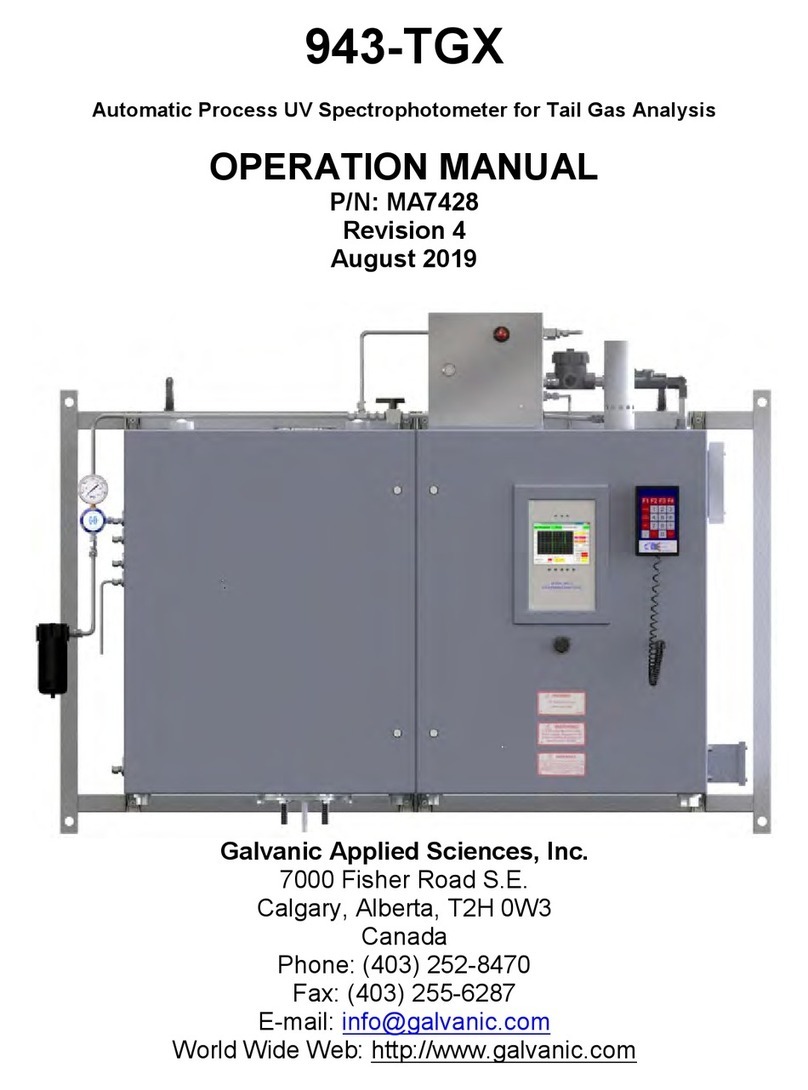

SPX LeakMaster User manual

LeakMaster™

Evaporative Emissions System Tester with UltraTraceUV ®dye Technology

Probador del sistema de emisiones de evaporatión y la tecnologia de tinte UltraTraceUV ®

Testeur de système absorbeur de vapeurs de carburant de colorants UltraTraceUV ®technologie

Part No. 6525

Operator’s Manual

Manual del operador

Manuel de l’opérateur

1

Table of Contents

Table of Contents .............................................................................1

Safety Precautions............................................................................2

Background......................................................................................3

Introduction......................................................................................4

Technical Specications...................................................................4

Tester Overview ...............................................................................5

Setup ...............................................................................................6

Phase One.........................................................................................7

Phase Two ........................................................................................9

Vacuum and Induction Leaks.........................................................10

Exhaust Leaks ................................................................................13

Miscellaneous Leaks......................................................................14

Oil Seals and Gasket Leaks.................................................14

Intercooler and Turbocharger Leaks ...................................14

Component Testing .............................................................15

Under-Dash Leaks...............................................................15

Wind and Water Leaks ........................................................16

Maintenance...................................................................................17

Parts List ........................................................................................18

Troubleshooting .............................................................................19

Diagnostic Lights................................................................19

Guide...................................................................................19

Fluid Change Record .....................................................................20

Quick Reference.............................................................................21

Warranty.........................................................................................22

Español...........................................................................................23

French ............................................................................................45

2

If the operator cannot read these instructions, operating instructions and safety

precautions must be read and discussed in the operator’s native language.

WARNING: To prevent personal injury and / or damage to equipment :

• Read, understand, and follow all safety precautions and operating

procedures.

• Do not use this equipment in a manner not specified by the

manufacturer.

• Wear eye protection that meets OSHA standards. If using an optional

ultraviolet light to search for leaks, wear yellow UV goggles that

meet OSHA standards. Never stare directly into a UV light or shine

UV light on skin.

•Because of an evaporative system’s volatile fumes, use an inert

gas, such as nitrogen, when testing an EVAP system.

• Do not perform tests near a source of spark or ignition.

•Correctly connect the power supply to the battery and chassis

ground.

•The spotlight is designed for intermittent use only, not constant

use.

• If the spotlight is hot, do not touch the top part of the lamp or lens,

donotplaceitnearammableitems,anddonotputitawayfor

storage until it cools.

• Do not use the spotlight if it is damaged.

Safety Precautions

3

The fuel vapor recovery system is the most

neglected part of a vehicle’s emission system,

according to the Environmental Protection

Agency (EPA).

The vehicle’s EVAP system is used to collect fuel

vapors from the fuel tank. These vapors are stored in

a canister lled with activated charcoal. The EVAP

system allows the fuel vapors to be drawn from

the canister and combust during certain operating

conditions. This process is called canister purging,

since the fuel vapors are purged from the canister.

OBD-II requires Powertrain Control Module (PCM)

monitoring for correct operation of the EVAP system

and for possible leaks to the atmosphere.

A faulty EVAP system will allow hydrocarbons (HC)

to escape into the atmosphere. Factory emission

tests have determined that an EVAP system

with a leak as small as .020 can yield an

average of 1.35 grams of HC per vehicle-

driven mile. This is over 30 times the current

allowable exhaust emissions standard.

In addition to causing HC emissions, failure of the

EVAP system wastes fuel and many times creates

customer-complaints of “gasoline odors.” With

the introduction of On-Board Diagnostics

(OBD), the automotive industry is capable of

determining if a vehicle’s evaporative system

has a leak. Prior to the LeakMaster No. 6525,

determining the location of an EVAP leak was a

difcult and time-consuming challenge.

LeakMaster Operation

The LeakMaster is a dual-phase tool. Phase One

uses an inert gas, such as nitrogen, to test the integrity

of the vehicle’s fuel vapor recovery system by quickly

determining if, in fact, a leak exists. Phase Two

quickly nds the leak using both visual vapor (smoke)

and UltraTraceUV®dye technology. UltraTraceUV®

is a unique chemical bonded to the smoke that deposits

an ultraviolet ngerprint at the exact location of the

leak.

Background

This dual-phase operation is accomplished

automatically. LeakMaster sets the critical pressure

that must be maintained during EVAP testing. You

don’t need to set ow rates, and you don’t need to be

concerned with ambient temperatures or barometric

pressures.

LeakMaster will not spill its solution regardless of

the position it’s placed in, and is rellable by the end

user when the smoke-producing solution is depleted.

The smoke it produces, as well as the UltraTraceUV®

dye, is non-toxic and non-corrosive.

LeakMaster needs no assembly, is self-calibrating, and

requires no maintenance, other than a recommended

annual smoke solution change.

Read this manual in its entirety before

performing any actual tests on a vehicle.

The LeakMaster should be operated only by

trainedandqualiedtechnicians.

Tech Tips

• When the vehicle’s engine is turned off, the

OBD-II EVAP system is generally venting in

one form or another. Use a scanner to close

the EVAP system in order to perform any

leak tests. Remember, ALL tests with

the LeakMaster are performed with

the engine OFF.

•It is best to perform all testing in calm air, so

the smoke exiting the leak will not be blown

away, impairing your view of the leak.

• Because of the EVAP system’s volatile

fumes, we always recommend you use an

inert gas, such as nitrogen, when testing the

evaporative system. However, LeakMaster is

also designed to perform its functions with

conventional shop air, if being used to test

systems other than the EVAP system.

4

Congratulations!

You are in possession of the most useful, yet simple to operate, Evaporative

Emissions (EVAP) system diagnostic tester available today. The LeakMaster’s

versatile12-voltdesignwas specicallydevelopedto diagnosevehicleEVAP

systems for leaks.

Inaddition,theLeakMasterwillalsondintakemanifoldsystemleaks,exhaust

system leaks, and under-dash vacuum system leaks. It will also diagnose many

other closed systems where you may suspect a leak, as well as pinpointing wind

and water leaks entering the vehicle’s passenger compartment.

TheLeakMaster’suniquedesignallowstheoperatortoconrmtheintegrityof

asystembyutilizingameteredairsystem.Ifthetoolhasconrmedaleakinthe

system being tested, it then introduces a non-toxic, diagnostic, marked vapor

(smoke) into the system. To locate the source of the leak, you simply look for the

smoke exiting the leak, or use a conventional ultraviolet (UV) lamp to view the

UV deposit left behind, which pinpoints the exact location of the leak.

TheLeakMasterisshippedlledwithafullchargeofsmoke-producingsolution

that will last approximately 500 tests.

Introduction

Height 23 in. (58.4 cm) Supply Pressure 13.0 in. H2O

Width 18 in. (45.7) Supply Volume 15 liters per minute

Depth 9 in. (24.1 cm) Operating Temperature Range 45°F to 140°F (7.2°C to 60°C)

Weight 17 lbs. (7.6 kg) Supply Line 12 feet (3.6 m)

Ship Weight 20 lb. (9.0 kg) Power Supply Line 12 feet (3.6 m)

Power Supply 12V DC Remote Starter Cable 12 feet (3.6 m)

Amperage Usage 15 amps

Technical Specications

5

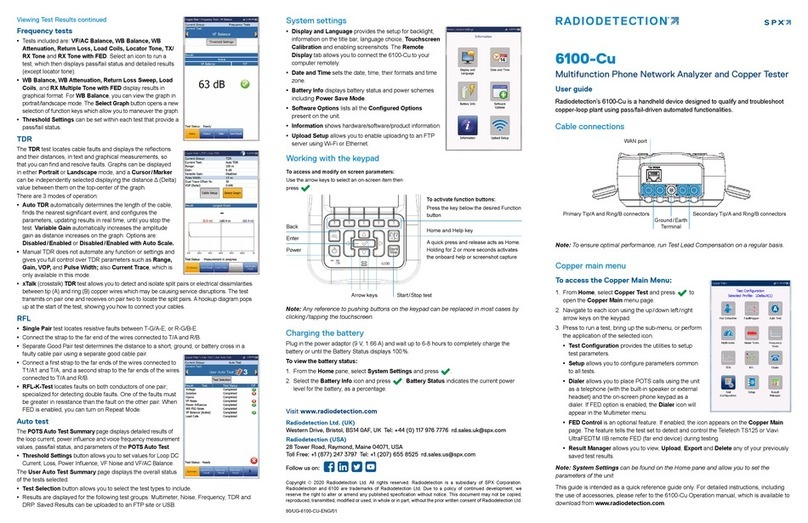

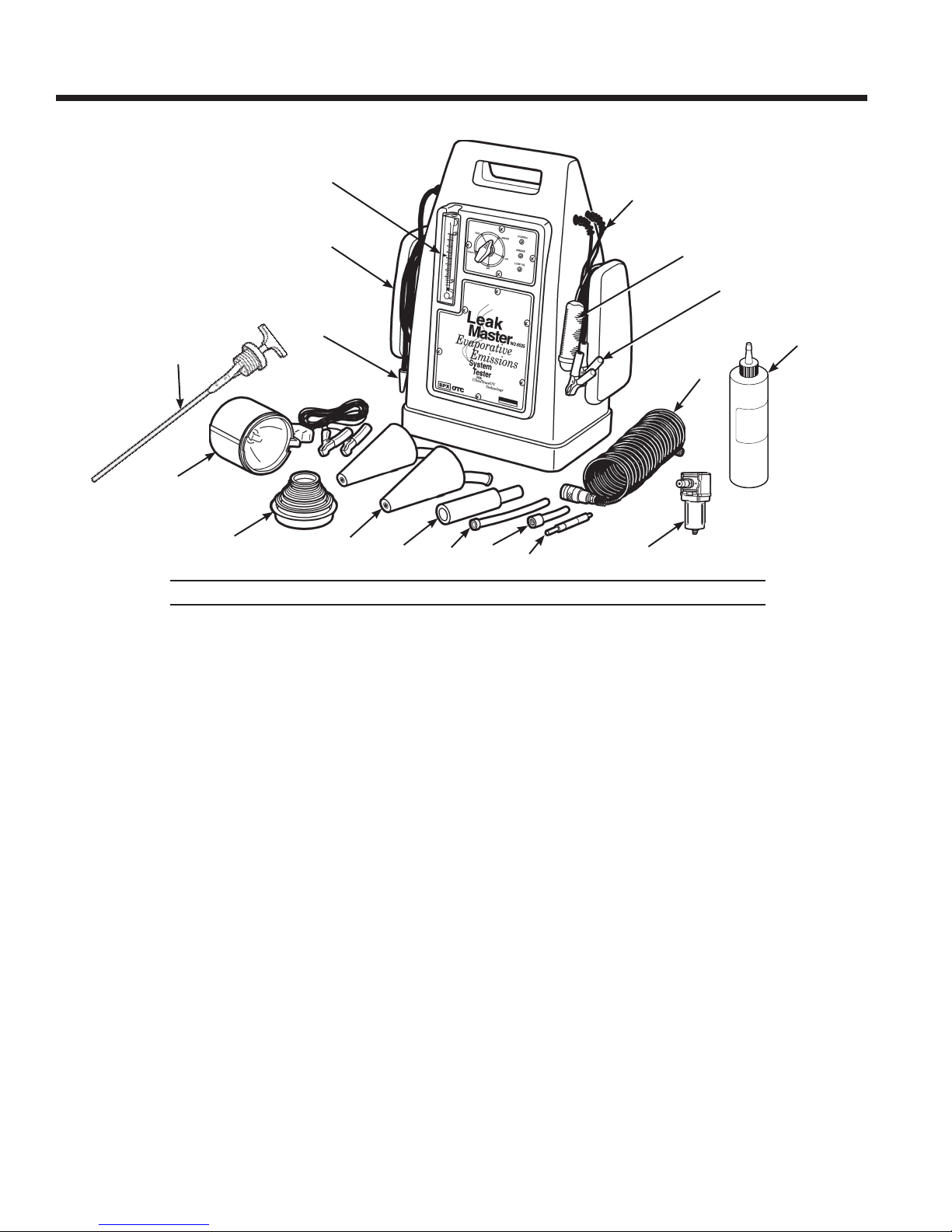

Tester Overview

Component Descriptions

1. Cap Plug Kit is used to seal the intake ducting of

the engine being tested. The plugs range in size from

1-3/4" to 4-1/2", and may be used to seal either the

inside diameter of an opening, or ip them over and

seal the opening at the outside diameter.

2. EVAP Service Port Adapter

(standard size)

connects directly to the factory service access port on

the vehicle when connecting to a vehicle’s fuel vapor

recovery system.

3. Exhaust Cones taper in size from 1" to

3-1/2" with a 5/16" opening at the small

end of the cone to which a short section

of hose is connected. The supply nozzle

is inserted into the end of the attached

hose to introduce smoke into any system

with an opening that ts these dimensions.

The exhaust cones may also be used as

exhaust plugs when testing intake vacuum

systems.

4. Flow Meter with pointer-ag establishes a quick

PASS / FAIL when determining if the vehicle being

tested has a leak.

5. EVAP Service Port Adapter (small size) connects

to the factory service access port on some vehicles.

6. “ON” Indicator Light turns ON after pressing the

remote starter button, indicating the tester is ON.

(There is a ve second self-diagnostic delay before

the light comes on.)

7. Power Indicator Light

turns ON when connecting the

power leads to a battery, indicating a good contact.

8. Remote Starter & Power Cables are used to

operate the tester. The tester stays ON for ve (5)

minutes after the remote button is pressed; press the

button again to turn the tester OFF.

9. Schrader Valve Removal / Installation Tool

is

designed to work on many different kinds of vehicles.

10. Selector Switch is used to select the functions of the

tester as explained in this manual.

11. Spotlight helps locate smoke when searching for

leaks.

12. Smoke Diffuser is designed to slow the velocity of

the smoke exiting the supply hose. The diffuser allows

the operator to lay down a thick bed of smoke along

the door, sunroof, windshield, and window seams, so

any air disturbance caused by unwanted airow may

be observed.

13. Supply Hose is used when conrming the integrity

of an EVAP system, when verifying any system for

leaks, or when introducing smoke into a system being

tested for leaks.

14. Hose (25 ft.) is used to deliver nitrogen to the EVAP

tester. Simply connect the 1/4" pipe thread to the

nitrogen regulator and the quick-disconnect tting to

the EVAP tester.

Features Included But Not Shown Here

Drain / Fill Area (located on the top-back of the tester):

Much like a motor oil dipstick, there are low and high marks

engraved on the tester’s dipstick. Remove the dipstick

to maintain the smoke solution level at the FULL mark,

and to drain and replace the smoke solution during yearly

maintenance service.

Smoke-Producing Solution: LeakMaster is shipped

with a full charge of smoke-producing solution – enough

to perform approximately 500 tests before needing a rell.

We recommend replacing the solution once a year (at the

minimum) to help keep the LeakMaster operating in a

like-new condition for many years to come.

Water Separator / Filter (on back of tester) ensures a

clean supply of nitrogen or air.

12

3

4

5

6

7

8

9

10

11

12

13

14

6

Setup

1. Connect the red power cable from the LeakMaster

to a 12V

DC power supply. If you are using a battery,

verify it is in good condition and fully charged. See

Figure 1.

2. Connect the black ground cable from the

LeakMaster to the vehicle’s chassis ground.

Connect black

battery clip to

chassis ground.

Connect red

battery clip to

positive battery

terminal.

3. Depending on the tests you are performing, connect

either a nitrogen or shop air supply line to the water

separator located on the back of the tester. See

Figure 2. Supply pressure must be between 50 psi

and 125 psi.

When testing EVAP systems: Connect the

nitrogen line to the water separator.

When testing systems other than EVAP:

Connect the air supply line to the water separator.

Remember, all tests performed with

the LeakMaster are performed with the

vehicle engine OFF.

CAUTION: To prevent

personal injury, do NOT connect

LeakMaster’s black cable to a

battery ground, because a spark

in the vicinity of the battery can

cause an explosion.

Figure 2

Water

Separator

Figure 1

7

Phase One

1. Verify the vehicle’s fuel level is below the base of

the fuel tank neck.

2. Determine if the vehicle’s EVAPsystem is governed

by a .040 or .020 acceptable leak standard.

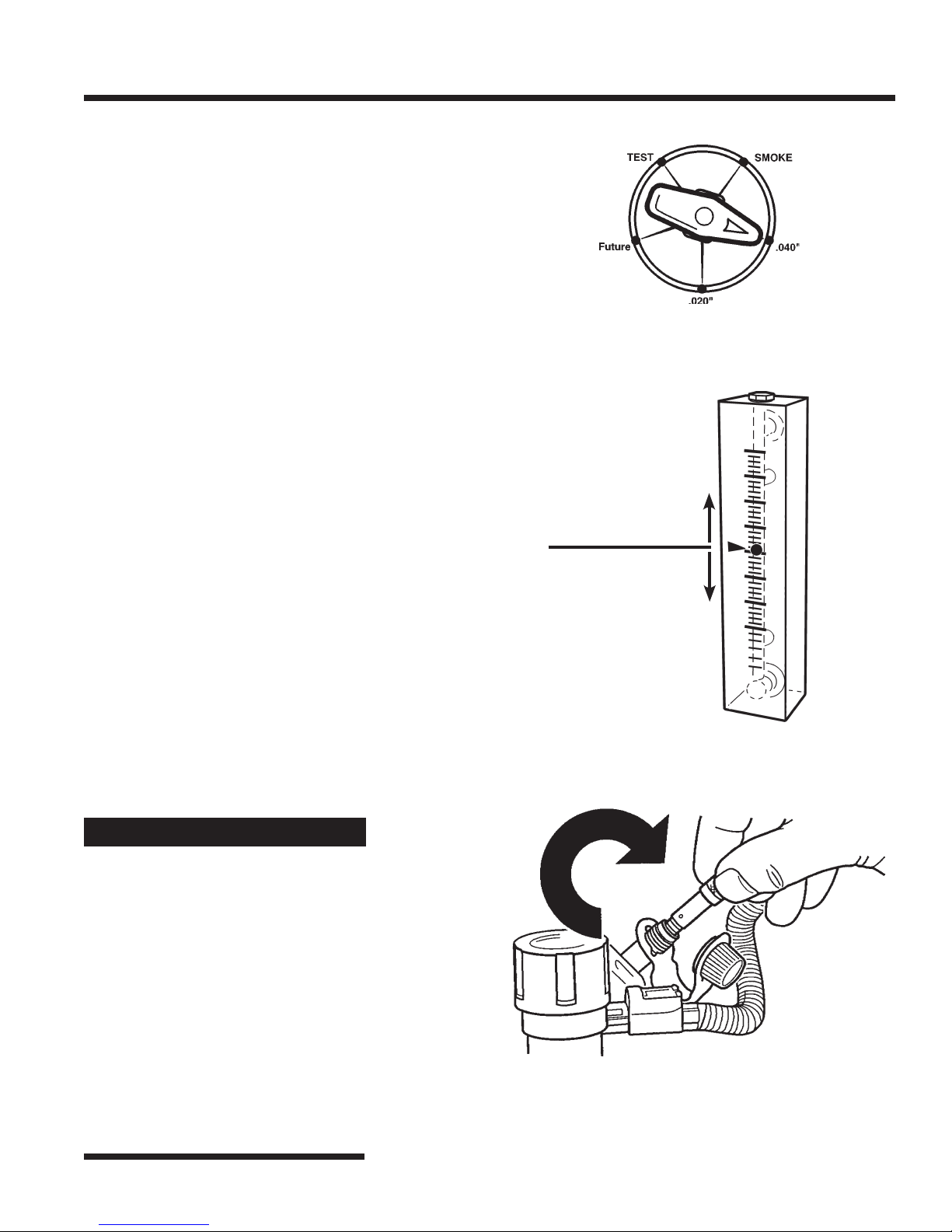

3. Position the selector valve on the tester control

panel to the correct standard. See Figure 3.

The “future” setting on the control valve is

reserved for another standard, should requirements

change.

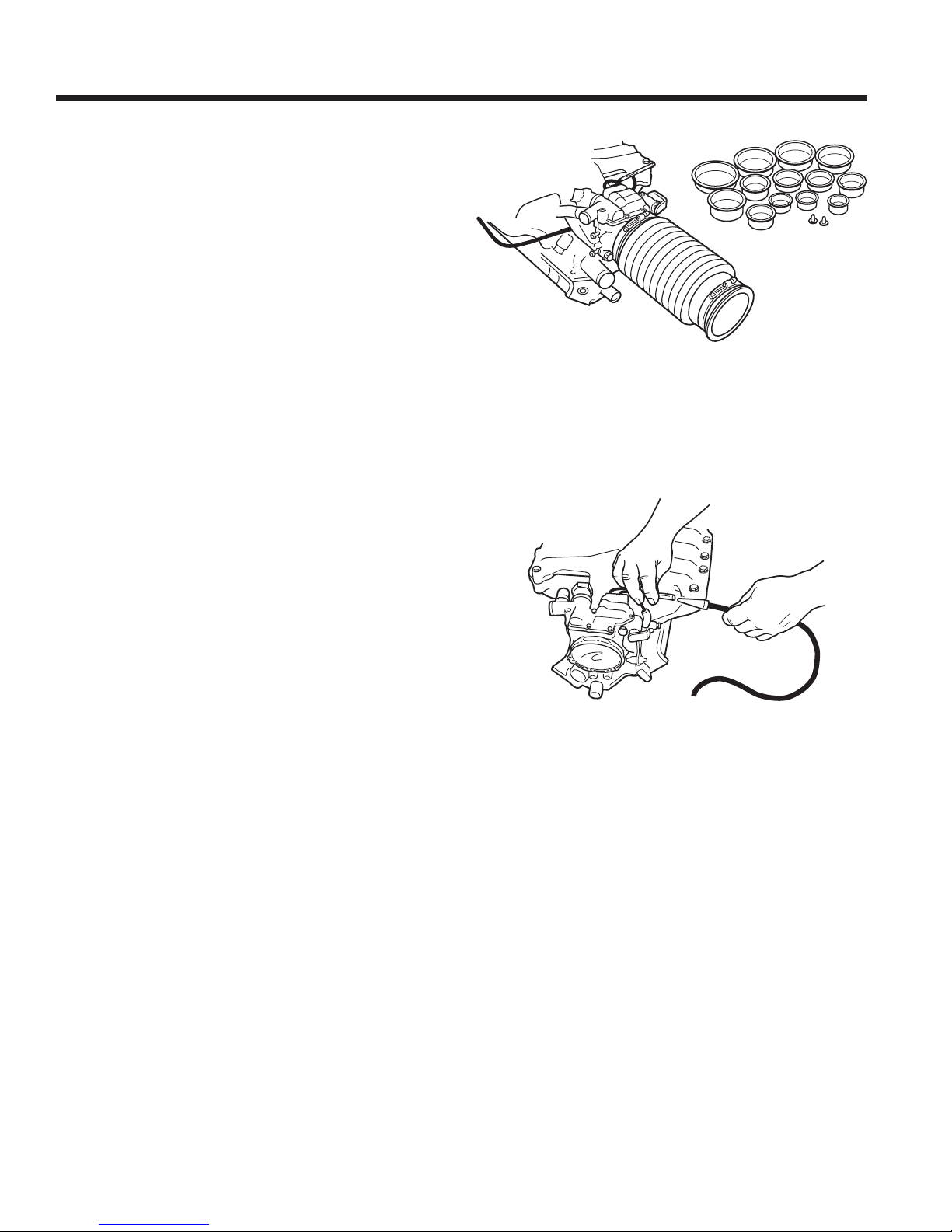

4. Turn the tester ON by pressing the remote starter

button. Observe the ow meter’s indicator ball.

Position the ow meter’s red ag so it aligns with

the ball. See Figure 4.

This measurement indicates the vehicle’s

Pass / Fail line.

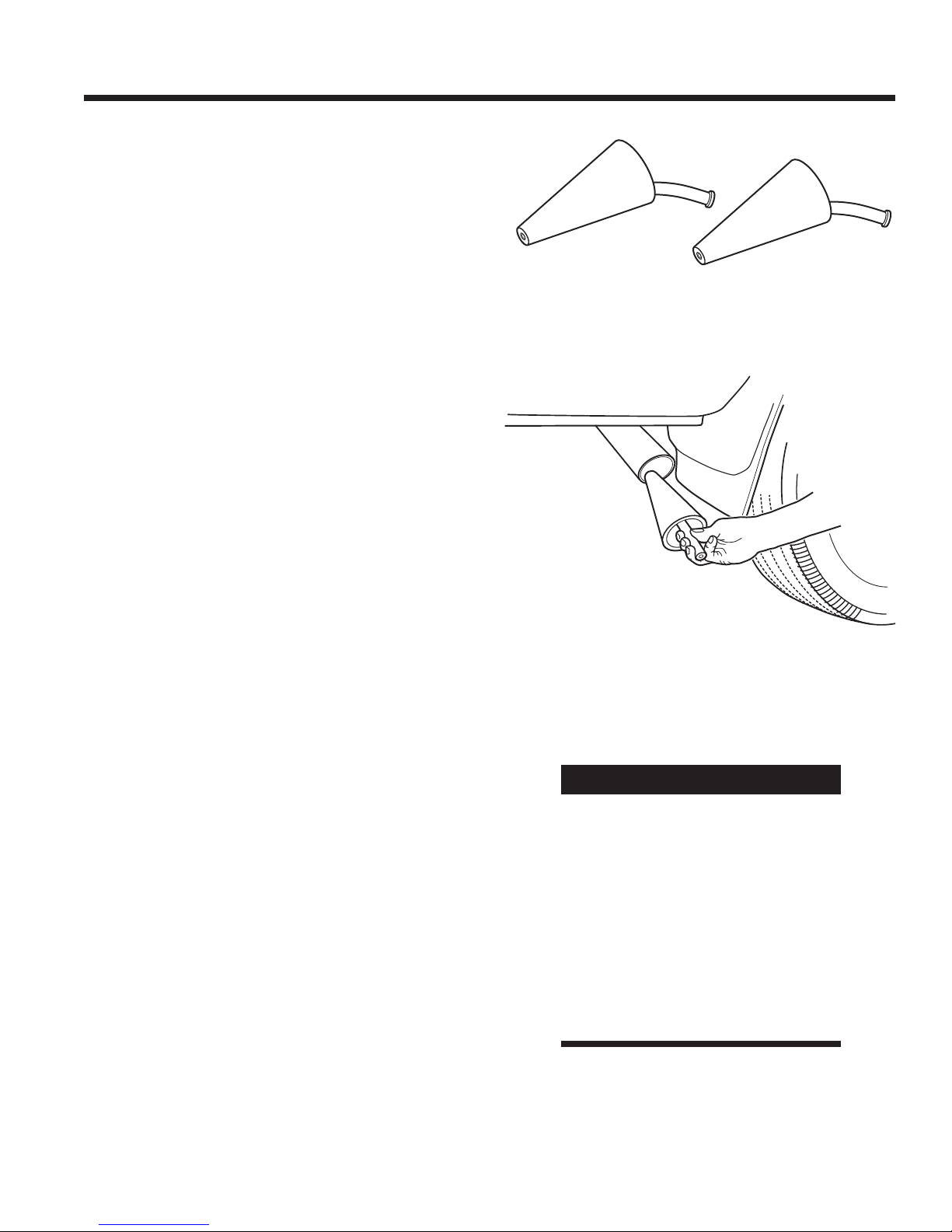

5. Press the remote starter button again to turn the

tester OFF.

6. Locate the vehicle EVAP service port. Remove the

green cap and the Schrader valve that is located

inside the service port. See Figure 5.

IMPORTANT: The Schrader valve is installed

with a left-hand thread.

7. Install the EVAP service port adapter (provided

with the tester) into the EVAP service port.

Tech Tips

The EVAP service port on OBD-II vehicles

was designed with a Schrader valve before

this smoke-producing test procedure was

developed for diagnosing EVAP leaks.

Smoke, when passed through a Schrader

valve, will partially condense. It will not be

dense enough to be effective for EVAP leak

diagnosis.

For this reason, when testing with smoke,

remove the Schrader valve before

introducing smoke into the EVAP system.

Remember to turn the Schrader valve

in a clockwise rotation to remove it.

Figure 3

Figure 4

Fail

Pass

Figure 5

Turn the

Schrader valve

clockwise to

remove it.

8

Phase One

8. Insert the supply hose from the tester into the EVAP

service port adapter. See Figure 6.

9. Close the vehicle’s EVAP system vent solenoid.

10

.Set the tester’s control valve to TEST.

11.

Press the remote start button to activate the tester.

At the beginning of the test procedure, the ow

meter’s indicator-ball is toward the top of the

ow meter scale. This indicates the EVAP System

is being lled. Usually in less than 60 seconds

– depending on capacity and fuel system level –

the ball will fall within the meter’s visible scale.

Continue to ll the system until the ball stops

descending. This could take an additional two

minutes.

The timer will automatically turn OFF in five

minutes. (The tester will turn OFF if the remote

switch is pressed again before the 5 minutes has

elapsed).

12.

Once the flow meter’s ball stops descending,

observe if the ball is above or below the red ag.

See Figure 7.

• AmeasurementABOVEthe pointer-ag

indicates an unacceptable leak in the EVAP

System (FAIL). Proceed to Phase Two.

• A measurement BELOW thepointer-ag

indicates no leak (or an acceptable leak)

in the EVAP System (PASS).

Figure 7

Fail

Pass

Tech Tips

•When testing a pre-OBD vehicle, or when

testing an OBD vehicle without an EVAP

service port, access the EVAP system in one

of two ways: disconnect the EVAP vent line

leading back to the fuel tank; or go through

the fuel tank neck using a fuel neck adapter

(not supplied).

•A common leak in a vehicle’s EVAP system

is due to an unsecured or faulty fuel cap.

We recommend NOT disturbing the fuel

cap before completing Phase One.

If an unacceptable leak has been deter-

mined after completing Phase One, you can

reposition or test the fuel cap, then perform

Phase One again. You may discover the

leak was due to a fuel cap problem.

If you disturb the fuel cap before perform-

ing Phase One, and the vehicle passes the

test, you will never know for sure if the

leak was due to the fuel cap or if you are

dealing with an intermittent condition.

Service Port

Service Port

Adapter

Supply

Line

Figure 6

9

Phase Two

1. Verify the vehicle’s fuel level is below the base of

the fuel tank neck.

2. Position the selector valve on the tester to SMOKE.

See Figure 8.

3. Remove the vehicle’s fuel cap.

ThissavestimewhenllingtheEVAPsystemwith

smoke.

4. Press the remote starter button to activate the tester.

The “ON” indicator light will come ON after a

5-second self-diagnostic delay, indicating the tester

is ON and producing smoke.

5. Replace the fuel cap once smoke is seen exiting the

fuel tank’s neck.

ThetimerwillautomaticallyturnOFFinveminutes.

ToshutthetesterOFFbeforetheveminutesareup,

simply press the remote button.

6. Continue to introduce smoke into the EVAP system

for about 60 seconds, or until the ow meter’s ball

stops descending.

It is not necessary to wait until the system is full

(indicatedbythedescendingowmeterball)before

looking for leaks.

7. Use the spotlight provided to follow the EVAP

path and look for smoke exiting a leak. Continue to

introduce smoke in 30 second intervals until the leak

is found.

This ON/OFF technique allows the EVAP system to

achieve test pressure, and then allows the pressure to

be relieved. Diagnostic Smoke®vapor is even more

visible at lower test pressures.

You could also use a UV light (not provided) to search

for the UltraTraceUV ®dye that would be deposited

at the exact location of the leak(s). The longer the

EVAP system is allowed to fill with Diagnostic

Smoke®vapor,themoreuorescentmaterialwillbe

deposited.

8. Repair the leak(s), and perform the Phase One test

again to verify the repair and make certain there are

no additional leaks in the EVAP system.

9. Reinstall the vehicle’s Schrader valve using a

counterclockwise thread rotation (OBD vehicles

only). Reinstall the EVAP service port green cap.

Figure 8

Tech Tips

•For an even quicker test procedure, it is

possible to combine Phase One and Phase

Two. Theowmeteris operational in both

phases.

If you already know the EVAP system has a

leak, start with Phase Two testing. (The leak

willstillbequantied,becausetheowmeter

is active.)

Then perform Phase One to verify the repair.

•If you are testing a vehicle that has a fuel roll-

over valve in the fuel tank, you may not see

smoke exiting the fuel tank neck.

You may need to introduce smoke through the

fuel tank neck, and vent the non-smoke air out

the vehicle’s service port; or at least partially

llthesystemwithsmokebeforeclosingthe

vent solenoid. Then, once smoke is seen exiting

the vent area, close the vent solenoid.

10

1. Seal the system to be tested by selecting the correct

size cap plug (supplied) and sealing the engine’s

air intake.

To inspect the entire system, it is best to seal the

engine’s intake as close as possible to the air inlet

origin. This is especially important on engines

equippedwith mass airow sensorsandrelated

ducting connecting it to the intake system.

2. Select a vacuum line on the engine that is easily

accessible, and insert the tester’s tapered smoke

nozzle into a section of this line that goes to the

engine.

The supply line to the brake booster is a good place

to introduce smoke into the intake manifold. Enter

this line at a point where the check valve will not

interfere(orstoptheowofsmoke).

3. With the engine shut OFF, press the remote button

once to turn the tester ON. Let the tester run until

the system is filled – usually 30 seconds to 1

minute.

4. Once smoke is observed exiting a leak, push the

remote button a second time to turn the tester

OFF.

5. Turn the tester ON and OFF in 30 second intervals

to pinpoint the source of the leak.

6. Use the spotlight to identify the origin of the

smoke, or use a UV light (not supplied) to look for

residual traces of the dye that was left behind by

the smoke.

Theexitingsmokedepositsaresidualuidthatis

either bright green or bright yellow in color when

viewed with a UV light.

Vacuum and Induction Leaks

One method to seal the system: Disconnect the rubber

hose at the air cleaner, and plug the end of the hose.

Cap Plugs

Select a vacuum line that is easily accessible, and insert

tester’s tapered smoke nozzle.

11

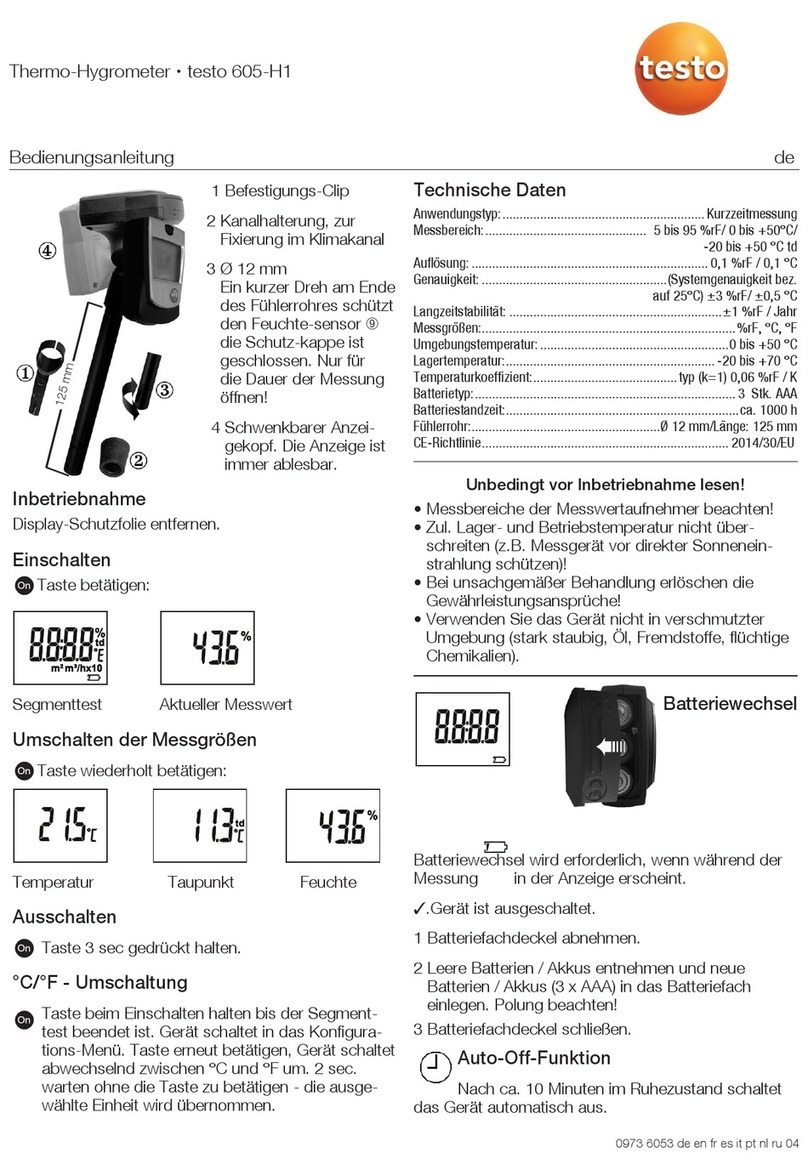

Vacuum and Induction Leaks

Typical Areas to Search on Fuel Injected Engines

Typical Areas to Search on Carbureted Engines

Air Cleaner

Hose

Loose

Clamps

Throttle Body

Shaft

Throttle Body Gasket

Injector O-ring

Positive Crankcase Vent Hose

(PCV)

Vacuum

Lines Air

Valves

Vacuum

Lines Throttle

Plate

Air Flow Meter

Intake Manifold

Air Cleaner Assembly

Injector

O-rings

Vacuum

Lines

Exhaust Gas

Recirculating Valve Vacuum

Hose Vacuum Switches

Vacuum Hose

Connections

Vacuum

Advance

Module

PCV Valve

& Hoses

Carburetor

Base

Gasket

Intake Manifold

Gasket

Choke Pull Off

Diaphragm

12

Vacuum and Induction Leaks

EGR Valve Leaks

The exhaust gas recirculating valve is at the heart of

the emission control system. Since the EGR valve

operates in such a hostile environment, it is always

susceptible to leakage. During a normal test for

vacuum leaks, the EGR valve will be exposed to

smoke and may show leaks at the seat, diaphragm, or

even the base gasket.

If smoke is seen exiting the EGR valve, disconnect the

vacuum supply line, and introduce smoke directly into

the valve. This will verify if the diaphragm is leaking,

or if the valve is leaking at the seat.

Smoke may also be used to check EGR ports for

restriction. Open or remove the valve, and introduce

smoke through the tail pipe to verify these ports are

open.

Idle Motors and Solenoid Leaks

A small leak in an idle motor or solenoid component

can make an engine idle rough or stall. Leaks in these

components are usually found during a normal vacuum

leak test. It is not unusual to nd base gaskets and

o-rings leaking in and around motors and solenoids.

Brake Booster Leaks

A leaking vacuum brake booster not only affects

engine performance like other types of vacuum

leaks, but more importantly, it can seriously affect the

stopping power of the vehicle.

Pressing on the brake pedal during this test

will falsify the test results.

1. Disconnect the vacuum supply line and the check

valve from the brake booster.

2. Insert the smoke supply nozzle into the brake

booster, and press the tester’s remote button once

to begin introducing smoke.

3. If the tester’s ow meter indicates ow, the brake

booster has a leak.

4. Under the hood, look for smoke exiting around the

crimped area of the booster canister. Also look for

smoke inside the vehicle under the dash.

Tech Tips

Testing the EGR Pintle Shaft – This will help

you diagnose a good or bad EGR valve and

other “metered” leaks.

1. Do not cap off any part of the engine –

leave it in a normal operating state (but

not running). Insert the LeakMaster supply

hose into a direct vacuum manifold source,

such as a brake booster hose or PCV. Press

the remote button on the LeakMaster. Watch

for smoke to escape from the EGR valve. If

you see a lot of smoke, the valve is bad; no

smoke, move on to the next step.

2. Cap off the intake using one of the cap plugs

supplied with the LeakMaster. Insert the

exhaust cone into the tailpipe. (The hose

on the exhaust cone should be plugged with

the cap plug provided.) Now that the system

is sealed, press the remote button and

watch for smoke. A small amount of smoke

indicates an acceptable EGR valve.

13

Exhaust Leaks

The exhaust cones were developed for the identi-

cation of leaks in a vehicle’s exhaust system. These

leaks can be difcult to locate, because they are often

hidden by metal shields, or become silenced as the

engine warms up.

1. Put the vehicle on a lift to expose the underside.

2. With the engine OFF, insert the exhaust adapter

cone into the tail pipe as shown.

On dual exhaust systems, install a cone in each tail

pipe.

3. Attach the tester’s SMOKE supply line to the hose

on the exhaust cone.

On dual exhaust systems, verify the other exhaust

cone is plugged with the cap plug supplied with the

cone.

4. Press the remote button once to start the ow of

smoke.

5. Using a spotlight, follow a path along the vehicle’s

exhaust system, and look for the source of the leak

(exiting smoke).

Exhaust Cones

Insert the exhaust

adapter cone into

the tail pipe.

Tech Tips

•This test is more accurate when testing a

cold exhaust system, because a very hot

catalytic converter consumes some of the

smoke. Also, many small exhaust leaks are

only visible on a cold exhaust system, due

to thermal expansion.

• Seal the vehicle’s intake system with the

cap plugs provided – this achieves correct

system pressure in the event both an intake

valve and an exhaust valve are open in the

same cylinder at the same time.

14

Miscellaneous Leaks

Oil Seals and Gasket Leaks

Many oil leaks can be located with the LeakMaster;

however, it is important to understand that the

LeakMaster will only nd leaks that allow air to ow

through them, causing the oil to bubble.

To nd oil leaks, it is necessary to pressurize the

crankcase with smoke:

1. Remove the vehicle’s oil dipstick, slip a hose over

the dipstick tube, and insert the smoke nozzle into

the hose.

2. Block or plug the PCV, air breather, and intake.

Remove the oil ller cap.

3. Introduce smoke into the crankcase until smoke is

seen exiting the oil ller port.

4. Install the oil ller cap, and continue lling the

system.

5. Use the spotlight to check for leaks, which could

appear as seeping smoke, bubbling oil with little

or no smoke, or dripping oil with no smoke at all.

Intercooler and

Turbocharger Leaks

Engine compartments with turbochargers tend to

run hotter than normally aspirated engines, causing

hoses and seals to dry out and leak. For turbocharged

systems to operate efciently, there can be no leaks in

the intercooler, ducting, exhaust, or the turbo itself.

1. Connect the smoke nozzle to the intake system.

2. Introduce smoke into this “cold” side of the

turbocharger.

3. While the intake is under smoke pressure, inspect

the intercooler, ducting, waste gate, and the cold

side of the turbo for leaks.

4. To inspect the “hot” or exhaust side of the turbo

for leaks, install the exhaust cone into the exhaust

pipe. Introduce smoke and inspect the exhaust,

the exhaust manifold, and the “hot” side of the

turbocharger.

To inspect the “hot” or exhaust side

of the turbo, install the exhaust cone

into the exhaust pipe.

15

Miscellaneous Leaks

Component Testing

(radiators, water pumps, valves, etc.)

When installing new or rebuilt parts, nothing is more

frustrating than to discover, on completion of the job,

that the component is faulty or has a leak. It is far easier

to inspect a radiator or water pump before it is installed

than to nd out later, after the antifreeze is added, that

there is a leak.

Component testing has endless possibilities; anything

from hoses to diaphragms can be tested. Supplied with

every LeakMaster are two exhaust cone adapters that

can be used to access any opening from 1" to 3-1/2".

Simply introduce smoke into the system being tested,

seal any interconnecting ports or passages, and look for

smoke to exit a leak.

Under-Dash Leaks

Under-dashboard leaks can be difcult to locate. The

LeakMaster can conrm or eliminate the possibility of

an under-dash leak in just minutes.

Most vehicles have a common vacuum supply line that

originates at the engine intake. This vacuum source

comes through the rewall to supply the climate control

functions, as well as other systems in the vehicle.

Vacuum systems under the dashboard are intended to be

closed systems; any ow through these systems would

indicate there is a leak present.

1. Set the control valve on the tester to TEST.

2.

Install the supply nozzle into the main vacuum line

(beyond the check valve) leading to the dashboard.

3. Introduce air into the system, and watch the ow

meter indicator ball. If the ball drops to zero, the

system is leak free.

4. Continue to introduce air into the system while testing

each setting on the climate control. Watch the ow

meter for any change of ow.

If the ow meter indicates ow in any of the positions

on the climate control, you will know what portion

of the system has a leak.

5. Set the control valve on the tester to SMOKE.

6. Introduce smoke into the system where a leak has

been determined. Shine the spotlight under the

dashboard, and look for smoke to pinpoint the leak.

Exhaust Cones

Tech Tips

Don’t forget that you may also identify leaks

by using an ultraviolet light (not supplied) to

look for traces of dye left behind by the smoke.

Theexitingsmokedepositsaresidualuidthat

is either bright green or bright yellow in color,

when viewed with a UV light.

16

Miscellaneous Leaks

Wind and Water Leaks

(sunroofs, windows, etc.)

The smoke diffuser was developed for quick

identication of air and water leaks in a vehicle’s

passenger compartment. These leaks can be caused

by faulty door and glass seals, windshield or sliding

roof seals, or by misalignment of any of these

components.

1. Park the vehicle to be tested indoors; avoid parking

in a windy environment.

2. Turn the ignition to the ACCESSORIES position.

3. Turn the heater/AC blower to FRESH AIR and

HIGH. (Verify the blower is NOT set to the

recirculation mode.)

4. Close the vehicle’s doors and windows. The

cabin of the vehicle is now under a slight positive

pressure.

5. Attach the smoke diffuser to the end of the tester’s

smoke nozzle.

6. Press the remote button.

7. From outside of the vehicle, position the tip of the

diffuser about 2 to 3 inches away from the vehicle,

and follow a path along the area you wish to test.

The smoke will linger on the path you are following

until a leak is present. The air exiting the vehicle

will cause the smoke to be disrupted, identifying

the source of the leak.

8. Once you nd a leak, mark its location with a wax

pencil or removable marker. Look for the cause of

the leak.

9. Turn the vehicle ignition OFF, and repair the

leak.

Diffuser

Attach the smoke diffuser to the

end of the tester’s smoke nozzle.

17

Maintenance

Dipstick

LOW

FULL

CAUTION: Use only the No. P-0716-UV

smoke-producing solution (obtained

from the manufacturer) in the LeakMaster.

Using solutions not recommended by the

manufacturer can damage the unit and cause

injury to the operator.

Checking the Smoke Solution Level

Check the smoke-producing solution in the tester

regularly, and top off the solution to the FULL mark.

(Order No. P-0716-UV.)

1. Remove the dipstick located on the back of the

tester and verify the solution level. Add solution,

if needed.

2. Install the dipstick, and then remove it again to

verify the solution level reads at the FULL mark

on the dipstick. Install the dipstick.

Replacing the Smoke Solution

We recommend changing the smoke-producing

solution in the tester at least once a year, regardless

of how often the tester has been used.

1. Remove the dipstick located on the back of the

tester.

2. Insert a suction tool into the dipstick tube,

and suction all the solution out of the smoke

chamber.

IMPORTANT: Do not damage the water

separator on the back of the tester.

3. Refull the smoke chamber by emptying 16 ozs. of

UltraTraceUV® smoke-producing solution (No.

P-0716-UV) into the smoke chamber through the

dipstick tube.

4. Install the dipstick, and then remove it again to

verify the solution level, which should read at the

FULL mark on the dipstick. Note:Donotoverll.

Install the dipstick.

5. Record your name and the date in the Fluid Change

Record in this manual.

6. Dispose of the waste smoke solution according to

local, state, and federal (OSHA) regulations.

18

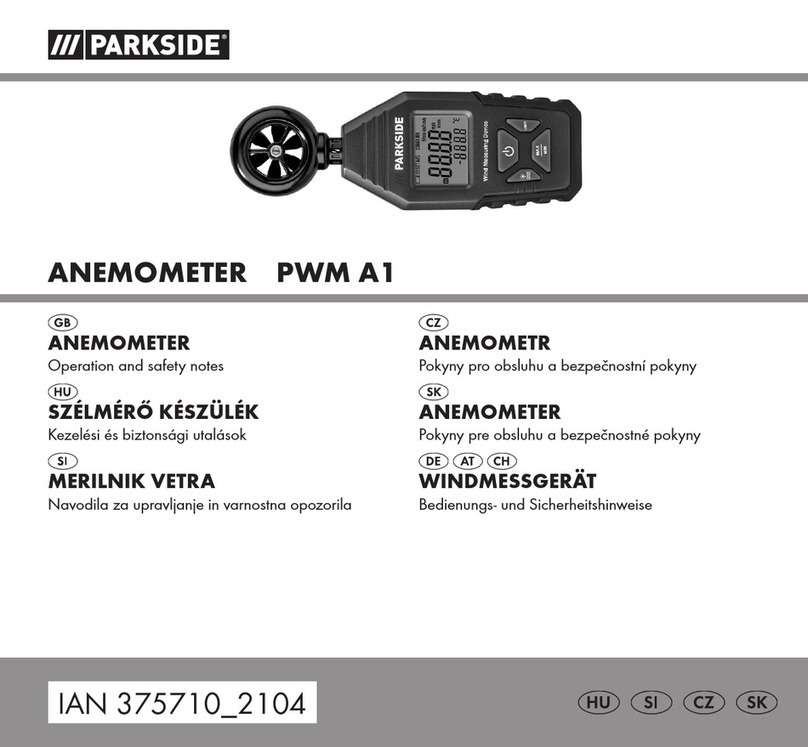

Parts List

2

3

1

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Item No. Part No. Qty. Description

1 6525-7 1 Remote Cable Assembly (includes switch)

2 6525-6 1 Remote ON/OFF (switch only)

3 6525-5 1 Battery Power Cable Assembly

4 CEA-041 1 Nitrogen Coiled Hose (25 ft.)

5 P-0716-UV 1 Smoke Producing Solution

6 6525-4 1 Water Trap w/ lter

7 CEA-049 1 Schrader Removal Tool

8 CEA-04 1 Standard Service Port Adapter

9 CEA-042 1 Small Service Port Adapter

10 CEA-03 1 Smoke Diffuser Adapter

11 CEA-01 1 Exhaust Cone (2 ea.)

12 CEA-02 1 Cap Plug Kit

13 HS-400AC 1 Halogen Spotlight

14 6525-2 1 Dipstick

15 6525-8 1 Brass Nozzle

16 6525-9 1 Brass Nozzle and Hose Assembly

17 6525-3 1 Pointer Flag (forowmeter)

Parts Included but Not Shown

6525-10 1 Rubber Feet (4 reqd.)

6525-11 1 Accessory Storage Bag

6525-12 1 Tech Tips Manual

107360 1 Operator’s Manual

Optional Parts Not Included

6625 1 EVAP Cart

6525-1 1 Pressure Regulator

19

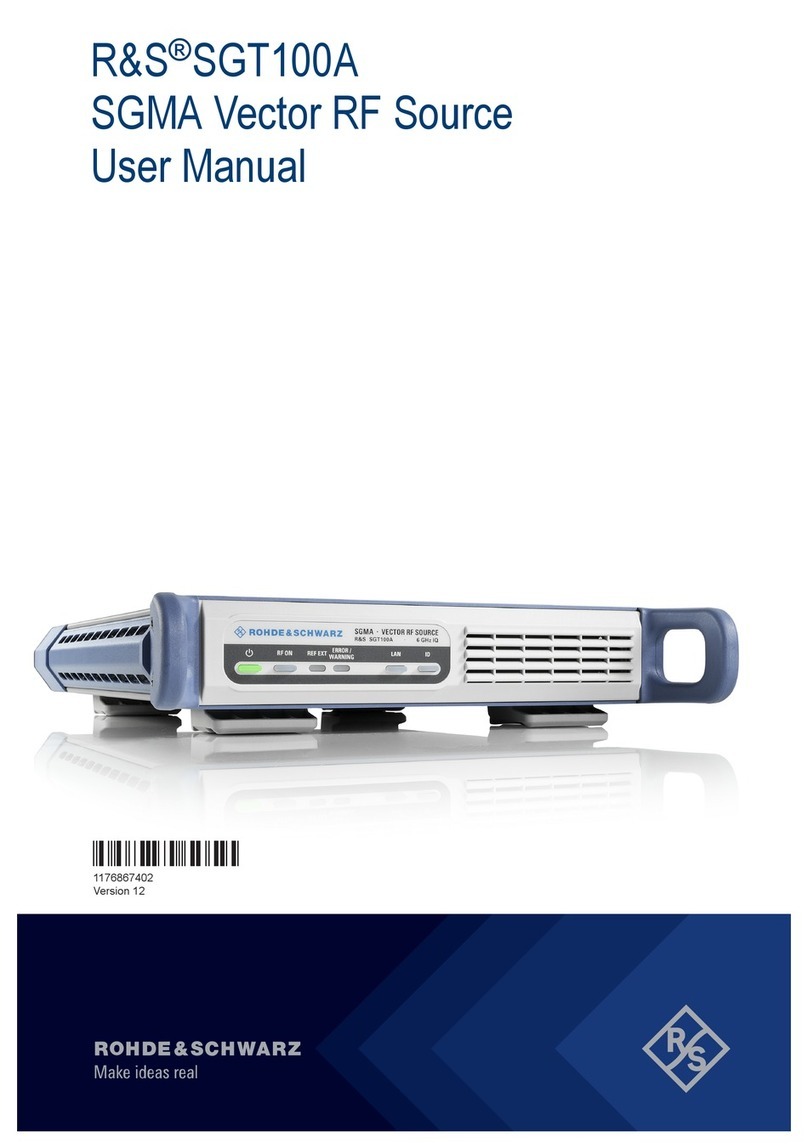

Troubleshooting

Diagnostic Lights

The LeakMaster has three diagnostic lights on the control panel that indicate if the tester is working correctly.

The following table describes the tester’s trouble codes.

Interval Probable Cause

√ Constant ON (switch in SMOKE position; smoke venting into atmosphere; Low oil

ow meter ball indicates ow)

√ Constant ON (switch in SMOKE position; system being tested; ow meter Normal temp. control function

ball near zero)

√ Occasionally blinks Normal temp. control function

√ ConstantON Sufcientpower

√ Blinkseveryone(1)second Insufcientpower

√ √ Blink simultaneously every one (1) second Power connection at battery is

loose or short in heating circuit

√ √ Blink simultaneously @ four (4) blinks per second Open heating circuit

√ √ Blink alternately @ one (1) blink per second Circuit board failure

j

j

Ifacircuitboardfailureoccurs,rsttrydisconnectingpowertotheunitfor10seconds;thenreconnectpower.Ifthisfailure

code occurs a second time during operation, disconnect the tester and contact the manufacturer.

Diagnostic Lights

Green

Red

Yellow

Troubleshooting Guide

Problem Cause Solution

Green power indicator lamp on

the tester does not come ON.

1. Power cables are reversed.

2. Poor power supply cable

connection.

3. Battery providing power is too

weak.

1. Correctly position the power cables.

2. Secure the connection at positive

terminal and chassis ground.

3. Verify battery is in good condition

and fully charged.

Smoke does NOT come out of

the fuel neck area when lling

the system with smoke during

Phase Two.

1. Fuel tank level is too high and is

blocking the fuel neck passage.

2. Vehicle has a roll-over valve

preventing pressure relief through

the tank neck.

1. Reduce the fuel level in the tank so it

is below the base of the fuel tank neck.

2. Introduce smoke from the fuel tank;

or if possible, disable the roll-over

valve;orpartiallyllthesystemwith

smoke before closing the vent solenoid.

Tester is ON, but NO smoke or

air coming out of hoses.

1. Poor power supply cable

connection.

2. Battery providing power is too

weak.

3. Tester’s internal solenoid is

stuck closed.

1. Secure the connection at positive

terminal and chassis ground.

2. Verify battery is in good condition

and fully charged.

3. Disconnect the air or nitrogen quick-

release at the tester’s water separator,

and then reconnect it.

Table of contents

Other SPX Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Bosch

Bosch Professional GLM 50-22 Original instructions

POSITAL

POSITAL ACS-080 manual

Svantek

Svantek SV105 instruction manual

Desco

Desco Statguard Flooring D19290 Installation, operation and maintenance

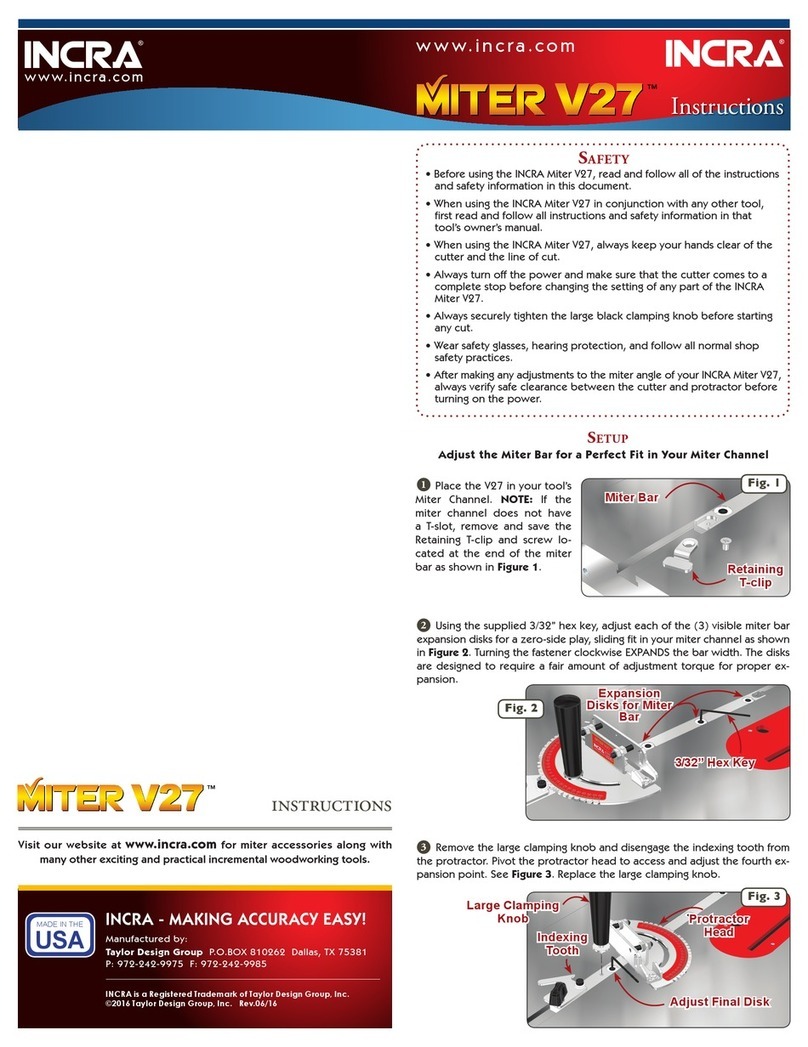

Incra

Incra V27 instructions

VERIS INDUSTRIES, INC.

VERIS INDUSTRIES, INC. E31E Series installation guide