Calibration system overview RM0345

6/38 Doc ID 024080 Rev 3

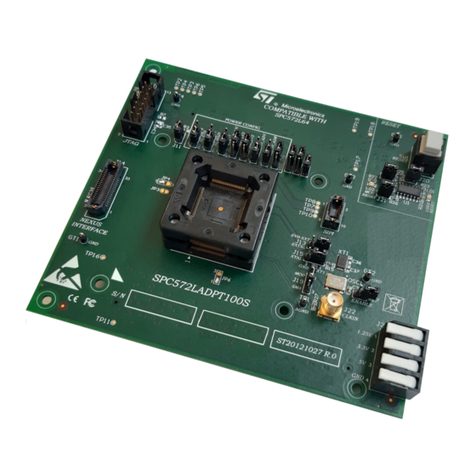

1 Calibration system overview

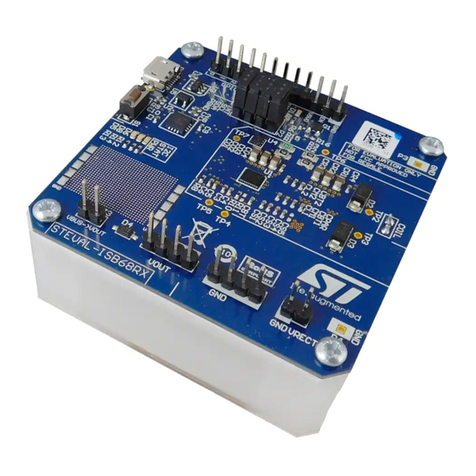

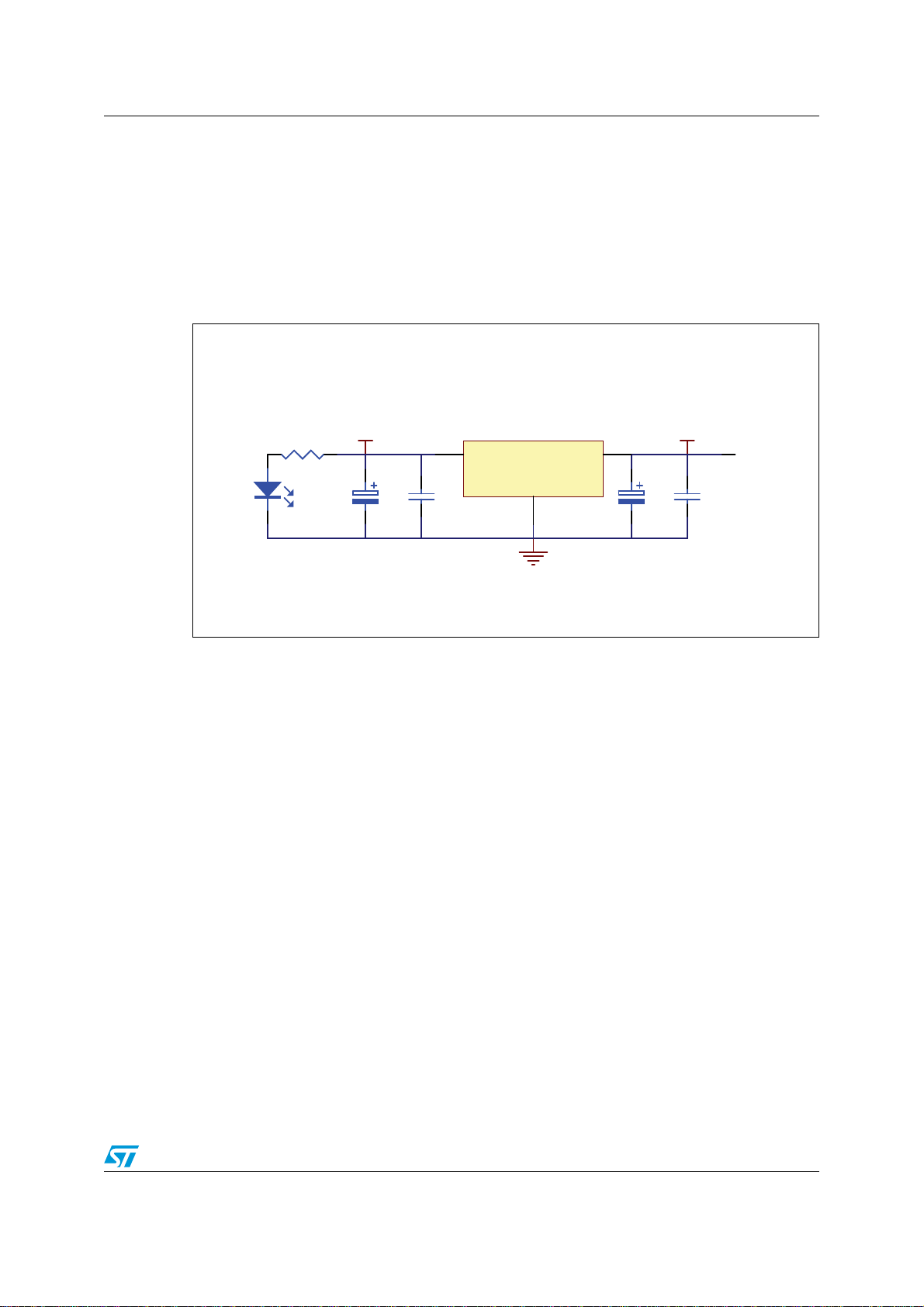

The Calibration Adapter board features 2 Mbytes of SRAM in order to substitute to the

SPC563M64xx internal Flash during calibration.

A voltage regulator is also integrated upon the board to generate, from selectable 5 V

source, the 3.3 V voltage for the RAM and the calibration bus interface.

Development connector (Mictor AMP38) is providing the interface for the debug and trace

tools.

A calibration connector (ERNI 154819) is providing an interface optimized for calibration

usage.

A high speed CAN transceiver is connected to the FlexCAN of the mcu device.

The components chosen in the design of this board are automotive qualified to allow system

evaluation over the full automotive evaluation range (-40 °C to 125 °C).

1.1 Features overview

calibration systems include these distinctive features:

●

Use 100% production silicon, ensuring full hardware and software compatibility

between production and calibration systems;

●

Support LQFP144 MCU production package allowing calibration systems to be built

without requiring modifications to the standard production system housing;

●

2MByte static RAM organized as 1024K words by 16 bits;

●

On-board latch providing a 16-bit de-multiplexed bus interface from the SPC563M64xx

16-bit multiplexed calibration interface;

●

Support for Nexus-based debug tools even if application PCB does not include Nexus

connector;

●

Nexus functionality with 12 Message Data Out (MDO) signals;

●

Support for full-feature calibration tools, via availability of comprehensive set of device

signals available on the connectors;

●

ERNI 154819 connector optimized for calibration;

●

High speed CAN transceiver with signals protection;

●

Allows system calibration without impacting standard MCU I/O resources;

●

Allows system calibration regardless of availability of standard MCU external bus;

●

Uses tried and tested technology.