SPX 300 Series User manual

300 Series

Compressed Air Filters

Models 302 (grade) through 317 (grade)

FORM NO.: 3259480 REVISION: 01/2014 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

General Safety Information

1.

Pressurized devices

• Do not exceed maximum operating pressure

indicatedonserialnumbertag.

• Makecertainlterisfullydepressurizedbefore

servicing.

2.

Breathing Air

• Air treated by this equipment may not

be suitable for breathing without further

purication.RefertoOSHAstandard1910.134

forbreathingairrequirements.

3.

Flammable gases

Whilethematerialsofconstructionarecompatible

with many flammable gases, the following

applicationlimitationsmustbeconsidered:

• Housing materials are slightly porous. The

productmustbeusedinawellventilatedarea

in the absence of sparks or ignition sources.

Do not use in Class 1, Division 1, Group D

environments.

• Thetypeofarea-forcedexhaustsystemused

(i.e.,highorlowlevel)wouldbedependenton

thegasinvolved.

• Eachapplication(otherthanforairorinertgas)

mustbereviewedtominimizereorexplosion

hazard.

Contents

ModelNumberConguration............................... 1

1.0 Installation....................................................... 2

2.0 Operation......................................................... 5

3.0 Maintenance.................................................... 7

DimensionsandWeights....................................... 8

WARRANTY............................................................. 9

1

Grade Identification

Filtergradecanbeidentiedbytheendcapcolorandmodelnumberprintedonthebottomendcap.

Grade Description Type End Cap Color

S3 Separator/filter Liquid separator and 3 micron coalescer Orange

P3 General purpose air line filter 1 micron coalescer White

H3 High efficiency oil removal filter High efficiency (99.99+%) coalescer Green

U3 Maximum efficiency oil removal filter Maximum efficiency (99.999+%) coalescer Yellow

C3 Oil vapor removal filter Activated carbon adsorber Black

Model Number Configuration

3(1) – (2) – (3)

( 1 ) Housing-Connection-Flow

Model* Connection Flow @

100 psig

Flow @

6.9 bar

in scfm nm3/h

02 1/4" 20 34

03 3/8" 35 59

04 1/2" 50 85

06 3/4" 75 127

07 3/4" 103 175

08 1.0" 157 267

10 1.5" 257 437

11 1.5" 360 612

12 2.0" 401 681

13 2.5" 584 993

14 2.5" 775 1317

15 2.5" 1030 1750

16 3.0" 1200 2039

17 3.0" 1500 2549

* BSP threads are available. Add B to the model number. Example 302B-S3-DP1

( 2 ) Element Grade

S3 Bulk Liquid Removal

P3 Particulate Removal

H3 Oil Removal

U3 High Efficiency Oil Removal

C3 Oil Vapor Removal

( 3 ) Options

TManual Drain

DInternal Automatic Drain

P1 Differential Pressure Slide Indicator

G1 Differential Pressure Gauge

MElectronic Filter Monitor

XExternal Drain Adaptor (02-12)

Z1* Electric Demand Drain (02-12)

Z2* Electric Demand Drain (13-17)

WExternal Mechanical Drain (13-17)

* Z1 and Z2 electric demand drain: Voltage 115 VAC 50-60 Hz

Example: 302-S3-DP1

Flow and Connection: 20scfm(34nm3/h);1/4"NPT

Element Grade: S3-bulkliquidremoval

Options:Internalautomaticdrain;differentialpressureslideindicator

2

1.0 Installation

A.

Where Used/Air Quality After Filtration

Grade Where used

Solid particle

removal (maximum

size in microns)

Particle removal

efficiency (at

rated conditions)

Oil removal

efficiency (at

rated conditions)

Remaining

oil content

(mg/m3)

S3 Separator - downstream of an aftercooler

Point-of-use - where no aftercooler/separator is

installed upstream

3 — 50% 5

P3 Prefilter

•UpstreamtoGradeH3&GradeU3-high

efficiency oil removing filters

•Upstreamofrefrigerateddryers

Afterfilter

•Downstreamofheatlessdesiccantdryers

Point-of-use - if aftercooler/separator is installed

upstream

1 99.999+% 80% 2

H3 Prefilter

•Upstreamofdesiccantdryers

Afterfilter

•Downstreamofrefrigerateddryer

Point-of-use - if aftercooler/separator is installed

upstream

0.01 99.999+% 99.9+% 0.01

U3 Prefilter

•Upstreamofdesiccantdryers

•Upstreamofmembranedryers(useaP3Grade

if heavy liquid loads are present)

Afterfilter

•Downstreamofrefrigerateddryers

0.01 99.9999+% 99.99+% 0.001

C3 AfterltertoGradeH3&GradeU3fortrueoilfree

applications

0.01 99.999+% — < 0.004

vapor

3

B.

Piping

(1) Beforeinstalling,blowoutpipelinetoremove

scaleandotherforeignmatter.

(2) Thelter hasDRYSEALpipethreads;usepipe

compoundorTeon™tapesparinglytomale

threadsonly.

(3) Mountsothatinletandoutletconnectionsare

horizontal(lterbowlvertical)toensureproper

liquiddrainage.

(4) FlowDirection-installsothattheairowisin

thedirectionofarrowsonthelterhead.

(5) Direct lter-to-lter (modular) connection -

Filterheadsmaybejoinedwithoutusingapipe

nipple.

(6) Isolationvalves andby-passpiping -For ease

of service, isolation and by-pass valves are

desirable. In critical applications, two lters

installedinparallelmaybenecessarytoavoid

interruptionofairsupply.

NOTE:Allgradesowfrominsidetooutsidethe

element.Observeowarrowsoncap.

C.

Wall Mount Bracket

(1) Mount bracket as shown on wall or other

structureusingtheholesprovidedontheback

(hardwarenotincluded).

(2) Set lter on bracket, resting inlet and outlet

nozzlesonthecurvedportions.

(3) Insert two U bolts (supplied) as shown in

Figure1.1throughtheholesinthebracket.

(4) Add4nuts(supplied)totheUboltsandtighten

untilsnug.

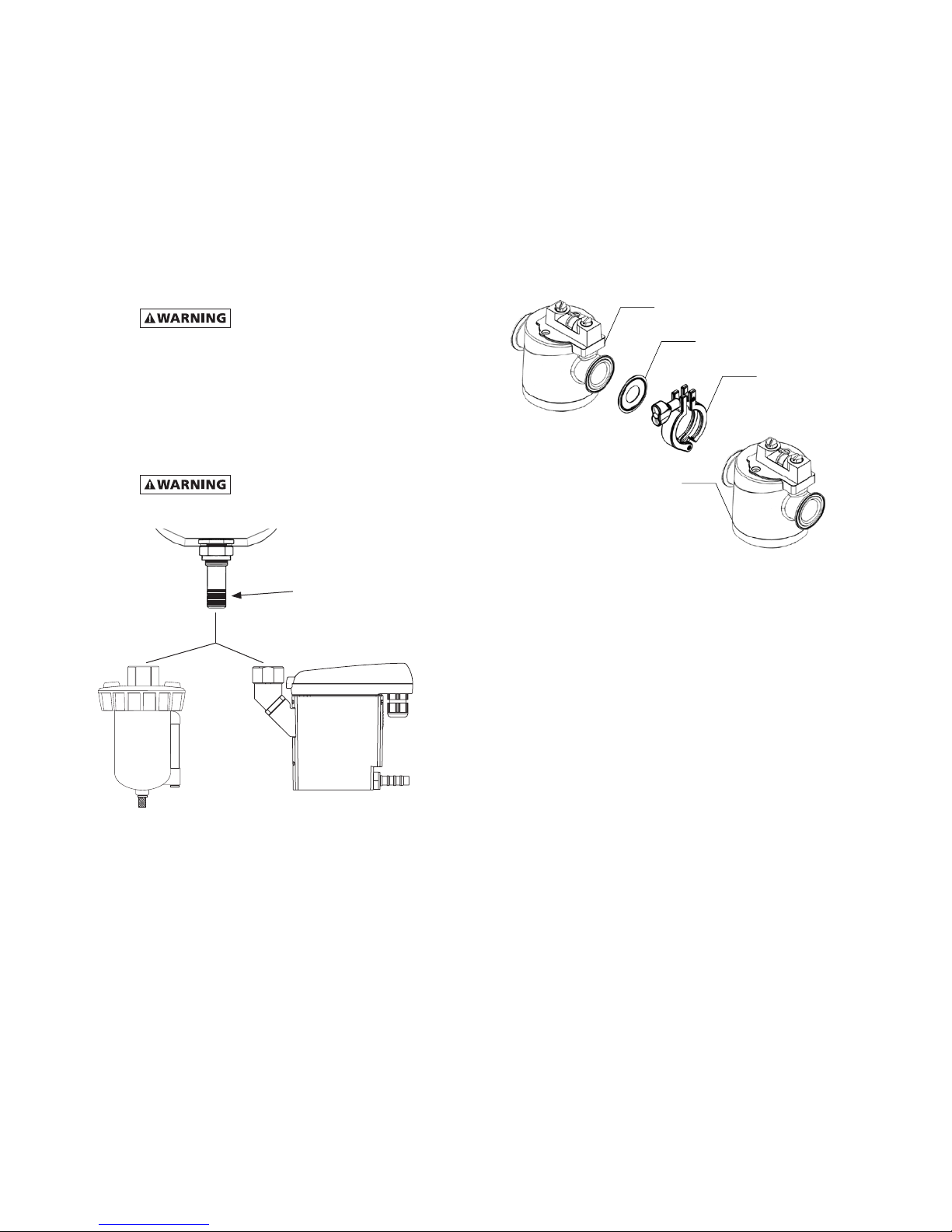

Figure 1.1

UBolts

FilterHead

WallBracket

Nuts

D.

Differential Pressure Gauge Mounting to

Filter Head (Figure 1.2)

(1) MakecertainO-ringsareinplaceonthebottom

ofthegaugebody.

(2) Connect the low pressure transmission bolt

(boltnexttotheredbandontheindicator)to

theportatthelteroutlet(downstreamside

oflter).

(3) Connect the high pressure transmission bolt

(boltnexttotheGreenbandontheindicator)

totheportatthelterinlet(upstreamsideof

thelter).

(4) Useacoinoraatheadscrewdrivertotighten/

loosenbolts.Thetipwidthifthescrewdriver

shouldbeatleast3/8inch(9.5mm).Torque

boltsto25±5inch-oz.DO NOT OVER TIGHTEN

Figure 1.2

4

E.

Drain Provisions

(1) InternalAutomaticDrains–DrainLine

The bottoms of internal automatic drains

are provided with 1/8" (inside threads) for

connectionofadrainlineifdesired.

(2) ExternalAutomaticDrains–

External automatic drains may be added as

follows:

(a) Models302through312–removeinternal

drain and install adaptor (available from

factory).Adaptoroutletconnectionis1/8"

(insidethreads).

Discharge is at system

pressure,anchordrainline.

(b) Models313through317–removeplugfrom

external drain adaptor tting at bottom

of bowl. The 1/2" (male threads) port is

available for external drain connection.

Filter may be drained with an electrical

demanddrain,ormechanically.

Do not attempt to remove

drainplugifunitispressurized.

Figure 1.3

1/2"NPT

DrainConnection

F.

Connector Clamps

(1) Aligntheclampgasketwiththeoutletange

onFilter#1makingsureitsiscenteredonthe

angegroove.

(2) Align the inlet ange from Filter #2 with the

clampgasketandFilter#1.

(3) Opentheclampassemblyandcenteritbetween

thetwolters.

(4) Closetheclampassemblyandtightenthewing

nutcompressingthegasketbetweenthetwo

lters.

Filter #1

Filter #2

Clamp

Clamp Gasket

Figure 1.4

5

2.0 Operation

Do not operate filter at pressures in

excessofMaximumWorkingPressureindicatedonSerial

NumberTag.

NOTE:MaximumOperatingTemperature-150°F(66°C).

Liquidltrationabove120°F(49°C)isnotrecommended

sincethereistypicallyoilpresentinavaporstatewhich

passesthroughthelterandcondensesdownstream.

NOTE:GradeC3-Ifoperatedabove100°F(38°C)may

experience less than 1000 hours of life because of

greateroilvaporcontent.

A.

Liquid Draining - Grades S3, P3, H3, and U3

NOTE: Collected liquids must be removed to ensure

properoperation.

NOTE: Depressurize slowly, to avoid filter element

damage.

1. ManualDrain-Turntotheright(clockwise)toopen

andtotheleft(counterclockwise)toclose.

2. AutomaticDrain-Liquidswillautomaticallydischarge

whensufcientaccumulationoccurs.

a) InternallyMountedAutoDrains-Thesedrains

maybemanuallydrainedbyturningtotheright

(clockwise) to open and to the left (counter-

clockwise)toclose.

NOTE:Manuallydraininternalautodrainsdailytoverify

drainfunction.

Figure 2.1

OPEN ( TO RIGHT )

B.

Operational Checkpoints

All Grades

Checkow,pressure,andtemperaturetomakecertain

lterisbeingoperatedwithindesignconditions.

Grades S3, P3, H3, and U3

Checkpressuredropacrossthelter

1. Pressuredifferentialinexcessof4.3psid(0.3bar)

- pressure indicator in red area - indicates that

thelterelementshouldbereplaced.Reference

page8,Figure3.3forgaugescaledetail.

NOTE:Elementshouldbechangedannuallyorwhen

indicatorchangestored,whicheveroccursrst.

NOTE: Pressure drop should never exceed 50psi

(3.4bar).

2. Checkforsuddenreductioninpressuredrop.This

mightindicate:

a. Possibleleakacrosselemento-ringseal.

b. Leak through the element due to physical

damage.

Grades S3, P3, H3, and U3

1. Checkto seethat lterisinstalled levelto insure

properdrainage.

2. Checkthatmanualdrainsaredrainedperiodically

orthatautomaticdrainsarefunctioning.

Grade C3 (Adsorber filter)

1. Checkforanoillikesmellbyopeningthemanual

valve.Ifanoilysmellexists,thefollowingshouldbe

checked:

a. Filterelementadsorptioncapacityexhausted.

b. Leakacrosselemento-ringseal.

c. Leakthroughelementduetophysicaldamage.

d. Presenceofliquidsbecauseoflackoforfailure

ofprelters.

e. Flow,pressureandtemperaturesoutsidedesign

conditions.

f. Presenceofgaseousimpuritieswhichcannot

beadsorbed.

Methane, carbon monoxide, carbon

dioxideandvariousinorganicgasescannotberemoved

byanactivatedcarbonlter.

6

Table 1 -

Maximum Flow @100 psig [6.9 bar]

Housing scfm

[nm3/h]

302 20

[34]

303 35

[59]

304 50

[85]

306 75

[127]

307 103

[175]

308 157

[267]

310 257

[437]

311 360

[612]

312 401

[681]

313 584

[993]

314 775

[1317]

315 1030

[1750]

316 1200

[2039]

317 1500

[2549]

Table 2 -

Air Flow Correction Factor

Inlet

Pressure

psig

20 30 40 60 80 100 120 150 200 250

bar

1.4 2.1 2.8 4.1 5.5 6.9 8.3 10.3 13.8 17.2

Correction Factor

0.30 0.39 0.48 0.65 0.83 1.00 1.17 1.44 1.87 2.31

C.

Flow Capacity

Maximum air ow for the various lters at 100psig

(6.9bar)isindicatedinTable1.Todeterminemaximum

airowsatinletpressuresotherthan100psig(6.9bar),

multiply flow from Table 1 by air flow correction

factorfromTable2thatcorrespondstotheminimum

operatingpressureattheinletofthelter.

NOTE:Filtersshouldnotbeselectedbypipesize.Select

usingowrateandoperatingpressureonly.

7

3.0 Maintenance

A.

When to Replace Filter Element

NOTE:GradesS3,P3,U3,H3,C3-completeelementis

replaced;

1. GradesS3,P3,U3,H3

a. Operating pressure drop: As lter becomes

liquid loaded (wetted), pressure drop will

increase. Further pressure drop occurs as

elementloadswithsolidparticles.

FOR MAXIMUM FILTRATION EFFICIENCY, REPLACE

ELEMENT WHEN PRESSURE DROP REACHES 4.3PSID

(0.3BAR) (INDICATOR IN RED AREA) OR ANNUALLY,

WHICHEVEROCCURSFIRST.

NOTE: Pressure drop may temporarily increase when

ow is resumed after ow stoppage. Pressure drop

shouldreturntonormalwithinonehour.

2. GradeC3-Oilvaporremovallter

a. Adsorption capacity - 1000 hours at rated

capacity.Elementlifeisexhaustedwhenodor

canbedetecteddownstreamofthelter.

B.

Procedure for Element Replacement

WARNING: THIS FILTER IS A PRESSURE CONTAINING

DEVICE.DEPRESSURIZEBEFORESERVICING.Iflterhas

notbeendepressurizedbeforedisassembly,anaudible

alarmwillsoundwhenthebowlbeginstoberemoved

fromthehead.Ifthisoccurs,stopdisassembly,isolate

andcompletelydepressurizelterbeforeproceeding.

1. Isolatelter(closeinletandoutletvalvesifinstalled)

orshutoffairsupply.

2. Depressurizelterbyslowlyopeningmanualdrain

valve.

3. Removebowl.

a. Unscrew the bowl from the lter head using

hand, strap wrench or C spanner. Pull bowl

straightdown.

4. Cleanlterbowl.

5. Replaceelement.

a. Replacingcompleteelement.

1) Pulloffoldelementanddiscard.

2) Makecertainthattheoldandnewelement

havethe same part number andthe end

capsarethesamecolor.

3) Wipe the wall inside the filter head to

removeanydirt.

4) Lubricate the new element o-ring on the

elementtopcap.

5) Aligntheslotintheelementtopcapwith

theprojectioninsidethelterhead.

Figure 3.1

6) Insert the element into the head making

sure the element slot and the projection

insidethelterheadremainaligned.

NOTE:Handleallelementsbybottomendcap

only.

6. Replace housing o-ring (located at the top of

thelter bowl) if needed. Make certaino-ring is

generouslylubricated(Uselubricantprovided).

7. Reassemblebowltohead.

NOTE:Threadedbowltoheadconnection,generously

lubricate threads with a high grade/temperature

lubricant150°F(66°C).(Uselubricantprovided)

C.

Auto Drain Mechanism

It is recommended that drain mechanism be

replacedannually.

Projection

ElementSlot

O-Ring

8

Dimensions and Weights

Model

Number

Max. Flow

@ 100 psig

(6.9 bar)

Connections Dimensions Weight

'A'

Width

'B'

Height

'C'

Height

'D'

Bowl Clearance

scfm nm3/h NPT in mm in mm in mm in mm lbs kg

302 20 34 1/4" 4.5 114 8.1 206 6.8 173 4.0 102 1.8 0.8

303 35 59 3/8" 4.5 114 8.1 206 6.8 173 4.0 102 1.8 0.8

304 50 85 1/2" 4.5 114 9.9 252 8.5 216 4.0 102 1.9 0.9

306 75 127 3/4" 5.2 132 10.3 262 8.7 221 5.0 127 3.1 1.4

307 103 175 3/4" 5.2 132 10.3 262 8.7 221 5.0 127 3.1 1.4

308 157 267 1.0" 5.2 132 12.8 325 11.7 297 5.0 127 3.5 1.6

310 257 437 1.5" 7.9 201 13.3 338 10.9 277 7.0 178 8.4 3.8

311 360 612 1.5" 7.9 201 17.1 434 14.7 373 7.0 178 9.9 4.5

312 401 681 2.0" 7.9 201 22.3 564 19.9 506 7.0 178 11.6 5.3

313 584 993 2.5" 9.1 231 24.9 633 21.7 551 8.0 203 18.6 8.4

314 775 1,317 2.5" 9.1 231 24.9 633 21.7 551 8.0 203 18.6 8.4

315 1,030 1,750 2.5" 9.1 231 32.2 818 28.9 734 8.0 203 27.7 12.6

316 1,200 2,039 3.0" 9.1 231 32.2 818 28.9 734 8.0 203 27.7 12.6

317 1,500 2,549 3.0" 9.1 231 42.7 1,085 39.4 1,001 8.0 203 41.3 18.7

NOTE:DimensionsandWeightsareforreferenceonly.Requestcertieddrawingsforconstructionpurposes.

Figure 3.2

Figure 3.3

Differentialpressuregaugeandslideindicator–

changeelementwhenindicationisintheredzone.

INLET OUTLET

CLEARANCE

FOR SERVICING

'D'

'C'

1" (26 mm)

'B'

'A'

INLET OUTLET

'A'

'D'

'C'

'B'

CLEARANCE

FOR SERVICING

2.3" (58.4 mm)

9

SERVICE DEPARTMENT: (724) 746-1100

WARRANTY

Themanufacturerwarrantstheproductmanufacturedbyit,whenproperlyinstalled,operated,applied,andmaintained

inaccordancewithproceduresand recommendationsoutlinedinmanufacturer’s instructionmanuals,tobefreefrom

defectsinmaterialandworkmanshipforaperiodofone(1)yearfromdateshipmenttothebuyerbythemanufacturer

ormanufacturer’sauthorizeddistributorprovidedsuchdefectisdiscoveredandbroughttothemanufacturer’sattention

withintheaforesaidwarrantyperiod.

Themanufacturerwillrepairorreplaceanyproductorpartdeterminedtobedefectivebythemanufacturerwithinthe

warrantyperiod,providedsuchdefectoccurredinnormalserviceandnotasaresultofmisuse,abuse,neglectoraccident.

Normalmaintenance itemsrequiringroutine replacementarenotwarranted.The warrantycovers parts and laborfor

thewarrantyperiod.Repairorreplacementshallbemadeatthefactoryortheinstallationsite,atthesoleoptionofthe

manufacturer.Anyserviceperformedontheproductbyanyoneotherthanthemanufacturermustrstbeauthorizedby

themanufacturer.

Unauthorizedservicevoidsthewarrantyandanyresultingchargeorsubsequentclaimwillnotbepaid.Productsrepaired

orreplacedunderwarrantyshallbewarrantedfortheunexpiredportionofthewarrantyapplyingtotheoriginalproduct.

Theforegoingistheexclusiveremedyofanybuyerofthemanufacturer’sproduct.Themaximumdamagesliabilityofthe

manufactureristheoriginalpurchasepriceoftheproductorpart.

THEFOREGOINGWARRANTYISEXCLUSIVEANDINLIEUOFALLOTHERWARRANTIES,WHETHERWRITTEN,ORAL,ORSTATUTORY,

ANDISEXPRESSEDINLIEUOFTHEIMPLIEDWARRANTYOFMERCHANTABILITYANDTHEIMPLIEDWARRANTYOFFITNESSFOR

APARTICULARPURPOSE.THEMANUFACTURERSHALLNOTBELIABLEFORLOSSORDAMAGEBYREASONOFSTRICTLIABILITY

INTORTORITSNEGLIGENCEINWHATEVERMANNERINCLUDINGDESIGN,MANUFACTUREORINSPECTIONOFTHEEQUIPMENT

OR ITS FAILURE TO DISCOVER, REPORT, REPAIR, OR MODIFY LATENT DEFECTS INHERENT THEREIN. THE MANUFACTURER,

HISREPRESENTATIVEORDISTRIBUTORSHALLNOTBELIABLEFORLOSSOFUSEOFTHEPRODUCTOROTHERINCIDENTALOR

CONSEQUENTIALCOSTS,EXPENSES,ORDAMAGESINCURREDBYTHEBUYER,WHETHERARISINGFROMBREACHOFWARRANTY,

NEGLIGENCEORSTRICTLIABILITYINTORT.

Themanufacturerdoesnotwarrantanyproduct,part,material,component,oraccessorymanufacturedbyothersand

soldorsuppliedinconnectionwiththesaleofmanufacturer’sproducts.

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL

IS RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

300 SERIES

Compressed Air Filters

Models 302 (grade) through 317 (grade)

SPX

1000 Philadelphia Street

Canonsburg, PA 15317-1700 U.S.A.

P: (724) 745-8647

F: (724) 745-4967

www.deltech-spx.com

Improvements and research are continuous at SPX.

Specifications may change without notice.

ISSUED 01/2014 Form No.: 3259480 Revision: C

COPYRIGHT ©2014 SPX Corporation

Table of contents

Other SPX Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Crystal Quest

Crystal Quest CQE-RC-00808 Installation and operation guide

RZ AIRflow

RZ AIRflow 10048 user guide

3M

3M Aqua-Pure AP902 Installation and operating instructions

AquaCo

AquaCo SYS -ROCOMP manual

Riello

Riello BAG2 MIX CLIMA INSTRUCTIONS FOR THE INSTALLER AND THE TECHNICAL ASSISTANCE SERVICE

SMC Networks

SMC Networks FH100 Series Operation manual