SRM B38 Manual

SVENSKA ROTOR MASKINER AB

BOX 15085

SE-104 65 STOCKHOLM, SWEDEN

FAX +46 8 466 45 01, PHONE +46 8 466 45 00

Doc no.: TI B38052

Rev.: 2012-09-28

TECHNICAL INFORMATION

B38 Gear box with heater

Doc no.: TI B38052

Rev.: B 2012-09-28

page 2 (11)

Contents

1. Technical data page 3

1.1 Specification –Gearbox B38

1.2 Description oil system

2. Installation padge4

2.1 Functional description

2.2 Transport and handling

2.3 Lubrication oil system

2.4 Checklist before initial start up page 5

3. Start up and operational instructions page 6

3.1 Start up and shut down procedure

3.2 Safety aspects of running the B38

4. Maintenance page 9

4.1 Service general

4.2 External oil system

4.3 Spare parts

4.4 Trouble shooting

5. Documentation page 10

5.1 Installation of heater

5.2 Installation of coupling

5.3 Drawing: B38052

Doc no.: TI B38052

Rev.: B 2012-09-28

page 3 (11)

1. Technical data

1.1 Specification Gearbox B38

Layout: A Gearbox for 250 kW power.

Drive configuration: Drive shaft A, max 8500 rpm, Shaft B 3200 rpm.

Ratio: 2.68:1 (Possible ratio: 1.53:1- 3.05:1)

Dimensions: LxWxH: 666x541x673 mm (excl couplings)

Weight: 280 kg (excl couplings)

Ambient temp: -45ºC to +50ºC

Orientation of Gearbox: According to layout drawing “B38052 sheet1”.

Material in housing: Cast iron SS 0125

Material in gears: Steel

1.2 Description oil system

Lubrication system: Circulating oil system. Integrated oil pump

Oil blocking system: Lip sealing package on all shaft ends

Oil pressure: 4.5 Bar abs

Oil flow: 15.1 lit/min

Oil reservoir volume: 23.0 lit + external devices

Lubrication oil type: Shell Omala 68 EP

Max oil temp. injected: 60ºC

Oil filter requirement: 15µm (Not necessary if the oil system not contain particle

lager than 15 my. The gear box has one magnetic plug).

Max pressure drop in cooler: 0.3 Bar

Pressure gage: Recommended to indicate pressure below 2 Bar abs at

injection point.

Doc no.: TI B38052

Rev.: B 2012-09-28

page 4 (11)

2. Installation

2.1 Functional description

The Gearbox B38 used to connect expander/compressor with generator/motor. Between the units

shall coupling be used. The B38 have one internal oil tank and oil pump but not any oil cooler. For

that reason B38 have two connections “Oil out to cooler” and “Oil injection from Cooler” se

Drawing B38052. Gearbox is enclosed with a heater to hold oil to 40 ºC.

2.2 Transportation and handling

Please take the following precautions when transporting and handling the B38 during installation:

•The B38 must be transported standing fixed with mounting feet. The Lifting eye shall be

used when the B38 needs to be lifted.

The lifting eye on the Gearbox can only be used to lifting the Gearbox B38 and not other units or

frames.

•Always cover the B38 connections in order to prevent water, dust and debris to enter the

B38 and cause damage.

•Do NOT remove the protective covers from the connections until the expander is mounted

in place and the oil piping will be fitted.

2.3 Lubrication oil system

Please acknowledge the following instructions and warnings to avoid injury.

An external oil cooler system is required in order to ensure proper operation of gears, drive shaft

seal and bearings. B38 have two connections “Oil out to cooler” and “Oil injection from Cooler”.

The position of this connections, see picture 2.2.2 and documentation in chapter 5.2.

The following functions are essential:

•Oil cooler

•Oil pressure guard if necessary

•Oil temperature guard

•Oil filter if necessary

The Gearbox B38 has following components integrated:

•Oil sump being vented to atmosphere

•Oil pump for pressure 4.5 Bar atm

•Over flow valve for specified pressure

•Magnetic plug in sump

Doc no.: TI B38052

Rev.: B 2012-09-28

page 5 (11)

2.4 Checklist before initial start up

Please acknowledge the following checklist before attempting to start up the B38:

1Check the oil level in the oil sump. A minimum of 23 litres +external devices.

2Check that it is oil in cooler and pipes.

3Check that the oil connections are correctly and properly secured.

See picture 2.2.2

4Check that all couplings are correctly and properly mounted and assembled.

See picture 2.2.3

Doc no.: TI B38052

Rev.: B 2012-09-28

page 6 (11)

3. Start up and operational instructions

3.1 Start up and shut down procedure

•Prime the pump with oil before start if B38 have been stationary for > 1 month.

•Oil pressure is to be applied immediately after the B38 is started.

•The acceleration up to nominal speed should be swift without unnecessary delay.

•Do not run continuously at operating speeds below 1000 rpm on shaft A.

•Check the oil pressure at inlets of the B38 immediately after start up.

•Please inspect the B38 and the oil system after the first test run and check for oil leakages.

•When the oil pressure is removed the unit must be stopped without delay.

•Do not operate B38 without applied oil pressure!

•Max allowed operating speed is 8500 rpm for shaft A

3.2 Safety aspects of running the Gearbox B38

Please acknowledge the following instructions and warnings to avoid injury.

•Hot surfaces: Make sure that appropriate precautions are taken to avoid any kind of injuries

related to contact with hot surfaces. The surface temperature of the B38 stage may exceed 80ºC

during operation and will stay warm for a long period after the B38 has been stopped.

•Noise: Make sure that appropriate precautions are taken to avoid any kind of injuries related to

the noise generated by the B38. Exposure to the noise levels from the B38 without wearing

noise protection will result in permanent hearing dysfunction.

•Damage: Always make sure to mount protection covers around the couplings to prevent

personal injury.

•Toxic oil: Make sure that appropriate precautions are taken to avoid any unnecessary contact

with any oil traces on the B38 or the lubrication oil system. Use protective gloves at all time.

Doc no.: TI B38052

Rev.: B 2012-09-28

page 7 (11)

Picture 2.2.2 Oil connections and information

Oil injection from

cooler (alt. place)

ISO 228/1-G 3/8”

Oil sump

ventilation

Sight glass

Oil level

Oil out to cooler

ISO 228/1-G 3/8”

Oil plug magnetic

Drainage

Heater

Doc no.: TI B38052

Rev.: B 2012-09-28

page 8 (11)

Picture 2.2.3 Gearbox with shafts information

Shaft B Ø70 m5

Flat key 20x12x105

Shaft A Ø50 g5

Flat key 14x9x75

Lifting eye

ONLY FOR LIFTING

GEARBOX B38

Mounting Feet

Hole 4x Ø22

Doc no.: TI B38052

Rev.: B 2012-09-28

page 9 (11)

4. Maintenance

4.1 Service general

Please follow the recommendations below:

Service interval: Gearbox B38: Every 17.500 hours or 3 years

witch ever comes first *

For service of B38 change the oil and clean the oil plug (or change oil filter).

* For other service please contact SRM for authorized service personal.

4.2 External oil system

Oil change interval: OEM Responsibility

Filter change interval: OEM Responsibility

4.3 Spare parts

Original spare parts will be provided by SRM’s authorized service personal.

4.4 Troubleshooting

Please make following actions and record following observations for the listed trouble items before

contacting SRM.

Gearbox oil temperature is higher than specified

1. Check supply of cooling water

2. Check oil amount in the gearbox

Gearbox leaks oil from the shaft seal

1. Check shaft alignment on both sides

Gearbox vibrates excessively

1. Check shaft alignment on both sides

2. Remove couplings and turn the input shaft slowly by hand to detect any abnormal sound

and uneven torque

Doc no.: TI B38052

Rev.: B 2012-09-28

page 10 (11)

5. Documentation

5.1 Installation of heater

See doc. Heater_140282_E_09

5.2 Installation of coupling

The couplings for Gearbox B38 are designed for key shaft and locking screws.

Move the unit (Expander/Generator) to line the shaft, see separate document for the coupling.

The distance between the two coupling parts on shafts shall have (100 mm) enough space for

mounting the spacer.

There is not any place reserved for speed sensor on gearbox.

Line the shafts before mounting the couplings.

NOTE! Positions marked as “Not included” are not included in B38 package.

The couplings must be order separately.

Coupling part on shaft

(Not included)

Coupling spacer

(Not included)

Speed disc

(Not included)

Coupling part on shaft

(Not included)

Gearbox B38

B38052

Stop screw

(Not included)

Doc no.: TI B38052

Rev.: B 2012-09-28

page 11 (11)

5.3 Drawing B38052

Table of contents

Other SRM Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

MRC

MRC PH-230SD Operation manual

RX only

RX only stryker user guide

SIGRIST-PHOTOMETER

SIGRIST-PHOTOMETER AquaMaster instruction manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS M625B01 Installation and operating manual

F&F

F&F LE-03MB user manual

Endress+Hauser

Endress+Hauser Proline Promag 10 operating instructions

Geosense

Geosense VWCM-4000 instruction manual

Mastech

Mastech MS5308 user manual

Metrohm

Metrohm 940 Professional IC Vario ONE/ChS/LPG Manual - Short Instructions

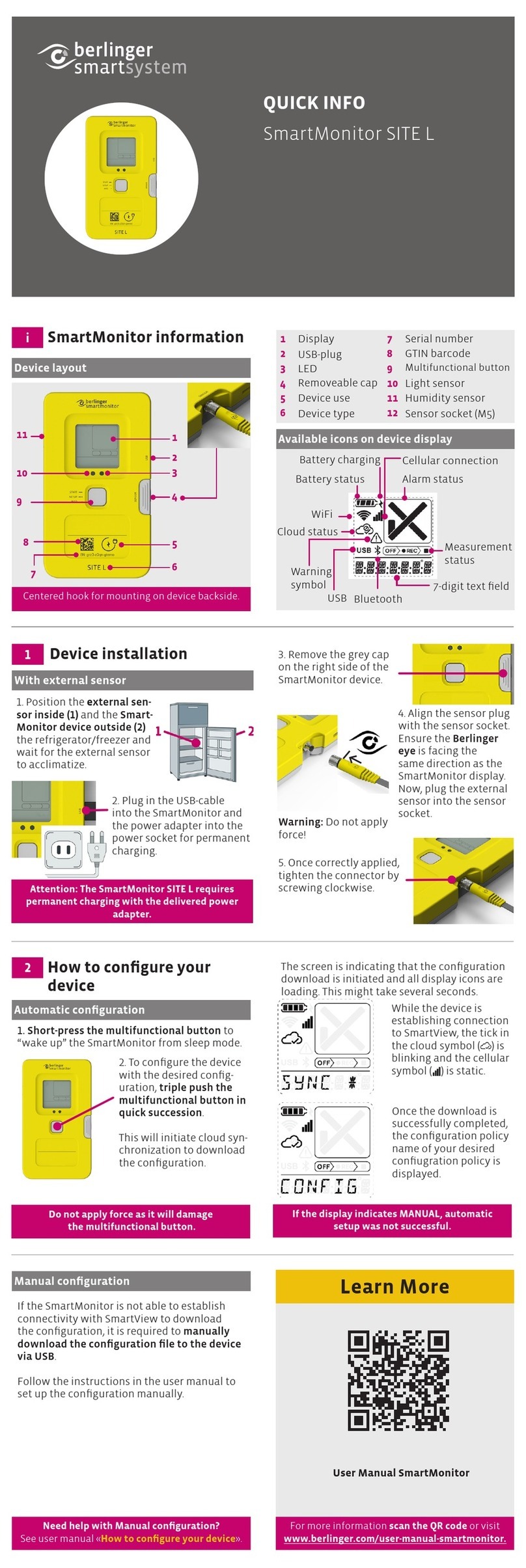

berlinger

berlinger SmartMonitor SITE L QUICK INFO

OmniSite

OmniSite SmarteLight manual

Gossen MetraWatt

Gossen MetraWatt Luna-star F instruction manual