SRS Labs SR400 User manual

MODEL SR400

GATED PHOTON COUNTER

1290-D Reamwood Avenue

Sunnyvale, California 94089

Phone: (408) 744-9040 • Fax: (408) 744-9049

Copyright © 1987 –2018 by SRS, Inc.

All Rights Reserved.

Revision 2.7 (11/2018)

Table of Contents

1

TABLE OF CONTENTS

CONDENSED INFORMATION

Safety and Preparation for Use 3

Specifications 5

Menu Display List 7

Abridged Command List 9

INSTRUMENT OVERVIEW

Signal Inputs / Discriminators 11

Counting 12

Gating 13

Count Modes 14

Outputs 14

Measurement Examples 17

OPERATION

Front Panel Summary 21

Power 21

Liquid Crystal Display 21

Menu Keys 21

Spin Knob 21

Start, Stop, and Reset 21

Instrument Status 22

Counter LED's 22

Inputs 22

Outputs 22

Rear Panel Summary 24

Power Entry Module 24

IEEE-488 Port 24

RS-232 Connector 24

Input 24

Output 24

Front Panel Menus 25

Mode Menu 25

Level Menu 27

Gate Menus 30

Setup Menu 31

Com Menu 31

INSTRUMENT SETUPS

Default Setup / Power On Clear 33

Quick Check 33

2 Photon Pile Up Correction 34

Gated Photon Counting 34

Synchronous or Chopped

Photon Counting 34

REMOTE PROGRAMMING

Communications 37

Command Syntax 37

Status LED's 38

RS-232 Echo 38

Try-out with ASCII Terminal 38

Detailed Command List 39

Mode 39

Levels 40

Gates 41

Front Panel 42

Interface 44

Store/Recall 45

Polled Data 45

Continuous Data 45

Examine Data 46

Status Byte 46

Secondary Status Byte 47

Errors / Data Window 47

Trouble Shooting Interface Problems 47

Common Hardware Problems 47

Common Software Problems 48

RS-232 INTERFACE

Data Communications Equipment 49

Echo 49

Wait Command 49

Termination Sequences 49

Example Programs 49

Microsoft BASIC 50

Microsoft FORTRAN 51

GPIB (IEEE-488) INTERFACE

GPIB Capabilities 53

Serial Polls and Service Requests 53

Example Programs 53

Microsoft BASIC 54

Microsoft C 56

TROUBLESHOOTING

LCD Contrast 59

Fan 59

Front Panel Test 59

Power On Reset 59

Quick Test 59

Counting 60

CALIBRATION AND REPAIR

Signal Input Offset 61

Signal Input Repair 61

Table of Contents

2

USING PHOTOMULTIPLIER TUBES

PMT Selection for Photon Counting 63

Geometry 63

Spectral Response 63

Gain and Risetime 63

Dark Counts 64

PMT Base Design 64

Dynode Biasing 64

Snubbing 66

PMT Base Conclusions 67

Cathode Shielding 67

Preamplifiers 67

Gain Requirement 67

Plateauing a PMT 67

The 'Correct' Way 68

The 'Fast and Pretty Good' Way 68

TYPICAL EXPERIMENT

Energy Levels of Ruby 69

Apparatus 69

Operation 69

Instrument Configuration 70

Computer Data Acquisition 70

CIRCUIT DESCRIPTION

Microprocessor Control 73

Microprocessor System 73

RS-232 Interface 73

GPIB Interface 73

Input Ports 73

Slow Counters 73

Output Ports 73

Front Panel 73

D/A Converter 74

Fast Counters 74

Signal Inputs 74

Discriminators 74

A and B Counters 74

T Counter 75

Start / Stop and Dwell 75

Gate Generators 76

Digital Delay 76

Analog Delay 76

Delay Reset 77

Gates 77

Power Supply 77

PARTS LISTS

Main Assembly 79

Power Supply 93

Miscellaneous 95

SCHEMATIC DIAGRAMS

Signal Amplifiers SR400-1

Discriminators SR400-2

Fast Counters A and B Prescallers SR400-3

Fast Counters T Prescaller SR400-4

Slow Counters (A, B, T) SR400-5

Dwell Timer: Start/Stop SR400-6

Fast Gate Delay Ramps SR400-7

Slow Gate Delay Counters SR400-8

Fast Gate Ramps SR400-9

Width Oscillators SR400-10

Slow Gate Width Counters SR400-11

Microprocessor System SR400-12

Counters and Timers:

Digital Interface 1 SR400-13

Output Ports:

Digital Interface 2 SR400-14

Digital to Analog Converter SR400-15

Power Supply

Safety and Preparation for Use

3

SAFETY AND PREPARATION FOR USE

**** CAUTION ****

This instrument may be damaged if operated with

the LINE VOLTAGE SELECTOR set for the

wrong ac line voltage or if the wrong fuse is

installed.

LINE VOLTAGE SELECTION

The SR400 operates from a 100V, 120V, 220V, or

240V nominal ac power source having a line

frequency of 50 or 60 Hz. Before connecting the

power cord to a power source, verify that the

LINE VOLTAGE SELECTOR card, located in the

rear panel fuse holder, is set so that the correct ac

input voltage value is visible.

Conversion to other ac input voltages requires a

change in the fuse holder voltage card position and

fuse value. Disconnect the power cord, open the

fuse holder cover door and rotate the fuse-pull

lever to remove the fuse. Remove the small

printed circuit board and select the operating

voltage by orienting the printed circuit board to

position the desired voltage to be visible when

pushed firmly into its slot. Rotate the fuse-pull

lever back into its normal position and insert the

correct fuse into the fuse holder.

LINE FUSE

Use 1 Amp slow blow fuse for 100V/120V as well

as 220V/240V.

LINE CORD

The SR400 has a detachable, three-wire power

cord for connection to the power source and to a

protective ground. The exposed metal parts of the

instrument are connected to the outlet ground to

protect against electrical shock. Always use an

outlet which has a properly connected protective

ground.

WARNING REGARDING USE WITH

PHOTOMULTIPLIERS

The signal inputs may be damaged if a

photomultiplier is used improperly with the photon

counter. When left completely unterminated, a

PMT will charge a cable to a few hundred Volts in

a very short time. If this cable is connected to a

signal input, the stored charge may damage the

front-end transistors. To avoid this problem,

provide a leakage path of about 100 KΩ to ground

inside the base of the PMT to prevent charge

accumulation.

CONNECTION TO OTHER INSTRUMENTS

All front panel BNC shields are connected to the

chassis ground and to the power outlet ground via

the power cord. Do not apply any voltage to either

the shields or to the outputs. The outputs are not

protected against connection to any potential other

than ground.

SRS Symbols

4

Symbols that may be found on SRS products

SR400 Specifications

5

SR400 SPECIFICATIONS

OVERVIEW

There are three complete counters identified as A,

B, and T. All counters count up to 200 MHz.

Counter A can count INPUT 1 or the 10 MHz

internal clock. Counter A is gated by AGATE, and

has a count capacity of 109.

Counter B can count INPUT 1 or INPUT 2.

Counter B is gated by BGATE, has a count

capacity of 109and may be used as the preset

counter to determine the count interval.

Counter T can count the internal 10 MHz clock,

INPUT 2, or the gate trigger. This counter may be

preset to determine the count period for up to 25

hours or 9 x 1011 counts, gates, or triggers. The

timer has an accuracy or 25 ppm from 0 to 50∞C.

SIGNAL INPUTS

Bandwidth: dc to 300 MHz

Input impedance: 50 Ohms

Linear range: ± 300 mV (at input)

Input protection: ± 5 Vdc, 50 V for 1 µs

Overload recovery: 5 ns for <10 µs duration

overload

DISCRIMINATORS

Counters A, B, and T have independent

discriminators when counting the signal inputs.

All discriminator levels may be set to a fixed level

or scanned. A rear panel INHIBIT input (TTL

active high) can inhibit the discriminators to stop

the count.

Referenced to the signal inputs:

Discriminator range: -300 mV to +300 mV.

Discriminator slope: Rising or Falling

Resolution: 0.2 mV

Input offset voltage: 1 mV

Minimum pulse input: 10 mV

Pulse pair resolution: 5 ns.

DISC outputs: NIM levels into 50 Ohms

TRIGGER INPUT

Impedance: 10 KOhms

Threshold: ±2.000 Vdc in 1 mV steps

Slope: Rising or Falling

Protection: 15 Vdc, 100 V for 1 µs

GATE GENERATORS

There are two independent gates, AGATE and

BGATE, which enable the A and B counters. Both

gates are triggered by the TRIGGER input. The

gates may be fixed in time or scanned. The GATE

outputs show the positions of the gates with

respect to the discriminator outputs.

Insertion delay: 25 ns

Maximum delay: 999.2 ms

Minimum gate width: 5 ns

Maximum gate width: 999.2 ms or CW

Resolution: 0.1%, 1 ns minimum

Accuracy: 2 ns +1%

Jitter: 200 ps rms +100 ppm

Maximum trigger rate:1 MHz

GATE view outputs: NIM levels into 50 Ohms

GATE view error: < 2 ns

COUNTING MODES

A and B for a period determined by T preSET and

T input.

A ± B for a period determined by T preSET and T

input.

A for a period determined by B preSET and B

input.

SCAN AND DWELL

The number of count PERIODS or data points in a

scan may be set from 1 to 2000. The duration of

one count period is determined by the preset

condition.

The time between consecutive count periods is the

DWELL TIME and can be set from 2 ms to 60 s.

The DWELL output will be TTL high during the

DWELL time. This output can be used to trigger

external devices.

At the end of a scan (of 1 to 2000 count periods)

counting may be programmed to STOP or START

the scan over again.

The START key begins the first count period of

the programmed scan.

SR400 Specifications

6

The STOP key terminates the current count period

and pauses the scan. If scanning, gates and disc

levels are held at their last value. The STOP key

pressed while in a paused condition will reset the

scan and all scanned parameters will return to their

start values. The START key pressed while paused

resumes the scan by starting the next count period.

The DWELL TIME may also be set to

EXTERNAL. In this mode, count periods begin

with the START key or EXTERNAL START

INPUT (TTL rising edge). Count periods

terminate with the preset condition, the STOP key,

or the EXTERNAL STOP INPUT (TTL rising

edge). A STOP key while not counting resets the

scan. This allows completely variable dwell times

and/or counting periods.

All count data is internally buffered for one scan.

Data may be read over the computer interfaces

during or after a scan.

DISPLAY MODE

CONTINUOUS: Displays current counter value

HOLD: Displays final count value

D/A OUTPUT

The front panel D/A Output is proportional to A,

B, A-B, or A+B depending upon the counting

mode selected. The D/A output is updated at the

end of each count period.

There are two rear panel D/A outputs, PORT 1 and

PORT 2. These outputs may be set or scanned

from the front panel or via the computer interface.

Full scale: ± 10 Vdc

Resolution: 12 bits (5 mV)

Current rating: 10 mA

Output Impedance: < 1 Ohm

Accuracy: 0.1% + 5 mV

COMPUTER INTERFACE

IEEE-488 (GPIB) and RS-232 (up to 19.2 kbaud).

Full instrument control and data transmission.

GENERAL

Dimensions: 16" x 13" x 3.5"

Weight: 10 lbs

Power: 35 Watts from 100, 120,

220, or 240 Vac

Warranty: One year parts and labor

on materials and

workmanship

Menu Display List

7

MENU DISPLAY LIST

MODE

COUNT=A,B FOR T PRESET

A=INPUT 1

B=INPUT 2 B SET=1E3

T=10MHZ T SET=1E0 s

N PERIODS=2000 [at 1234]

AT N=STOP DWELL=1E0s

D/A=A

D/A RANGE=LOG

DISPLAY=CONTINUOUS

A GATE

AGATE=SCAN ∆=1.000 µs

A DELAY=1.000 µs

A WIDTH=1.000 µs

B GATE

BGATE=SCAN ∆=1.000 µs

B DELAY=1.000 µs

B WIDTH=1.000 µs

LEVEL

TRIG SLOPE=RISE

TRIG LVL=+2.000 V

A DISC SLOPE=FALL

A DISC=SCAN ∆=-1.0 mV

A DISC LVL=-10.0 mV

B DISC SLOPE=FALL

B DISC=SCAN ∆=-1.0 mV

B DISC LVL=-10.0 mV

T DISC SLOPE=FALL

T DISC=SCAN ∆=-1.0 mV

T DISC LVL=-10.0 mV

PORT1=SCAN ∆=+0.100 V

PORT1 LVL=+0.500 V

PORT2=SCAN ∆=+0.100 V

PORT2 LVL=+0.500 V

SETUP

LCD CONTRAST=12

STORE=3 EXECUTE=>

RECALL=3 EXECUTE=>

COM

GPIB ADDR=23

RS-232 BAUD=9600

RS-232 BITS=8

RS-232 PARITY=NONE

RS-232 WAIT=6

RS-232 ECHO=OFF

DATA=

Menu Display List

8

Abridged Command List

9

ABRIDGED COMMAND LIST

The parameter i is 0,1,or 2 to select counter A,B, or T

MODE

CM j Set COUNT to mode j; A,B(0), A-B(1), A+B(2) for preset T,or A FOR B preset(3).

CI i,j Set counter i to input j; 10 MHz(0), INP 1(1), INP 2(2), TRIG(3).

CP i, n Set counter i preSET to 1 <= n <= 9E11.

NP m Set Number of PERIODS in a scan to 1 <= m <= 2000.

NN Read current count period number or scan position.

NE j Set end of scan mode to mode j; START(1) or STOP (0).

DT x Set DWELL time to 2E-3 <= x <= 6E1 s or EXTERNAL(0).

AS j Set D/A to source j; A(0), B(1), A-B(2), A+B(3).

AM j Set front panel D/A to RANGE j; LOG(0) or LINEAR (1-7).

SD j Set DISPLAY to mode j; CONTINUOUS(0) or HOLD(1).

LEVELS

TS j Set TRIG to SLOPE j; RISE(0) or FALL(1).

TL v Set TRIG LVL to -2.000 <= v <= 2.000 V.

DS i,j Set DISC i to SLOPE j; RISE(0) or FALL(1).

DM i,j Set DISC i to mode j; FIXED(0) or SCAN(1).

DY i,v Set DISC i scan step to -0.0200 <= v <= 0.0200 V.

DL i,v Set DISC i LVL to -0.3000 <= v <= 0.3000 V.

DZ i Read current DISC i LVL (during scan).

PM k, j Set PORT k (1 or 2) to mode j; FIXED(0) or SCAN(1).

PY k,v Set PORT k (1 or 2) scan step to -0.500 <= v <= 0.500 V.

PL k,v Set PORT k (1 or 2) LVL to -10.000 <= v <= 10.000 V.

PZ k Read current PORT k (1 or 2) LVL (during scan).

GATES

GM i,j Set GATE i to mode j; CW(0), FIXED(1), or SCAN(2).

GY i,t Set GATE i DELAY scan step to 0 <= t <= 99.92E-3 s.

GD i,t Set GATE i DELAY to 0 <= t <= 999.2E-3 s.

GZ i Read current GATE i DELAY position (during a scan).

GW i,t Set GATE i WIDTH to 0.005E-6 <= t <= 999.2E-3 s.

FRONT PANEL

CS Count start, same as START key.

CH Count pause, same as STOP key while counting.

CR Count reset, same as STOP key pressed twice.

CK j Simulate key press j.

RR Rotate knob right (CW or UP) 1 step.

RL Rotate knob left (CCW or DOWN) 1 step.

SC Read cursor position. Left(0), right(1), or inactive(2).

MI j Set front panel to mode j; local(0), remote(1), locked-out(2). RS-232 only.

MS string Display string on menu line.

MS Return menu line to normal display.

MD j,k Display line k of menu j.

MM Read menu number of display (j).

ML Read menu line of display (k).

Abridged Command List

10

STORE/RECALL

ST m Store instrument settings to location m (1 to 9).

RC m Recall instrument settings from location m (1 to 9).

RC 0 Recall default settings.

INTERFACE

CL Clear instrument.

SV m Set GPIB SRQ mask to 0 <= m <= 255.

SS Read status byte.

SS j Read bit j(0-7) of status byte.

SI Read secondary status byte.

SI j Read bit j (0-2) of secondary status byte.

SW m Set RS-232 character wait interval to m*3.33 ms 0 <= m <= 25. RS-232 only.

SE j,k,l,m Set RS-232 terminator sequence to j,k,l,m (ASCII codes). RS-232 only.

SE Clear RS-232 terminator sequence to defaults. RS-232 only.

DATA

QA Read last count in counter A.

QB Read last count in counter B.

QA m Read from scan buffer point m(1-2000) for counter A.

QB m Read from scan buffer point m(1-2000) for counter B.

EA Send entire counter A buffer.

EB Send entire counter B buffer.

ET Send entire counter A and B buffer.

FA Start scan and send N PERIODS data points from counter A.

FB Start scan and send N PERIODS data points from counter B.

FT Start scan and send N PERIODS data points from both counters.

XA Read current contents of counter A.

XB Read current contents of counter B.

STATUS BYTE

Bit Description

0 Parameter changed

1 Data ready

2 Scan finished

3 Counter overflow

4 Rate error

5 Recall error

6 Service request

7 Command error

SECONDARY STATUS BYTE

Bit Description

0 Triggered

1 Inhibited

2 Counting

3-7 Unused

Instrument Overview

11

INSTRUMENT OVERVIEW

SR400 OVERVIEW

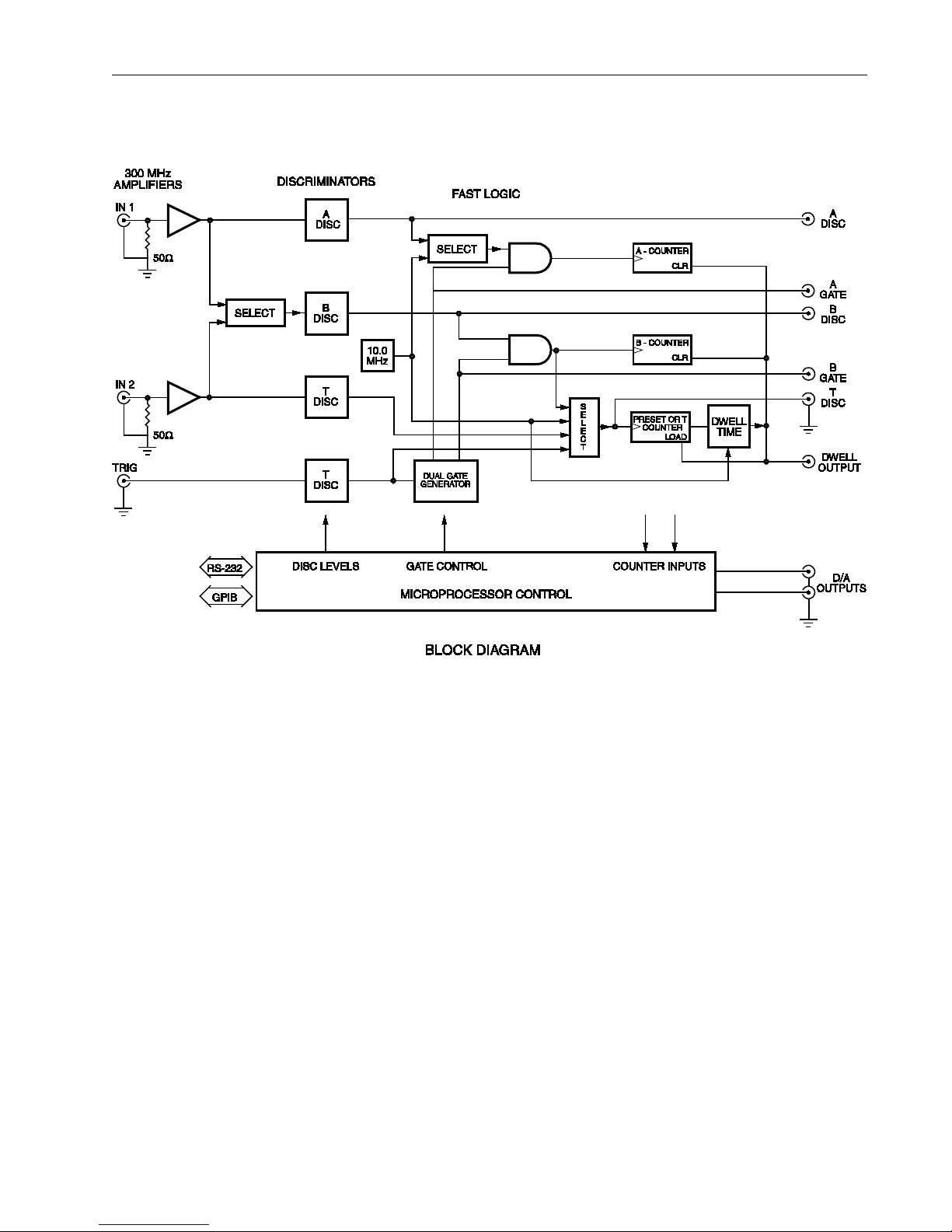

The SR400 architecture is diagrammed above.

There are three fast counters identified as counters

A, B, and T. All three counters operate at rates up

to 200 MHz. The input to each counter is selected

from a number of sources, including the two

analog signal inputs, the crystal timebase, and the

external trigger input. Counter T is presettable and

determines the measurement period. For pulsed

experiments, counters A and B may also be

synchronized to external events via the two

independent gate generators. The gate generator

provides gates from 5 ns to 1 s in duration with a

delay from external trigger ranging from 25 ns

to 1 s.

SIGNAL INPUTS AND DISCRIMINATORS

There are two independent analog signal inputs

labelled INPUT 1 and INPUT 2. They are

internally terminated into 50 Ω. The inputs can

accept signals of either polarity up to ±300 mV

and are protected to ±5V dc. Each input is

followed by a dc to 300 MHz amplifier. This

allows detection of pulses as small as 10 mV. If

greater sensitivity is required, the SR445A remote

amplifier is available. The SR445A can provide

gains from 5 to 625 at bandwidths up to 350 MHz.

There are three discriminators, one for each

counter. Each discriminator has selectable slope

and a threshold programmable from -300 mV to

+300 mV in 0.2 mV steps (referenced to the

inputs). Pulse-pair resolution is 5 ns and pulses of

either polarity may be detected. Each threshold

Instrument Overview

12

may be programmed to scan in either direction

with selectable step size.

COUNTING

Each counter's input may be selected from a

number of sources. All multiplexing of counter

inputs is done internally to provide accurate timing

and ease of operation. Input cables should rarely

need to be swapped or disconnected to change

measurement modes.

The actual inputs to the counters can be viewed as

NIM level pulses from the DISC outputs on the

front panel. The DISC pulses are negative going

from 0 to -0.7 V. The falling edge is the active or

counted edge regardless of the discriminator slope

setting. The DISC outputs are very useful when

adjusting discriminator thresholds or gate timing.

When the START key is pressed, a START

command is received from the computer interface,

or the EXTERNAL START input is pulsed,

counter T is enabled to count. The COUNT

PERIOD begins with the first pulse from T

counter's input after START. The COUNT

PERIOD enables counters A and B to count their

respective inputs. If the A GATE and B GATE are

CW or continuous, all pulses that occur during the

COUNT PERIOD are counted. If the gates are

enabled, only the pulses that occur during those

gates which fall within the COUNT PERIOD are

counted.

Counter T is presettable from 1 to 9E11. When

counter T reaches the preset count, the COUNT

PERIOD is terminated and counting is halted on

all counters. When the input to counter T is the 10

MHz crystal timebase, the COUNT PERIOD is a

fixed time interval from 100 ns to 25 hours. When

the input is INPUT 2, the COUNT PERIOD is

externally determined and can be as short as 5 ns

and indefinitely long. This mode is used for source

compensation or reciprocal measurements. If the

input is TRIGGER, the COUNT PERIOD is a

fixed number of gates (each trigger provides one

gate). This results in a constant gate aperture time

during each COUNT PERIOD. N+1 Triggers are

required for N gates per period. If the input is B

PRESET, then counter T counts the B DISC

output gated by B GATE. This is for gated ratio or

reciprocal counting.

The SR400 may be programmed to cycle through

1 to 2000 COUNT PERIODS in a single scan. At

the end of the programmed scan, the counters may

be stopped or the scan may be restarted. If the end

of scan mode is STOP, then after the last COUNT

PERIOD in the scan, the counters are halted

indefinitely. A counter RESET is required to

rearm the counters and a START command starts

another scan. If the Number of PERIODS in the

scan is 1, then each START command results in

one COUNT PERIOD. If N PERIODS is greater

than 1, then consecutive COUNT PERIODS are

separated by the DWELL time. The DWELL time

may be set from 2 ms to 60 s. During the DWELL

time, counting is disabled and data may be

transferred or external parameters scanned. The

DWELL OUTPUT is a TTL output which is high

during the DWELL time. At the end of the

DWELL time, the next COUNT PERIOD begins

and the scan continues until N PERIODS have

been measured. If the end of scan mode is

START, one DWELL time separates the last

COUNT PERIOD of the completed scan and the

first COUNT PERIOD of the next scan.

Another DWELL mode is EXTERNAL. In this

mode, the EXTERNAL START input enables

counter T. The COUNT PERIOD begins with the

first pulse to counter T after START. Counting

then proceeds normally until the preset is reached.

At the end of the preset COUNT PERIOD, the

DWELL time is indefinite and the next COUNT

PERIOD starts with the next EXTERNAL START

pulse. In this way, preset COUNT PERIODS may

be synchronized to external events. If externally

determined COUNT PERIODS are desired, then

the preset COUNT PERIOD can be set to a value

much larger than actually required and the

EXTERNAL STOP input used to terminate the

COUNT PERIOD. The COUNT PERIOD then

starts with the first pulse to counter T after

EXTERNAL START and ends with EXTERNAL

STOP. The next EXTERNAL START begins the

next COUNT PERIOD in the scan. When the scan

is finished and the scan end mode is STOP, a

RESET from the front panel or computer interface

is required to reset the scan. If the scan end mode

Instrument Overview

13

is START, the next EXTERNAL START begins

the first COUNT PERIOD of the next scan.

SCANNING

In all scan modes, a number of parameters may be

scanned. These parameters are the three

discriminator thresholds (Pulse Height Analysis),

the two gate delays (Boxcar mode), and the two

D/A output ports (X-axis of recorder, scope, or

analog control of other apparatus).

After each COUNT PERIOD, each scanning

parameter is adjusted by one step. All changes are

made during the DWELL time so that all values

are stable during the COUNT PERIODS. The scan

limits are determined by the start position, the step

size, and the number of PERIODS in a scan. The

range of a scan is N PERIODS times the step size.

When the counters are reset, all scanned

parameters return to their start positions.

GATING

The gate generators may be disabled by setting the

gate modes to CW. In this mode, the gates are

continuously open and counting is enabled solely

by the COUNT PERIOD. This is appropriate for

CW sources or long counting intervals. If the

signal is pulsed or so weak that synchronous (lock-

in) measurement is required, then the gate

generators are required. The gates prevent pulses

that occur outside the time interval of interest from

being counted and improve signal to noise ratio.

When the gates are scanned, the time behavior of

the signal may be recovered.

The gates are triggered by the TRIGGER input.

The TRIGGER threshold is adjustable from -2V to

+2V and slope may be either RISE or FALL. The

discriminated trigger pulse may be viewed through

the T DISC output when the input to counter T is

set to TRIG. This can be helpful when setting the

trigger threshold.

The minimum insertion delay from trigger to gate

is 25 ns. The additional delay may be programmed

from 0 ns to 999.2 ms with a resolution of 1 part in

1000 or 1 ns, whichever is greater. The gate width

is adjustable from 5 ns to 999.2 ms with the same

resolution. The two gates are output as NIM pulses

from the GATE outputs. The gates are open when

the outputs are low. The gate outputs have a

timing accuracy with respect to the discriminator

outputs of 2 ns. This allows accurate timing of fast

gates relative to the signal.

The two gates have independent modes, delays,

and widths. This allows for a variety of

measurements. For example:

1) "Boxcar" mode. The gates are used to enable

the counters only when the signal is present. If the

gates are scanned, then the time profile of the

signal is recovered. Background subtraction can be

included by using one gate for the signal and an

equal width gate on the background, either before

or after the signal. The signal gate may be scanned

while the background gate held fixed. Gated

source compensation is also possible since

counters A and B may count different sources at

the same time or the same source at different

times. In the compensation mode, the COUNT

PERIOD is determined by the gated output of the

B discriminator and the COUNT MODE is A FOR

B PRESET.

2) "Lock-in" or "Chopped" mode. In this case, a

cw signal is chopped on and off. This can be

accomplished with a light chopper such as the

SR540. The light chopper reference output is used

to trigger the gates. The A GATE is positioned

during the "open" cycle and counts signal plus

noise. The B GATE is positioned during the

"closed" cycle and only counts the noise. The

counter outputs are subtracted to give only the

signal. The widths of both gates should be equal

and less than half of the chopper period. This

prevents frequency jitter in the chopper from

affecting the overlap of the gates with the open

and close cycles of the chopper.

When counter T is preset and its input is set to

TRIG, then each COUNT PERIOD consists of a

constant number of gates. N+I triggers are needed

for N gates per preiod. This is the usual mode of

gated operation. However, a number of other

modes are available. For example, if the input is

set to 10 MHz, each COUNT PERIOD consists of

the number of gates which occur during the

COUNT PERIOD time interval. If the input is a

signal input, then counting is both gated and

Instrument Overview

14

source compensated. If the DWELL mode is

EXTERNAL, an EXTERNAL START pulse starts

counting and an EXTERNAL STOP pulse stops

counting. The counters are enabled only during

those gates which occurred between the two

EXTERNAL pulses.

COUNT MODES

The length of a COUNT PERIOD is the time it

takes counter T to reach its preset count. If Ntis

the preset count in counter T, and Raand Rtare the

mean pulse rates of the inputs to counters A and T,

then the COUNT PERIOD is

T = Nt / Rt

The number of counts in counter A will be

A = RaT = RaNt/ Rt

Rate:

If Rt= 10 MHz, then the COUNT PERIOD is a

constant amount of time and

A = Ra( Nt/ Rt) ~ Ra

and counter A measures the mean rate of its input.

Gated:

If Rtis the gate trigger rate and counter A is

gated, then the COUNT PERIOD is Nt/Rtbut the

"effective" time the counter is enabled is NtWa

where Wais the width of A gate and

A = Ra( NtWa) ~ Ra

In this case, counter A measures the mean rate

during the A gate.

Source Compensated:

If Rt is INPUT 2, then the COUNT PERIOD is

determined by the pulse rate of INPUT 2 and the T

discriminator. Count A will be

A = NtRa/ Rt~ Ra / Rt

and is proportional to the ratio of the rates of

counters A and T. If INPUT 2 monitors source

intensity, then the COUNT PERIOD will adjust

for fluctuations in the source. Counter A measures

the ratio of its mean input rate and the mean rate

of INPUT 2.

Reciprocal:

If Rtis INPUT 2, then the COUNT PERIOD is

Nt/Rt. If Rais 10 MHz, then counter A measures

A = RaNt/ Rt= ( RaNt) / Rt~ 1 / Rt

and is proportional to the reciprocal of the count

rate of INPUT 2. Note that each COUNT PERIOD

is determined by Ntcounts of INPUT 2, thus the

measurement time is determined by the signal

strength. Measurements of both strong and weak

signals are made to the same accuracy for constant

signal to noise ratio.

Counter B:

Counter B may be used in all of the above modes

except Reciprocal. Since counter B is completely

independent of counter A, 2 sources of counts may

be measured simultaneously. These sources may

be the same signal or 2 different signals; the

sources may be discriminated at separate

thresholds; they may be non-gated or gated; if

gated, the 2 gates may be independently set.

Almost any measurement can be made.

In addition, counter B has a preset mode called A

FOR B PRESET. In this mode, the input to

counter B is sent to counter T. The COUNT

PERIOD is now determined by the B

discriminator and the B gate. If Rais INPUT 1,

then counter A is source compensated by the gated

input of counter B. This allows source

compensation of gated signals and sources. If Rais

10 MHz, then counter A measures the reciprocal

of the rate of counter B's gated input.

OUTPUTS

The front panel can display counts up to 109- 1.

Counters A and B can be displayed as separate

counters or combined as A-B or A+B. When A

FOR B PRESET is the count mode, then only A

data is displayed.

Instrument Overview

15

The front panel D/A output provides an analog

output proportional to A, B, A-B, or A+B

depending on the counting mode. The scale may

be logarithmic (1V/decade) or linear to any 3

digits.

If a chart recorder is used, the D/A output should

drive the Y axis. The X axis can be recorder

driven (strip chart mode) or the PORT1 or PORT2

outputs can be used to drive the X axis (scans).

This latter method allows accurate determination

of the X value of each point. If the DWELL output

is used as the pen lift, the points will be

unconnected.

If count rates are high and count periods short,

then scans may be displayed on an X-Y scope. The

D/A output is the Y drive and PORT1 or PORT2

is the X drive. The DWELL output should be used

as the blanking pulse.

Instrument Overview

16

Measurement Examples

17

MEASUREMENT EXAMPLES

Example 1: Internally Triggered Gate Mode

This example, described under the heading “QUICK TEST” on page 59 of this manual, is easy to perform and

will quickly acquaint the user with the basic operation of the SR400.

Example 2: Externally Triggered Gate Mode

In this example, the SR400 is programmed to make 10 counting measurements of a 10 kHz pulse train. For

each measurement, a gate will be delayed 500 ms from an external trigger pulse and will open of 500 ms

duration. Following the gate, there will be a 6 second dwell period* during which the counter will be

disarmed. After the dwell period, the counter will reset to 0 counts, re-arm and repeat the measurement. After

10 measurement cycles, the SR400 will stop counting and disarm. You will need a 10 kHz signal source and a

0.5 Hz square wave generator for this example.

*It is important to note that the dwell period begins at the first external trigger pulse arriving after the

gate is closed. Thus, even though there is only one gate opened for each measurement cycle, a minimum

of two external triggers are needed: one to trigger the gate and another to begin the dwell period.

The following timing diagram illustrates this example.

Measurement Examples

18

1. Turn the SR400 off. Hold down the STOP (RESET) button while turning the SR400 on. Wait three seconds

and release the button.

2. Press the MODE key. Using the four arrow keys and the front panel knob, select the following parameters.

Unless otherwise indicated, leave all other settings at their default values:

T = TRIG TSET = 1E0

N PERIODS = 10 [AT 0]

AT N = STOP DWELL = 6E0 S

3. Press the A GATE key and select the following parameters:

A GATE = FIXED

A DELAY = 500 mS

A width = 500 mS

4. Press the LEVEL key and select the following parameters:

A DISC SLOPE = RISE

A DISC LVL = +150 mV

5. Using a function generator or a pulse generator, apply a 0.5 Hz, 5 V (TTL) signal to the TRIGGER INPUT

on the SR400.

6. Using a second signal source, apply a 10 kHz square wave (or pulse train) with an amplitude of

approximately 500 mV to the SIGNAL INPUT 1 on the SR400.

7. To view the COUNT PERIODS, press the MODE key and use the up/down arrow keys to display “N

PERIODS = 10 [at 0]”

Arm the counter by pressing the START button. (Alternatively, a TTL pulse applied to the START BNC on

the front panel will arm the counter.) Each measurement cycle should result in approximately 5,000 counts.

As an extension of the above example, the SR400 can be programmed to accumulate counts over numerous

gates. This is often done to improve the signal to noise ratio of low light level experiments. To accumulate

counts, set TSET (MODE menu) to the desired number of gates. For example, if you wish to accumulate over

five gates, set TSET – 5E0. In this case, six external triggers are required for each measurement cycle: five to

trigger the five gates and one to start the DWELL PERIOD. Any additional triggers received during the

DWELL PERIOD are ignored.

Table of contents