SSM NM-11 User manual

INSTRUCTION

MANUAL

NM-11

Manual.en © 09/2014 SSM

Produkt

AB

NM-11

Riveting Machine

Congratulations

on

your

purchase

of

a NM-11

Riveting

Machine.

We

sincerely

thank

you

for

selecting

a

product

from

SSM

Produkt

AB.

To

obtain

an

additional

copy

of

this

manual, please

contact

SSM

at:

SSM

PRODUKT

AB

TABLE

OF

CONTENTS

Vaksala-Eke

SE-755 94 Uppsala, Sweden

Tel: +46 (0)18 500840

E-mail: [email protected]

Internet:

www.ssmprodukt.com

Limited Warranty................

...

...............

..

...............

...

................

...

................................................2

Functional Description..............................................................................................................

..

3

Assembly

....

..

...............

...

........................................................................

...

...............

..

..

..............4

Technical Specifications and Dimensions..................................................................................4

Operation..............................................

...

...............

..

...............

..

..

...............

...

...........................5-9

Accessories................................................................................................................................

10

LIMITED WARRANTY

Scope

of

warranty

This warranty covers any defects

in

materials and workmanship under normal use.

Period

of

coverage

This warranty runs for two (2) years from the date

of

purchase. Please save your receipt or invoice.

Limitations

Failures due to abuse, misuse or

an

event or effect that cannot

be

reasonably anticipated or controlled (such as

flood, earthquake, act

of

God etc.) are not covered by this warranty. Surface coating problems caused by excessive

humidity, in-use scratches or abrasions, and direct exposure to the elements are also not covered.

Repair

or

replacement is the only option available under this warranty. SSM Produkt

AB

(SSM)

is

not responsible

for damages

of

any kind, including incidental and consequential damages.

Incidental damages include but are not limited to such damages as loss of time and loss of use. Consequential

damages include but are not limited to the cost

of

repairing or replacing property that was damaged ifthe product

from SSM does not work properly.

Correction

of

details

If your product cannot

be

repaired, we will replace your product free of charge.

How

to

get

service

Please return the defective product together with the purchase receipt or the invoice.

You

can obtain service by

contacting a dealer of SSM products or SSM directly. At our discretion, the dealer or SSM will either repair or replace

your product.

How

country

and

state

laws

relates

to

the

warranty

This warranty gives you specific legal rights.

You

may also have other rights that vary from country to country and

from state to state.

SSM

PRODUKT

AB

RESERVES THE RIGHT TO

MAKE

IMPROVEMENTS

AND

MODIFICATIONS TO DESIGN

WITHOUT

PRIOR NOTICE.

SSM

PRODUKT

AB

VAKSALA-EKE,

SE-75594

UPPSALA,

SWEDEN

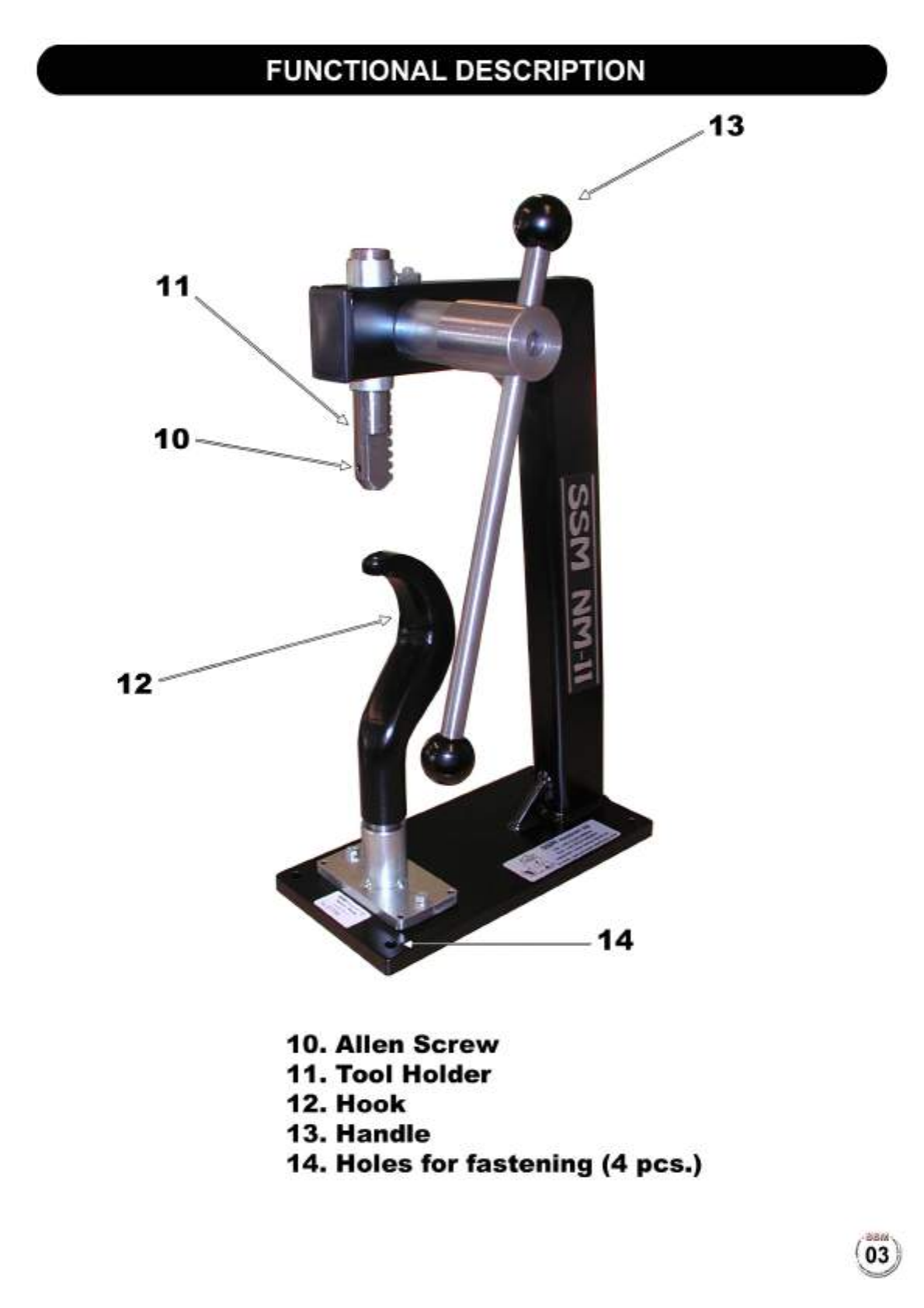

FUNCTIONAL DESCRIPTION

10

=

12

=======14

10.

Alien

Screw

11.

Tool

Holder

12.

Hook

13.

Handle

14.

Holes

for

fastening

(4

pes.)

ASSEMBLY

Your Riveting Machine

NM-11

is

delivered complete and protected inside its delivery box.

Remove all contents from the box and inspect to ensure

no

damage was incurred during shipping.

Your NM-11/21 package should include the following:

DESCRIPTION PART #QTY

Getting

started:

Instruction Manual

Riveting Machine

Hook

Tool

Set N-21+N-E

NM-11

Manual.en

NM-11

V12

N-21

, N-E 1

+1

Place the machine

on

a stable, level surface.

You

can fasten the machine with four screws through the holes (14)

in

the bottom plate.

TECHNICAL SPECIFICATIONS AND DIMENSIONS

HEIGHT:

WIDTH:

LENGTH:

WEIGHT (with hook):

DISTANCE (between

lower

and

upper

tool

holder):

FORCE:

TUBE RIVET:

COPPER RIVET + WASHER:

EYELET:

HOOKS FOR SHOELACE:

LARGER RIVET, JOINT RIVET:

495

mm

215mm

300

mm

14.5 kg

120

mm

(130

mm

with

the

ski

hook)

23 *

force

from

the

hand

Use

type

SN

from

SSM.

Use

type

KN

from

SSM.

Use

type

EL

from

SSM.

Use

type

FE

from

SSM.

Contact

the

manufacturer

of

the

ski

boot.

Your SSM

Produkt

AB

distributor:

N-f

OPERATION

, 2 3 5 7

REMOVING TUBE RIVETS

Screw tool

no.

1 into the fastening hole

in

the hook 12 (use the nut that

is

included).

Loosen the Alien screw

in

the tool holder

11

and fasten tool no. 4 (08).

Position the skate above the hook 12

so

that you can feel tool no. 1

in

the rivet.

(Note that

in

narrow positions the rivet may

be

mounted obliquely.)

Lower the tool holder

11

so that the tool 4 fits around the head of the rivet.

Press down and the rivet should come loose. It will not come completely free;

remove it with a pair of tongs.

REMOVING COPPER RIVETS

Copper rivets should be filed down to the copper washer. After that you can knock

it

out with a centre punch.

If possible, cut the copper rivet off with a pair of cutting nippers.

It

must

not

be

ground

away (the heat

that

arises can

melt

the plastic).

OPERATION

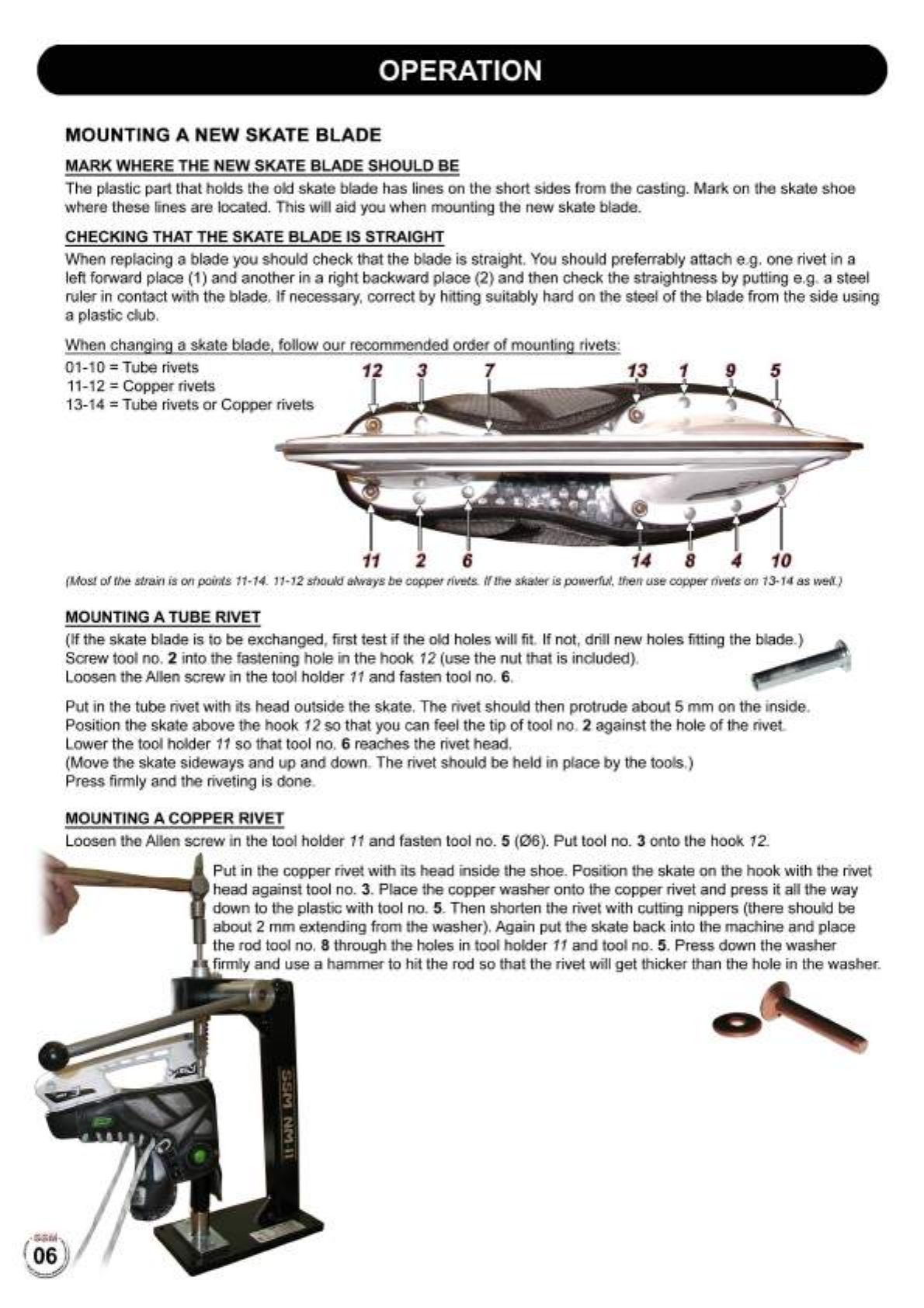

MOUNTING A NEW SKATE BLADE

MARK WHERE THE NEW SKATE BLADE SHOULD BE

The plastic part that holds the old skate blade has lines

on

the short sides from the casting. Mark

on

the skate shoe

where these lines are located. This will aid you when mounting the new skate blade.

CHECKING THAT THE SKATE BLADE

IS

STRAIGHT

When replacing a blade you should check that the blade is straight.

You

should preferrably attach e.

g.

one rivet

in

a

left forward place (1) and another

in

a right backward place (2) and then check the straightness by putting e.g. a steel

ruler

in

contact with the blade. If necessary, correct by hitting suitably hard

on

the steel

of

the blade from the side using

a plastic club.

When changing a skate blade, follow our recommended order

of

mounting rivets:

01-10 =Tube rivets 12

11-12 =Copper rivets

13-14 =Tube rivets or Copper rivets

11

2 6 14 8 4 10

(Most

ofthe

strain is on points 11-14. 11-12 should always be copperrivets.

If

the skateris powet1ul, then use copperrivets on 13-14 as well.)

MOUNTING A TUBE RIVET

(If the skate blade

is

to be exchanged, first test if the old holes will fit. If not, drill new holes fitting the blade.)

Screw tool

no.

2 into the fastening hole

in

the hook 12 (use the nut that

is

included).

Loosen the Alien screw

in

the tool holder

11

and fasten tool no.

6.

Put

in

the tube rivet with its head outside the skate. The rivet should then protrude about 5

mm

on

the inside.

Position the skate above the hook 12

so

that you can feel the tip

of

tool

no.

2 against the hole

of

the rivet.

Lower the tool holder

11

so that tool

no.

6 reaches the rivet head.

(Move the skate sideways and up and down. The rivet should

be

held

in

place by the tools.)

Press firmly and the riveting

is

done.

MOUNTING A COPPER RIVET

Loosen the Alien screw

in

the tool holder

11

and fasten tool no. 5 (06). Put tool

no.

3 onto the hook

12.

Put

in

the copper rivet with its head inside the shoe. Position the skate

on

the hook with the rivet

head against tool

no.

3.

Place the copper washer onto the copper rivet and press

it

all the way

down to the plastic with tool

no.

5.

Then shorten the rivet with cutting nippers (there should

be

about 2

mm

extending from the washer). Again put the skate back into the machine and place

the rod tool

no.

8 through the holes

in

tool holder

11

and tool no.

5.

Press down the washer

firmly and use a hammer to hit the rod so that the rivet will get thicker than the hole

in

the washer.

OPERATION

REMOVING AN EYELET

Put tool

no.

20 onto the hook

12.

Loosen the Alien screw

in

the tool holder

11

and fasten tool no. 21.

Position the skate above the hook 12

in

such a way that tool no. 20 protrudes through the outer part of the eyelet.

Lower the tool holder

11

so that the tool

21

fits around the outer part of the eyelet.

Press down and the eyelet should come loose.

It will not come completely free; remove it with a pair of tongs.

MOUNTING AN EYELET V 20

Put tool

no.

22 onto the hook

12.

Loosen the Alien screw

in

the tool holder

11

and fasten tool no. 23.

Put the two eyelet parts

in

the skate with the light part from the inside and the dark part from the outside.

Position the skate above the hook 12 such that you feel that tool

no.

22 fits the inner part of the eyelet.

Similarly lower the tool holder

11

so that tool

no.

23 fits the outer part

of

the eyelet.

Press firmly and the riveting

is

done.

Innerpart

of

eyelet

Y Outer

part

of

eyelet

NOTE! N-RE

is

extra equipment and not part of NM-11/21!

V 22 V 23

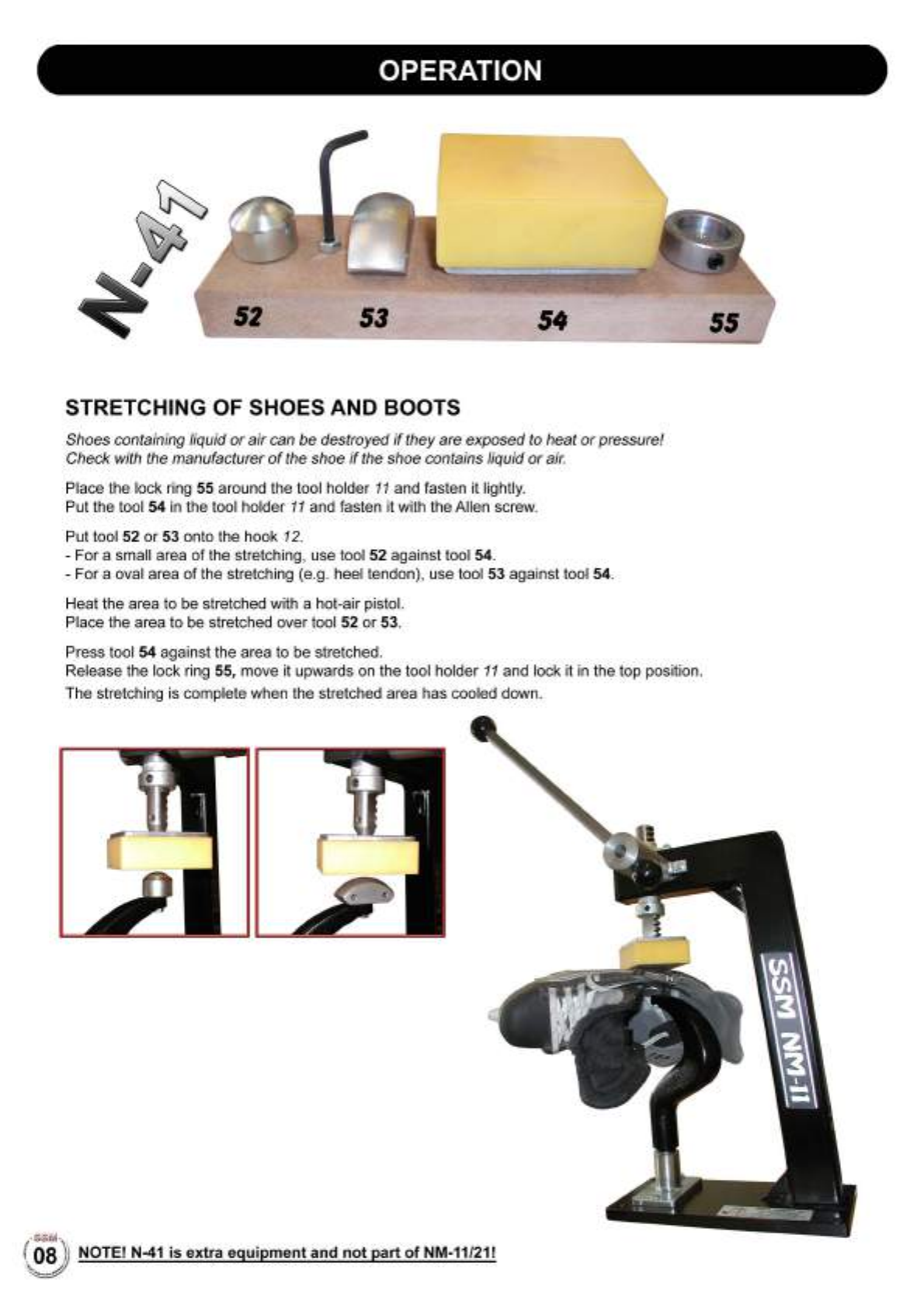

OPERATION

52

53 54

STRETCHING OF SHOES AND BOOTS

Shoes containing liquid

or

air

can be destroyed

if

they are exposed to heat or pressure!

Check with the manufacturer

of

the shoe

if

the shoe contains liquid

or

air.

Place the lock ring 55 around the tool holder

11

and fasten

it

lightly.

Put the tool 54

in

the tool holder

11

and fasten

it

with the Alien screw.

Put tool 52

or

53 onto the hook

12.

-For a small area

of

the stretching, use tool 52 against tool 54.

-For a oval area of the stretching (e.g. heel tendon), use tool 53 against tool

54.

Heat the area to

be

stretched with a hot-air pistol.

Place the area to

be

stretched over tool 52 or

53.

Press tool 54 against the area to

be

stretched.

Release the lock ring 55, move it upwards

on

the tool holder

11

and lock

it

in

the top position.

The stretching

is

complete when the stretched area has cooled down.

,®®j\J],

(08 )) NOTE! N-41 is extra equipment and not part

of

NM-11/21!

~

55

OPERATION

MOUNTING OF SHOE LACE HOOKS ON FIGURE SKATES

Put tool

no.

2 (from N-21) onto the hook

12.

Loosen the Alien screw of the tool holder

11

and fasten tool

no.

24.

Put the outer part of the lace hook

in

tool

no.

24. Then place

it

in

the hole

on

the figure skate.

Position the skate above the hook 12

so

that you can feel the tip

of

tool

no.

2 against the hole

in

the lace hook.

(Move the skate sideways and up and down. The lace hook should be held

in

place by the tools.) '\\

f7

0)/,1

Lower tool holder

11

and press firmly so that the outer part

of

the lace hook locks onto the skate. \Y

~

The outer part of the lace hook should still

be

positioned

in

tool

no.

24.

Remove tool no. 2 and put tool

no.

3 (from N-21) onto the hook

12.

Put the inner part of the lace hook

in

tool no. 3 and aim it into the hole

on

the cracked outer part.

Lower tool holder

11

and press firmly so that the inner part locks onto the outer part.

Inner

part

of

shoe

lace

hook

Outer

part

of

shoe

lace

hook

V2

SKI HOOK FOR SKI BOOTS

Ski boots (not all) have regular tube rivets that keeps the belt buckles

in

place.

Some also has large joint rivets

on

the sides.

REMOVAL OF TUBE RIVETS FOR THE BELT BUCKLES

Do

it

in

the same way as it

is

done

on

a skate but use

ski

hook

30 instead of hook 12. (See page 5.)

MOUNTING OF TUBE RIVETS FOR THE BELT BUCKLES

Do

it

in

the same way as it

is

done

on

a skate but use

ski

hook

30 instead of hook 12. (See page 6

MOUNTING OF LARGE JOINT RIVETS (with

025

mm

as maximum size)

Put tool

no.

28 onto the ski hook

30.

Loosen the Alien screw

in

the tool holder

11

and fasten tool

no.

29. Put

in

the joint rivet

with its head outside the ski boot. Position the ski boot above

the ski hook

30

so

that you can feel the tip

of

tool

no.

28 fits

in

the hole

of

the joint rivet. Lower the tool holder

11

so

that the

tool no. 29 fits the the joint rivet

on

the outside.

Press firmly and the riveting

is

done.

(Tools

no.

28 and 29 have guides making it possible

to

mount two different sizes.)

NOTE! V 24, V 28, V 29 and V 30 are extra

equipment

and

not

part

of

NM-11/21!

ACCESSORIES

------------------------------------------------- lr()()L.

~E:lr~

-------------------------------------------------

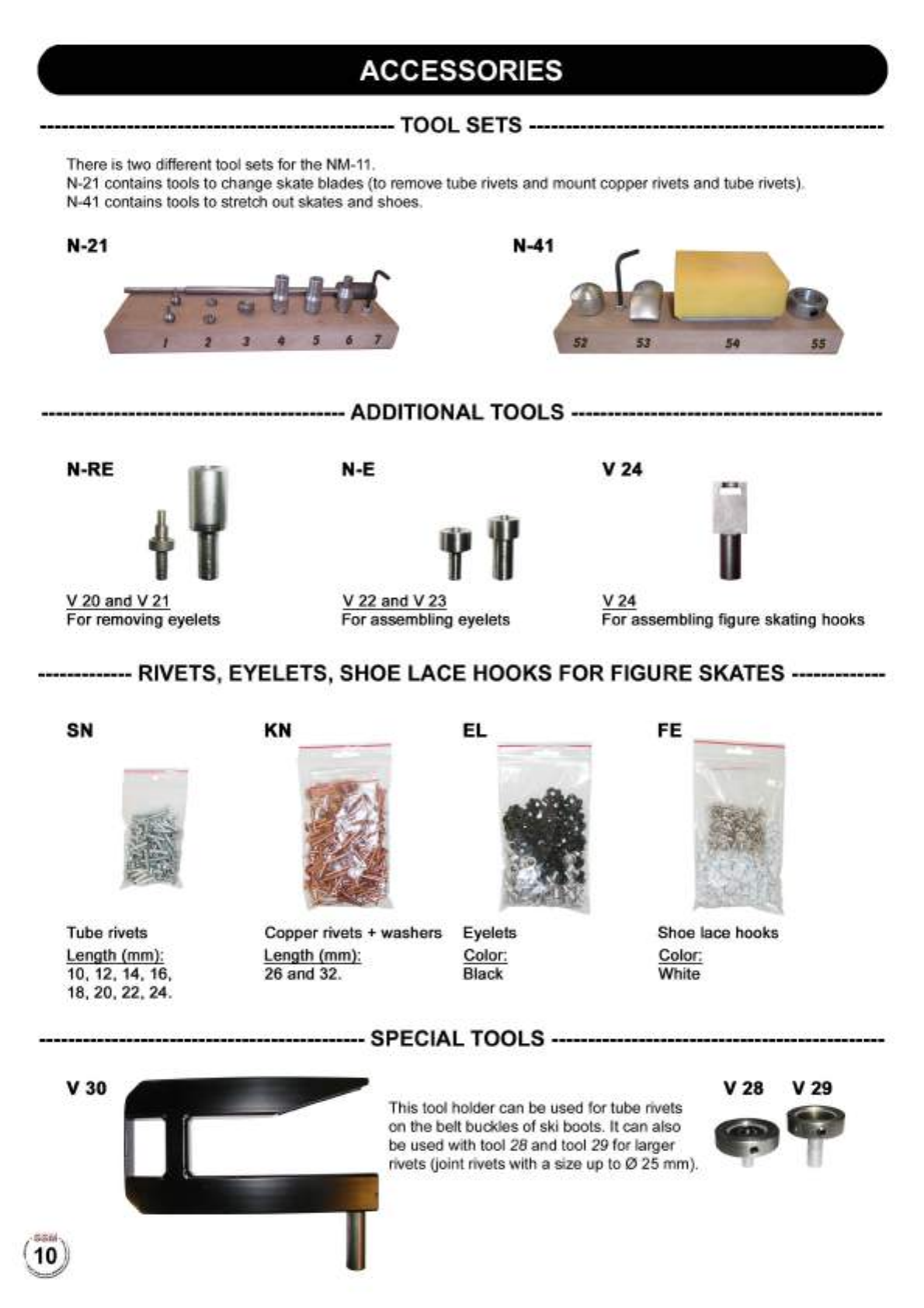

There is two different tool sets for the NM-11.

N-21

contains tools to change skate blades (to remove tube rivets

and

mount copper rivets and tube rivets).

N-41

contains tools

to

stretch out skates

and

shoes.

N-21 N-41

------------------------------------------

J\[)[)llrl()~J\L.

lr()()L.~

-------------------------------------------

N-RE N-E

V24

V 20 and V

21

V 22 and V 23

V24

For

removing eyelets

For

assembling eyelets

For

assembling figure skating hooks

-------------

RIVE:lr~,

E:YE:L.E:lr~,

~H()E:

L.J\CE:

H()()K~

F()R

FIGURE:

~KJ\lrE:~

-------------

SN

Tube rivets

Length (mm):

10, 12, 14, 16,

18,20,22,24.

KN

EL

Copper rivets + washers Eyelets

Length (mm): Calor:

26 and 32. Black

FE

Shoe lace hooks

Calor:

White

---------------------------------------------

~JlE:CIJ\L.

lr()()L.~

----------------------------------------------

V30

This tool holder

can

be

used for tube rivets

on

the belt buckles of ski boots. It

can

also

be

used with tool 28 and tool 29 for larger

rivets

Uoint

rivets with a size

up

to

0 25 mm).

V 28 V 29

Table of contents

Popular Rivet Tools manuals by other brands

Gesipa

Gesipa FireFox F operating instructions

Silver Eagle

Silver Eagle SE200 operating instructions

Central Pneumatic

Central Pneumatic 97857 Set up and operating instructions

Titgemeyer

Titgemeyer RL60-2 operating manual

Metabo

Metabo NMP 18 LTX BL M10 Original instructions

Cherry Aerospace

Cherry Aerospace G702A manual