Contents UM1079

2/38 DocID018789 Rev 4

Contents

1 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Quick start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Development toolchain supporting the 32L152CDISCOVERY . . . . . . . . . 7

2.5 Demonstration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

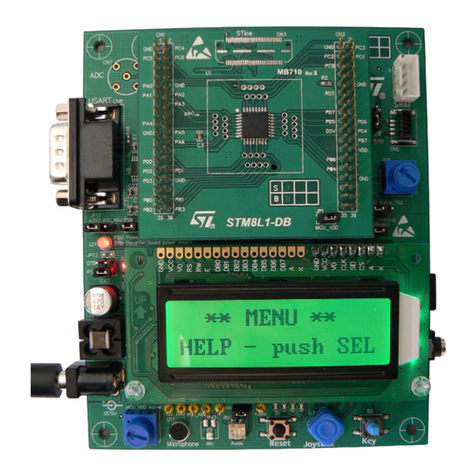

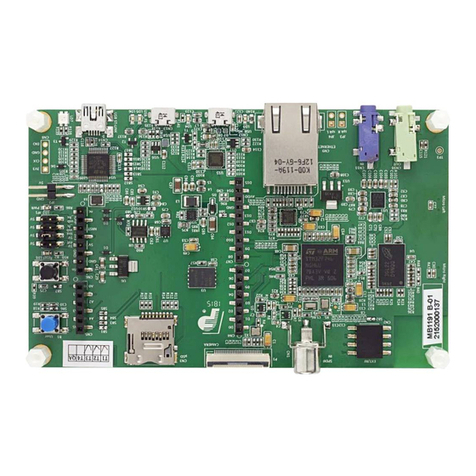

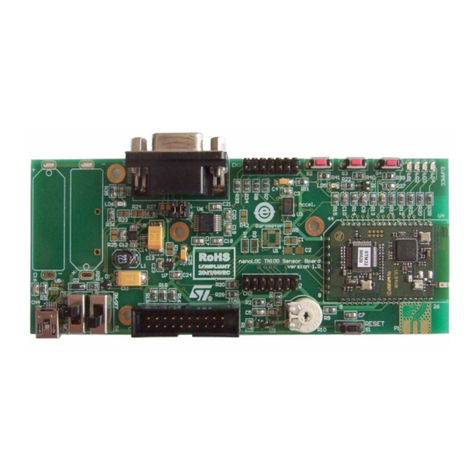

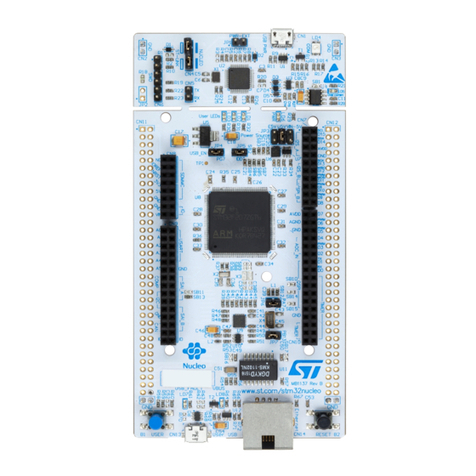

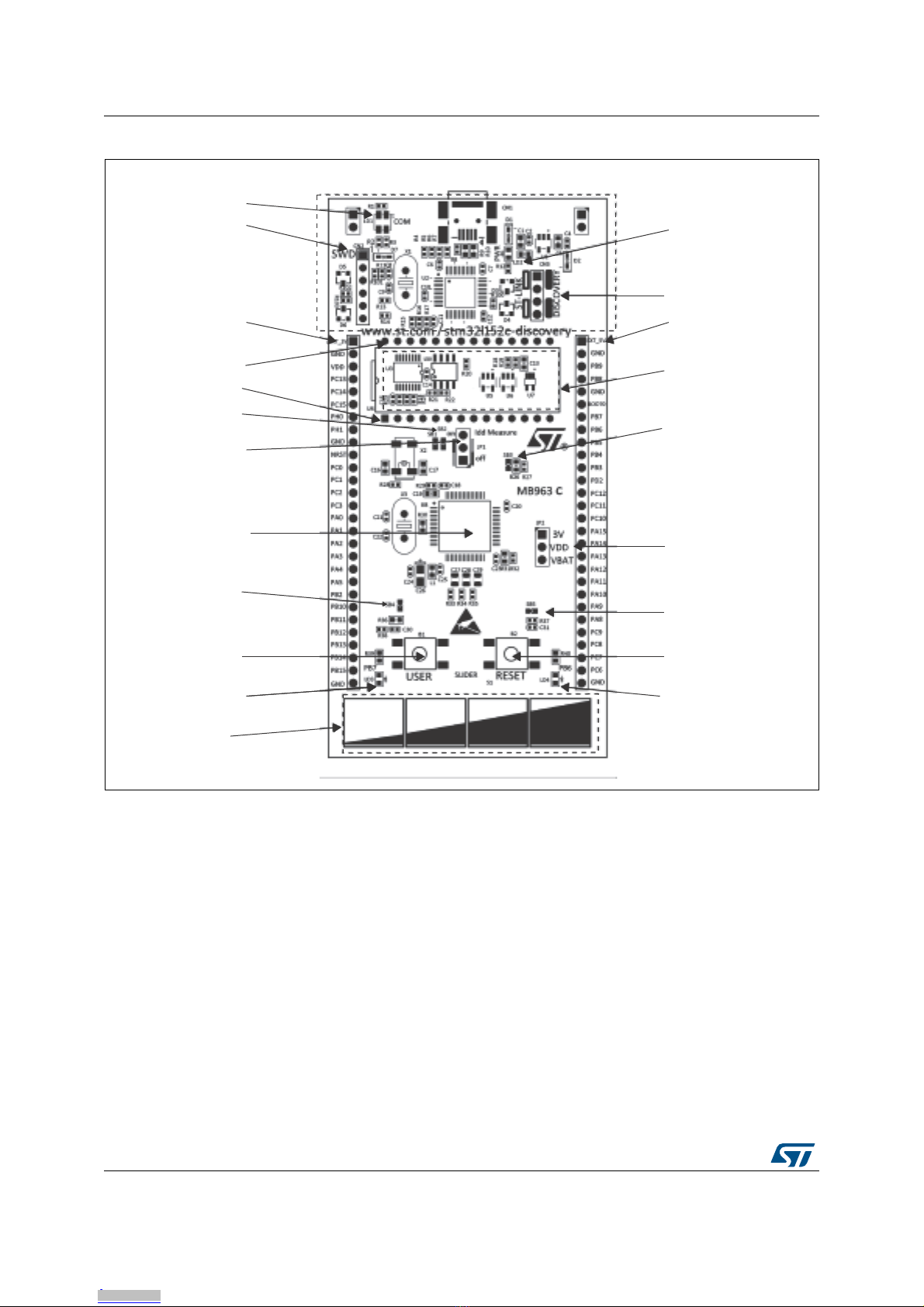

4 Hardware and layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 STM32L152RCT6 microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.2 Embedded ST-LINK/V2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Using the ST-LINK/V2 to program/debug the microcontroller on board 14

4.2.2 Using the ST-LINK/V2 to program/debug an external application . . . . . 15

4.3 Power supply and power selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5 Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

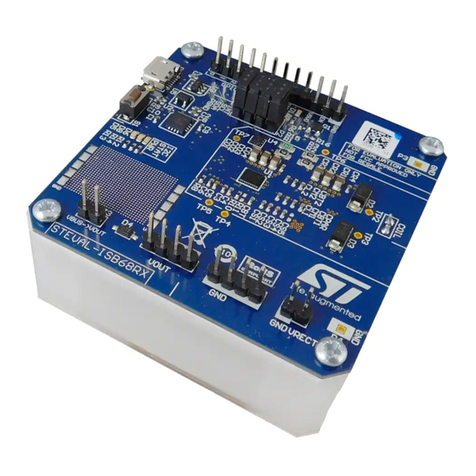

4.6 Linear touch sensor / touchkeys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7 Built-in IDD measurement circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.7.1 High IDD range mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.7.2 Low IDD range mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.7.3 IBIAS current measurement procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.8 Solder bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.9 LCD (24 segments, 4 commons) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 Extension connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Mechanical drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Electrical schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Downloaded from Arrow.com.Downloaded from Arrow.com.