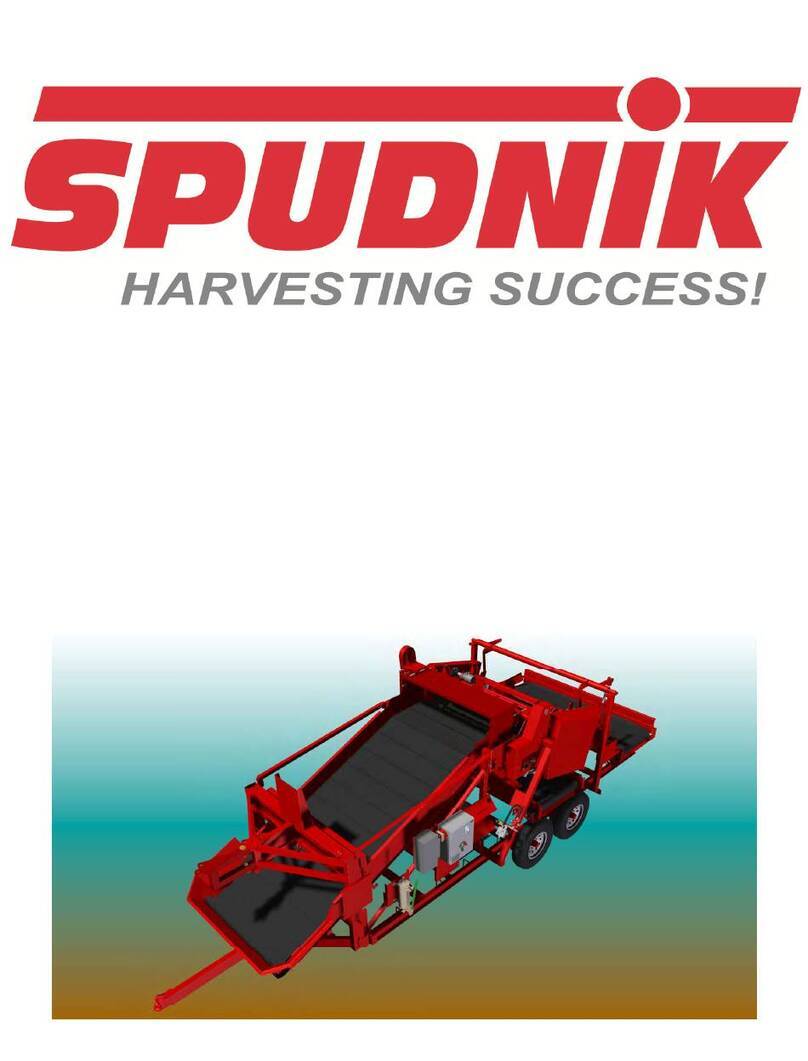

Spudnik BBL 1000 User manual

PARTS MANUAL

BBL 1000 Harvester

PART #29XXXX

SERIAL #:BBL 1000-55-25

Revision: 12/15/2021

Part #: 290360

Revision: 12/15/2021 i

Spudnik®, SimpleSep™, MultiSep™, RollerStar™, Star Table™, AirSep®, Terra Float™, are trademarks of Spudnik

Equipment Company LLC. John Deere, Case, IH, Case-IH, CAT, Challenger, are trademarks of their respective trade-

mark owners.

Copyright © 2017 by Spudnik Equipment Company LLC. All rights reserved.

Corporate Headquarters

584 West 100 North

P.O. Box 1045

Blackfoot, ID 83221

Phone: (208) 785-0480

E-Mail: [email protected]

Web Site: www.spudnik.com

BLACKFOOT, ID

584 West 100 North

Blackfoot, ID 83221

Phone (208) 785-0480

Fax (208) 785-1497

HEYBURN, ID

300 Centennial Dr.

Heyburn, ID 83336

Phone (208) 436-8052

Fax (208) 495-9170

GRAFTON, ND

1410 12th St. West

Grafton, ND 58273

Phone (701) 352-9603

Fax (701) 352-9610

PRESQUE ISLE, ME

80B Airport Drive

Presque Isle, ME

Phone (207) 764-4686

Fax (207) 764-4674

Service Centers

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

ii

Table Of Contents

Introduction ................................................................................................................................................ vi

Foreword .................................................................................................................................................... vii

Digital/Online Documents ........................................................................................................................... vii

Limited Warranty Policy for New Spudnik Machinery ................................................................................. viii

General ...................................................................................................................................................... ix

Product Characteristics .............................................................................................................................. x

1. Safety

1.1 Recognize Safety Information .................................................................................................. 1

1.2 Understanding Safety Signal Words ........................................................................................ 1

1.3 Exemption from Liability ........................................................................................................... 1

1.4 General Guidelines................................................................................................................... 1

1.5 Identification of Training Requirements .................................................................................... 2

1.6 Accident Prevention Guide & Regulations ................................................................................ 2

1.7 Risks of Ignoring Accident Prevention ...................................................................................... 3

1.8 Connecting a Tractor to the Machine ....................................................................................... 3

1.9 Connecting Machine PTO ........................................................................................................ 3

1.10 Connecting Machine Hydraulics ............................................................................................... 3

1.11 Operating Safety Practices ....................................................................................................... 3

1.12 Transporting/Towing Safety Practices ...................................................................................... 4

1.13 Electrical System and Electronics ............................................................................................ 5

1.14 Hydraulic Systems.................................................................................................................... 5

1.15 Machine Storage ...................................................................................................................... 5

1.16 Maintenance and Inspection Guidelines ................................................................................... 5

1.17 Acknowledgement Signature .................................................................................................... 7

1.17.1 Safety Acknowledgement Signature Form .................................................................... 7

2. Labels

2.5 Safety and Information Labels .................................................................................................. 8

2.6 Label Identification and Part Number ....................................................................................... 9

2.7 Installing Replacement Labels ................................................................................................. 9

2.8 Label Locations ........................................................................................................................ 9-20

3. Parts Manual

3.1 Standard Parts

Intake

FB6918 - INTAKE,BBL-1000 .................................................................................................... 22-24

134898 - AIR CONVEYOR AND BANDSAW ........................................................................... 26-34

134915 - BLOWER ASSMEBLY,BBL-1000 ............................................................................. 36

Secondary

FB6916 - SECONDARY,BBL-1000 .......................................................................................... 38

134907 - SHAKER TRAY,ASSEMBLY, BBL-1000 ................................................................... 40

134909 - TRASH AUGER ASMB, BBL-1000 ........................................................................... 41

Infeed

FB6906 - INFEED, BBL-1000 .................................................................................................. 42

Optical Sorter

FB6915 - OPTICAL SORTER,BBL-1000 ................................................................................. 43

134906 - MOUNT,TOMRA DISPLAY,BBL-1000 ...................................................................... 43

Product Spray Bar

FB6898 - PRODUCT SPRAY BAR, BBL-1000 ........................................................................ 44

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021 iii

Table Of Contents

Rear Cross

FB6888 - REAR CROSS, BBL-1000 ........................................................................................ 46

134867 - REAR CROSS, BBL-1000......................................................................................... 48

134866 - SCRAPER, BBL-1000 ............................................................................................... 49

134959 - E-STOP, REAR CROSS, BBL-1000 ......................................................................... 50

Elevator

FB6887 - ELEVATOR, BBL-1000............................................................................................. 52

134889 - LH SHIELD, SHEILDS, BBL-1000 ............................................................................ 54

Trash Conveyor

FB6889 - TRASH CONVEYOR, BBL-1000 .............................................................................. 56

134868 - TRASH CONVEYOR, BBL-1000 ............................................................................... 57

134869 - ROLL DIVIDER, BBL-1000 ....................................................................................... 58

Main Frame

FB6914 - MAINFRAME,STD PARTS,BBL-1000 ...................................................................... 60

135024 - WIREWAY,MAINFRAME,BBL-1000 ......................................................................... 62

134902 - RT SIDE PLATFORM, MAINFRAME, BBL-1000 ...................................................... 63

134901 - CAB LADDER,MAINFRAME,BBL-1000 .................................................................... 64

134905 - SHIELDS,ENGINE COMPARTMENT,BBL-1000 ...................................................... 66

134904 - TAIL LIGHT ASSEMBLY,BBL-1000 .......................................................................... 68

Axles

FB6920 - AXLE,REAR STEER, TRACKS, BBL-1000 .............................................................. 70

134916 - LF, RR, SCRAPER,TRACKS,BBL-1000 ................................................................... 72

134982 - RF, LR, SCRAPER,TRACKS,BBL-1000 ................................................................... 73

134938 - BRAKE RELEASE HEADER, BBL 1000 ................................................................... 74

134940 - GROUND DRIVE CASE DRAIN, BBL 1000 .............................................................. 75

134941 - MOTOR SHIFT HEADER, BBL 1000 ........................................................................ 76

134942 - REAR AXLE FLOW DIVIDER, BBL 1000.................................................................. 77

Shields

FB6913 - SHIELDS, BBL-1000 ................................................................................................ 78

134890 - RH SHIELD, SHEILDS, BBL-1000 ............................................................................ 80

Cab

FB6917 - CAB, BBL-1000 ........................................................................................................ 82

134913 - MOUNT,CAB CONTROLS,BBL-1000 ....................................................................... 83

134946 - STEERING VALVE ASSEMBLY,BBL 1000 .............................................................. 84

134842 - REAR AXLE FLOW DIVIDER, BBL 1000.................................................................. 85

134914 - A/C RECEIVER DRYER MOUNT,BBL-1000 ............................................................ 86

134943 - FREON COMPRESSOR ASSEMBLY, BBL 1000 ..................................................... 87

Fuel/Water Tanks

FB6912 - FUEL/WATER TANKS, BBL-1000 ............................................................................ 88

HA1253 - WATER SYSTEM, BBL-1000 ................................................................................... 90-92

134958 - WATER FILL VALVE, BBL-1000 ............................................................................... 94

134897 - WATER PUMP, BBL-1000 ........................................................................................ 95

134956 - WATER, PRESSURE FILTER, BBL-1000 ................................................................ 96

Standard Hydraulic Parts

FB6921 - STD HYD PARTS, BBL-1000 ................................................................................... 98

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

iv

Table Of Contents

Power Unit

FB6922 - POWER UNIT, BBL-1000 ......................................................................................... 100-104

134920 - COOLER ASSEMBLY 2, BBL 1000 .......................................................................... 106

134919 - COOLER ASSEMBLY 1, BBL 1000 .......................................................................... 107

134918 - CASE DRAIN MANIFOLD, BBL 1000 ....................................................................... 108

134917 - BRAKE AND MOTOR SHIFT VALVE ASSEMBLY,BBL ........................................... 109

134934 - AUXILLARY PUMP STACK ASSEMBLY, BBL 1000 ................................................ 110

134957 - AIR GOVERNOR, BBL-1000 .................................................................................... 112

134921 - DOUBLE PRESSURE FILTER ASSEMBLY,BBL 1000 ............................................ 113

134922 - GROUND DRIVE CHARGE DISTRIBUTION, BBL ................................................... 114

134932 - TRACK TENSION CHARGE ASSEMBLY, BBL 1000 ............................................... 115

134923 - HYDRAULIC RESERVOIR ASSEMBLY,BBL 1000 .................................................. 116

134924 - LS DUMP VALVE ASSEMBLY, BBL 1000 ................................................................ 117

134933 - GROUND DRIVE PUMP ASSEMBLY, BBL 1000 ..................................................... 118

134930 - SUCTION MANIFOLD ASSEMBLY, BBL 1000......................................................... 120

134929 - STEERING PRIORITY VALVE ASSEM, BBL 1000 .................................................. 121

134927 - RETURN FILTER ASSEMBLY 2, BBL 1000 ............................................................. 122

134926 - RETURN FILTER ASSEMBLY 1, BBL 1000 ............................................................. 123

134925 - REAR VALVE ASSEMBLY,BBL 1000 ....................................................................... 124-126

Standard Electrical

FB6923 - STD ELC PARTS, BBL-1000 .................................................................................... 128

Camera

FB6919 - CAMERA KIT,BBL-1000 ........................................................................................... 130

Schematics

4.1 Electrical ................................................................................................................................... 132-139

4.2 Hydraulic .................................................................................................................................. 140-285

4.3 Pneumatics .............................................................................................................................. 286-303

4.4 Water System ........................................................................................................................... 304-312

5. Miscellaneous Specifications & Reference

5.1 Fastener Torque Guidelines ..................................................................................................... 314

5.1.1 Fastener Torque Chart (SAE) ........................................................................................ 314

5.1.2 Fastener Torque Chart (Metric) ..................................................................................... 314

5.1.3 Fastener Grade/Class Marking ...................................................................................... 314

5.2 Shear Pin Guidelines ..................................................................................................... 315

5.3 Hydraulic Fittings Guidelines .................................................................................................... 315

5.3.1 Flare Connection Torque Methods ................................................................................ 315

5.3.2. Hydraulic Flare Type (JIC) Fitting Torque Chart ............................................................ 315

5.4 Belted Chain Repair ...................................................................................................... 316-319

5.5 Lubricant Specifications ........................................................................................................... 319

5.5.1 Fluids and Lubricants .................................................................................................... 319

5.5.2 Storing Lubricants .......................................................................................................... 319

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021 v

Table Of Contents

This page intentionally left blank

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

vi

Introduction

Welcome to the Spudnik line of Baby Leave Spinach harvesting equipment. We appreciate your decision to make our

equipment a part of your operation, and look forward to a long term partnership. We strive to put the best quality and

workmanship into each of our machines, and hope as you use your Spudnik Harvester that you will find this to be true.

This manual has been prepared to aid you in the safe operation and servicing of your machine.

Read this manual carefully to learn how to operate your machine safely, efficiently, and within the design limits of the

machine. Failure to operate the machine as instructed could result in personal injury and/or damage to the machine.

This manual is considered to be an important part of the machine. Keep the manual in the storage container provided so

it is always available for reference and to document the training of new operators. This manual should be transferred to

the new owner if the machine is sold.

Warranty is provided, as part of the Spudnik Equipment Company LLC service program, for customers who operate and

maintain their equipment as outlined in this manual. See page viii for the Warranty Policy.

Understanding Information Signal Words

IMPORTANT and NOTE are signal words which

accompany messages which do not involve safety issues.

The appropriate signal word for each message has been

chosen according to the following guidelines.

IMPORTANT: Indicates situations or practices that

may result in machine damage. Also provides

instruction that must be followed to ensure proper

operation or installation of the equipment.

NOTE: Emphasizes useful tips, recommendations,

and information to assist the operator and ensure

smooth and efficient operation.

Examples of the format used for informational messages

are shown below.

This is an example of a NOTE message.

NOTE

This is an example of an IMPORTANT message notice.

IMPORTANT

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021 vii

Foreword

This manual is intended to familiarize the user with the Spudnik BBL-1000 Harvester and its designated use.

This manual contains important information on how to operate the machine safely, properly, and efficiently. Observing

the instructions in this manual helps avoid dangers, reduce repair costs and down-time, and increases the reliability and

service life of the machine.

This manual includes by reference all relevant local and national rules and regulations concerning accident prevention

and environmental protection. In addition to country or regional rules and regulations, the generally recognized technical

rules for safe and proper use/operation are included by reference and must be observed. When transporting this

machine on roadways, all traffic regulations must be observed.

This manual must be available whenever the machine is in use.

This manual must be read and applied by all persons involved with the machine, such as:

Operation: including setting up, normal operation, troubleshooting during operations, and disposal of

consumables.

Maintenance: including servicing, inspection, and repair.

Transport: including loading/unloading onto transport vehicle, towing, and operational movement.

The Parts Manual is stored inside toolbox.

Machine documentation in digital form can be found online at

www.spudnik.com

Select SPECIFIC MACHINE DETAIL from the PARTS AND SERVICE dropdown menu found at

the top of the webpage.

Enter the serial number of the machine and click ‘Search’.

Scanning the given QR code will also open the website.

DIGITAL/ONLINE DOCUMENTS

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

viii

Limited Warranty Policy for New Spudnik Machinery

On the terms and conditions set forth herein, Spudnik Equipment Company LLC (“Spudnik”) warrants to the original

purchaser of each new Spudnik machine that the machine is free from defects in material and workmanship. Spudnik

will repair or replace, at its option, any part covered by this warranty that is found to be defective during the warranty

period outlined below. Warranty service must be performed by an authorized dealer or representative of Spudnik. This

warranty is applicable only for the normal service life expectancy of the product or components, as noted in the following

table. Once the warranty period has begun, it cannot be suspended, interrupted, or extended.

What is included in the Spudnik Warranty:

Those items that are excluded from this warranty are as follows:

(1) Any merchandise or components thereof, which, in the opinion of the company have been subject to: (a) Rock chip

damage and other abuse to painted surfaces, (b) Damage caused by weather (including UV damage), accident, or acts

of God, (c) Any product that has been altered or modified in ways not approved by Spudnik, (d) Depreciation or

damage caused by normal wear, lack of reasonable and proper maintenance, misuse, failure to follow the product’s

Operator Manual recommendations, (e) Using machine for other than normal moving of agricultural products during

planting, harvest, and processing seasons. Agricultural products to include: Potatoes, beets, onions, carrots, grains,

etc. (2) Used products. (3) Repairs made by unauthorized dealers.

To Obtain Warranty Service

To be eligible for the Spudnik warranty, purchaser must: (a) Have already remitted payment in full (b) When

purchased by an authorized dealer, have entered the delivery declaration into the Spudnik warranty website

tools.spudnik.com, (c) Report the product defect to an authorized dealer or Spudnik sales representative and request

repair within 30 days of noticing the defect, (d) Repair or replace failed parts immediately upon failure to prevent

additional damage (e) Make the product and/or failed parts available to the dealer or service center within 90 days

following submittal of claim, transportation/shipping charges prepaid.

The selling dealer has no authority to make any representation or promise on behalf of Spudnik, or to modify the terms

or limitations of this warranty in any way.

Limited Warranty Statement

Except as expressly stated herein, to the full extent permitted by law, Spudnik disclaims any and all warranties,

representations, and promises, express or implied, as to the quality, performance, or freedom from defect of any

Spudnik new machinery. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS IS MADE. IN NO EVENT

WILL SPUDNIK, AN AUTHORIZED SPUDNIK DEALER, OR ANY COMPANY AFFILIATED WITH SPUDNIK BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. This warranty is subject to any existing conditions of supply

which may directly affect Spudnik’s ability to obtain materials or manufacture replacement parts. Spudnik reserves the

right to make improvements in design or changes in specifications at any time, without incurring any obligation to owners

of units previously sold. No one is authorized to alter, modify or enlarge this warranty nor the exclusion, limitations, and

reservations set forth herein. This limited warranty policy supersedes and replaces all other policies pertaining to

warranty.

To obtain more information please contact your dealer, or Spudnik at 1-208-785-0480.

Product Warranty Term

Rollers, Sprockets, Roller Chain, Belt Lacing, and Bearings. 180 Days from 1st day of operation or 250 Hours of

machine operation, whichever comes first.

All paint to include: Insufficient coverage, failure of paint adher-

ence, and excessive runs. NOTE: Runs are excessive if they

exceed more than 15% of the painted surface on the machine.

12 Months from date of delivery of new Spudnik

product to the original retail customer.

All other materials and workmanship (except as noted below). 12 Months from date of delivery of new Spudnik

product to the original retail customer.

Genuine Spudnik replacement parts and components.

30 days from date of purchase, or the remainder of

the original equipment warranty period, whichever is

longer.

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021 ix

General

Designated use of the machine:

The Spudnik BBL-1000 Harvester is designed exclusively for normal agricultural operations, which is its designated use.

Using the machine for other purposes or exceeding its designated limits shall be considered contrary to the designated

use. The manufacturer shall not be liable for any damages caused as a result of such use. The user shall be solely

responsible for such risks.

Operating the machine in accordance with its designated use also includes observing the instructions specified in the

Owner/Operator manual and complying with the inspection and maintenance directives.

The machine may only be operated, serviced, and repaired by persons who are familiar with the machine and have been

informed of the possible dangers.

In order to prevent dangerous situations, the information contained in this manual must be read and observed by all

persons who operate, service, or check this machine. Particular attention should be paid to the “Safety” section. Any

instructions which are not understood must be clarified before initial operation of the machine. In such cases, please

consult your Spudnik agent or contact Spudnik directly.

Unauthorized modification and/or the use of spare parts, accessories, and auxiliary equipment not supplied and/or not

approved by Spudnik can have a detrimental effect on the structural integrity and/or functionality of the machine. Any

such modification could compromise the engineered safety controls designed to prevent accidents and/or result in

machine damage. Spudnik does not accept liability for any damage resulting from this.

Conversions of, or modifications to the machine, may only be carried out after consultation with and authorization by

Spudnik.

Technical data, dimensions, and weights, are not binding. Spudnik reserves the right to make modification in the course

of further engineering developments.

Front and rear, right and left, are always referenced in the direction of normal travel.

Direction of Travel

Left Side

Right Side

Rear

Front

Figure 2

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

x

Product Characteristics

Manufacturer’s address:

Spudnik Equipment Company LLC

584 W 100 N

PO Box 1045

Blackfoot, ID 83221

Phone: (208) 785-0480

Fax: (208) 785-1497

Web: www.spudnik.com

E-mail: [email protected]

Advice concerning inquiries and orders

Please quote the machine serial number when ordering accessories and/or spare parts.

Disposing of replaced parts

The following points should be observed before replacing or disposing of parts.

Replaced parts which still function should be cleaned and stored in an orderly manner.

Machine parts which cannot be repaired should only be disposed of at appropriate collecting points or be collected

by a scrap metal dealer.

So called “valuable” materials should be disposed of in a proper way, i.e. plastics, rubber, scrap metal, etc. should

be recycled.

Collect and dispose of used oil in accordance with local regulations.

The entire designation of the Identification Tag has the

status of a legal document and may not be removed,

changed, or rendered illegible.

IMPORTANT

Identification Tag

The machine Serial Number is stamped

into the Identification Tag located on the

mainframe.

Figure 3

The use of spare parts and/or accessories supplied by third party manufacturers and/or suppliers shall only be permitted

after consultation with a Spudnik representative. Original spare parts and accessories approved by Spudnik are a

contribution to safety and overall performance of the machine. The use of other parts may invalidate the liability of

Spudnik for any consequences arising from such use. Please refer to the ‘Warranty Policy’ and ‘General’ section of this

manual for further clarification.

NOTE

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021 1

Section-1 Safety

1.4. General Guidelines

1. This manual contains basic directions which should be

observed during setting-up, operation, and

maintenance. Therefore, this manual must be read and

understood by all applicable personnel, prior to starting

up and using the machine. The manual must be

available to operators/users at all times. Any

instructions which are not understood must be clarified

before initial operation of the machine. For clarification,

please consult your Spudnik agent or contact Spudnik

directly.

2. All safety instructions must be observed, both the

general safety instructions given here, and the specific

safety instructions given elsewhere in this manual.

3. Observe the advice contained in this manual as well as

generally applicable safety and accident prevention

regulations.

4. Always wear proper protective clothing/equipment

when operating, adjusting, or servicing the machine.

5. If safety instructions are not complied with, the

operator/user risks injury to themselves and others, as

well as damage to the environment or the machine.

Non-compliance with safety instructions can void

claims for damages.

1.3. Exemption From Liability

1. The Owner/Operator assumes all responsibility/liability

for possible dangers or injuries arising from operating

the machine in a way which does not comply with its

designed use.

2. Damage to agricultural produce which is particularly

vulnerable to damage during processing cannot be

entirely eliminated. Weather conditions, the quality of

the produce and many other factors beyond the

manufacturer’s or operator’s control have an impact on

the susceptibility to damage of the produce being

processed. For example, the fertilizing (nitrogen

content), the degree of maturity (firmness of the skin),

the temperature during processing, and many other

factors can have an effect on the vulnerability of the

produce. The examples are not intended to be

exhaustive.

3. To avoid damage to agricultural produce the user must

adapt the machine to the existing operating conditions.

The results produced by the machine must be

constantly monitored and checked.

4. Spudnik shall not be liable for any damage to

agricultural produce and other items, which occur as a

result of operating and adjustment errors or other

incorrect usage.

5. Spudnik accepts no liability for any damage caused as

a result of operators not complying with the specified

use of the machine. This includes damage of

agricultural produce which, because of uncontrollable

external influences, cannot be avoided within the

current state of the art.

1.1. Recognize Safety Information

1. This Safety Alert symbol

identifies important safety

information on the equipment

and in this manual. When you

see this symbol, be alert to the

possibility of injury or death.

ATTENTION!

YOUR SAFETY IS

INVOLVED!

1.2. Understanding Safety Signal Words

DANGER, WARNING, and CAUTION are signal words

which accompany important safety messages. The

appropriate signal word for each message has been

chosen according to the following guidelines.

DANGER: Indicates an immediate and specific

hazard, which will result in severe injury, or death, if

proper precautions are not taken. These hazards

include machine components which for functional

reasons cannot be guarded.

WARNING: Indicates a specific hazard, or unsafe

practice, which could result in severe injury or death.

This includes hazards that are exposed when guards

are removed.

CAUTION: Indicates potentially unsafe situations

or practices, which could result in minor to moderate

personal injury if proper precautions are not taken.

The following are examples of safety messages combined

with the safety signal words.

DANGER messages identify the most severe safety

hazards.

DANGER!

CAUTION messages identify unsafe situations or

practices.

CAUTION!

WARNING messages identify specific safety hazards.

WARNING!

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

2

Section-1 Safety

1.5. Identification of Training Requirements

1. Any work on or with the machine may be performed by

authorized personnel only. Statutory minimum age

limits may apply and must be observed.

2. Employ only trained and fully instructed staff. The

individual responsibilities of the personnel for

operation, set-up, maintenance, and repair, must be

clearly established.

3. Define the machine operator’s responsibilities with

regard to observing traffic regulations. The operator

must have the authority to refuse any instruction

issued by third parties which contradicts safety

responsibilities.

4. Persons requiring specialized training, instruction, or

certification, and those in an apprenticeship or general

training course, should not be allowed to work on or

with the machine unless they are under the constant

supervision of an experienced/certified person.

5. Work on the machine’s electrical system may only be

carried out by a qualified electrician, or by persons

working under the supervision and guidance of a

qualified electrician. All such work must be carried out

in accordance with electrical standards/regulations

applicable in the jurisdiction where the machine is

being operated.

6. Work on the wheels, braking, and steering systems

may only be performed by specially trained personnel.

7. Work on the hydraulic system may only be carried out

by personnel with specialized knowledge and

experience in hydraulics.

8. Structural frame repairs may only be performed by

qualified personnel, after consultation with and written

approval by Spudnik engineers.

3. The primary responsibility for safe operation of the

machine lies with the owner/operator.

4. Before starting work, the operator must familiarize

themselves with the equipment, including all controls,

and their functions. Learning the equipment after start-

ing work is too late.

5. The operator must ensure they have adequate all-

around visibility at all times.

6. Check on and around the machine to ensure all per-

sonnel/bystanders are clear of danger areas before

moving or starting the equipment.

7. The operator and other personnel should wear close-

fitting clothing and restrain long hair. Avoid loose or

dangling jewelry, and loose-fitting or tattered clothing

that could become entangled in moving parts.

8. Remove metal rings, bracelets, watches, and other

jewelry before working on or around electrical circuits.

9. Always match operational speed to the current condi-

tions. Avoid sudden turning maneuvers when driving

uphill or downhill or when traveling across a slope.

10. Take into account the wide overhang and/or the side-

ways force acting on the machine when turning or ne-

gotiating curves.

11. Only operate the machine when all guards are at-

tached and in their correct protective position.

12. Stay clear of all rotating, turning, and pivoting areas of

the machine.

13. Keep hands, feet, long hair, and clothing away from

moving and/or rotating parts.

14. Do not attempt to service, lubricate, clean, or adjust

the machine while it is running.

15. Inspect all mechanisms before starting the machine.

Replace all worn or damaged parts.

16. Replace all worn or missing bolts with SAE Grade 5 or

greater, unless specifically directed otherwise.

17. Keep the machine clean to avoid the risk of fire.

18. Observe applicable regulations when using public

roads.

19. Use a spotter when backing the equipment, especially

when the operator’s view is obstructed. To avoid

crushing risks, ensure the spotter stands clear of the

machine and its path of travel.

20. Always dispose of used chemicals in accordance with

local and national regulations.

1.6. Accident Prevention Guide & Regulations (Cont.)

1. Warning signs and other notices on the machine pro-

vide important information for safe operation and

maintenance. Observe and follow all safety notices to

ensure personnel safety.

2. The Occupational Safety and Health Administration

(OSHA) requires that all operators be trained by the

employer in the safe operation of the machine, at the

time of initial assignment, and annually thereafter.

Document training compliance on the Safety Acknowl-

edgment Signature Form located at the end of the

Safety section.

1.6. Accident Prevention Guide & Regulations

This manual provides safety advice and information

necessary to safely operate and maintain this Spudnik

machine. In addition, users are encouraged to follow

applicable national accident prevention regulations,

employer mandated safety practices, and operator

directions.

IMPORTANT

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021 3

Section-1 Safety

1.8. Connecting a Tractor to the Machine

1. When backing the tractor or towing vehicle up to the

Hitch on the machine, make sure no personnel are

between the tractor and equipment where they could

be crushed.

2. Lock the tractor or towing vehicle in position before

allowing personnel to insert the draw pin. Use the

parking brake or chocks to prevent vehicle movement.

3. Never allow persons to stand between the tractor and

the machine unless the tractor is secured against

rolling. Immobilize the tractor using the parking brake

and/or wheel chocks.

4. Attach the machine according to the instructions in the

tractor Owner/Operator and Spudnik equipment

Owner/Operator manuals.

5. Use only specified connecting components, rated to

withstand the draw weight and forces experienced

while operating the machine.

6. Never exceed the permissible nose weight of the

machine coupling.

7. Never exceed the permissible axle load and total

weight of the tractor. (See the tractor Owner/Operator

manual for the specifications.)

8. Use proper safety practices when operating the

support foot/Jack. The support foot/Jack presents a

serious risk of injury through crushing and/or shearing.

1.9. Connecting Machine PTO

1. Follow the operating instruction of the PTO shaft

manufacturer. An operator’s manual is supplied with

every PTO shaft installed on Spudnik equipment.

2. Only use the PTO shafts specified by the

manufacturer.

3. The PTO shaft housing and guard cone, as well as

PTO shaft guard, must be fitted and in safe operational

condition.

1.9. Connecting Machine PTO (Cont.)

4. For PTO shafts, make sure the tube overlaps by the

manufacturer specified amount, in both transport and

working positions.

5. Only attach and remove the PTO shaft when it is

disengaged, with the engine switched off and the

ignition key removed.

6. When using PTO shafts with overload or freewheel

couplings which are not covered by the guard on the

towing vehicle, fit the overload or freewheel coupling

on the machine side.

7. When connecting the machine PTO driveline to the

PTO spline on the tractor, always make sure the PTO

is correctly mounted and locked securely to prevent

unintended separation.

8. Attach the PTO shaft guard chain to prevent the shaft

guard from turning.

9. Before engaging the PTO shaft, ensure the selected

speed and direction of rotation of the tractor’s PTO

shaft agree with the permissible speed and direction of

rotation of the machine.

10. Before engaging the PTO shaft, make sure that no

persons are within the danger areas of the machine.

1.11. Operating Safety Practices

1. Unless specifically designed to carry the load while

moving, always empty machinery of product before

moving or transporting. This reduces weight, making

the machine easier to move, and lessening the chance

of damage to the equipment.

2. Use caution when setting up or operating the

machinery on uneven terrain, hillsides, or near ditches

to avoid the potential of overturning the equipment.

1.7. Risks of Ignoring Accident Prevention

1. Endangerment of the operator and/or other nearby

persons as a result of safety shields/devices not being

fitted or in their correct protective position.

2. Damage to important machine functions.

3. Errors when carrying out maintenance or repair work.

4. Endangerment of the operator and/or other nearby

persons through chemical exposure.

5. Endangerment of the operator and/or other nearby

persons through exposure to high speed projectiles.

6. Environmental pollution due to leaks in the hydraulic

system and gearboxes.

1.10. Connecting Machine Hydraulics

1. The hydraulic system operates under high pressure.

2. Depressurize the hydraulic system, on both the tractor

and machine, before making or breaking connections.

3. Connect the hydraulic lines to the tractor as specified

in the Owner/Operator manual. Ensure the tractor can

provide the required flow rate and pressure to operate

the implement.

4. Keep hydraulic lines clear of moving parts which could

damage the hoses.

Hydraulic oil escaping under high pressure can

penetrate the skin and cause serious injuries. If such

an injury occurs, immediately call a doctor who is

familiar with treating this type of injection injury. The

risk of infection from such injuries is high.

WARNING!

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

4

Section-1 Safety

1.11. Operating Safety Practices (Cont.)

3. Keep safety decals, signs, and reflectors clean and

legible at all times.

4. Replace safety decals, reflectors and signs that are

missing or have become illegible.

5. When replacing a part that displays a safety decal,

reflector, and/or sign, make sure that the new part also

displays those items.

6. Safety decals, reflectors, or signs are available from

your dealer parts department.

7. Do not allow personnel on the equipment during

operation, except in areas specifically designed for

occupation.

8. The design and function of intake and discharge

mechanisms, e.g. belted chains, tables, blowers, Vine

Chains, chutes, and conveyors, mean they cannot be

fully protected. Therefore, keep a safe distance from

such moving parts when in operation. This advice

applies to all other similar systems and auxiliary

equipment.

9. Always keep clear of discharge areas of the

equipment, especially those with the risk of high speed

projectiles.

10. Before carrying out cleaning, maintenance, or repair

work, always switch off the engine/power, remove the

ignition key or otherwise lock out the power source,

and make certain the equipment has come to a

complete stop.

11. Unless troubleshooting requires exposure of shielded

components, only start up the machine when all safety

devices are attached and in the correct protective

position. The equipment should never be put into

operation if any safety devices have been opened or

removed. This includes shields, covers, flaps, and all

other engineered protective devices on the machine.

12. Dangerous components are located behind safety

covers. Moving parts do not necessarily come to a

standstill as soon as the drive is switched off. Keep

well clear of moving parts and keep protective shields

in place until all moving parts have come to a

complete standstill.

13. Never open safety devices such as covers, flaps, etc.

while the machine is in operation.

14. Never reach under or behind safety shields and

devices.

15. Keep clear of pinch points on opening/hinged covers

and guards.

1.12. Transporting/Towing Safety Practices

1. Use proper safety practices when hitching or

unhitching the machine to/from the tractor or towing

vehicle.

2. Never allow personnel to stand in front of, between, or

behind the tractor and machine unless the equipment

is secured against rolling. Secure the tractor and

machine using the parking brake and/or wheel chocks.

3. Never exceed the permissible nose weight of the

machine coupling.

4. Never exceed the permissible axle loads and total

weight of the tractor/towing vehicle. (See the tractor

Owner/Operator manual for the specifications.)

5. Before transport, secure all moving parts on the

machine using the retainers provided.

6. Only transport the machine when all safety devices are

attached and in the correct protective position.

7. Make sure the wheels are centered/locked into

position to ensure the machine will track straight

behind the towing vehicle.

8. Never allow personnel to ride on the machine during

transport.

9. Check the driving, steering, and braking response of

the tractor/towing vehicle and towed equipment before

entering public roads.

10. Maximum towing speed is 20 MPH (32 KPH).

11. The Slow Moving Vehicle sign (SMV), along with any

other lights and reflectors required by the local

highway and transport authorities, must be in place.

12. Lights and reflectors must be clean and visible to

overtaking and oncoming traffic.

13. Avoid excess speed to keep the towing vehicle and the

towed machine/equipment under control when going

down long and/or steep grades.

14. Before dismounting the tractor/towing vehicle, switch

off the engine, remove the ignition key, and secure the

towing vehicle and machine against rolling/unexpected

movement. Use the parking brake and/or wheel

chocks as necessary to prevent movement.

Exceeding the maximum towing speed could result in

catastrophic failure of the farm rated tires and wheels.

CAUTION!

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021 5

Section-1 Safety

1.15. Machine Storage

1. Thoroughly clean the machine before placing it in

storage.

2. Lubricate moving parts and protect bare metal before

placing the machine in storage.

3. Store the machine in a dry, level, protected area.

4. Store the machine away from human activity.

5. Do not permit children to play on or around the stored

machine.

1.13. Electrical System and Electronics

1. Remove conductive jewelry, e.g. metal rings,

bracelets, watches, etc., before working on or around

electrical circuits.

2. Use only original fuses with the specified current

rating. Switch off the machine immediately if a fault

occurs in the electrical power supply.

3. Always disconnect the wiring harness between the

machine and the tractor before servicing the electrical

system or welding on the machine.

4. Work on the electrical system or equipment may only

be carried out by a qualified electrician, or by specially

instructed personnel under the control and supervision

of a qualified electrician, and in accordance with the

applicable electrical standards/regulations.

5. The machine’s electrical equipment is to be inspected

and tested at intervals specified in this manual.

Defects such as loose connections or scorched cables

must be rectified immediately.

6. The machine is fitted with electronic components and

modules, the function of which may be influenced by

the electromagnetic fields of other equipment. Such

interference can lead to potentially dangerous

situations if the following safety advice is not observed.

7. If electrical or electronic devices and/or components

are retrofitted to the machine then it is the

responsibility of the user to check whether such

installations interfere with the vehicle's electronics or

other components.

This applies particularly to:

Mobile telephones

Radio equipment

8. The following conditions must be satisfied if mobile

communication systems (e.g. radio, telephone) are to be

installed after the original delivery of the machine.

Only approved devices complying with the relevant

national regulations may be installed.

The device(s) must be installed permanently.

The mobile device(s) in the tractor or on the machine

must be connected to a permanent external aerial.

A properly installed aerial must maintain a good ground

connection between the aerial and vehicle chassis.

The transmitter assembly must be isolated from the

vehicle electronics.

9. Use only the specified wiring/conductor gauge for

electrical systems on the machine.

10. Do not exceed the maximum specified current

consumption for any electrical system.

1. Always observe the relevant safety measures and in-

structions specified in the Owner/Operator manual

when carrying out the operation, maintenance, inspec-

tion, repair, adaptation, or conversion of the machine.

2. Keep all operational and maintenance areas clean and

dry. Clear dirt, snow, ice or any other debris that could

pose a hazard, from handles, steps, handrails, plat-

forms, landings and ladders.

1.16. Maintenance and Inspection Guidelines

To prevent accidents, all relevant rules and

regulations concerning safe and competent working

must be observed.

IMPORTANT

1.14. Hydraulic Systems

1. Lower the machine, depressurize the system, switch

off the engine and remove the key before working on

the hydraulic system.

2. Use caution when working on the hydraulic system.

Hot hydraulic oil can cause serious burns. Allow the

hydraulic system to cool before starting work, and

wear gloves. Collect and dispose of used oil in

accordance with local/national regulations.

3. Hydraulic hoses should be inspected at intervals

specified in this manual, and replaced if damaged or

worn. New hoses must comply with the technical

specification of the machine manufacturer. Hoses and

hose couplings undergo a natural aging process, even

if stored and used correctly; therefore, their period of

storage and use is limited. The service life of a hose

may deviate from manufacturer estimates. Considering

the potential danger from hydraulic hose failure,

replacement decisions should err on the side of

caution.

WARNING!

The hydraulic system operates under high pressure.

Depressurize the system before working on any

component in the system.

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

6

Section-1 Safety

To avoid the risk of accidents, cover sharp edges,

corners, and dangerous projections on suspended

loads. Attach a warning sign or caution tape.

Never work or stand under suspended loads.

11. A signaler giving instructions must be within sight of

the crane operator and must be provided with a radio

or comparable verbal link.

12. Use blocks or safety stands to support the machine

when working around or under areas that pose a fall-

ing/crushing hazard.

13. For overhead assembly work, use suitable ladders

and/or platforms. Never climb on the machine itself.

Wear a safety harness when carrying out maintenance

work at heights of 6 feet or greater.

14. Clean the machine, especially connections and thread-

ed unions of any traces of oil, fuel or preservatives

before carrying out maintenance/repairs. Never use

aggressive detergents. Use lint-free cleaning cloths.

15. Before cleaning the machine with water, steam, high-

pressure washer, or cleaning agents, protect all sensi-

tive components against ingress of water, steam, or

chemical agents. Take appropriate protective precau-

tions with electric motors, switching cabinets, circuit

cards, and other sensitive electronic components. After

cleaning, completely remove any materials used to

protect components.

16. After cleaning, examine all fuel, lubricant, and hydrau-

lic oil lines, for leaks, loose connections, scuffing, or

other damage. Correct any defects immediately.

17. Reinstall and/or tighten any screw connections that

have been loosened or removed during maintenance

and repairs.

18. After completing any adjustment, maintenance, or re-

pair work, reinstall and test all safety devices, shields

and guards, before returning the machine to operation.

19. Ensure that consumables, lubricants, and replaced

parts, are disposed of safely and with proper environ-

mental consideration.

1.16. Maintenance and Inspection Guidelines (Cont.)

3. Perform adjustment, maintenance, and inspection ac-

tivities according to the directions and schedule speci-

fied in this manual. These tasks must be performed by

trained personnel.

4. Alert operating personnel before undertaking any

maintenance work. Appoint a person who is responsi-

ble for overseeing the maintenance work and coordi-

nating with the operating personnel while the equip-

ment is out of operation.

5. Locate the machine on a flat, stable area before per-

forming lubrication, adjustments, repairs, or other

maintenance work. Chock and brace the machine as

necessary to prevent movement or shifting.

6. Secure the maintenance area before starting work. All

bystanders, especially children, should be moved to a

safe distance.

7. Prepare the machine for safe performance of the

maintenance work.

Place all controls in a neutral or off position.

Isolate the machine from its power source.

In the case of tractors and engine-driven ma-

chines, switch off the engine, remove the ignition

key, and as appropriate lock or otherwise secure

the control station. Attach a warning sign if neces-

sary.

In the case of electrically driven machines, discon-

nect the power cable. As appropriate lock or oth-

erwise secure the control station. Attach a warning

sign if necessary.

In the case of hydraulically driven machines, dis-

connect the hydraulic supply lines. As appropriate

lock or otherwise secure the control station. Attach

a warning sign if necessary.

8. Use the correct tool(s) for the job. Tools should be

inspected regularly and immediately removed from

service if worn or damaged.

9. When replacing large parts and subassemblies, over-

head lifting may be required.

10. Entrust the securing and hoisting of loads to certified

crane operators only.

Inspect all hoisting and lifting gear before each

use. Confirm lifting gear is structurally sound, is in

proper working condition, and has adequate load

capacity for the intended lift.

1.16. Maintenance and Inspection Guidelines (Cont.)

To prevent inadvertent activation of systems or

components, do not allow access to machine controls

while maintenance is being performed.

WARNING!

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021 7

Section-1 Safety

Safety Acknowledgment Signature Form

Machine Serial Number:__________-_____-__________

Date Employee Signature Employer Signature

Section-1 Safety

Anyone who will operate and/or maintain the equipment must read and clearly understand ALL Safety, Operating and

Maintenance information presented in this manual. Do not operate or allow anyone else to operate this equipment until such

information has been reviewed. It is recommended that this information be reviewed annually before season start-up.

Make these periodic reviews of SAFETY and OPERATION a standard practice for all equipment. An untrained operator does

not qualify to operate and/or maintain this machine.

This signature sheet is provided for record keeping to show that all personnel who will work with the equipment have read

and understood the information in this manual and have been instructed in the operation of the equipment.

1.17. Acknowledgement Signature

1.17.1. Safety Acknowledgement Signature Form

Par ts Ma nual BBL 1000 Har veste r

Part #: 29XXXX

Revision: 12/15/2021

8

Section-2 Safety and Information Labels

2.5. Safety and Information Labels

Labels are placed on the machine to communicate

important user safety and operational information. To

ensure continued personnel safety and proper machine

operation, replace any label which is damaged or becomes

illegible.

Item#:6 Part#:300097

Item#:2 Part#:300092

Item#:9 Part#:300089

Item#:1 Part#:300091

Item#:8 Part#:300086

Item#:3 Part#:300087

Item#:12 Part#:300466

Item#:16 Part#:300401

Item#:17 Part#:300402

Item#:15 Part#:300400

Item#:4 Part#:300088 Item#:5 Part#:300090

Item#:10 Part#:300093

Item#:14 Part#:300213

Item#:11 Part#:300922

Item#:19 Part#:300055

Item#:22 Part#:300166

Item#:23 Part#:300168

Item#:18 Part#:300106

Item#:20 Part#:300250

Item#:21Part#:300251

Item#:7 Part#:300096

Item#:13 Part#:300601

Item#:25 Part#:300166

Item#:24 Part#:300166

Table of contents

Other Spudnik Farm Equipment manuals

Spudnik

Spudnik 930 User manual

Spudnik

Spudnik 6160 WINDROWERS User manual

Spudnik

Spudnik 5140 Owner's manual

Spudnik

Spudnik 995 Owner's manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 9706 User manual

Spudnik

Spudnik 6740 User manual

Spudnik

Spudnik 2400 Programming manual

Spudnik

Spudnik 1110 User manual

Spudnik

Spudnik 1255 Owner's manual

Spudnik

Spudnik 1860 User manual

Spudnik

Spudnik 2230 Owner's manual

Spudnik

Spudnik 780 User manual

Spudnik

Spudnik AIRSEP 992 Owner's manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik AIRSEP 992 User manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 2350 User manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 560 Owner's manual