V 1.3 Feb 19

It is VITAL that personnel responsible for the installation and use

of the VWCM-4000 Crack Meters READ and UNDERSTAND the

manual, prior to working with the equipment.

**********

As stated before, it is vital to check all the equipment in the shipment soon after

taking delivery and in good time before installation is to be carried out. Check that

all components that are detailed on the shipping documents are included.

5.0 INSTALLATION

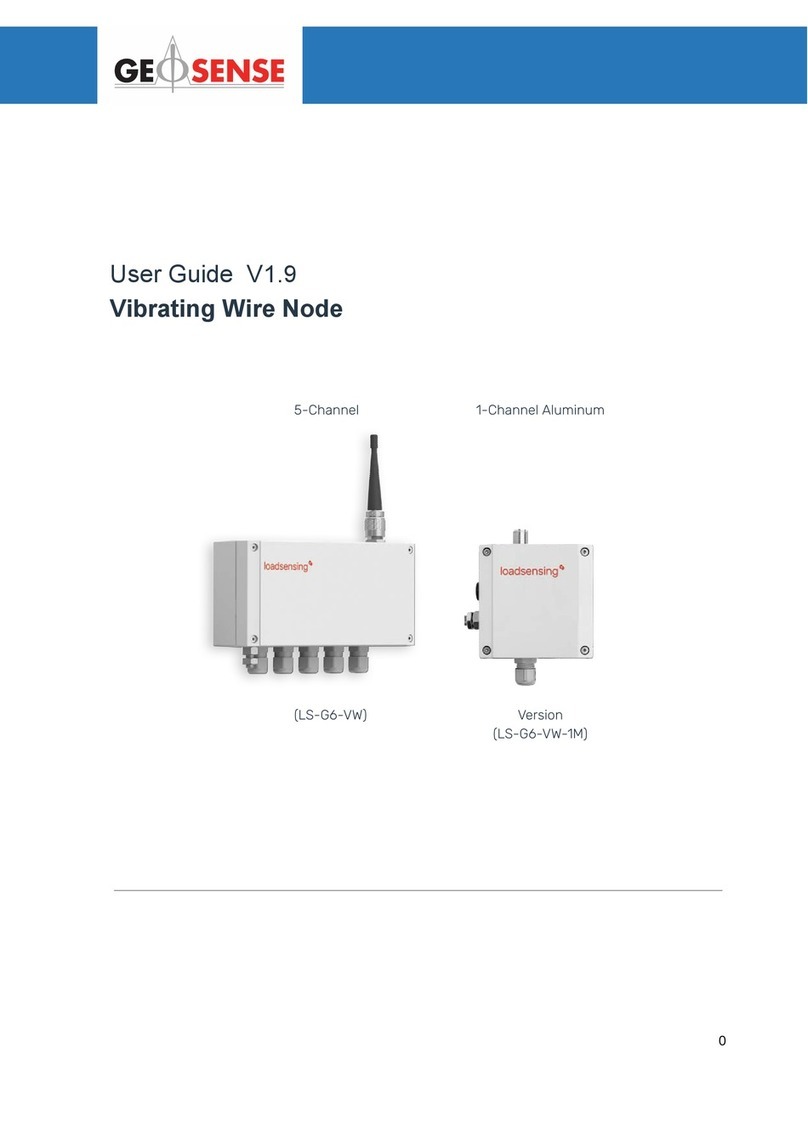

This section of the manual is intended for all users of VWCM-4000 Crack Meters

manufactured by Geosense® and is intended to provide guidance with respect to

their installation.

It must be remembered that no two installations will be the same and it is inevitable

that some ‘fine tuning’ of the following procedures will be required to suit specific site

conditions.

5.1 Getting started - Preparation for Installation

Prior to installation of a VWCM-4000 Crack Meters it is essential to establish and

confirm details of the installation to be carried out. Some of the main considerations

are listed below :-

1. Intended location and subsequent Protection

2. Expected Movement of the Crack or Joint (see setting range)

3. Anchoring Method

4. Cable routing and marking

The end of the cables connected to VWCM-4000 Crack Meters is marked with the

unique serial number of the sensor to which it is attached.

All instrument cables should be marked with unique identification (e.g. colour codes).

Markings should be repeated at regular intervals along the cable where multiple

cables are to be grouped together, so that in the event of cable damage, there may

be a chance that the identification could be exposed and the cables re-joined

correctly. Multiple cable marks are particularly important close to the end of the

cable. The spacing of markings can vary according to specific site requirements but

a guide of 5m to 10m separation is commonly applied (marking materials available on

request from Geosense).

Cable routing must be carefully considered so as to ensure that it is not vulnerable

from intentional or accidental damage. Vibrating Wire signals can be affected by

electrical interference (EMI), so cable routing should AVOID close proximity to

possible sources.

10