•STBC15 ultra-low current consumption linear battery charger. It is bases on a constant current and constant

voltage (CC/CV) charging algorithm. It embeds overdischarge and overcurrent protections to protect the

battery. The device can be put in shelf-mode, consuming only 10 nA and not discharging the battery before

the activation. The power consumption is of only 250 nA when the power source is removed. It is 10 nA if the

overdischarge protection is triggered.

Note: The battery charger can be used only with rechargeable batteries (LIR2032). By default, it is bypassed.

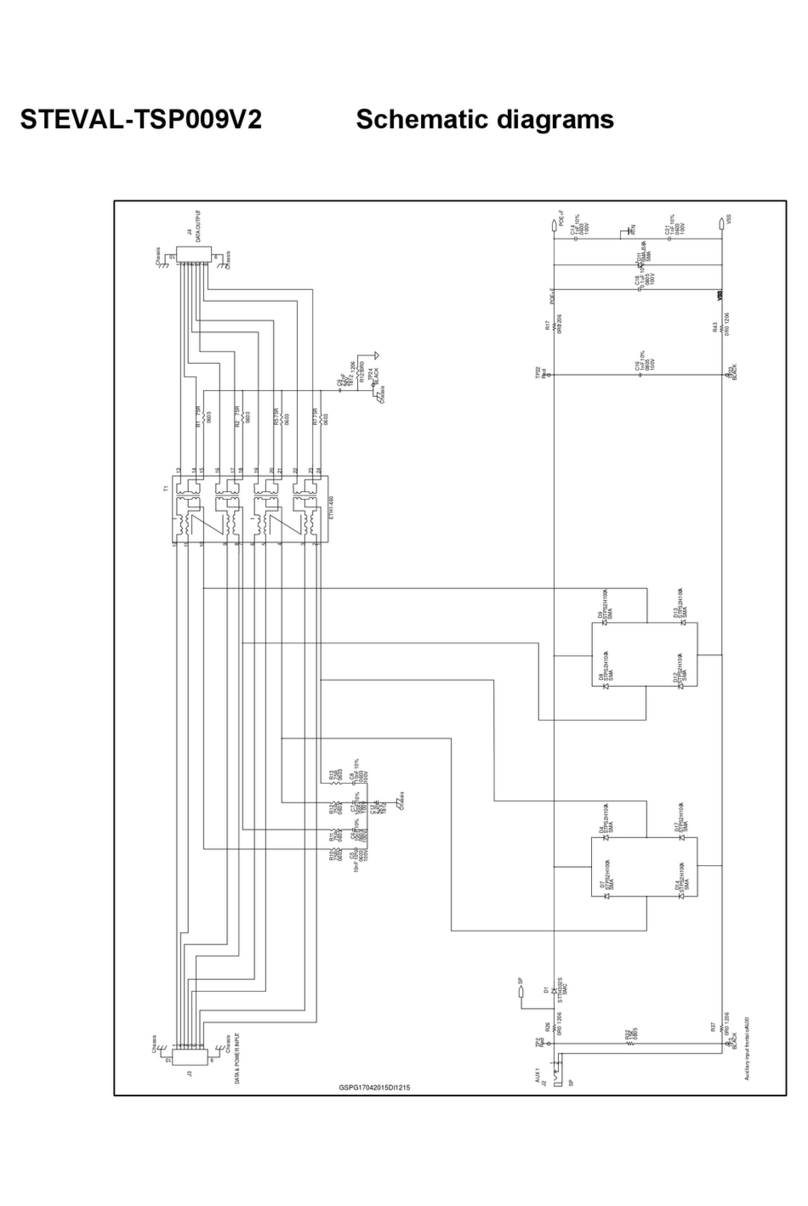

– The battery charger is fed by a full-wave rectifier for NFC energy harvesting. The following components

are also needed with the battery charger:

◦ Optional inductors to regulate the harvesting and keep the tuning of the NFC antenna

◦BAT54SFILM: four diodes in a full-wave rectifier configuration

◦STL4P3LLH6 P-channel MOS to gate the full-wave rectifier. It is driven by an N-channel MOS and

it is off by default

◦STL6N3LLH6 N-channel MOS to drive the P-channel MOS. It is driven by the MCU

◦ Capacitor bank to store the harvested energy

◦ Zener protection diode to clip and protect from overvoltage

◦ Exit shelf-mode button needed to deactivate the shelf mode

Note: The full-wave rectifier might need to be gated and disabled to improve the NFC communication. For the

same reason, you should limit the charging current from the battery charger.

•STSAFE-A110 secure element that supports the authentication and state-of-the-art cryptographic security.

It features the signature verification service to support secure boot and firmware upgrade of the host

microcontroller. It embeds usage monitors with secure counters. It also features pairing and secure channel

with the host microcontroller, symmetric data encryption and decryption (up to 16 keys), on-chip key pair

generation, advanced asymmetric cryptography (elliptic curve, NIS, or Brainpool 256-bit and 384-bit), elliptic

curve digital signature generation and validation with SHA-256 and SHA-384, protection against faults and

side-channel attacks, logical and physical attacks.

The following components are also needed with the secure element:

–STL4P3LLH6 P-channel MOS to gate the power to the secure element and enable 0-power standby. It

is driven by the MCU and it is off by default.

Note: If the STSAFE-A110 is mounted on the board, the anti-tamper function of the STM32 cannot be used as

the pins are shared with the I²C bus interface used by STSAFE-A110.

•M41T62 real-time clock with the embedded crystal oscillator to support accurate time keeping. It can be

adjusted within ±2 parts per million (±5 seconds per month).

Note: If the M41T62LC is mounted on the board, the anti-tamper function of the STM32 cannot be used as the

pins are shared with the I²C bus interface used by M41T62LC.

Additional devices can be connected on the same I²C bus interface of the STSAFE-A110 and M41T62. The

anti-tamper function of the STM32 cannot be used as the pins are the same.

Some components have a footprint and pinout chosen to enable the substitution with other pin-to-pin compatible

components:

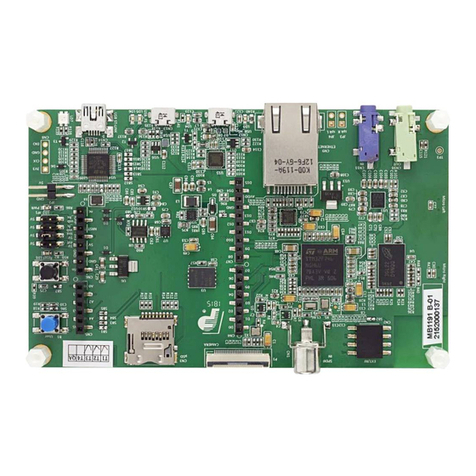

• Microcontroller in UFQFPN48 pin package: the STM32L4+ Cortex-M4F microcontroller (STM32L4P5CGU6)

can be swapped with a pin-to-pin compatible STM32L0 Cortex-M0 (STM32L071CZU6) to optimize cost and

power consumption.

• iNEMO inertial modules in LGA-14L package: the LSM6DSO32X inertial module can be replaced with the

following components:

–LSM6DSR accelerometer and gyroscope with enhanced temperature stability; 2, 4, 8, 16 g

accelerometer full scale; 125, 250, 500, 1000, 2000, 4000 dps gyroscope full scale. The output data

rate is from 1.6 Hz to 6.6 kHz. The peak power consumption is of 1.2 mA in the high-performance

mode at a 6.6 kHz data rate.

–LSM6DSRX has the same features of the LSM6DSR but it is also equipped with an MLC and FSM

core.

–LSM6DSV16X accelerometer and gyroscope with triple processing chain; 2, 4, 8, 16 g accelerometer

full-scale, 16 g for the secondary channel; 125, 250, 500, 1000, 2000, 4000 dps gyroscope full-scale.

The output data rate is from 1.875 Hz to 7.68 kHz. It features an enhanced MLC and FSM core. The

FSM core can also reconfigure the sensor.

UM3034

Overview

UM3034 - Rev 1 page 7/38