Page 10English Manual 1019621-A

Use and Care

!READ BEFORE USING

GENERAL OPERATION &

MAINTENANCE

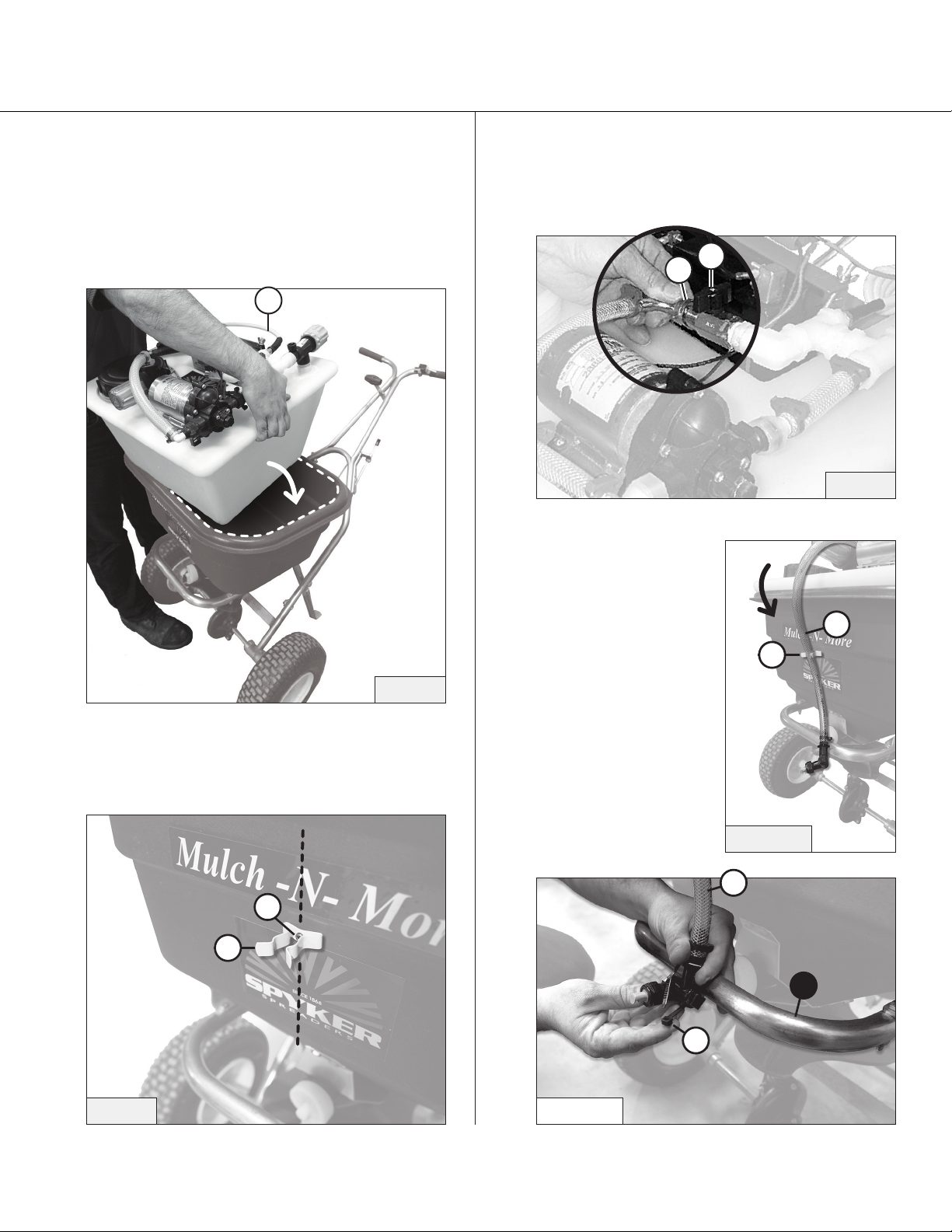

The sprayer pump is turned on and off by the thumb

switch mounted on the handlebar of the spreader. The

hand spray wand is activated by closing the ball valve on

topofthetanktoturnoffowtothefrontnozzle.

To drain the tank of unused liquids, remove the spray tip

from the wand and pump the remaining liquid into the

proper receptacle.

• Cleanpumplterdaily.

• Preventfromfreezing.

• Cleantipscreenregularly.

• Flushwithwateraftereachuse.

BATTERY RECHARGING

The SPYDSS-9G’s battery is a sealed,

maintenance-free 12-volt battery.

Charging at a low rate (3 amp max.) with an automotive

quality battery charger will extend battery life.

A 110-volt powered plug-in battery charger is available

as an optional accessory to recharge the battery when

not in use. The battery can also be recharged by the

service truck’s charging system by using the optional

vehicle charging kit.

INITIAL START-UP

& PRESSURE TESTING

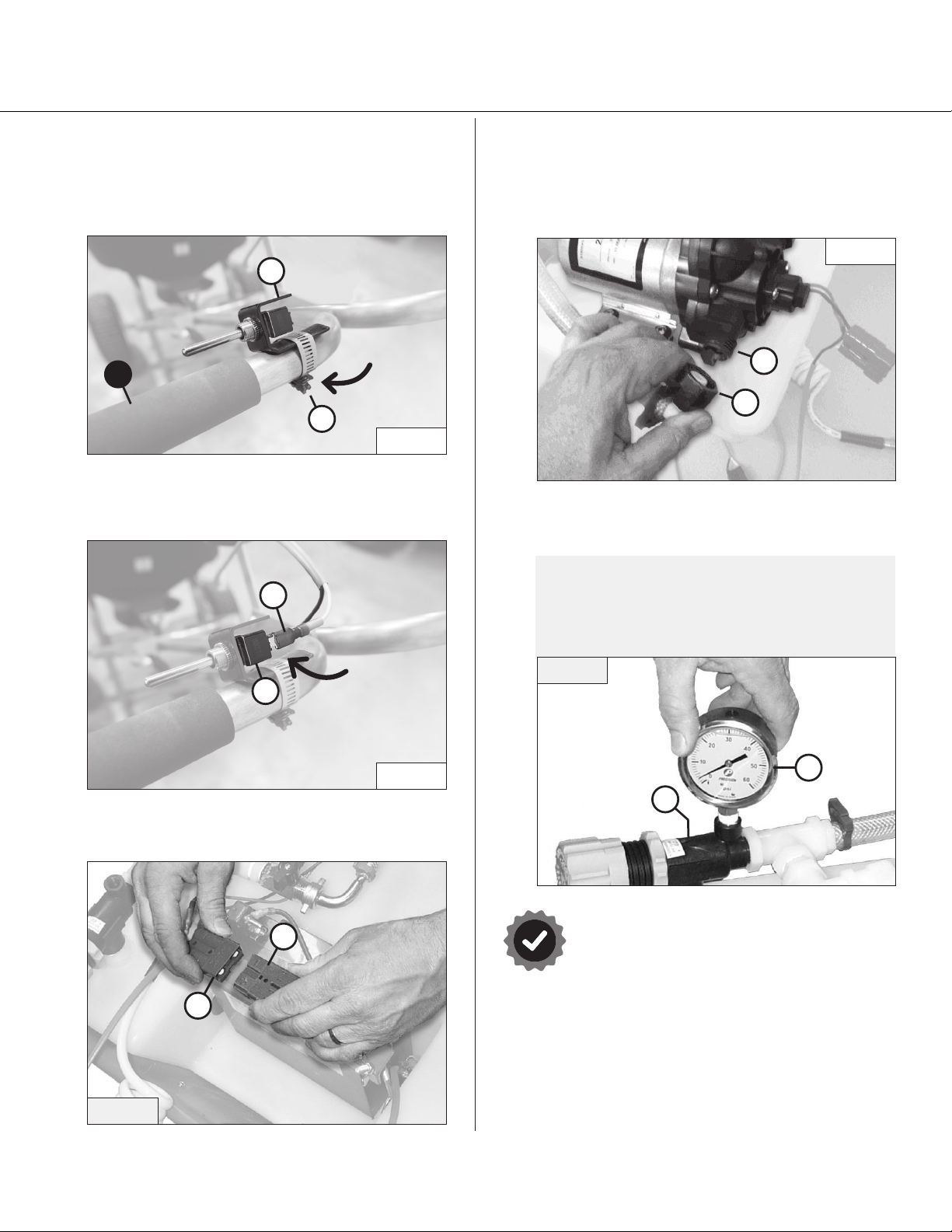

1. Turn the pressure regulator knob counter-clockwise

all the way.

2. Put about one gallon of water in the tank for testing.

3. Be sure that the spray line valve is turned off.

4. Turn on the handlebar thumb switch. You should hear

the pump running and see water moving through the

hoses.

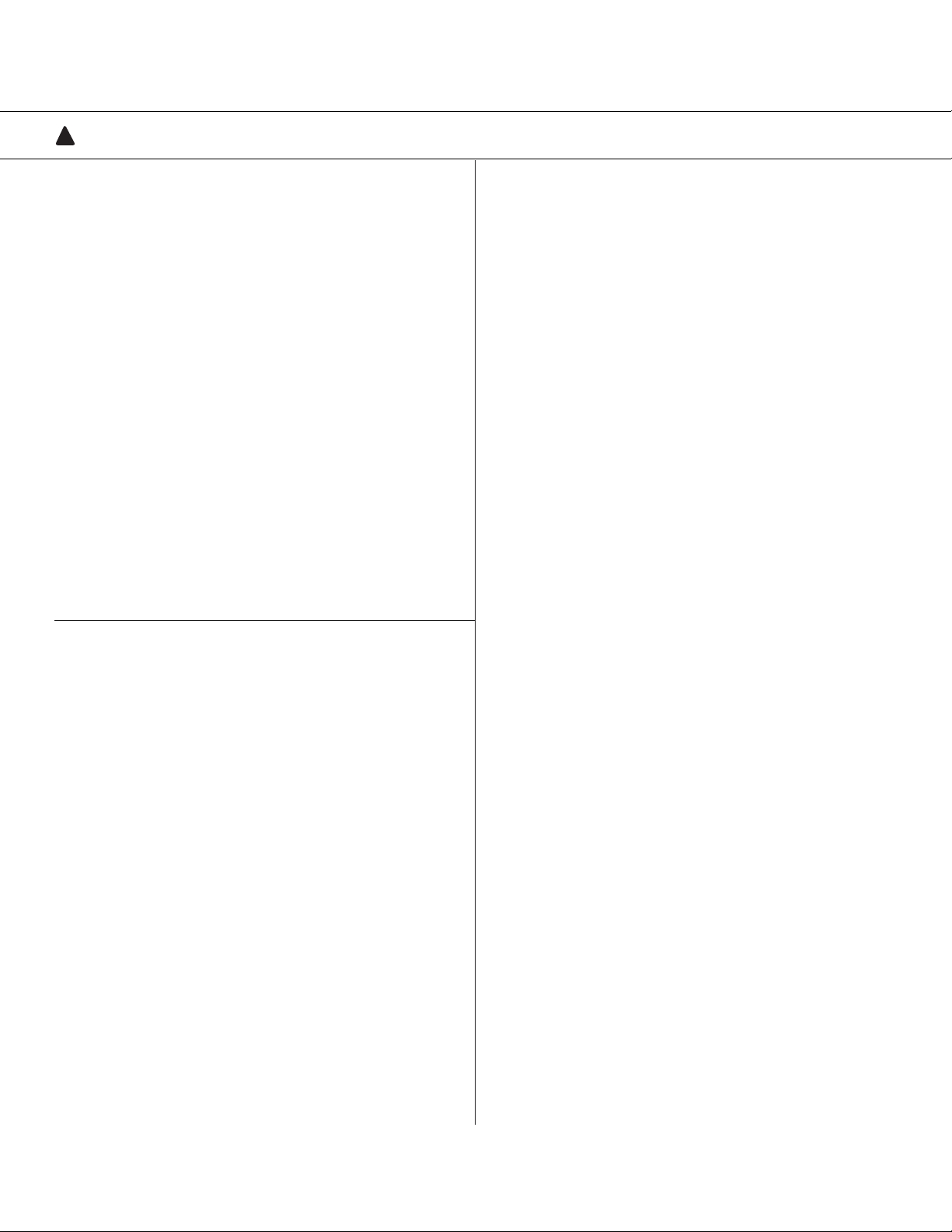

5. Slowly turn the pressure regulator knob clockwise to

increase the pressure. You should notice movement

of the needle on the pressure gauge. Adjust the

pressure to 30 psi for testing.

6. With the spray wand assembled, operate the trigger

valve and check it for leaks. Note the trigger lock.

Also adjust the nozzle and angle adapter orientation

to the desired position.

7. Turn off the switch. Turn on the spray line valve.

8. Turn on the switch and observe the spray pattern

from the spray nozzle. Check the hose assembly

for leaks.

9. Once the unit has been pressure tested and you

are familiar with its operation, you can begin the

calibration procedure.