Contents

Legal Information............................................................................................5

Safety Information...........................................................................................6

Recycling.........................................................................................................7

Preface.............................................................................................................8

Specifications..................................................................................................9

Feed Water Specifications..........................................................................................10

Product Water Specifications......................................................................................11

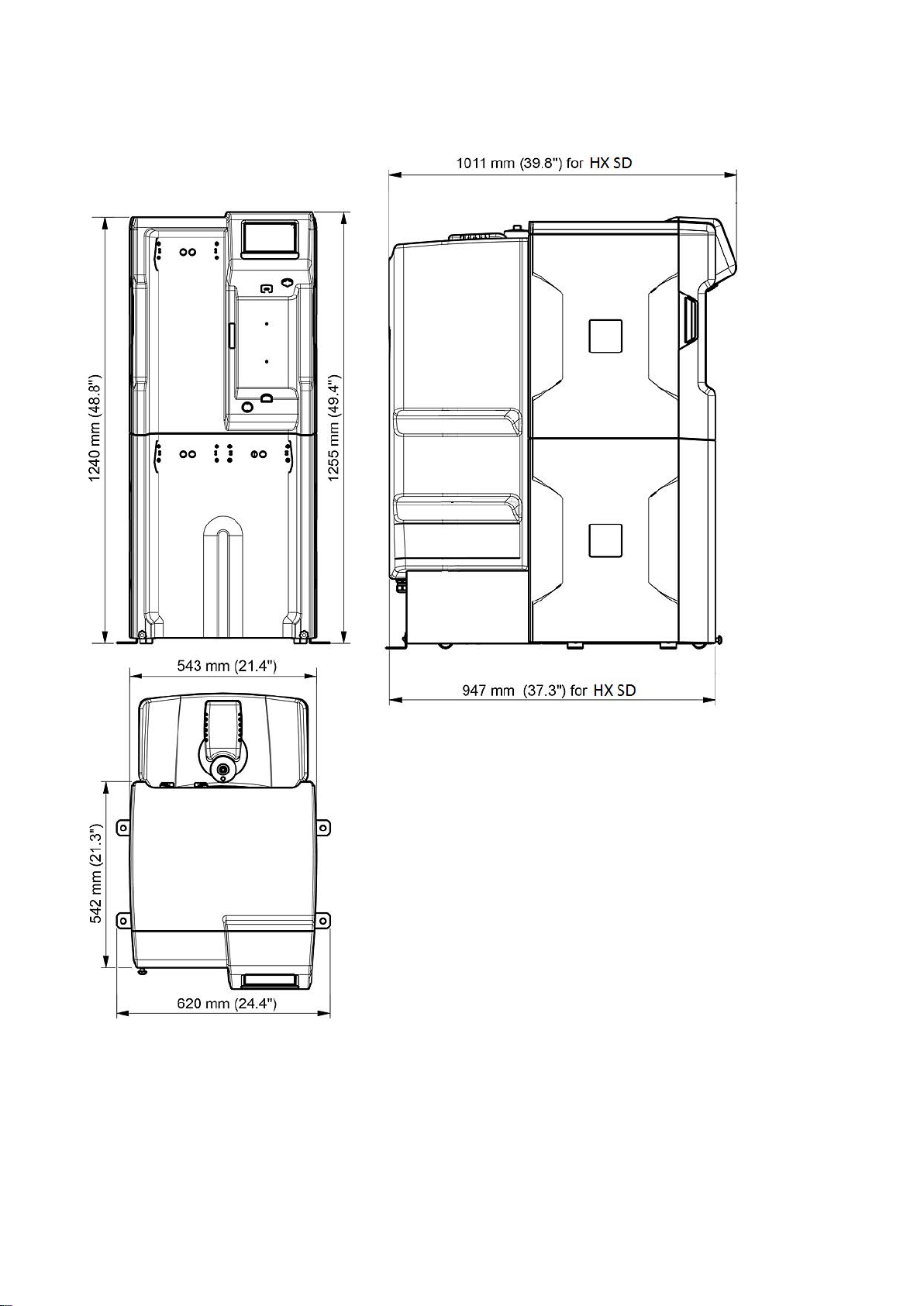

System Dimensions....................................................................................................12

Weight Specifications..................................................................................................13

Electrical Specifications..............................................................................................14

Environmental Specifications......................................................................................15

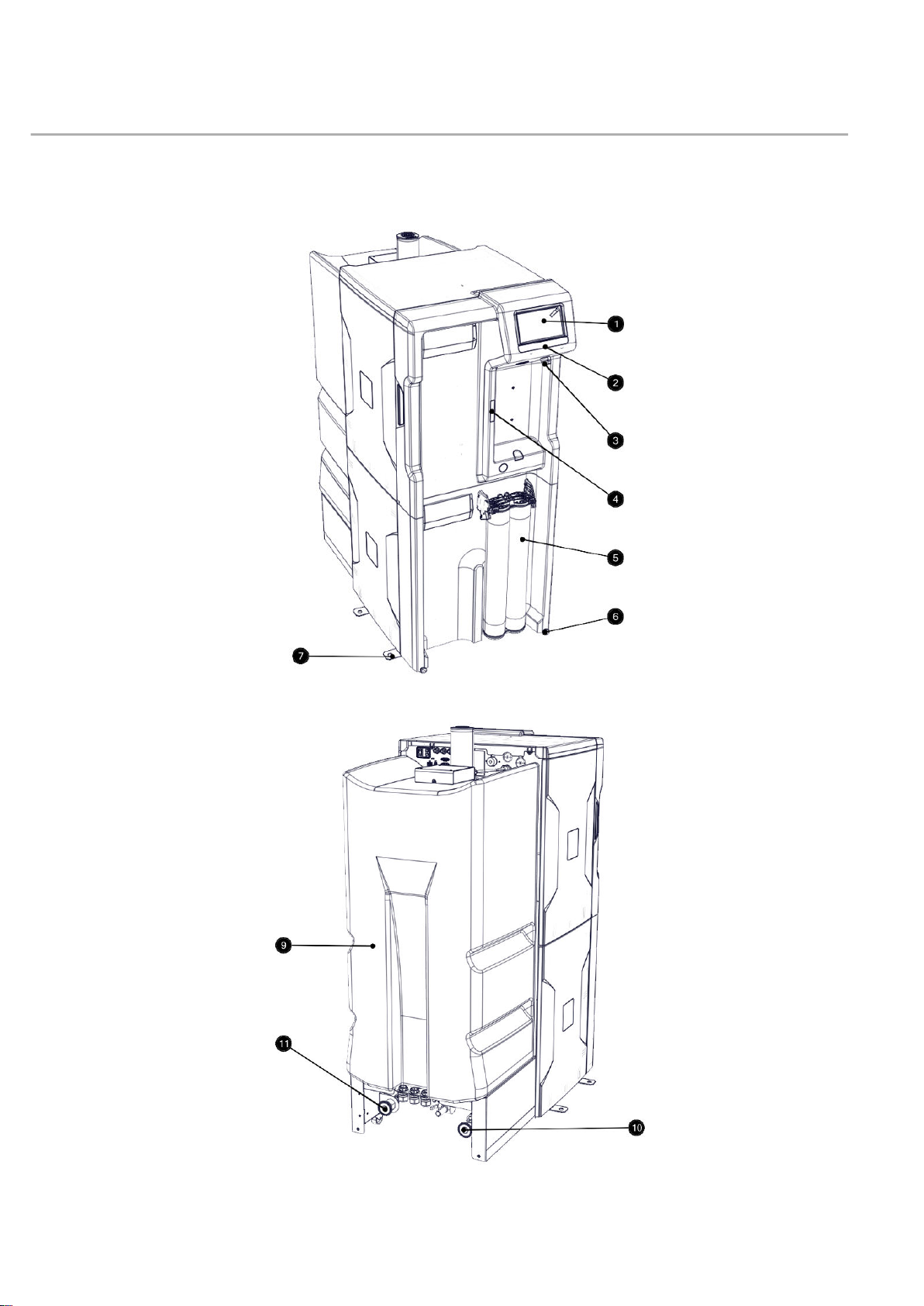

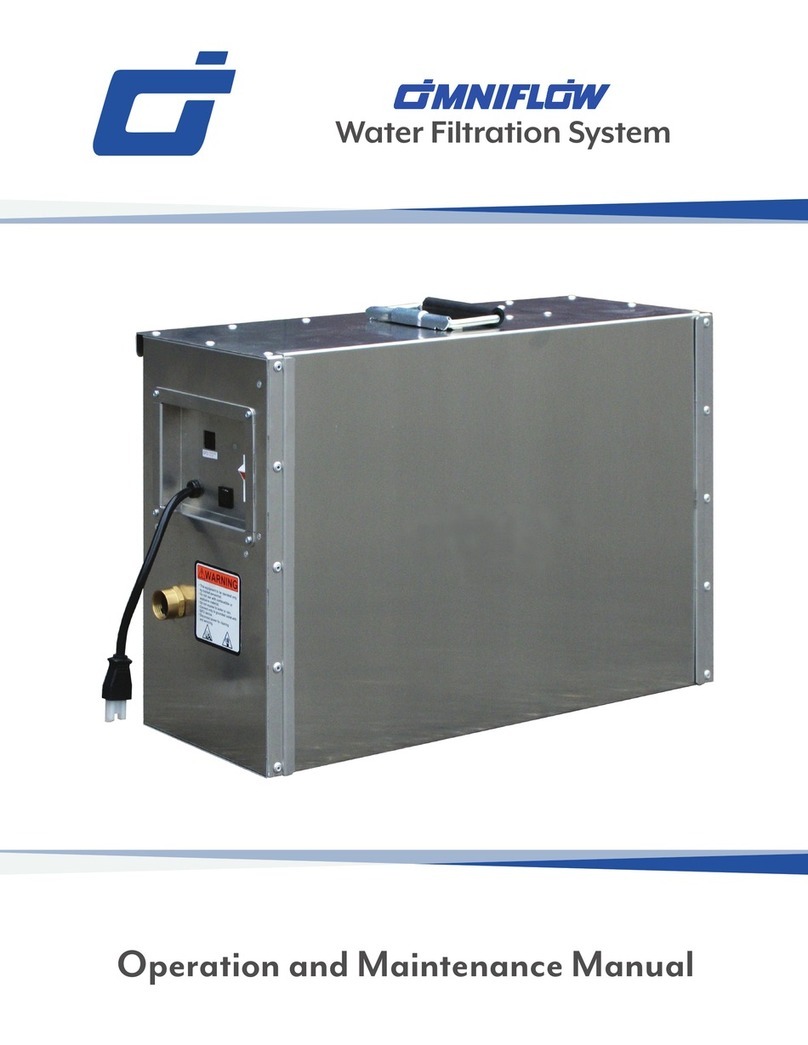

System Overview.......................................................................................... 16

Operating Principle .................................................................................................... 18

System Display..............................................................................................19

How to Navigate Between Overview and Workspace Screens.................................. 20

Overview Screen.........................................................................................................21

How to Change the System from Standby to Ready.................................................. 25

Workspace Screens....................................................................................................27

Glance Workspace.............................................................................................28

Maintenance Workspace................................................................................... 32

Configuration Workspace...................................................................................34

How to View Hidden Applications......................................................................38

Alarms and Alerts - Definition..................................................................................... 39

How to Acknowledge Alarms and Alerts............................................................40

Screensaver................................................................................................................42

Maintenance.................................................................................................. 43

How to Use Maintenance Wizard................................................................................44

RO Cleaning tools.......................................................................................................46

RO Cleaning............................................................................................................... 47

Loop Filter (Opticap) option on distribution loop.........................................................48

How to replace (install) Loop Filter............................................................................. 49

Communication Ports & Software...............................................................52

How to Change the Network Configuration.................................................................54

How to Power On and Power Off the Water System..................................56

How to Use the Distribution Schedule........................................................57

Contents | 3