UM0696 Starting PractiSPIN™.spmd

Doc ID 15599 Rev 2 5/15

2 Starting PractiSPIN™.spmd

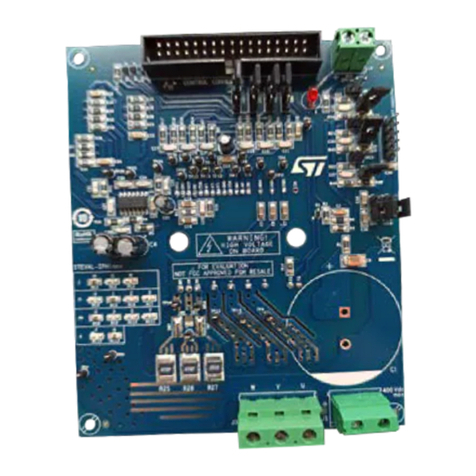

Since the PractiSPIN™.spmd system is capable of supporting several module

demonstration boards the user must first select the module that is evaluated.

●Module demonstration board set up: configure the jumpers/switches on the target

board and the control board as described in the paragraph for the specific

demonstration board being used.

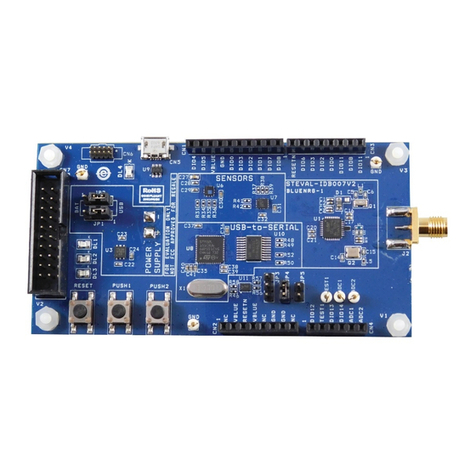

●Control board - PC connection: connect the control board to a serial COMM port of the

PC via a standard (straight through) 9 pin D connector cable.

●Powerup: energize the power supply

●Start PractiSPIN™.spmd software: on the PC, start the PractiSPIN™.spmd program

●Communication settings: click the drop down list under "port selection" and select the

COMM port being used. Baud rate and other communication parameters are fixed on

both sides of the link and do not need to be set.

●Establish COMM link: click the "connect to ST7 hardware". At this point the

PractiSPIN™.spmd software transmits several commands to the control board to

initialize the processor. The PractiSPIN™.spmd software reads the revision code of the

firmware currently stored in the Flash memory of the ST7 and determine if the correct

version of firmware resides in the ST7. If the PractiSPIN™.spmd software detects that

a firmware update is necessary, either because there is an old version of firmware or

the firmware currently in the Flash memory is not the correct firmware for the motor

type selected, one or more dialogue boxes appear asking if the program should

proceed with the update. Accept the updates and the PractiSPIN™.spmd software

automatically updates the firmware. The system then initializes the settings to the last

stored settings and open the appropriate PractiSPIN™.spmd software for the selected

target board.

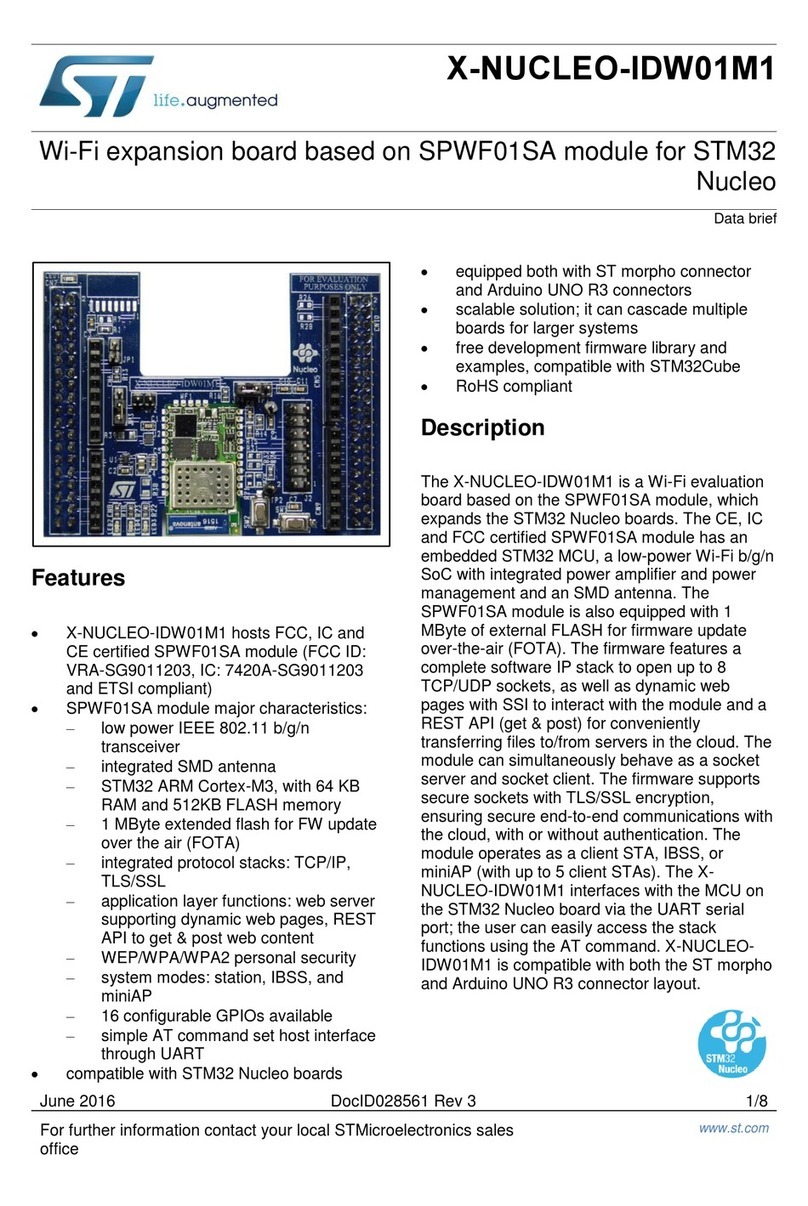

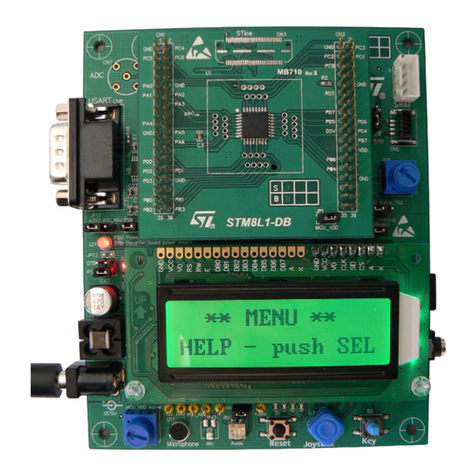

Figure 2. PractiSPIN™ launch window

●Calibrate current setting: when communication is established the user has the option to

adjust the offset and maximum current settings. If this is the first time you use the

system, calibration may be needed to adjust out the offset in the reference bias

circuitry. Calibration ensures that the reference voltage provided to target module

follows the PractiSPIN™.spmd software current settings. Calibration is a two-step

process; first the offset is adjusted then the maximum current is set. Clicking on

"connect ST7 hardware" button, the calibration window appears.

AM04220v1