SPW VARIPROFILE VP-64 User manual

made by

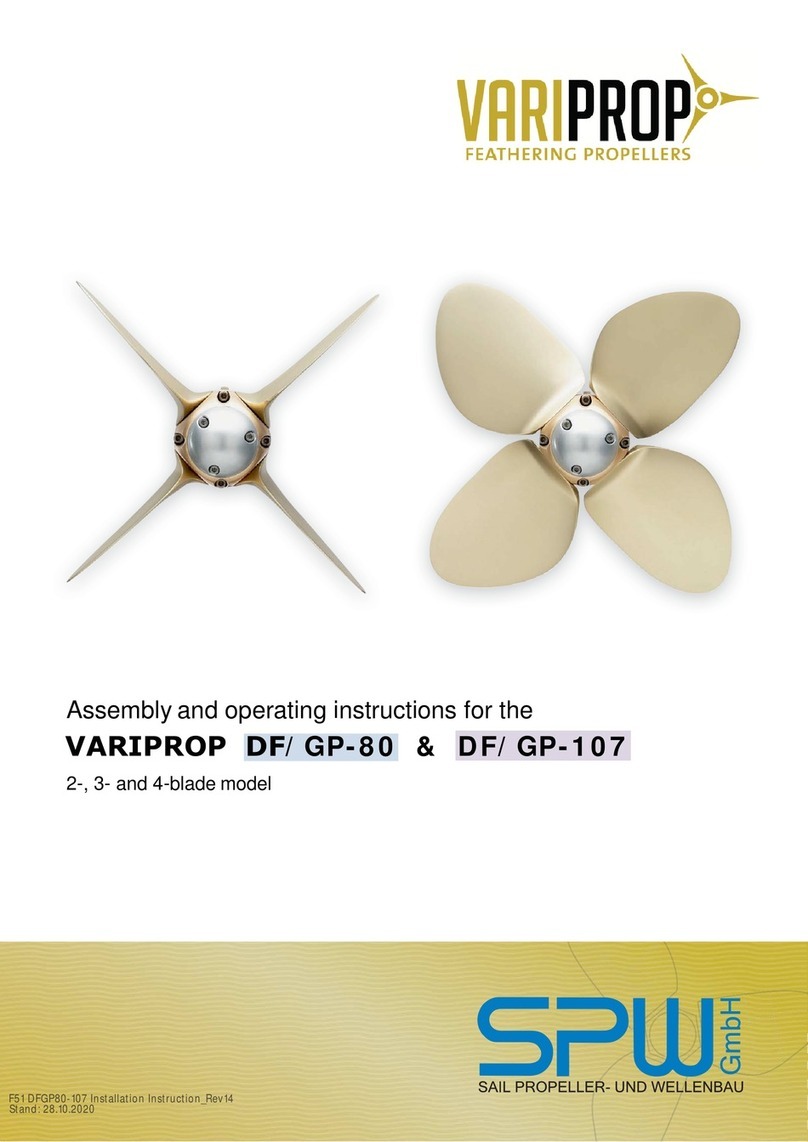

Manual for the

Feathering Propeller VP-64 and VP-76

2- and 3-blade model

Feathering Propeller

®

Feathering Propeller

®

Formular-Nr. 125 Rev.-Nr.:02 10/20

Installation on a saildrive...........................................................................................Seite 3

Installation on a shaft................................................................................................Seite 4

Pitch Adjustment .......................................................................................................Seite 5

Pitch adjustment table...............................................................................................Seite 9

Operation & Servicing.................................................................................................Seite 7

Removal instructions.................................................................................................Seite 8

Torque settings for the prop-nut ...............................................................................Seite 8

Installation on a saildrive

Formular-Nr.:51 Rev.-Nr.:09 08/07

2 3

»See that the spacer supplied with your saildrive is mounted.

»Make sure your anode has good contact with the saildrive.

»Mount the hub (1) on the splined shaft (2) and apply a

small drop of loctite “low” to the thread of the nut (3).

Tighten the nut (3) while countering the hub with the hook

wrench (7). (See the torque specication for nut (3) in

the installation instruction of your saildrive)

After installation, check that the hub does not move axial

on the saildrive shaft. If so, t one or more of the different

spacer disc (8) between the forward end of the prop and

the saildrive disc to reduce it. The spacer discs are deliv-

ered with the prop.

»Apply a small drop of loctite “low” to the thread of the

set-screw (4) and tighten (17 Nm / 15 Ft.lb) to secure the

prop nut (3).

»Now screw the blade assembly (5) clockwise onto the

large thread of hub (1) until you t the prop strongly onto

the hub (1). Do not use Loctite on the thread of the blade

assembly (5)!

»Take care that the set screws (6) are plane with housing

while set the 6off screws tighten.

»Apply a small drop of loctite “medium” to each thread

of the 6 off set screws (6) and tighten (20 Nm / 15 Ft.lb)

together with washer (7).

»Make sure that the set screw holes for set screw (6)

are aligned with the borings of the hub.

»Check the function and see that the blade movement

is free.

1. Hub

2. haft

3. Nut (SW24)

4. Set-Screw M8x20

5. Blade assembly

6. Set-Screw M8x16 and

washer dia. 8 (7)

7. Hook Wrench 45-50

8. Spacer-Disc

1off -0,5 & 2off - 0,25mm

(Only use if needed)

WARNING:

Engage forward/reverse at idling RPM`s only. Stop the engine immediately if any strange sounds or vibrations

are noticed coming from the propeller. Check that the propeller works in both forward and reverse before starting

each voyage. Do not start the the engine until the boat is in the water. Keep away from moving parts while handling

the propeller, the blades are like knives, and can cause considerable damage. Do not attempt to come close to the

propeller unless the engine is stopped.

1

3

7

7

4

5

6

2

8

Slightly paint the thread of the propeller hub (1) with the

enclosed TIKAL Tef gel to enable a later easy disassembly

»

Pitch Adjustment

A. Adjusting the forward pitch:

1. Remove the set screw (1) (3 mm allen key).

Under water: only 2 turns loosen.

2. Turn the adjusting screw (2) which is marked as

“AH” or “V” with the 4 mm Allen-key as follows:

2a. Increasing of pitch:

»Turn the adjusting screw (2) clockwise.

(see “NOTE” and page 8)

»Secure set screw (1) with LOCTITE low (pink)

Lock set screw (1) 3 Nm / 2 Ft.lb.

2b. Reducing of pitch:

»Turn the adjusting screw (2) anti-clockwise.

(see “NOTE” and page 8)

»Secure set screw (1) with LOCTITE low (pink)

Lock set screw (1) 3 Nm / 2 Ft.lb.

B. Adjusting the reverse pitch:

1. Remove the set screw (3) (3 mm allen key).

Under water: only 2 turns loosen.

2. Turn the adjusting screw (4) which is marked as

“AS” or “R” with the 4 mm Allen-key as follows:

2a. Increasing of pitch:

»Turn the adjusting screw (4) anti-clockwise.

(see “NOTE” and page 8)

»Secure set screw (3) with LOCTITE low (pink)

Lock set screw (1) 3 Nm / 2 Ft.lb.

2b. Reducing of pitch:

»Turn the adjusting screw (4) clockwise.

(see “NOTE” and page 8)

»Secure set screw (3) with LOCTITE low (pink).

Lock set screw (1) 3 Nm / 2 Ft.lb.

It is quite possible to set the pitch con-

tinuously variable and independently for

forward and reverse. The turning of the

adjusting screws (2) & (4) in Figure “Exam-

ple” by half a revolution changes the pitch

approx. 1“. That means a quarter turn (90°)

changes the pitch by ½” and a one full turn

by 2” etc. For a check of pitch adjustments

there are markings on the hub rotating

ange. To return to original factory pitch

settings, line up “V” resp. “R” markings on

the hub face. (see example beside)

Marked lettering of a LH Propeller

++

--

Formular-Nr.:51 Rev.-Nr.:09 08/07

4 5

Installation on a Shaft

»mount the hub (1) on the shaft (2). Make sure the prop

taper and keyway mate properly with shaft and key and

the top of the key does not touch the hub! File key if

necessary.

»Fit the counter screw (9) into the thread for the setscrew.

Pay attention not to set the prop nut with the counter

screw!

»apply a small drop of loctite “medium” to the threads of

the nut (3) and tighten strongly 80 Nm / 60 Ft.lb), while

blocking the hub with one hand against the counter

screw.

»after tightening the prop nut (3) remove the counter screw

(9)

»apply a small drop of loctite to the thread of the setscrew

(4) and tighten (20 Nm / 15 Ft.lb.).

»align the blade assembly (5) with the boring and pivot

pins and push onto the hub (1).

»mount the socket screws (7) with washers (6) and tight-

en (50 Nm / 37 Ft.lb). use loctite “medium” to secure the

socket-screws (7).

»apply a small drop of loctite “low” to the threads of the

set screws (8) and tighten (10 Nm / 7 Ft.lb)

»check the function and see that the blade movement is

free.

»make sure you have a shaft anode with good contact to

the shaft.

WARNING:

Engage forward/reverse at idling RPM`s only. Stop the engine immediately if any strange sounds or vibrations are

noticed coming from the propeller. Check that the propeller works in both forward and reverse before starting each

voyage. Do not start the the engine until the boat is in the water. Keep away from moving parts while handling the pro-

peller, the blades are like knives, and can cause considerable damage. Do not attempt to come close to the propeller

unless the engine is stopped.

1

1

3

3

7

4

5

6

9

2

8

1. Hub

2. Shaft

3. Nut SW24 (VP-64)

or SW30 (VP-76)

4. Set-Screw M8x12 (VP-64)

or M8x16 (VP-76)

5. Blade assembly

6. Washer ø10

7. Socket Screws M8x25 (VP-64)

or M10x30 (VP-76)

8. Set-Screw M6x10 (VP-64)

or M8x12 (VP-76)

9. Counter Screw M8x120

In general the pitch settings are done in the factory and are

ready set for your boat and engine. Should it be necessary

to adjust the pitch it is very simple on the VARIPROFILE,

and can be done in or out of the water in a matter of few

minutes.

Possible reasons for pitch adjusting might be:

»If the engine does not reach the desired RPM

reduce the forward pitch.

»If the engine exceeds the desired RPM

increase the forward pitch.

»If the prop walk in astern is too strong

reduce reverse pitch.

Possible adjustment range see pitch sheet at page 6.

Example below is showing a RH display

LH lettering is marked to Detail “D” & “E”

R= AS (Astern) V= AH (Ahead)

NOTE: It is quite possible to set the pitch continuously variable and independently for forward and reverse. Turning

of the adjusting screws (2) & (4) by half a revolution (180°) changes the pitch approx. 1“. This will change the engine

revolution by approx. 200.

Möglich einstellbare Steigung

siehe Tabelle S. 5!

Pay attention

not to set the

prop nut with the

counter screw

Pitch adjustment table Operation & Servicing

The VARIPROFILE feathers automatically when the shaft rotation is stopped. After engine start-up and shifting into gear the

blades will engage in either forward or reverse.

THE BEST WAY TO FEATHER THE PROPELLER IN THE SAILPOSITION IS:

VARIPROFILE sailposition with

mechanical gear-box:

»Power at 2 to 3 knots in forward.

»Stop the engine and engage the transmission in

reverse to stop the freewheeling of the shaft.

VARIPROFILE sailposition with

hydraulic transmission:

»Power at 3 to 4 knots in forward.

»Stop the engine while still engaged in forward.

The remaining oil pressure of the transmission

will stop spinning the shaft to feather the blades

in the sailposition.

If the propeller is not feathered in the sailposition the shaft will freewheel like with a xed propeller. In that case start the

engine again and repeat the steps above. Once the prop is feathered , you may remain in gear or shift into neutral.

DO NOT stop the engine while it turns in reverse. In this case the blades will stay in the reverse position and will not feather.

You can actually use this feature to drive a shaft generator.

TROUBLE SHOOTING: If the propeller does not work in forward or reverse go systematically through the points below:

»Check low idle of the engine. It should be 900 to 1000

rpm in idle.

»Check shifting movement of the transmission lever.

Make sure that the shifting travel is not too short. The

amount of lever travel, as measured at the pivot point of

the actuating lever, between the neutral position and end

positions for forward and reverse can be found in the

owners manual of your transmission. A larger amount of

lever travel is in no way detrimental.

»Check the clutch discs of the transmission. They could

be worn out.

Formular-Nr.:51 Rev.-Nr.:09 08/07

6 7

Prop.-ø min. tolerance:

±0.3“

max. tolerance:

±0.3“

2 blade

ahead

(V)

13“ 7.5“ 12“

14“ 8“ 13“

15“ 9“ 14“

16“ 9.5“ 15“

17“ 10“ 15.5“

18“ 10.5“ 16“

2 blade

astern

(R)

13“ 7“ 12“

14“ 8“ 13“

15“ 9“ 14“

16“ 10“ 15“

17“ 10.5“ 16.5“

18“ 11“ 17“

Prop.-ø min. tolerance:

±0.3“

max. tolerance:

±0.3“

3 blade

ahead

(V)

13“ 7“ 12“

14“ 7.5“ 12.5“

15“ 8“ 13“

16“ 9“ 14“

17“ 9.5“ 14.5“

18“ 10“ 15“

3 blade

astern

(R)

13“ 6.5“ 11.5“

14“ 7“ 12“

15“ 8“ 13“

16“ 9“ 14“

17“ 9.5“ 14.5“

18“ 10“ 15“

Prop.-ø min. tolerance:

±0.3“

max. tolerance:

±0.3“

2 blade

ahead

(R)

17“ 11“ 17“

18“ 11.5“ 18“

19“ 12.5“ 18“

20“ 12.5“ 19“

21“ 13“ 19“

22“ 14“ 20“

2 blade

astern

(R)

17“ 9“ 15“

18“ 10“ 16“

19“ 11“ 17.5“

20“ 11“ 17.5“

21“ 12“ 18.5“

22“ 13“ 19.5“

Prop.-ø min. tolerance:

±0.3“

max. tolerance:

±0.3“

3 blade

ahead

(V)

17“ 10“ 16“

18“ 10“ 16.5“

19“ 11“ 17“

20“ 12“ 18“

21“ 13“ 19“

22“ 14“ 20“

3 blade

astern

(R)

17“ 10“ 16“

18“ 10“ 16.5“

19“ 11“ 17“

20“ 12“ 18“

21“ 13“ 19“

22“ 14“ 20“

Prop.-ø min. tolerance:

±0.3“

max. tolerance:

±0.3“

2 blade

ahead

(V)

17“ 11“ 17“

18“ 11.5“ 18“

19“ 12.5“ 18“

20“ 12.5“ 19“

21“ 13“ 19“

22“ 14“ 20“

2 blade

astern

(R)

17“ 9“ 15“

18“ 10“ 16“

19“ 11“ 17.5“

20“ 11“ 17.5“

21“ 12“ 18.5“

22“ 13“ 19.5“

Prop.-ø min. tolerance:

±0.3“

max. tolerance:

±0.3“

3 blade

ahead

(V)

17“ 10“ 16“

18“ 10“ 16.5“

19“ 11“ 17“

20“ 12“ 18“

21“ 13“ 19“

22“ 14“ 20“

3 blade

astern

(R)

17“ 10“ 16“

18“ 10“ 16.5“

19“ 11“ 17“

20“ 12“ 18“

21“ 13“ 19“

22“ 14“ 20“

VP-64

RH and LH

VP-76 RH

VP-76 LH

WARNING: It is important to follow the instructions below

carefully so as to avoid excessive load and shock to the

gears, shortening their life.

»When going from ahead to astern or the opposite, it is

necessary to idle down and shift at low rpm’s (max

.1200rpm) between gears to allow smooth reversing of

rotation without binding. This will substantially length-

en the service life of your propeller gears.

»When going from ahead to astern or the opposite, you

can hear the turning-noise of the feathering blades.

This is normal and not a problem or a defect of your

VARIPROFILE.

»The propeller body must always be completely lled

with a high viscosity grease. We recommend synthetic

grease typ TW.2 GEL or mineral multi-purpose grease

EP/SAL

»The propeller must be protected from electrolytic cor-

rosion by tting the usual zinc anodes on the shaft plus

the prop anode. We recommend the replacement of the

anode once a year.

»If you want to protect your VARIPROFILE with Antifoul-

ing, use only Antifouling which needs a primer rst.

Otherwise chemical interaction and decomposition

could occur. Our recommendation is Velox TF plus

including a primer ( offers also protection against elec-

trolyses ), available from your VARIPROFILE distributor.

Never dismantle the VARIPROFILE yourself!

Disassembly and reassembly require special tools and technical know-how only available at the factory

or their approved service centres.

SERVICING

The VARIPROFILE needs to be greased a minimum of once a year with the

special EP/SAL lubricant available from your VARIPROFILE dealer. The VARIPRO-

FILE body should always be completely lled with a high viscosity grease of a

hydrophobic nature. Remove the cap screw and screw in the lubricating nipple

which is supplied with the tools. Further remove the zinc anode! With each pump

of the grease gun rotate the propeller from forward stop to reverse stop to allow

the grease to work through the propeller. Stop to pump when enough grease

comes out of the anode drill hole on top of the prop (Fig.1).

Factory supplied special grease EP/SAL is recommended and available from

your VARIPROFILE distributor. Avoid regular white grease (sterntube-grease ) !

Removal instructions Torque settings for the prop-nut

DO NOT DISMANTLE THE PROPELLER UNIT (5)!

»Remove the blade assembly (5) from the hub (1).

»Therefore remove rst the 3 off Set-Screws (8).

»Now you can remove the Socket Screws (7). Take care

that the prop will not fall off after removing all Socket

Screws!

»Dismount the blade assembly (5) from the hub (1).

»Remove the Set-Screw (4) completely and screw into the

same hole (M8) the Counter Screw (9). Pay attention not

to set the prop nut with the counter screw!

»now remove the prop nut (3) while blocking the hub with

one hand against the counter screw.

»align the puller with the socket screws (7) of the hub (1)

and tighten (20 Nm / 15 Ft.lb).

»do not tighten the set screws (8)!

»tighten the extractor screw clockwise strongly, while hold-

ing by hand the counter screw (9).

»you can now remove the hub from the shaft.

Standard – thread

M 14 x 2

UNC 1/2 “-13

40 Nm

30 ft/lb

M 16 x 2

BSW 5 / 8 “ – 11

UNC 5 / 8 “ - 11

60 Nm

45 ft/lb

M 16 x 2

Yanmar Saildrive

SD 20 & SD 31

60 Nm /

45 ft/lb

M 20 x 2,5

BSW 3 / 4 “ – 10

UNC 3 / 4 “ - 10

125 Nm

/ 95 ft/lb

UNC 7 / 8 “-9 160 Nm

115 ft/lb

M 24 x 3

BSW 1 “ - 8

UNC 1 “ - 8

210 Nm

155 ft/lb

M 27 x 3 315Nm

230 ft/lb

M 30 x 3,5

UNC 1 1/8” - 7

350 Nm

255 ft/lb

Fine – thread

M 14 x 1,5

BSF 1/2 “- 16

40 Nm

30 ft/lb

M 16 x 1,5

BSF 5 / 8 “ – 14

UNC 5 / 8 “ - 18

70 Nm

50 ft/lb

M 20 x 1,5

BSF 3 / 4 “ – 12

UNC 3 / 4 “ - 16

135 Nm

100 ft/lb

M 20 x 2

Yanmar Saildrive

SD 40 & SD 50

100 Nm /

75 ft/lb

M 24 x 2

BSF 1 “ - 10

UNF 1 “ - 12

225 Nm

165 ft/lb

M 30 x 2 430 Nm

315 ft/lb

SUBJECT TO TECHNICAL ALTERATIONS; ERRORS and MISPRINTS

Formular-Nr.:51 Rev.-Nr.:09 08/07

8 9

1

1

3

3

7

4

5

6

9

2

8

1. Hub

2. Shaft

3. Nut SW24 (VP-64)

or SW30 (VP-76)

4. Set-Screw M8x12 (VP-64)

or M8x16 (VP-76)

5. Blade assembly

6. Washer ø10

7. Socket Screws M8x25 (VP-64)

or M10x30 (VP-76)

8. Set-Screw M6x10 (VP-64)

or M8x12 (VP-76)

9. Counter Screw M8x120

Pay attention

not to set the

prop nut with the

counter screw

It is recommended to only use the special puller available from your VARIPROFILE dealer.

NotesNotes

Formular-Nr.:51 Rev.-Nr.:09 08/07

10 11

Westkai 58, 27572 Bremerhaven

Telefon +49 (0)471 / 7 70 47

Telefax +49 (0)471 / 7 74 44

[email protected], www.spw-gmbh.de

86 517-09 DE-HH

GL Rules I, Part 1, Chapter 2,Section 6

For further informations visit

www.variprofile.com

The VARI-Family

Feathering Propeller

®

Feathering Propeller

®

made by

This manual suits for next models

1

Table of contents

Popular Boating Equipment manuals by other brands

VariProp

VariProp DF-80 Assembly and operating instructions

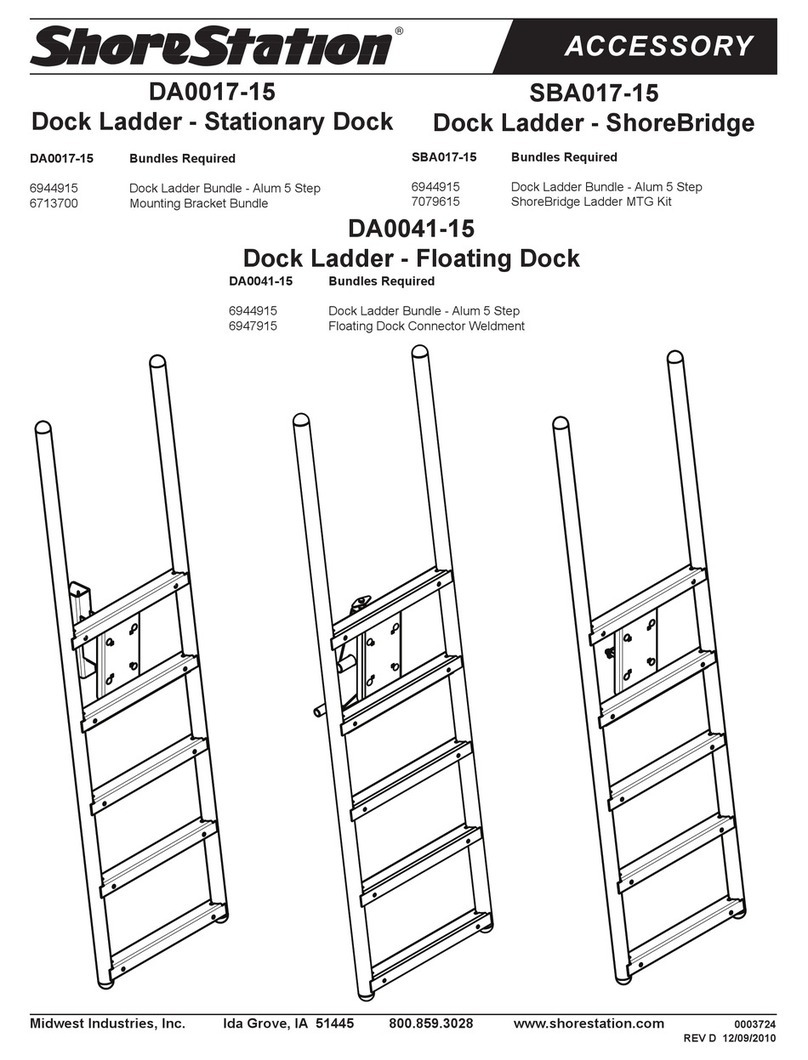

ShoreStation

ShoreStation DA0017-15 manual

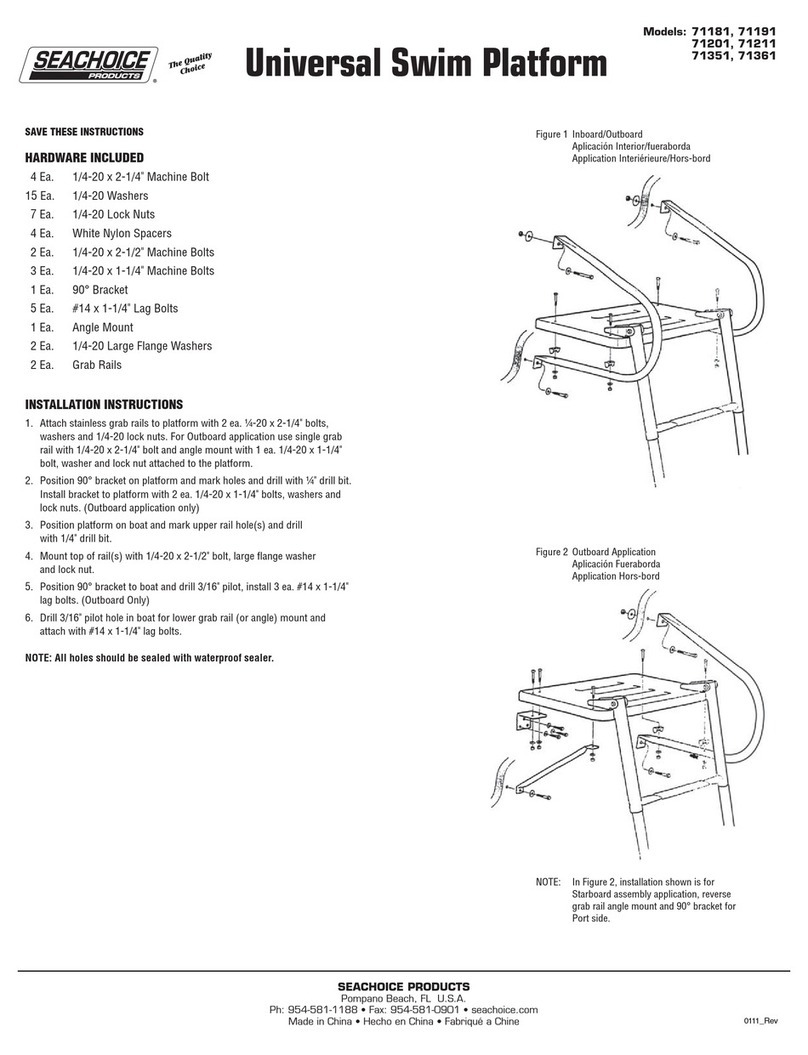

SEACHOICE

SEACHOICE 71181 installation instructions

Side-Power

Side-Power MIDI201 Installation and user manual

Vetus

Vetus WWS Installation instructions and owner's manual

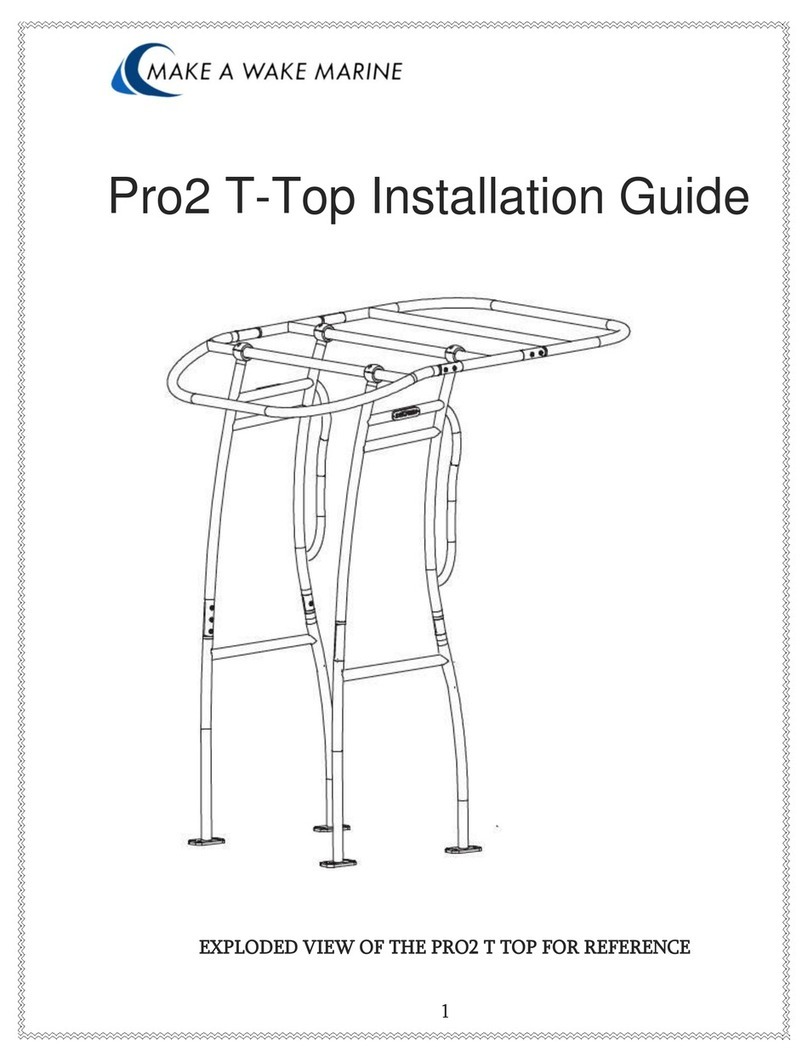

MAKE A WAKE MARINE

MAKE A WAKE MARINE Pro2 T-Top installation guide