10

Fig. 10 Dosato e olio f esco Fig. 11 Olio sintetico a t. 21CR (optionale)

6.0 RECHARGE OF GAS (Charge in ernal bo le)

The amount of f eon, which is p esent in the inte nal bottle, has been inse ted fo the pe fo mance of the check and

cont oll of the station and is sufficient fo pe fo ming a complete cha ging; The efo e it is advisable at switch-on to

cha ge the necessa y gas with the use of an exte nal bottle.

At switch-on appea s the amount of f eon on the display, which is available within the inne bottle; by p essing the

a ow keys + o – the continuous menu will be shown, it will be displayed in subsequent o de (by constantly p essing

the key +) 1.MANUAL 2. HALF AUTOMATIC; 3. AUTOMATIC; 4. DATA BASE; 5. UTILITY; go back to the

amounts of gas, which a e p esent in the bottle;

- Choose the p og am “UTILITY’’ and confi m with “ENTER”;

- Choose “Gas Recha ge” with the keys “+ and –“ and confi m with “ENTER”;

- The display shows the message “CHARGE” and a ce tain amount of gas;

- P og am the amount of gas which is equested to pe fo m the echa ge with the a ow keys “+ and –“ ;

- Confi m with key “ENTER”;

- Like that sta t the pe fo mance of the echa ge, the display will show the gas, which is ecove ed and

additionally the amount of the total gas which is being ecove ed until the end of the ope ation;

Attention!!! At the end of the ecove y the display shows the message “Attention 9” close the cock of the bottle

and p ess the key “ENTER”, like that the emaining gas within the exte nal tubes is ecove ed.

- If the exte nal bottle is empty the display will show the message “Attention 8 exte nal bottle empty”. The same

message appea s, if the bottle empties du ing the ecove y phase.

The device is equipped with a secu ity device, which cont ols the amount of gas, which is available within the inte nal

bottle; if it fo the pe fo mance of the ecove y with the efilled bottle the bo de of the ala m (1,5 kg) on the display

then appea s the message of the full bottle in addition to the message ERR 4. In this case you can only pe fo m the steps

of the vacuum and cha ging until the amount of gas within the bottle has fallen again unde 15 kg.

If the amount of gas available within the inte nal bottle is insufficient afte the p og amming, the display will show

ERR1 as well as the message of the insufficient gas in the bottle, in this case it is necessa y to ca y-on as mentioned

unde “ echa ge gas;

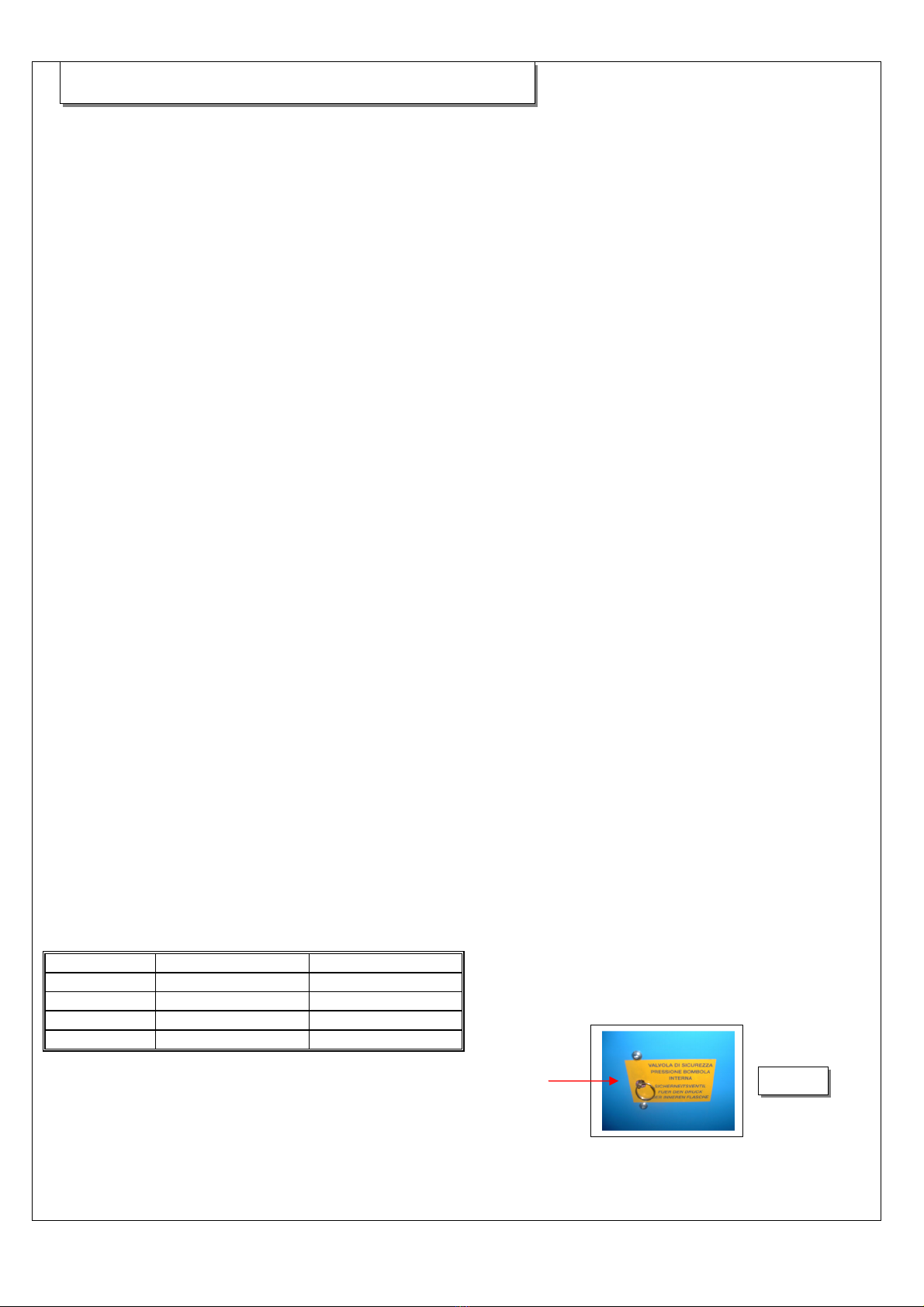

The inte nal bottle is supplied with a mechanic secu ity valve, which opens automatically, when the p essu e ises ove

16 ba . A second, bette eachable valve is positioned at the side of the small oil discha ge bottle.

6.1 PRESSURE TEST OF PLANT A/C

- The two high- and low p essu e cocks need o be closed.

- P ess the key “C” on the keyboa d.

- Sta t the vehicle in gea of 1500 .p.m.

- Switch-on the A/C device.

- Cont ol the p essu e on the gauges “A” and “B” acco ding to the following list:

T. su ounding LOW PRESSURE HIGH PRESSURE

°C 15 0,5 – 2,0 7,5 - 13

°C 20 0,5 – 2,5 10 - 16

°C 25 0,5 – 2,5 12 - 18

°C 30 0,5 - 3 12 - 20

CHAP. 6 USE F THE CENTRAL UNIT