10

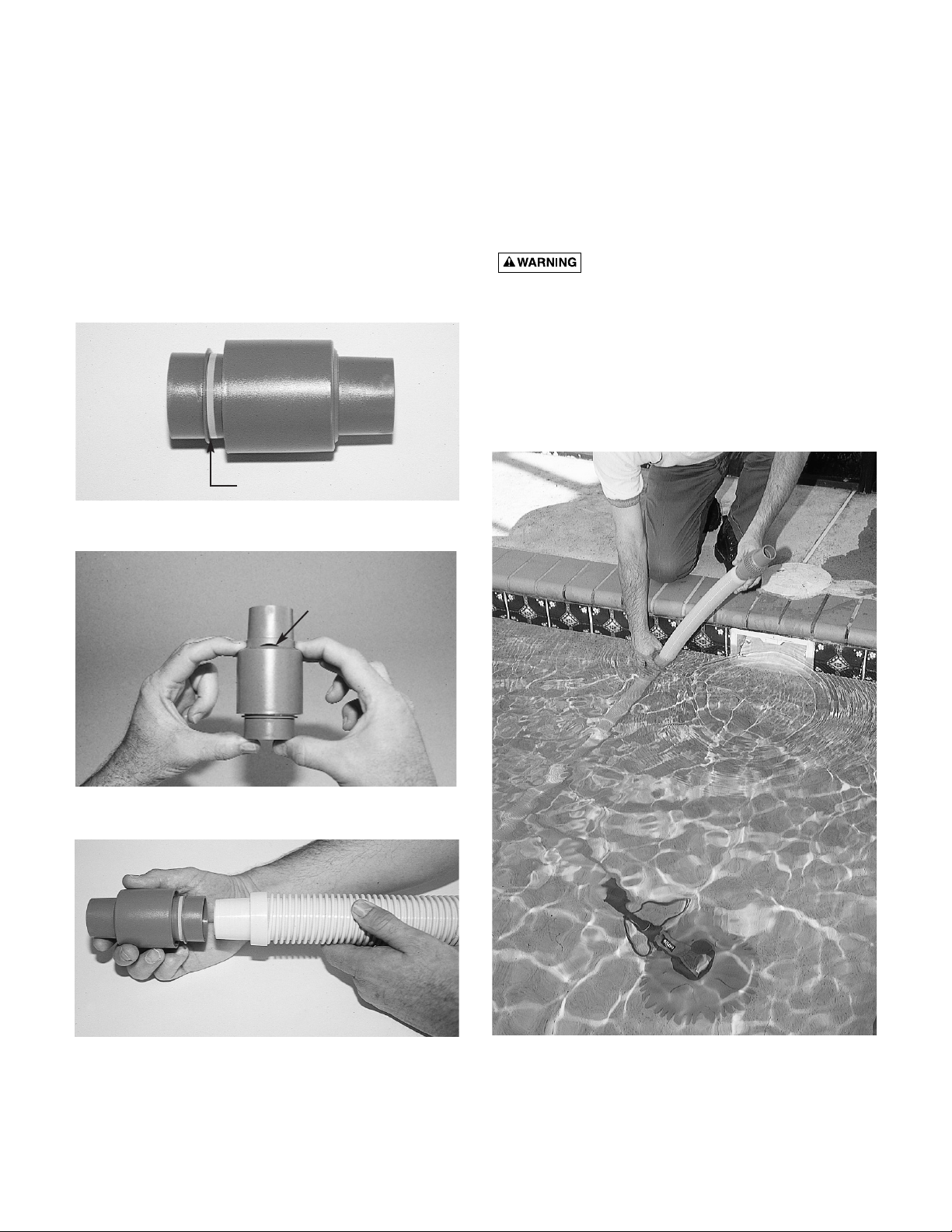

•STOP THE PUMP and check that the flapper valve is

not worn or damaged.

•STOP THE PUMP and check that the foot-pad is not

worn through.

•STOP THE PUMP and check that the vacuum seal is not

wearing thin.

3. If air bubbles are noticeable at the return jets:

•Check for leaks in the hose.

•Is the water level below the level of the regulator

valve or another intake source? If so, raise the water

level until all intake sources are submerged.

•Make sure the the pump strainer lid is not leaking;

check the O-ring seal.

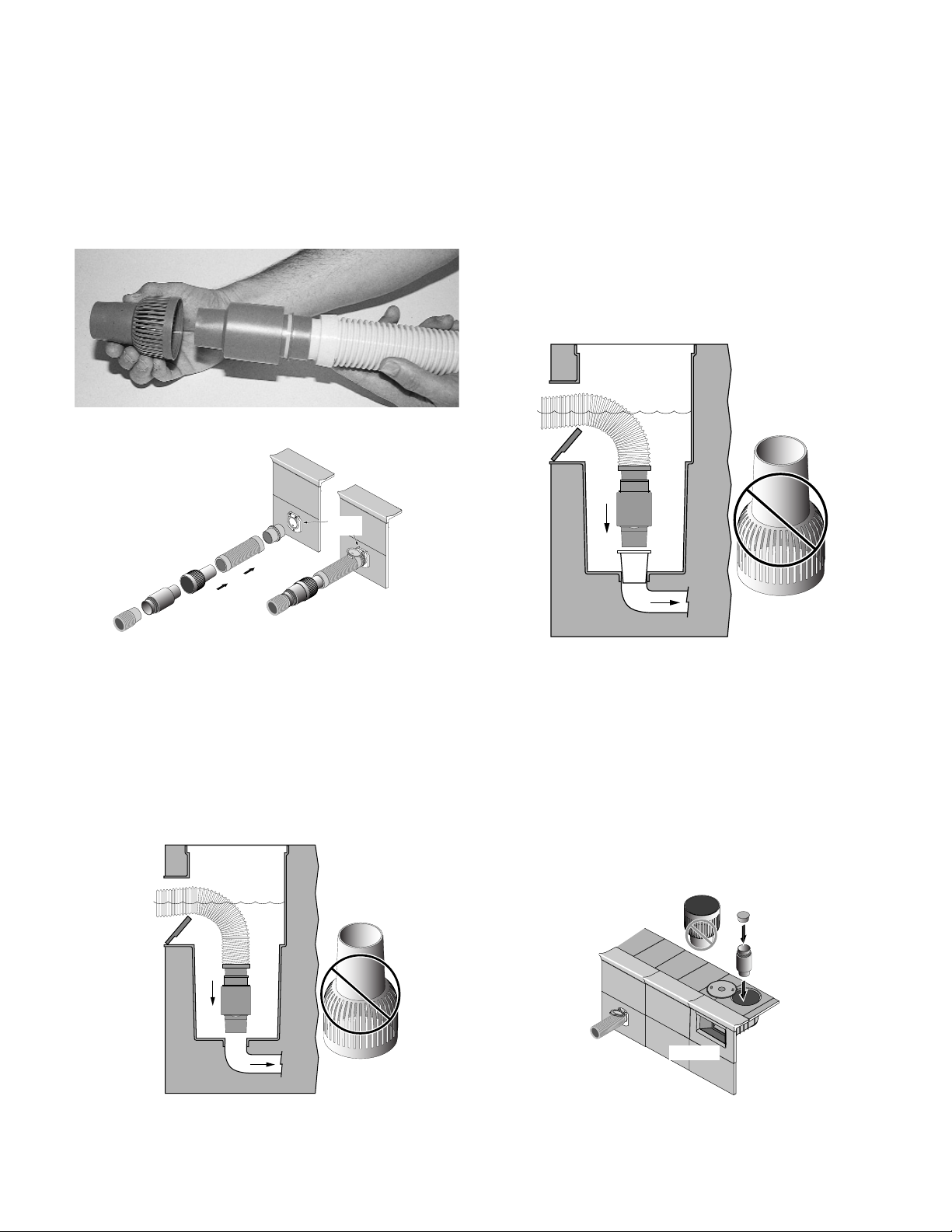

•Adjust the filter system valve to allow a small quan-

tity of water through the floor drain or another in-

take source that may have been shut off completely.

This will often eliminate the bubbles.

4. If the cleaner travels in a repetitive pattern and does

not visit sections of the pool:

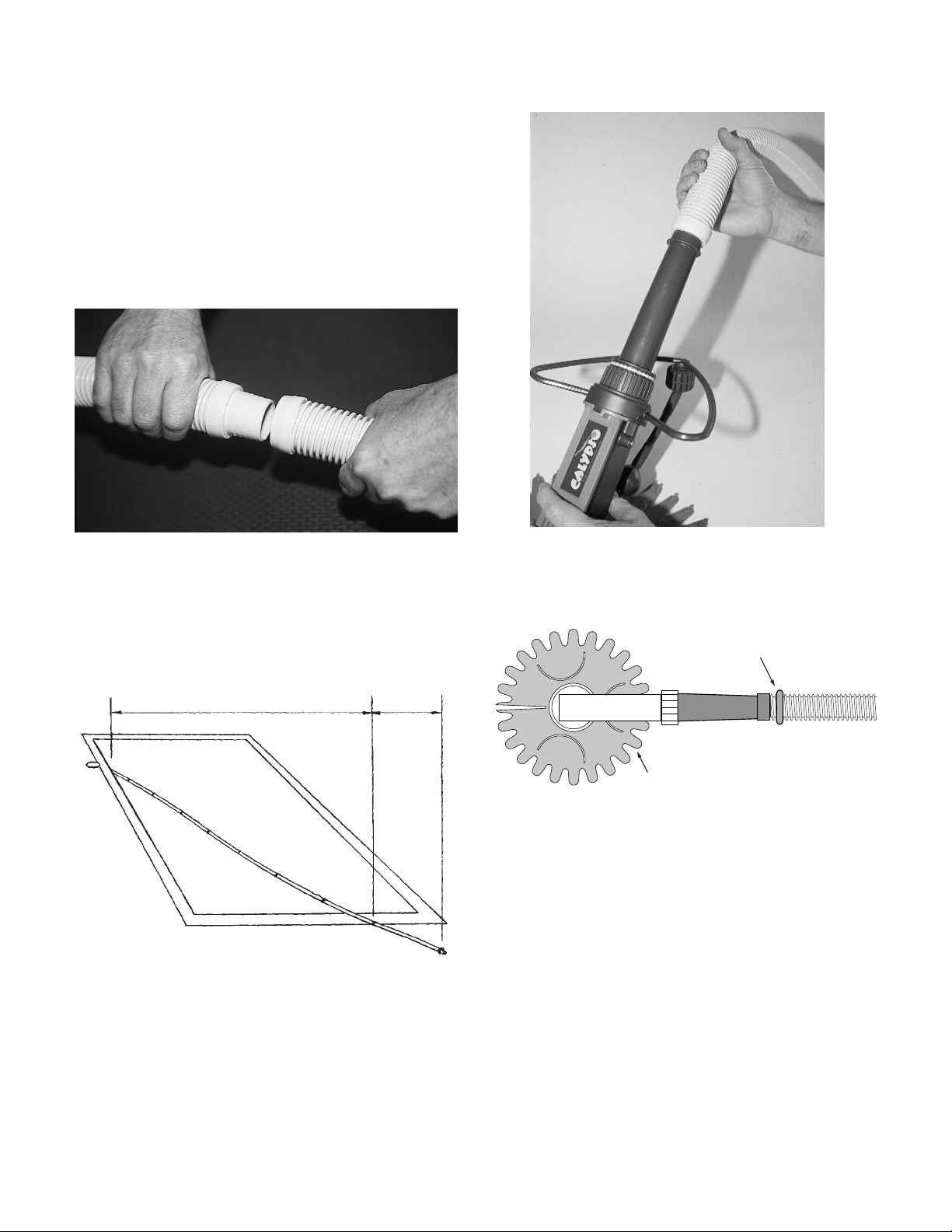

•Check that the cleaner and hose are balanced. See

Figure 16, Page 8, for information on balancing the

hose.

NOTE: The closer that the weight is to the cleaner, the

smaller the patterns of travel over the pool floor and walls.

However, putting the weight too close to the cleaner may

make it nose-heavy.

NOTE: In larger pools, the buoyancy of the hose can make

the cleaner hug the walls too much. In this case, move the

weight closer to the joint of the third and fourth sections,

then observe the pattern of operation. If the cleaner is still

not getting to the deep regions of the pool, you should pur-

chase another weight (Part No. 41201-0238) and attach it

to the fourth section of hose. Then observe the pattern

again and adjust the location of the weights as necessary.

•Are the hose sections straight? If the sections have

been coiled during storage, this will impair the

cleaner’s operation. Try to straighten the sections by

laying the lengths of connected hose out in the

warm sun. Never use the hand vacuum hose or an-

other manufacturer’s hose – use only genuine

Calypso hose.

•Are the hose and/or cleaner being affected by return

flow? Adjust the pool return jets to avoid unwanted

flow against the hose or cleaner. Of course, the flow

may also be directed in a particular direction if it

will help to position the hose or improve the travel

pattern of the cleaner.

•Try adding or subtracting a section of hose. This will

change the behavior of the cleaner and may be nec-

essary to break a repetitive pattern of travel.

•Is there too much or too little suction? Refer to the

suggestions under (1) above.

5. If the Calypso is being trapped in a corner or near the

steps:

•Make sure that the bumper and roller are properly

attached.

•Adjust the return jet closest to the trap so that the

flow of water from it will help to move the hose or

the cleaner itself. This adjustment is best done a lit-

tle at a time.

•Add or subtract a section of hose. This will help the

cleaner avoid the trap or free itself if it gets trapped.

•Change the position of the hose weight to help

swing the cleaner out of the trap.

•Adjust the suction through the cleaner; try lower

and higher levels.

6. If the cleaner falls on its side:

•Check that the connecting tube swivels freely. If not,

flush the area around the swivel connection. If nec-

essary, replace the connecting tube (Part No. 41101-

0126).

•Check that the float is attached, is not damaged, and

is not filled with water (Part No. 41101-0128).

7. Hopper bottomed and square bottomed pools:

•Due to the shape of the floor of these pools, the

cleaner may have a tendency to hug the perimeter

of the pool.

•To reduce adhesion to the floor, operate the cleaner

on a lower suction. This will make it easier for the

cleaner to move away from the perimeter.

If you still need help call

Sta-Rite customer Service at 1-800-752-0183.