6

RL60-2 / Manual

Titgemeyer / 10342EN1121 / 1

English

4. Occupational health and safety

The following instructions and directives

apply to the riveting tool described in

these operating instructions and to all

user groups.

In addition to the general instructions

in this chapter that concerns the entire

document and all procedures of using

the riveting system, some parts of this

document may contain additional safety

instructions which then specically rela-

te to the described matter.

5. Safety measures

Basic safety measures to avoid damages

and injuries.

Improper use of the tool may lead to

an injury or damage of property. To

avoid damages, always adhere to the

corresponding safety instructions of the

safety measure. Only qualied staff are

authorized to perform maintenance and

repairs of the tool.

6. Special safety advice

The riveting tool is exclusively designed

for setting blind rivets. The Customer

bears individual responsibility for each

and every change of the riveting tool!

ATTENTION!

— Use the tool only after reading and un-

derstanding the operating instructions.

— Do not operate with the tool if you are

ill, under the inuence of drugs, alcohol.

— Do not use the tool when it is incom-

plete and when it has visible mecha-

nical defects.

— Never aim the riveting tool at people

and do not rivet without material.

— Use the riveting tool only at working

temperature ranging from 5°C to 45°C.

— Never get over the maximum limit of

input air-pressure of 7 bar

— In case the provided air pressure

exceeds the max of 7 bar, use appro-

priate equipment to reduce it.

— Use only ttings and hoses for an

approved operating pressure of 10

bar in pneumatics.

— When adjusting or replacing com-

ponents, always disconnect the tool

from the compressed air supply

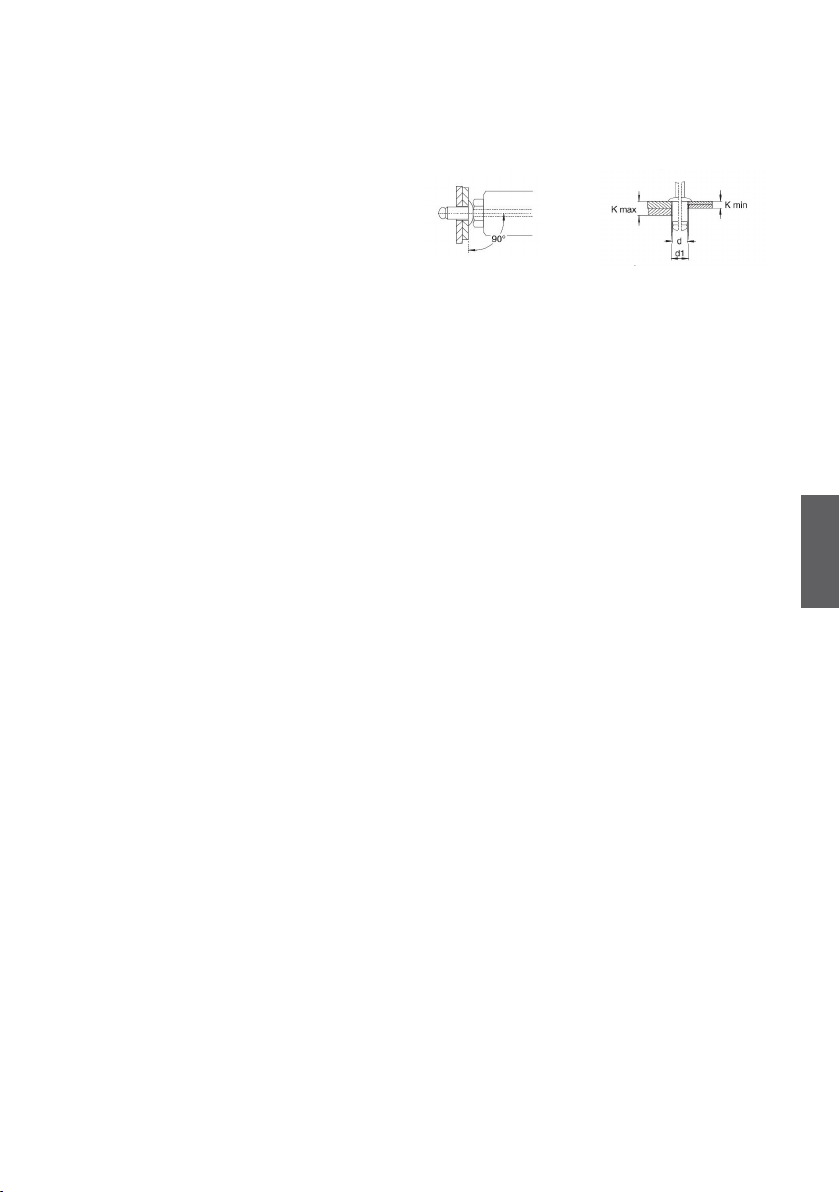

— For the used rivet diameter, use the

suitable nosepiece (5) accordingly.

— Always use personal protective equip-

ment.

— Tool not in current use must not be con-

nected to the compressed air supply

— Use the tool only for riveting

— Do not use the tool without assem-

bled nosecap (6).

— The riveting tool must not be carried

or lifted by the air hose

— Make sure, the suction system is not

activated, while disassembling the

mandrel collector (2), for emptying.