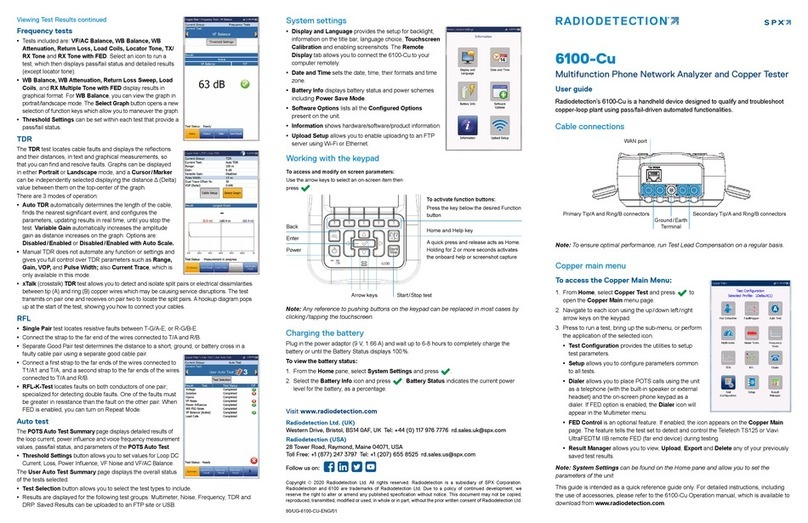

SPX APV DELTA User manual

Read and understand this manual prior to

operating or servicing this product.

Operating Manual

DELTA

Inline Measuring Techniques

1. Gerneral Terms 2

2. Safety Instructions 2

3. Field of Application 2

4. Measuring Devices 3 - 4

5. Cleaning 4

6. Installation 4

7. Maintenance 5

8. Materials 5

9. Dimesions / Weights 6

10. Technical Data 6

11. Assembly Instructions 7

12. Trouble Shooting 7

13. Spare Parts Lists

RN 01.256

Table of Contents Page

1

Inline Measuring Techniques

Operating Manual

Rev.0

UK

This operating manual has to be read carefully and observed by

the competent operating and maintenance personnel.

We have to point out that we will not accept any liability for

damage or malfunctions resulting from the non-compliance with

this operating manual.

Descriptions and data given herein are subject to technical

changes.

2. Safety Instructions

DANGER!

- The line system must be depressurized before any maintenance.

- Observe assembly instructions to ensure safe maintenance of the

measuring device.

- Moreover, the special safety instructions of the individual measuring

devices (e.g. for electric connections) must be observed.

3. Field of Application

- The APV Inline housings with different measuring devices are used

in applications in which hygienic process conditions must be

provided by crevice-free sealing and reliable cleaning.

- Two different measuring devices can usually be used in one

housing.

- With larger nominal diameters special housings can be equipped

with 4 connections for measuring devices.

- For applications with increased line pressures special housing are

available.

1. General Terms

2

Inline Measuring Techniques

Operating Manual

Rev.0

UK

All measuring devices have the same dimensions of flange

connection and can, thus, be used independently of the nominal

diameter.

Selection can be made from different measuring devices:

Temperature measurement

- Thermometer:

bimetal thermometer according to type sheet TM 52.01

type series R 5216

accuracy class: 1

-Temperature sensor:

resistance thermometer PT 100 according to DIN/IEC

751 cl. B in twin core wiring

electric terminal box out of polycarbonate

protective type: IP 67

Pressure measurement

- Pressure gauge:

pressure transmitter for front flush stainless steel membrane

radial output with different connecting directions

filling: glycerine

quality class: 1.0

- Pressure measuring transducer:

pressure measuring transducer 141 GB with front flush stainless

steel membrane

with or without LCD

temperature: + 120oC

filling: Silicone oil

protective type: IP 66

-Pressure sensor

pressure transmitter type CERABAR with ceramic measuring cells

and potential-free analog output,

pressure transmitter with front flush stainless steel membrane

filling: Silicone oil

quality class: 0.2

protective type: IP 65

Flow measurement

-Flow controller

immersion sensor ST 74614 according to calorimetric measuring

principle

measuring range: 1 ... 150 cm/s

different analysis devices

protective type: IP 67

Conductivity measurement

- Conductivitiy transmitter LMIT 08:

compact device with electrodeless measuring cell out of Teflon,

different measuring range change-overs

with and without LCD

protective type: IP 67

4. Measuring Device

3Inline Measuring Techniques

Operating Manual

Rev.0

UK

Optical measuring technique:

turbidity measurement

colour measurement

concentration measurement

Ultrasonic measuring technique:

concentration measurement

density measurement

Sight glass:

with and without illumination.

5. Cleaning

As a result of the design of the Inline housing being free of dead

spaces (no sump and no dome) all product-wetted parts can be

cleaned properly during the cleaning process.

6. Installation

The housing must be installed in such a way that a faultless

function of the measuring device is given. Moreover, the installation

must allow for fluids to drain off the housing.

With horizontal installation, measuring devices must be installed

vertically.

Attention!

- Observe welding instructions!

6.1 Welding Instructions

Before welding, the measuring devices and the housing cover must

be removed. See to a careful handling to avoid damage.

- Welding may only be carried out by certified welders (EN 287-1).

(Seam quality EN 25817 „B“).

- The welding of the valve housings must be effected in such a way

that deformation strain cannot be transfered to the valve body.

4. Measuring Device

4

Inline Measuring Techniques

Operating Manual

Rev.0

UK

- The preparation of the weld seam up to 3 mm thickness must be

carried out in butt manner as an square butt joint without air.

(Consider shrinkage!)

- TIG orbital welding should be aimed at!

- After welding of the valve housings, the pipelines must be cleaned

from welding residues and soiling in order to prevent other

components from being damaged.

- Any damage resulting from the nonobservance of these

welding instructions is not subject to our guarantee.

7. Maintenance

- The maintenance intervals depend on the individual application and

are to be determined by the operator himself by temporary checks.

- Installation of measuring devices see assembly instructions.

-All seals must be slightly greased before their installation.

Recommendation:

APV food grade grease for EPDM, HNBR and FPM

(0,75 kg /tin - ref.-No. 000 70-01-019/93)

(60 g /tube - ref.-No. 000 70-01-018/93)

! For all applications, use only those greases which are suited for the

corresponding seal material !

8. Materials

Product-wetted parts : 1.4571 / 1.4404

Seals : standard EPDM

option HNBR, FPM

Measuring devices : see technical documents

of manufacturer or item 4.

6.1 Welding Instructions

5Inline Measuring Techniques

Operating Manual

Rev.0

UK

10. Technical Data

max. line pressure : 10 bar

(higher pressure on request)

max. operating temperature :140

oC EPDM, HNBR

135o C FPM

sterilization temperature :150

o C EPDM, HNBR

(short-term) : 140o C FPM

For information about the measuring devices refer to the technical

documents of the manufacturers.

9. Dimensions / Weights

6

DN

A

˘˘

B

˘˘

C

D

weightin

kg

25

68

26

29

25,5

40

67

38

41

31,5

50

72

50

53

37,5

65

85

66

70

45,5

80

98

81

85

53,0

100

111

100

104

62,5

125

130

125

129

75,0

150

150

150

154

87,5

Inline Measuring Techniques

Operating Manual

Rev.0

UK

The item numbers refer to the spare parts list RN 01.256.

11.1 Dismantling from the line system

a. Shut off line pressure in the product line and discharge line if

possible.

b. Disconnect electric and pneumatic connecting lines.

c. Remove hex. screws (3). Screw two screws into the threaded holes

of the housing cover (2), thus, pressing the measuring device and

the housing cover off.

11.2 Dismantling of wear parts

- If the measuring device has additional wear parts, the

corresponding operating instruction must be observed.

a. Pull off housing seal (4).

11.3 Installation of seals and measuring devices

a. Pull the slightly greased seal on the flange of the measuring

device or of the housing cover (2).

See to a correct fit of the seal.

b. Place the measuring device or housing cover straightly on the

housing flange and tighten it by the hex. screws (3).

c. Connect electric and pneumatic lines.

12. Trouble Shooting

- leakage between housing flange

and flange of measuring device or

housing cover : replace housing seal.

13. Spare Parts Lists

(see annex)

11. Assembly Instructions

7Inline Measuring Techniques

Operating Manual

Rev.0

UK

Your local contact:

APV

Zechenstraße 49

D-59425 Unna

Phone: +49(0) 23 03/ 108-0 Fax: +49(0) 23 03 / 108-210

For more information about our worldwide locations, approvals, certifications, and local representatives, please visit www.apv.com.

Copyright © 2008 SPX Corporation

The information contained in this document, including any specifications and other product details, are subject to change without notice.

While we have taken care to ensure the information is accurate at the time of going to press, we assume no responsibility for errors or

omissions nor for any damages resulting from the use of the information contained herein.

UK

Translation of original manual

rev. 0

BA INLM 000002

ID-No.: H175760

Table of contents

Other SPX Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Matheson

Matheson 819 Series operating manual

Keysight Technologies

Keysight Technologies B1500A Configuration and Connection Guide

N4L

N4L SFRA45 user manual

LaMotte

LaMotte DC1500 PHOSPHATE manual

Magneti Marelli

Magneti Marelli Smart Gas operating manual

Agilent Technologies

Agilent Technologies 8590 Series Service guide