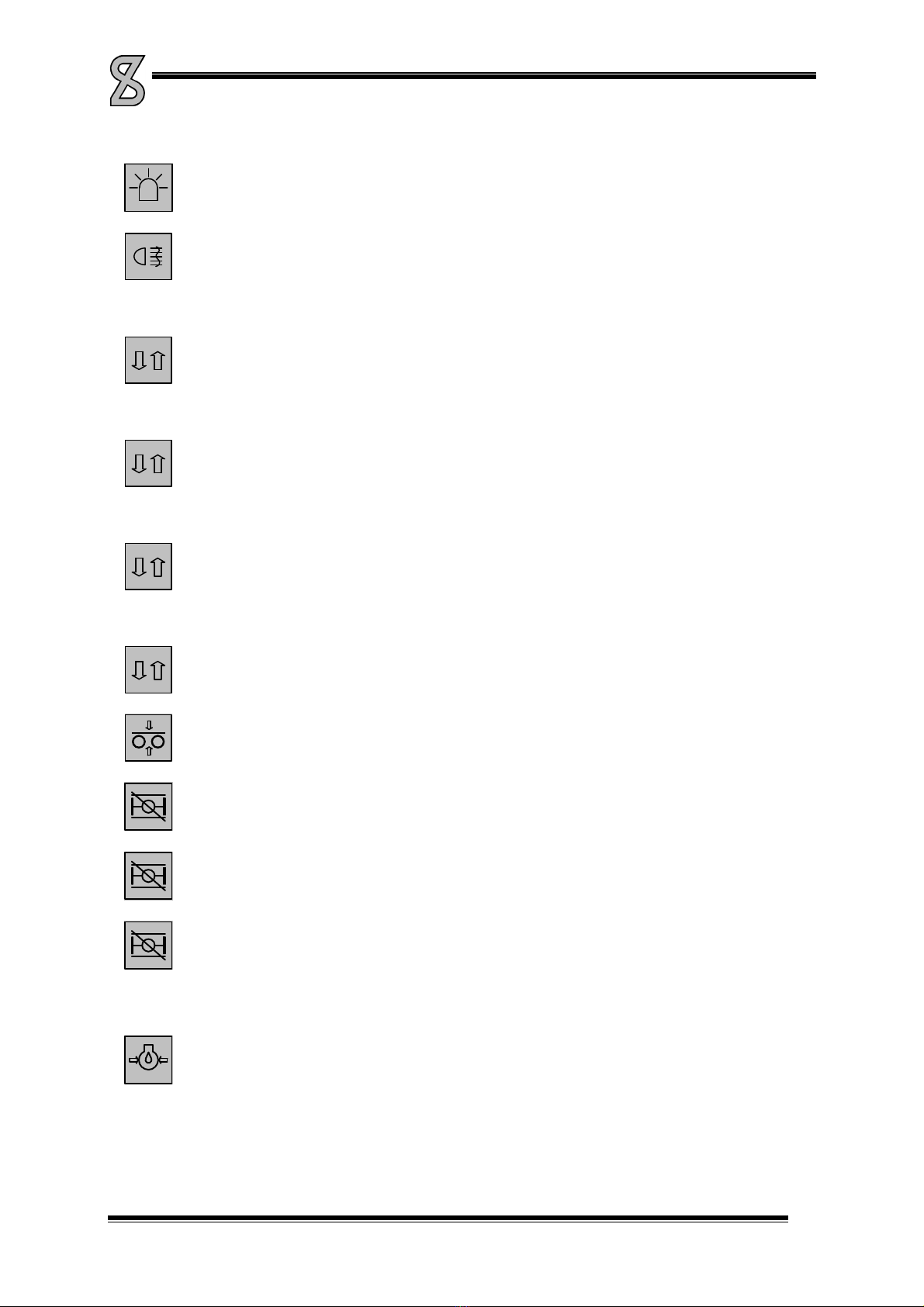

Explanation of the symbols used

CAUTION!

Wear safety goggles!

Wear safety gloves!

Wear safety boots!

Wear head protection!

Use safety belt!

Check!

Manual action!

Automatic action!

Wrong!

Right!

Information!

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 IV

Index

PREFACE ................................................................................................................................................................ I

LIABILITY CLAUSE................................................................................................................................................ II

EXPLANATION OF THE SYMBOLS USED .......................................................................................................... III

INDEX .................................................................................................................................................................... IV

1. GENERAL DATA AT7 .............................................................................................................................. 1-1

2. OPERATION............................................................................................................................................. 2-1

2.1. Get to know the truck .................................................................................................................. 2-1

2.2. Truck cab .................................................................................................................................... 2-3

2.2.1. Getting in ....................................................................................................................... 2-3

2.2.2. Doors............................................................................................................................. 2-3

2.2.3. Wing mirrors .................................................................................................................. 2-3

2.2.4. Seats ............................................................................................................................. 2-3

2.2.5. Safety seatbelts ............................................................................................................. 2-4

2.2.6. Storage room................................................................................................................. 2-5

2.2.7. Sun blind ....................................................................................................................... 2-5

2.2.8. Fuse box........................................................................................................................ 2-6

2.2.9. Windscreen washer reservoir ........................................................................................ 2-6

2.2.10. Central lubrication system (optional) ........................................................................... 2-6

2.2.11. Battery charger remote control batteries ..................................................................... 2-6

2.2.12. Fire extinguisher .......................................................................................................... 2-6

2.3. Control panel............................................................................................................................... 2-7

2.4. Driving the Spierings crane ....................................................................................................... 2-15

2.4.1. Starting ........................................................................................................................ 2-15

2.4.2. Turning off the engine.................................................................................................. 2-16

2.5. Driving on the road .................................................................................................................... 2-16

2.6. Braking system.......................................................................................................................... 2-16

2.6.1. Operating brake........................................................................................................... 2-16

2.6.2. Parking brake .............................................................................................................. 2-17

2.6.3. Vacuum brake ............................................................................................................. 2-17

2.7. Retarder (Optional)/ESC/CC ..................................................................................................... 2-17

2.7.1. The Bremsomat (Optional) .......................................................................................... 2-18

2.7.2. Cruise Control (CC) ..................................................................................................... 2-18

2.7.3. Variable vehicle speed limit ......................................................................................... 2-19

2.7.4. Speed control (ESC).................................................................................................... 2-19

2.8. Driving off the road.................................................................................................................... 2-19

2.8.1. Off the road gear shift high/low transfer case .............................................................. 2-19

2.8.2. Longitudinal differential lock ........................................................................................ 2-20

2.8.3. Transverse differential lock.......................................................................................... 2-20

2.9. Parking ...................................................................................................................................... 2-21

2.10. Axle height adjustment .............................................................................................................. 2-21

2.11. Independent rear axle steering.................................................................................................. 2-23

2.11.1. Driving with independent rear axle steering............................................................... 2-23

2.11.2. Limits of using the independent rear axle steering .................................................... 2-24

2.11.3. Disengage the independent rear axle steering .......................................................... 2-24

2.12. Driving with erected tower ......................................................................................................... 2-24

2.13. Towing the crane....................................................................................................................... 2-24

2.13.1. Towing when the diesel engine can still run .............................................................. 2-24

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 V

2.13.2. Towing when the diesel engine is out of order........................................................... 2-25

2.14. Dolly .......................................................................................................................................... 2-26

2.14.1. Controls ..................................................................................................................... 2-26

2.14.2. Manual dolly wheels alignment.................................................................................. 2-27

3. MAINTENANCE........................................................................................................................................ 3-1

3.1. General ....................................................................................................................................... 3-1

3.1.1. Clothing ......................................................................................................................... 3-1

3.1.2. Surroundings ................................................................................................................. 3-1

3.1.3. Diesel engine................................................................................................................. 3-1

3.1.4. Moving parts.................................................................................................................. 3-1

3.1.5. Oils and coolant............................................................................................................. 3-2

3.1.6. Environment .................................................................................................................. 3-2

3.1.7. Refreshing oil/cooling system ........................................................................................ 3-2

3.1.8. Fire-risk ......................................................................................................................... 3-2

3.1.9. Cleaning of components................................................................................................ 3-2

3.2. Maintenance plan AT4 truck........................................................................................................ 3-3

4. DIESEL ENGINE....................................................................................................................................... 4-1

4.1. Services in the first period of use ................................................................................................ 4-1

4.2. Access to the diesel engine......................................................................................................... 4-2

4.3. Engine oil .................................................................................................................................... 4-2

4.3.1. Check engine oil level.................................................................................................... 4-2

4.3.2. Fill up engine oil............................................................................................................. 4-3

4.3.3. Engine oil change .......................................................................................................... 4-3

4.4. Engine oil filter............................................................................................................................. 4-4

4.4.1. Oil filter replacement...................................................................................................... 4-4

4.5. Cooling system............................................................................................................................ 4-5

4.5.1. Check coolant level ....................................................................................................... 4-5

4.5.2. Fill up coolant ................................................................................................................ 4-6

4.5.3. Change coolant ............................................................................................................. 4-6

4.5.4. Anti-frost ........................................................................................................................ 4-7

4.5.5. Radiator and intercooler ................................................................................................ 4-7

4.6. Air inlet system............................................................................................................................ 4-7

4.6.1. Cleaning the air filter...................................................................................................... 4-7

4.6.2. Air filter cartridge change............................................................................................... 4-9

4.7. Fuel system................................................................................................................................. 4-9

4.7.1. Fuel filter change ........................................................................................................... 4-9

4.8. Fuel filter/Water separator......................................................................................................... 4-11

4.8.1. Drain the water separator ............................................................................................ 4-11

4.8.2. Fuel filter/water separator change ............................................................................... 4-12

4.9. V-belts ....................................................................................................................................... 4-12

4.9.1. Check the V-belts ........................................................................................................ 4-12

4.9.2. Adjust the V-belts ........................................................................................................ 4-13

4.9.3. Gear belt check ........................................................................................................... 4-14

4.9.4. Gear belt adjustment ................................................................................................... 4-15

4.10. Exhaust system......................................................................................................................... 4-15

4.11. Check and adjust the valve clearance....................................................................................... 4-16

4.12. Check and adjust the DEB clearance........................................................................................ 4-17

5. DRIVE LINE .............................................................................................................................................. 5-1

5.1. Clutch and gear box .................................................................................................................... 5-1

5.1.1. Specifications gear box ................................................................................................. 5-1

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 VI

5.1.2. Maintenance gear box ................................................................................................... 5-2

5.1.3. Check oil level of the gear box....................................................................................... 5-2

5.1.4. Gear box oil change ...................................................................................................... 5-3

5.2. Transfer case .............................................................................................................................. 5-3

5.2.1. Specifications transfer case........................................................................................... 5-3

5.2.2. Maintenance transfer case ............................................................................................ 5-3

5.2.3. Check oil level transfer case.......................................................................................... 5-4

5.2.4. Transfer case oil change ............................................................................................... 5-4

5.3. Axles ........................................................................................................................................... 5-5

5.3.1. Maintenance axles......................................................................................................... 5-5

5.3.2. Check oil level differentials ............................................................................................ 5-5

5.3.3. Differential oil change .................................................................................................... 5-6

5.3.4. Check oil level hubs....................................................................................................... 5-7

5.3.5. Hubs oil change............................................................................................................. 5-7

5.4. Tires ............................................................................................................................................ 5-8

5.4.1. Maintenance tires .......................................................................................................... 5-8

5.4.2. Tire pressure ................................................................................................................. 5-8

5.5. Check the brake lining thickness................................................................................................. 5-8

5.5.1. Brakes ........................................................................................................................... 5-8

5.6. Clutch .......................................................................................................................................... 5-9

5.6.1. Checking the clutch ....................................................................................................... 5-9

5.6.2. Venting the clutch .......................................................................................................... 5-9

5.6.3. Clutch fluid change ...................................................................................................... 5-10

6. STEERING SYSTEM ................................................................................................................................ 6-1

6.1. Check the steering system .......................................................................................................... 6-2

6.2. Align the steering system ............................................................................................................ 6-2

7. ELECTRICAL SYSTEM............................................................................................................................ 7-1

7.1. Lighting........................................................................................................................................ 7-1

7.2. Dashboard lighting ...................................................................................................................... 7-1

7.3. Batteries ...................................................................................................................................... 7-2

7.3.1. Check the batteries........................................................................................................ 7-2

7.3.2. Recharging the batteries ............................................................................................... 7-2

7.3.3. Replacing batteries........................................................................................................ 7-3

8. HYDRAULIC SYSTEM ............................................................................................................................. 8-1

8.1. Check oil level hydraulic tank ...................................................................................................... 8-1

8.2. Hydraulic oil change.................................................................................................................... 8-2

8.3. Hydraulic return filter change ...................................................................................................... 8-3

8.3.1. Hydraulic return filter ..................................................................................................... 8-3

8.4. Check the suspension’s accumulators ........................................................................................ 8-3

8.5. Hoses and connections hydraulic system ................................................................................... 8-4

9. PNEUMATIC SYSTEM ............................................................................................................................. 9-1

9.1. Primary system: brake system .................................................................................................... 9-1

9.2. Secondary system: accessories and gearbox ............................................................................. 9-1

9.3. Air dryer....................................................................................................................................... 9-2

9.3.1. Air dryer filter change .................................................................................................... 9-2

9.4. Air vessels................................................................................................................................... 9-3

9.5. Air lubricator/water separator ...................................................................................................... 9-3

9.5.1. Refill air lubricator.......................................................................................................... 9-4

9.5.2. Water separator............................................................................................................. 9-4

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 VII

9.6. Check brake pressure ................................................................................................................. 9-5

9.7. Hoses and connections pneumatic system ................................................................................. 9-5

10. LUBRICATION........................................................................................................................................ 10-1

10.1. Central lubrication system ......................................................................................................... 10-1

10.1.1. Greasing points central lubrication system ................................................................ 10-2

10.2. Manual lubrication ..................................................................................................................... 10-3

10.2.1. Outrigger beam cylinders .......................................................................................... 10-3

10.2.2. Driven axles............................................................................................................... 10-3

10.2.3. Cardan shafts ............................................................................................................ 10-4

10.2.4. Steering system......................................................................................................... 10-4

10.2.1. Tower supports.......................................................................................................... 10-5

10.2.2. Dolly pin-lock connection........................................................................................... 10-5

11. VARIOUS................................................................................................................................................ 11-1

11.1. Window washer fluid ................................................................................................................. 11-1

11.2. Fire extinguisher........................................................................................................................ 11-1

12. TECHNICAL DATA................................................................................................................................. 12-1

13. ENCLOSURES ....................................................................................................................................... 13-1

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 1-1

1. General Data AT7

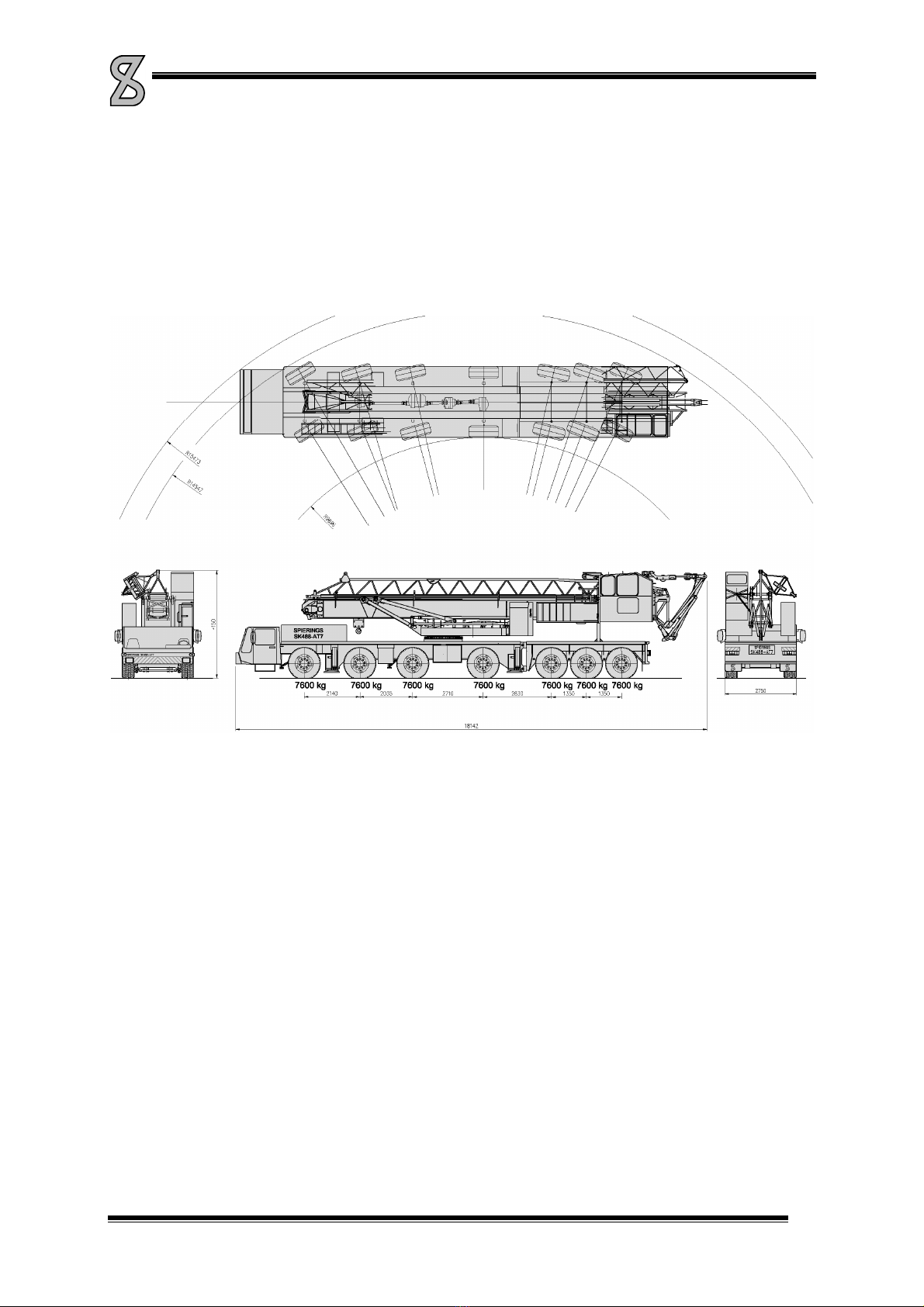

The AT7 carriage is especially designed for the Spierings SK488 folding crane. Extra attention is paid to a smooth

and comfortable transport to the work site. The crane is suited for driving on public roads, fully equipped with

counterweights and tools. The chassis is an especially rigid structure to create a good crane support.

In Picture 1-1 you will find the measurements of the SK488 with the AT7 carriage. The dimensions given are the

overall dimensions, axle bases and turning circle.

Picture 1-1

Measurements:

Length: 18.2m (59.7 ft)

Width: 2.8m (9.2 ft)

Height: 4.37m (14.34 ft)

Drive unit:

12.6 litre DAF-diesel engine with turbo compressor and intercooler (type XE 315).

ZF gearbox with sixteen gears forward and two gears reverse.

STEYR high/low shift, transfer case, with high speed (road) and low speed (off the road) transmission.

Electronic accelerator "E-gas” with speed control.

Four Ginaf axles, where axle two, three and four are driven.

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 1-2

Steering with dolly:

All axles are steered except axle four.

Mechanically coupled steering, where 1, 2 and 3 are steered in the opposite direction of axle 5, 6 and 7,

realizing a small turning circle.

Hydraulically powered steering system.

Fitted with an emergency steering pump, so when the main steering pump malfunctions, the truck remains

steer able until it is at a standstill.

Provisions for driving off the road:

- axle height adjustable

- high/low gear shift transfer case can be put in low gear for driving off the road

- longitudinal and transverse differentials can be locked

Steering without dolly:

Axle 1, 2, and 3 are steered. Axle 4 remains fixed.

Mechanically coupled steering.

Axle 4 can be mechanically uncoupled and manually steered using a joystick. Independent rear axle steering

is also possible.

Hydraulically powered steering system.

Fitted with an emergency steering pump, so when the main steering pump malfunctions, the truck remains

steer able until it is at a standstill.

Provisions for driving off the road:

- axle height adjustable

- high/low gear shift transfer case can be put in low gear for driving off the road

- longitudinal and transverse differentials can be locked.

Suspension:

Hydro-pneumatic suspension.

The suspension can be blocked (e.g. when driving with erected tower.)

Braking system:

Pneumatic brakes with anti-blocking system (ABS).

4-point outrigger system:

wide support base = 6,9 m x 6,85 m (22.64 ft x 22.47 ft)

Narrow support base = 6,9 m x 5,15 m (22.64 ft x 16.9 ft)

Further data:

Maximum speed limit to 83 km/h (52 mph)

Minimum speed at 1250 rpm: 1,9 km/h (1.2 mph) = 32 m/min (105 ft/min)

Truck weight including superstructure: 53.2 tons

De axle load is 7600kg (16755 lbs) per axle

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 1-3

Identification:

Engine number: Left-hand side on the engine block above the fuel pump.

Vehicle identification number: On the identification plate in the co-driver’s leg-room (See Picture 1-1) and

stamped in the right frame girder in front of the first axle. (Picture 1-2)

Picture 1-1

Picture 1-2

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-1

2. Operation

2.1. Get to know the truck

Picture 2-1

1. Truck cab

Besides driving the crane, with the controls in the truck cab you can support the crane on outriggers and adjust

the carriage axle height.

2. engine housing

3. Storage box/battery box

In this storage box, the batteries are placed.

4. Storage box

This box is lockable and can be used for hoisting equipment.

5. outriggers

At both sides of the truck there are 2 extending outrigger beams (Picture 2-2, 4), and to each beam a hydraulically

operated outrigger (1). These outriggers provide stability during hoisting operation. The outrigger beams have an

antiskid coating (5) to prevent skidding. The outrigger pad holders (3) can be used to facilitate stepping on the

outrigger beam (2).

With a separate (remote) control box the outriggers can be radio controlled. On the rear outrigger beams are

levels to check if the crane set-up is level.

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-2

Picture 2-2

6. Storage room support plates

To obtain a solid support base on a week ground, support plates can be used. Under the toolbox as well as under

the fuel tank there are 2 support plates each.

7. Hydraulic oil tank

On this side of the truck you will find the hydraulic oil tank.

8. Fuel tank

The fuel tank capacity is 430 litres.

9. Work lamps

To the rear of the cab and truck are mounted work lamps, which can be

switched on/off from the cab.

By unscrewing the knob, the lamp support can be moved to the left and right

(see Picture 2-3).

Picture 2-3

11. Truck ladders

To facilitate getting on the truck, three ladders are mounted. Pick up the

free end of the ladder so the pin comes out of the deck (see Picture 2-4)

and swing the ladder outside the frame. When swinging back the ladder,

make sure the pin returns in the hole.

Picture 2-4

12. Coupling camera

For easy coupling of the dolly, a camera is mounted on the truck. The camera view is shown on the truck cab’s

monitor.

13. Hydraulic quick-coupling dolly

14. Parking brake dolly

15. Steering system control box dolly

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-3

2.2. Truck cab

In the truck cab you drive the crane safely and comfortably to its destination. This chapter makes you familiar with

the cab.

2.2.1. Getting in

Use the step under the door. Make use of the steering wheel to hold on to.

2.2.2. Doors

Turn the handle up to open the door from the inside. The door can only be locked up from the outside.

There is an ashtray on the inside of the door. After opening the ashtray, you push the locking device down to

remove the ashtray from the holder to empty it.

Use the switches on the dashboard to operate the door windows electronically.

2.2.3. Wing mirrors

The wing mirrors may be adjusted by hand. Make sure the mirrors are adjusted before driving off, so that you

have satisfactory view. The mirror heating can be switched on with the switch on the control panel.

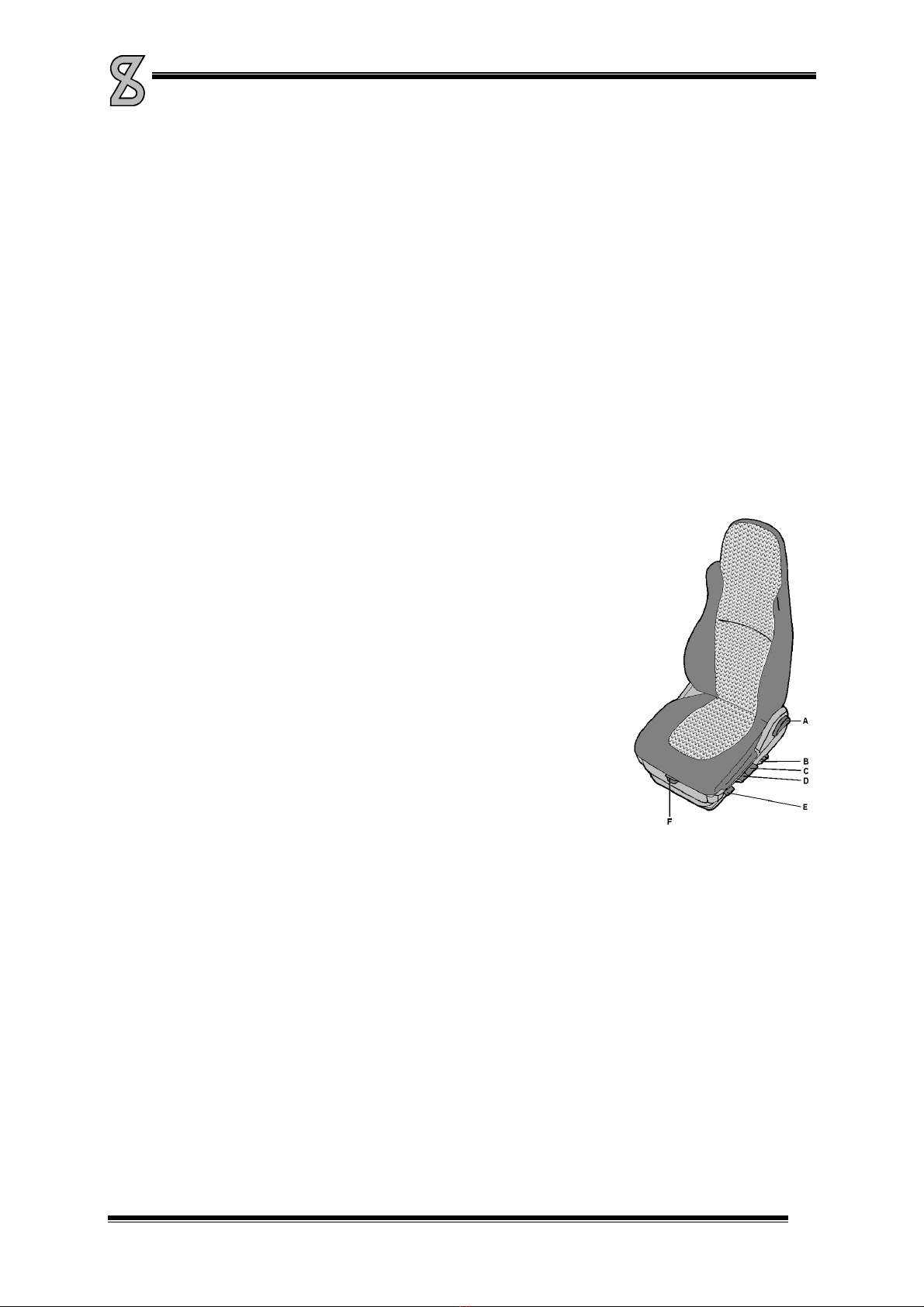

2.2.4. Seats

The cab has room for the driver and a co-driver. The driver's seat has pneumatic

suspension. The seats' position can be adjusted. This should only be done when

the vehicle stands still.

A) Back adjustment

B) Lumbar support adjustment (push = pumping up an pull = deflating)

C) Height adjustment (pulling the handle = up and pushing it = down)

D) Tipping the seat

E) Handle fast lowering

F) Adjustment seat

Picture 2-5

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-4

2.2.5. Safety seatbelts

For the safety of the driver, the seats of the Spierings cab are equipped with seatbelts.

Caution!

The seatbelts should always be used while driving in the Spierings crane.

1. Before using the seatbelts, always check the emergency locking

mechanism of the retractor.

Firmly pull the metal mating plate of the buckle downwards (Picture

2-6).

The retractor should lock

Picture 2-6

Beware!

It is prohibited to drive in the crane if the emergency locking mechanism is out of order.

2. Slowly pull the seatbelt over the shoulder and lap and lock the metal mating plate in the buckle. (Picture 2-7)

Picture 2-7

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-5

3. Make sure the seatbelt is securely fastened

(check buckle) and check the tension of the

seatbelt.

4. Release the seatbelt by pressing the release

button on the buckle (Picture 2-8).

Picture 2-8

While using the seatbelts make sure that:

1. The seatbelt is used by one person at a time.

2. The webbing of the seatbelt is not twisted.

3. The webbing of the seatbelt does not rub against sharp edges.

4. No hard or breakable items (for example spectacles or pens) are between the webbing of the seatbelt and

the person using the seatbelt.

5. The opening for the metal mating plate of the buckle is free from small items (for example pieces of paper).

These items could cause failure of the buckle lock mechanism.

6. Do not wear very thick clothing (for example winter jacket) because this could cause failure of the emergency

locking mechanism.

Maintenance of the seatbelts:

1. Keep the webbing, the buckle and retractor of the seatbelts clean and free from dust and small item at all

times.

2. Clean the webbing of the seatbelts with a regular cleaning product only.

3. In case of an accident the emergency locking mechanism should always be replaced.

4. Only authorized/certified persons are allowed to repair or replace seatbelts.

2.2.6. Storage room

In the middle of the cab ceiling is a storage compartment. It has a lockable lid at the driver's side and at the side

of the co-driver.

2.2.7. Sun blind

To prevent sunlight from blinding you, a sun blind is mounted above the windscreen for the driver and the co-

driver. Pull down the blind with the joggle in the middle of the blind. The blind will remain in the desired position.

Push the button on the side of the blind to roll it up

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-6

2.2.8. Fuse box

The fuse box is at the co-driver's side in the centre console (Picture 2-9, B). You will find the fuses listed in the

enclosures.

2.2.9. Windscreen washer reservoir

(Picture 2-9, C)

2.2.10. Central lubrication system (optional)

The central lubricating system controls are on the centre panel at the co-driver's side. It can be opened by means

of 2 clamps (Picture 2-9, B).

Picture 2-9

2.2.11. Battery charger remote control batteries

You will find the battery charger for the remote controls on the left under the dashboard at the driver's side

(Picture 2-9, D).

Every remote control comes with 2 batteries each. While the batteries are charged, the indicator lamp lights up.

As soon as they are fully charged, the lamp starts flashing.

2.2.12. Fire extinguisher

One fire extinguisher is behind the co-driver's seat. On the right behind the control box in the crane cab is the

second fire extinguisher.

The fire extinguishers must be inspected every year by the authorities

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-7

2.3. Control panel

Picture 2-10

1a Indicator lamp steering pressure circuit

1b Indicator lamp parking brake

2a Indicator lamp steering pressure circuit 2

2b Indicator lamp coolant level

3 Switch/Indicator lamp ABS

4a Indicator lamp ABS dolly)

4b Indicator lamp parking brake dolly

5a ESC malfunction diagnosis lamp

5b Indicator lamp sensor intermediate position

6 Not in use

7 Light switch, off/parking light/dipped beam

8 Dimmer dashboard lighting

9 Switch work lamps

10 Switch mirror heating

11 Switch rotating beacon

12 Switch fog tail-light

13 Switch alls axles up/down

14 Switch axles 1, 2 and 3 up/down

15 Switch axle 4, 5, 6 and 7 left-hand side

up/down

16 Switch axle 4, 5, 6 and 7 right-hand side

up/down

17 Switch/indicator lamp levelling

18 Switch driving/blocking

19a Indicator lamp off the road mode

19b Indicator lamp blocking

20 Indicator lamp max. pressure outrigger-

/suspension system

21 Not in use

22 Switch outrigger beam front left-hand side

retract/extend

23 Switch outrigger front left-hand side

retract/extend

24 Switch outrigger beam rear left-hand side

retract/extend

25 Switch outrigger rear left-hand side

retract/extend

26 Switch outrigger front right-hand side

retract/extend

27 Switch outrigger beam front right-hand side

retract/extend

28 Switch outrigger rear right-hand side

retract/extend

29 Switch outrigger beam rear right-hand side

retract/extend

30 Switch outrigger controls on/off

31 Reservoir clutch fluid

32 Ignition lock

34 Voltmeter batteries

35 Oil-pressure gauge (lubrication circuit)

37 Lever parking brake

38 Tachograph, speedometer, mileage counter,

clock

39 Revolution counter, hour counter

40 Fuel gauge

41 Coolant temperature gauge

42 Air-pressure gauge circuit 2

43 Air-pressure gauge circuit 1

44 Oil temperature gauge retarder (optional)

45 Radio

46 Gauge pump pressure steering system

48 Switch/indicator lamp transverse differential

lock axle 2, 3 and 4

49 Indicator lamp transverse differential lock

axle 2 and 3

51 Switch/indicator lamp longitudinal differential

lock

52 Indicator lamp longitudinal differential lock

53 Control heater/fan

54 Switch alarm light

55 Switch cab lighting on the left

56 Switch cab lighting on the right

57 Indicator lamp high/low gear shift

58 Indicator lamp transfer case neutral

59 Switch transfer case neutral

60 Switch position transfer case high/low/neutral

61 Indicator lamp quick coupling dolly uncoupled

62 Indicator lamp wheels of truck aligned

63 Indicator lamp wheels of dolly aligned

64 Indicator lamp dolly pins unlocked

65 Indicator lamp dolly pins locked

66 Switch dolly upper pin lock cylinder

67 Switch dolly lower pin lock cylinder

68 Switch for blinker, windscreen wiper, horn,

signal, full beam headlamp

69 Clutch pedal

70 Brake pedal

71 Accelerator pedal

72 Lever range selector with splitter

73 Vacuum brake

75 Cigarette lighter/24V-connection

76 Indicator lamp charging voltage batteries

77 Indicator lamp blinker

78 Indicator lamp air-pressure

79 Indicator lamp full beam headlight

80 Indicator lamp oil pressure (transmission oil)

81 Indicator lamp air cleaner

82 Indicator lamp flame starting system

83 Control electrical window (left-hand)

84 Switch aeronautical warning light on jib and

tower (optional)

85 Control electrical window (right-hand)

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-8

1a. Indicator lamp steering pressure circuit 1

This Lamp lights up as soon as the oil pressure in steering circuit 1 is too low. Have the malfunction

repaired as soon as possible. If this lamp lights together with lamp 2a: STOP IMMEDIATELY!

1b. Indicator lamp parking brake

As long as the parking brake is engaged, this lamp is on (when starting the engine the parking

brake remains engaged as long as the air-pressure is below 5.5 bar (80 PSI).

2a. Indicator lamp steering pressure circuit 2

This lamp lights up as soon as the oil pressure in steering circuit 2 is too low. Have the malfunction

repaired as soon as possible. If this lamp lights together with lamp 1a: STOP IMMEDIATELY! When

the vehicle stands still, this lamp will light.

2b. Indicator lamp coolant level

This lamp lights up as soon as the coolant level is too low. Replenish coolant.

3. Indicator lamp/switch ABS

This lamp is on when operating the ignition and remains on until a driving speed of 7 km/h

(4.4 mph) is reached. From 7 km/h (4.4 mph) it goes out and will only light up in case of a

malfunction. At first, push and release the switch to reset the system. If this doesn’t resolve the

problem, have the malfunction repaired as soon as possible.

4a. Indicator lamp ABS dolly

See indicator lamp ABS (3).

4b. Indicator lamp parking brake dolly

This lamp is on when the dolly is attached to the truck and the parking brake of the dolly is

engaged.

5a. E-gas diagnosis lamp

Indicator lamp flashers: Stop the vehicle and switch off the engine to prevent damage on the

vehicle and/or engine.

Indicator lamp lights up: There is a malfunction. Some functions will not work correctly. You can

drive the vehicle but repair the problem as soon as possible.

7. Light switch

By pressing this switch halfway, the parking lights are switched on. By pressing the switch all the

way, the dipped beams are switched on.

8. Dimmer dashboard lighting

When switching on the vehicle lighting also the dashboard lighting goes on. With this dimmer you

can change the dashboard lighting intensity.

9. Work Lamps

At the rear of the cab and truck are 2 work lamps each. With this switch the 4 work lamps are

switched on and off.

10. Mirror heating

With this switch the mirror heating in the left en right wing mirror is switched on and off.

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-9

11. Rotating beacon

With this switch the rotating beacon can be switched on and off.

12. Fog tail-light

With this switch the fog tail-light on the cab can be switched on and off.

ALL

AXLES

13. Switch for all axles up/down

With this switch the cylinders of all axles are moved in and out simultaneously (i.e. when supporting

the crane on outriggers).

ALL

AXLES

14. Switch axles 1, 2 and 3 up/down

With this switch the cylinders of axles one, two and three can be moved in and out.

LEFT

4-7

15. Switch axle 4-7 left-hand side up/down

With this switch the cylinders on the left side of the fourth to seventh axle can be moved in and out.

RIGHT

3-4

16. Switch axle 3 right-hand side up/down

With this switch the cylinders on the right side of the third and fourth axle can be moved in and out.

17. Switch/indicator lamp levelling

18. Switch driving/blocking.

19a. Indicator lamp off the road mode

19b. Indicator lamp blocking

20. Indicator lamp maximum pressure outrigger-/suspension system

This lamp goes on and a buzzer sounds at the rear outriggers as soon as the pressure in the

outrigger/suspension system becomes too high. This may happen when the outriggers, the axles or

the outrigger beams are fully in or out, or because there is an obstacle in the way when extending

the outrigger beams.

During levelling operation and when moving the axles up or down, this light could also go on. This

does not present a problem. When the outrigger/suspension system is not operated, this indicator

lamp shows a malfunction. (I.e. a not correct functioning switch)

MANUAL SPIERINGS TRUCK AT7

AT7-EN-050420 2-10

Outrigger Operation (on the dashboard from left to right)

22. Switch outrigger beam front left-hand side retract/extend

23. Switch outrigger front left-hand side retract/extend

24. Switch outrigger beam rear left-hand side retract/extend

25. Switch outrigger rear left-hand side retract/extend

26. Switch outrigger front right-hand side retract/extend

27. Switch outrigger beam front right-hand side retract/extend

28. Switch outrigger rear right-hand side retract/extend

29. Switch outrigger beam rear right-hand side retract/extend

30. Switch outrigger controls on/off

Switch off the outrigger controls when the outriggers are not operated or when the crane is rigged

up/rigged down or in operation. The remote control is also de-activated. Failing to switch off the

controls means the crane can not be set to the full hoisting program (full support base).

32. Ignition lock

By turning the key to the right, three positions are possible, from left to right:

0 = ignition off

1 = Contact

2 = starting

34. Voltmeter batteries

On this meter you can read the battery condition. The meter must be in the middle (approx. 24 V)

35. Oil-pressure gauge lubrication circuit

When starting, this gauge will read approx. 5 bar (72.5 PSI). As soon as the oil is warm approx.

3 bar (43.5 PSI).

37. Lever parking brake

Pulling this lever backwards the parking brake is engaged. Pulling out the knob and pushing the

lever forwards will release the parking brake.

Other manuals for AT7

1

Table of contents

Other SPIERINGS Construction Equipment manuals