1. Preface ········································································································································ 3

1.1 Important ········································································································································ 3

1.2 How To Use This Manual················································································································ 3

2. Safety ·········································································································································· 3

2.1 General Safety Informaon············································································································ 3

2.2 Unpacking the System····················································································································· 4

3. ES250 Overview ··························································································································· 5

3.1 Electrostacs Spraying Overview··································································································· 5

3.2 System Components and Installaon Requirements····································································· 5

4. Electrostac Spray Control Panel·································································································· 6

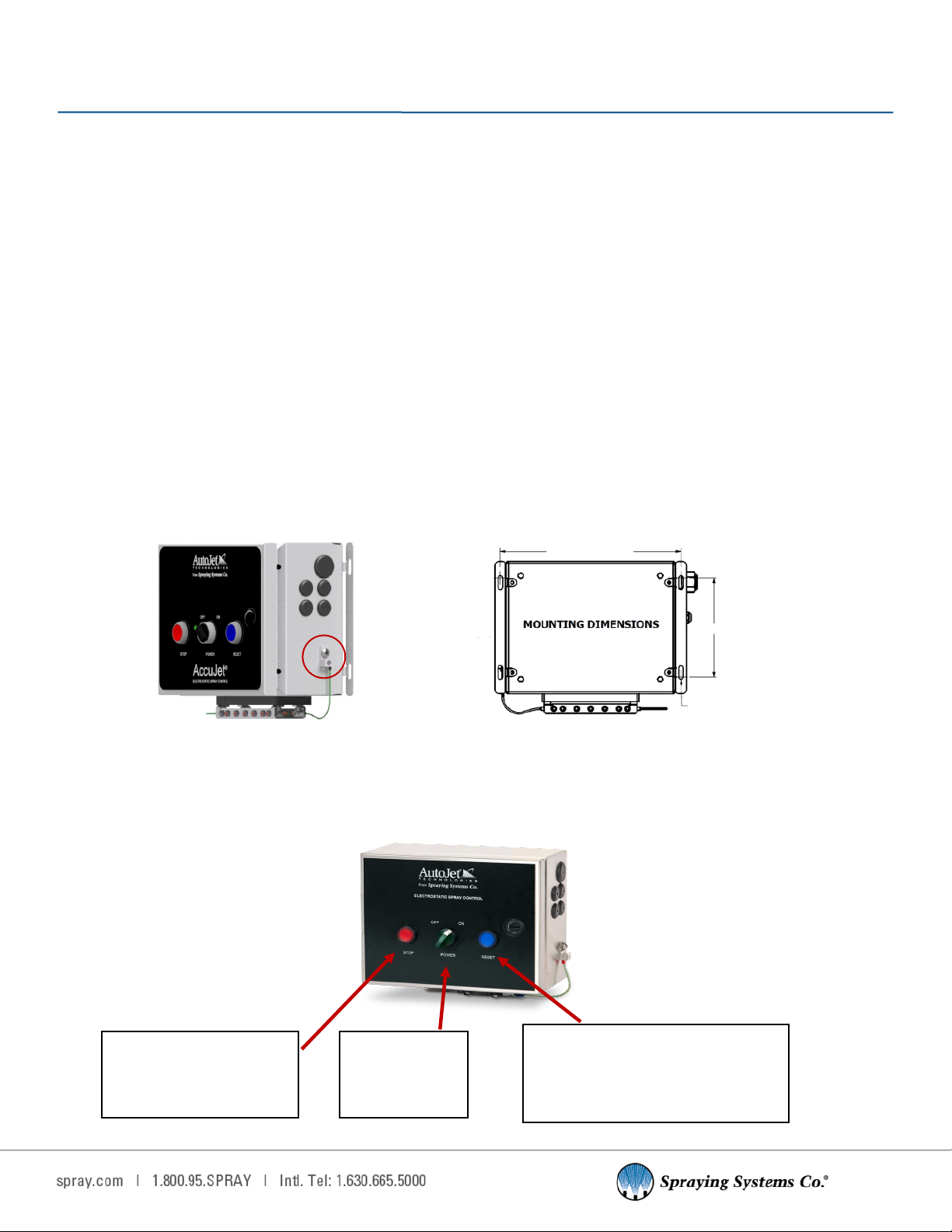

4.1 Mounng the Panel and Door Diagram ························································································· 6

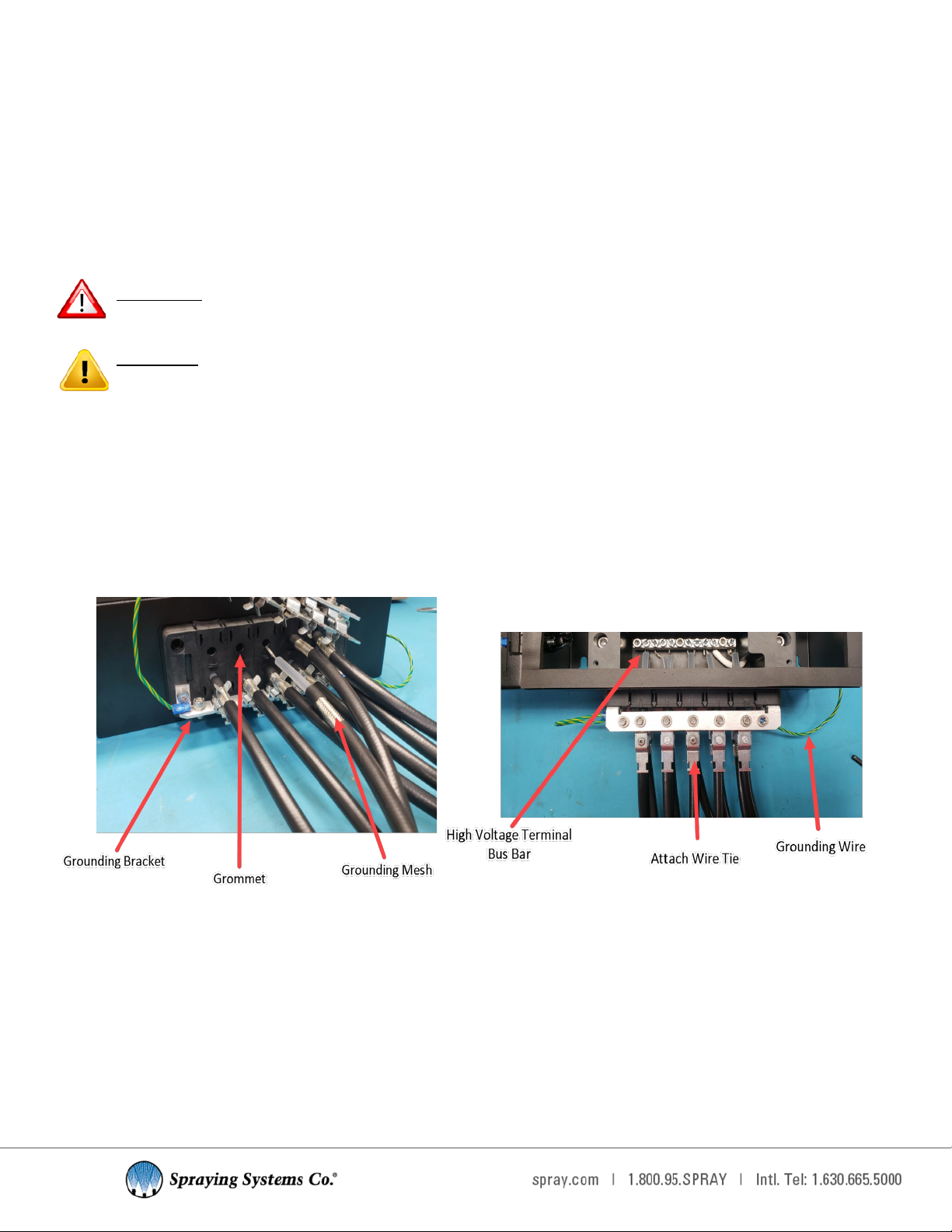

4.2 Connecng the High Voltage Cable································································································ 7

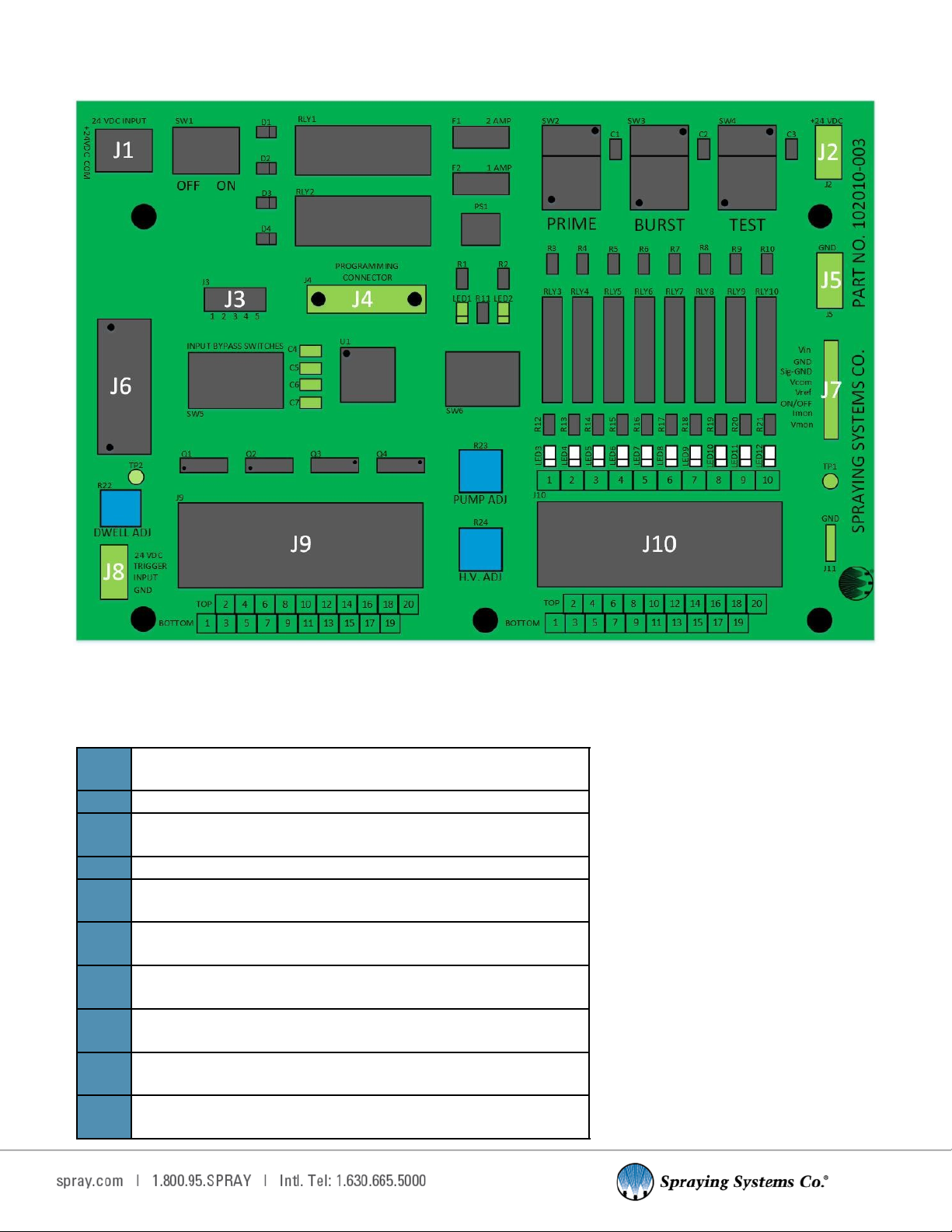

4.3 Circuit Board (PCB) and Terminal Block Diagram··········································································· 8

4.4 Input Details ································································································································· 11

4.5 Output Details ······························································································································ 13

4.6 Potenometers ···························································································································· 16

4.7 System Modes······························································································································ 16

4.8 Oponal PCB Inputs and Connecons ························································································· 18

4.9 Verifying the Spray Control Panel Set Up ···················································································· 19

5. Fluid Reservoir Assembly ··········································································································· 20

5.1 Mounng and Posioning············································································································ 20

5.2 Fluid Reservoir Connecons········································································································· 21

5.3 Lubricant Pump ···························································································································· 22

5.4 Components ································································································································· 23

5.5 Air Pressure Regulator·················································································································· 23

5.6 Parculate Filter··························································································································· 25

5.7 Verifying the Fluid Reservoir Assembly Set Up············································································ 25

6. Electrostac Chain Oiler Spray Nozzle························································································· 26

6.1 Nozzle Overview··························································································································· 26

6.2 Nozzle Connecons······················································································································ 27

6.3 Nozzle Disassembly Procedure ···································································································· 27

6.4 Nozzle Conguraon and Adjustment························································································· 28

7. Faults and Troubleshoong········································································································ 29

7.1 Faults and Fault Codes ················································································································· 29

7.2 Fault LED Status···························································································································· 30

7.3 General System Troubleshoong································································································· 32

7.4 Arc Fault Troubleshoong············································································································ 33

8. Spare and Replacement Parts····································································································· 34

TABLE OF CONTENTS