9

•move forward, lift and lower the roller slowly and smoothly without sudden jerks,

making sure that nobody stays in the vicinity,

•obey traffic rules while travelling on public roads and attach transport equipment such

as lights as well as reflective and warning devices,

•do not stand on the machine or apply additional loads during operation and transport,

•while making U-turns, pay due caution if anyone is in the vicinity,

•any repairs, lubrication or cleaning of working components may be performed as long

as the engine is not running and the unit is lowered and unfolded,

•while taking a break, lower the machine onto the ground and stop the tractor engine,

store the machine properly so that no person or animal can be injured.

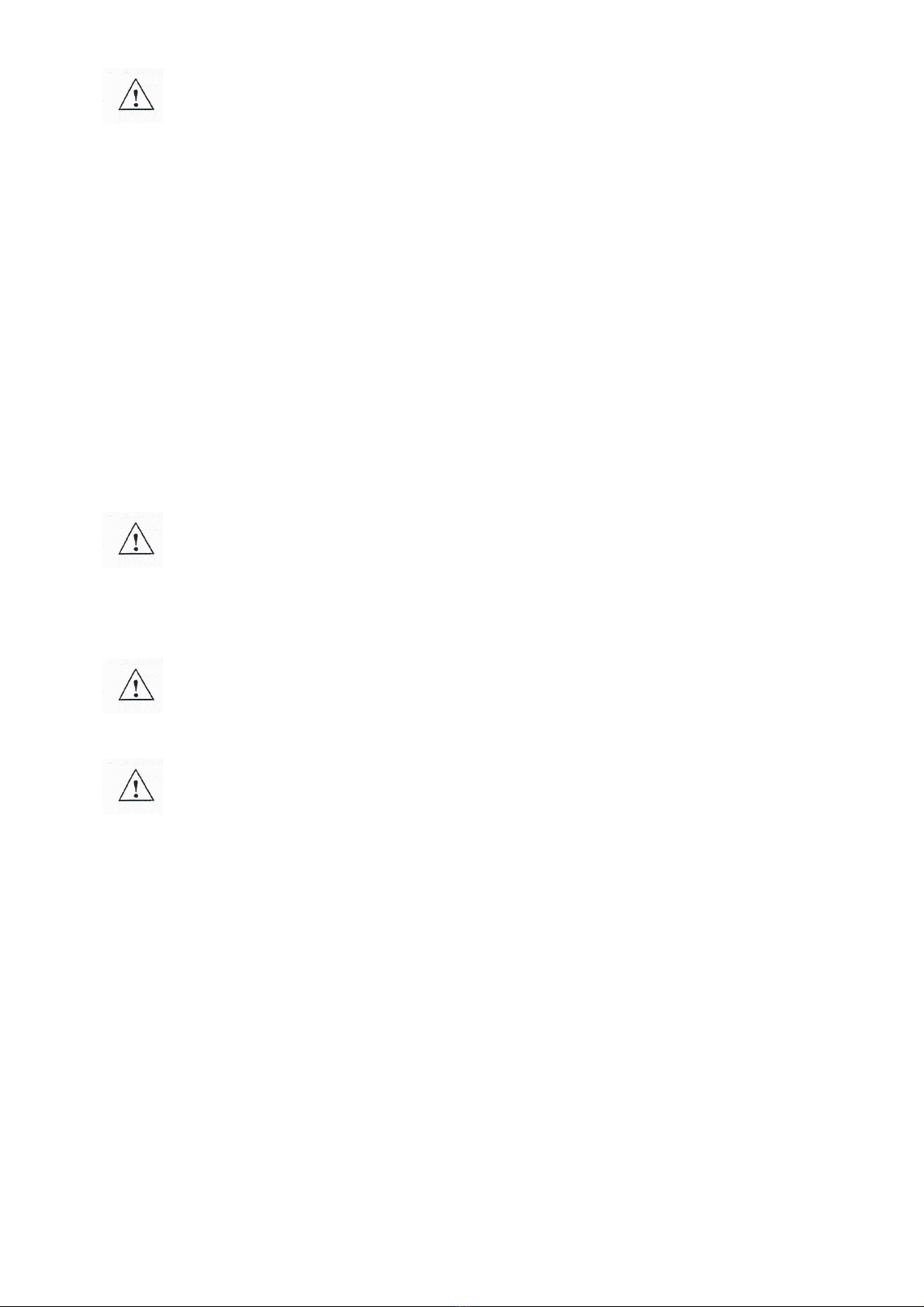

3.1. Attaching the tractor

•Attaching the machine to the tractor must be carried out in accordance with the

guidelines, bearing in mind the need to secure the suspension using bolts.

•While attaching the tractor to the roller, it is forbidden for any person to stay between

the machine and the tractor.

•The tractor used together with the roller must be fully operable. It is forbidden to attach

the roller to any tractor with a malfunctioning hydraulic system.

•Make sure that the tractor with the attached unit is stable, and the tractor steerability

and stopping power can be maintained. The load on the front axle cannot decrease to

less than 20% of the total load on the tractor axle –use a set of front-mounted

weights.

•When in resting position and disconnected from the tractor, the machine must be

stable all the time.

•The supporting foot must rest on a stable ground. It is forbidden to use any pads

under the foot as it may result in support instability.

3.2. Hydraulic system

The hydraulic system operates under high pressure. Apply all precautionary

measures, in particular:

•do not connect and disconnect hydraulic hoses when the tractor hydraulic system is

pressurised (hydraulics set to neutral),

•check regularly the conditions of connections and hydraulic hoses,

•while repairing a hydraulic or pneumatic malfunction, withdraw the machine from

service.

3.3. Transport on public roads

For the period of transport, the side sections of the roller MWC/MWW must be put in

transport position using the hydraulic system. Before folding, the machine must be lifted

sufficiently high until the folded side sections do not collide with the ground.

The roller must be protected against unfolding by means of the mechanical lock.

While in transport, the clearance under the machine must be at least 30 cm.

While transporting the unit on public roads, it is absolutely mandatory to use lights, an

identification sign and reflective side lights in case it is attached to the rear three-point