List of figures UM0174

6/46

List of figures

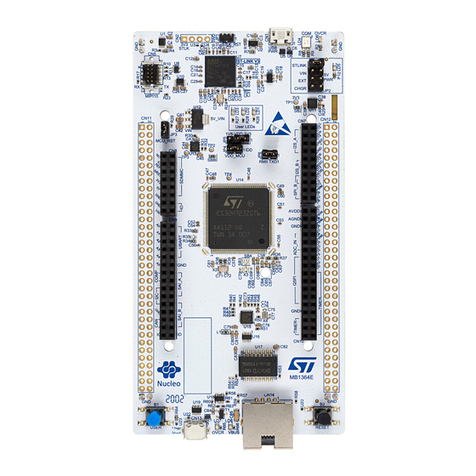

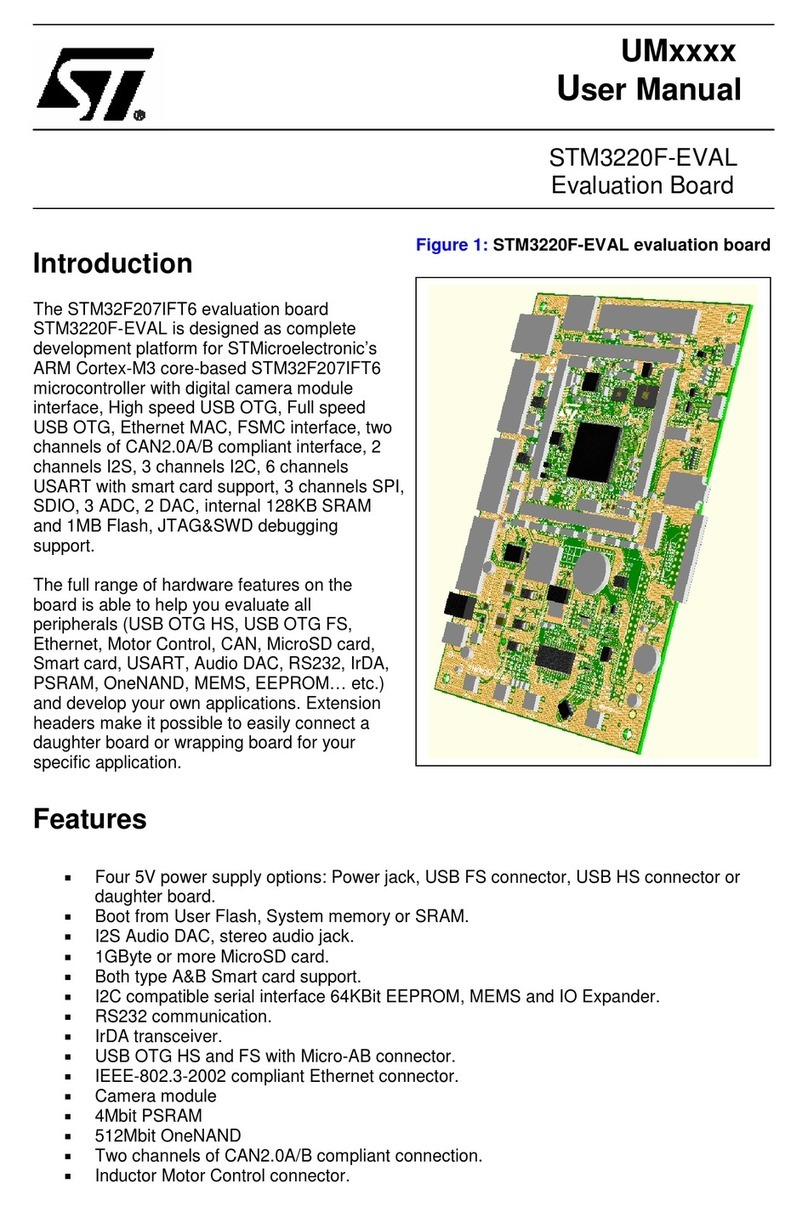

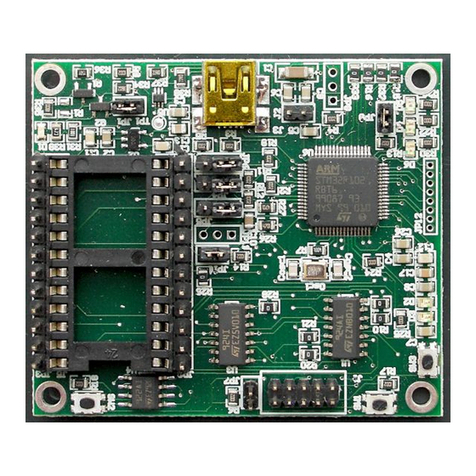

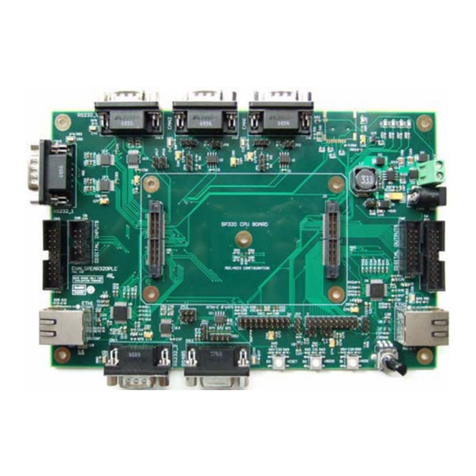

Figure 1. STR910-EVAL evaluation board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Connecting development tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Hardware block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. STR910-EVAL evaluation board layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. Settings for two-pin jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. STR910-EVAL evaluation board connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 7. Motor control connector (CN1, top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 8. Power supply connector (CN2, front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 9. USB type B connector (CN3, front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 10. CAN type D, 9-pin male connector (CN4, front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 11. ETM trace connector (CN7, top view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 12. RS232 connector (CN8, front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13. JTAG debug connector (CN9, top view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. RS232 connectors (CN10 and CN12, front view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 15. Ethernet RJ45 connector (CN11, front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 16. Find the version of your evaluation board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 17. STR910-EVAL microcontroller connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 18. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 19. CAN and USB connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 20. UART and IrDA connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 21. Ethernet connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 22. Audio peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 23. JTAG, ETM and daughter board connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 24. LCD and joystick. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38