IM-P402-62 AB Issue 54

4. Setting up the transmitter

4.1 Setting up the transmitter

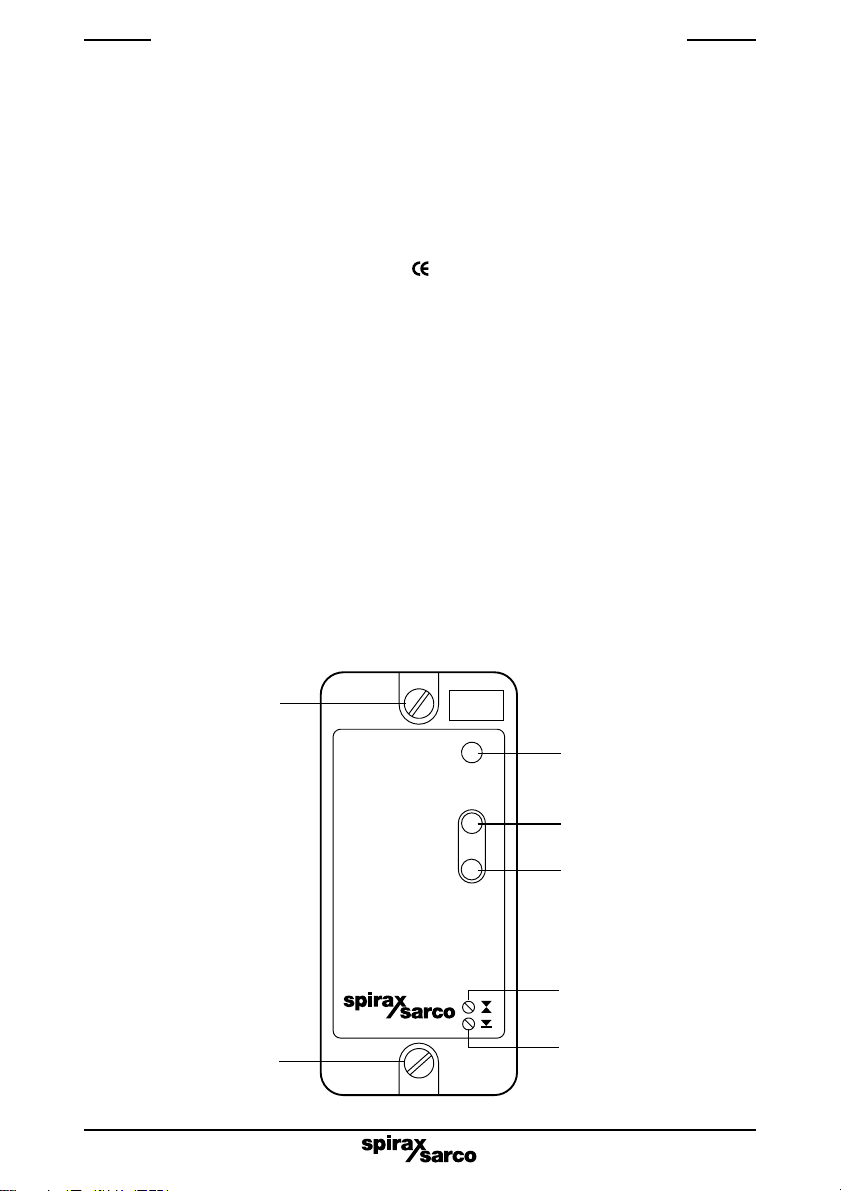

The transmitter is set up as follows:

-230 V mains supply.

-Wave filter off.

-4-20 mA.

-Normal (non-inverse) output.

-Capacitance probe input (voltage).

4.2 To change the mains supply voltage:

-Unplug the transmitter from its base.

-Remove the rear cover panel.

-Slide out the printed circuit board.

-Slide the voltage selector switch to the 115 V setting.

-Replace the printed circuit board.

-Ensure that the LED’s engage with the holes in the front panel.

-Replace the rear cover panel.

Slide switch

up for 115 V

setting

230 Transformer

Fig. 2

3. Installation

WARNING:

Isolate the mains supply before unplugging the transmitter since hazardous voltages will be

exposed on the transmitter base.

To unplug the transmitter from its base, undo the two retaining screws and pull the transmitter

straight forwards. Rocking the transmitter in the vertical plane will ease removal.

The transmitter must be installed in an enclosure or control panel to provide environmental

protection (Pollution Degree 2). Spirax Sarco can provide suitable metal or plastic enclosures.

The transmitter may be mounted on a 'top hat' DIN rail using the clip provided or the clip can be

removed and the transmitter base screwed directly to a chassis plate.

Caution: Allow 15 mm spacing between multiple units for air circulation.

The transmitter is for installation Category II (Overvoltage category) and must be installed in

accordance with IEC 60364 or equivalent. The transmitter and all connected circuits must

have a common isolation system which meets the relevant requirements of IEC 60947-1 and

IEC 60947-3 or equivalent. This must be positioned close to the transmitter and clearly identified

as the disconnect device.

A quick blow 3 amp external fuse must be fitted in all phases of the transmitter supply.

For the US and Canadian markets the transmitter must be wired in accordance with the National

and Local Electrical Code (NEC) or Canadian Electrical Code (CEC).

Screened high temperature, 3 core, 1 mm²(18 - 16 AWG) copper cable is required for the probe

wiring.Themaximumpermittedlengthis100metres(328ft).Usecablewithasuitabletemperature

rating for the installation. Pirelli FP200 or Delta Crompton Firetuf OHLS are suitable cables for the

standard version. Use NEC Class 1 wiring for the UL version.

Cabling should be installed in accordance with BS 6739 - Instrumentation in Process Control

Systems: Installation design and practice or local equivalent.

Connect the screens as shown in the wiring diagrams (Section 5).

If the product is not used in the manner specified by this IMI, then the protection provided

may be impaired.

20 mm fuse

100 mA anti-surge (T)