Operating Instructions MT-xx6-A Device function

Page 8 of 60 R. STAHL HMI Systems GmbH / OI_MT_xx6_A_en_V_03_00_26.docx / 03.11.2020

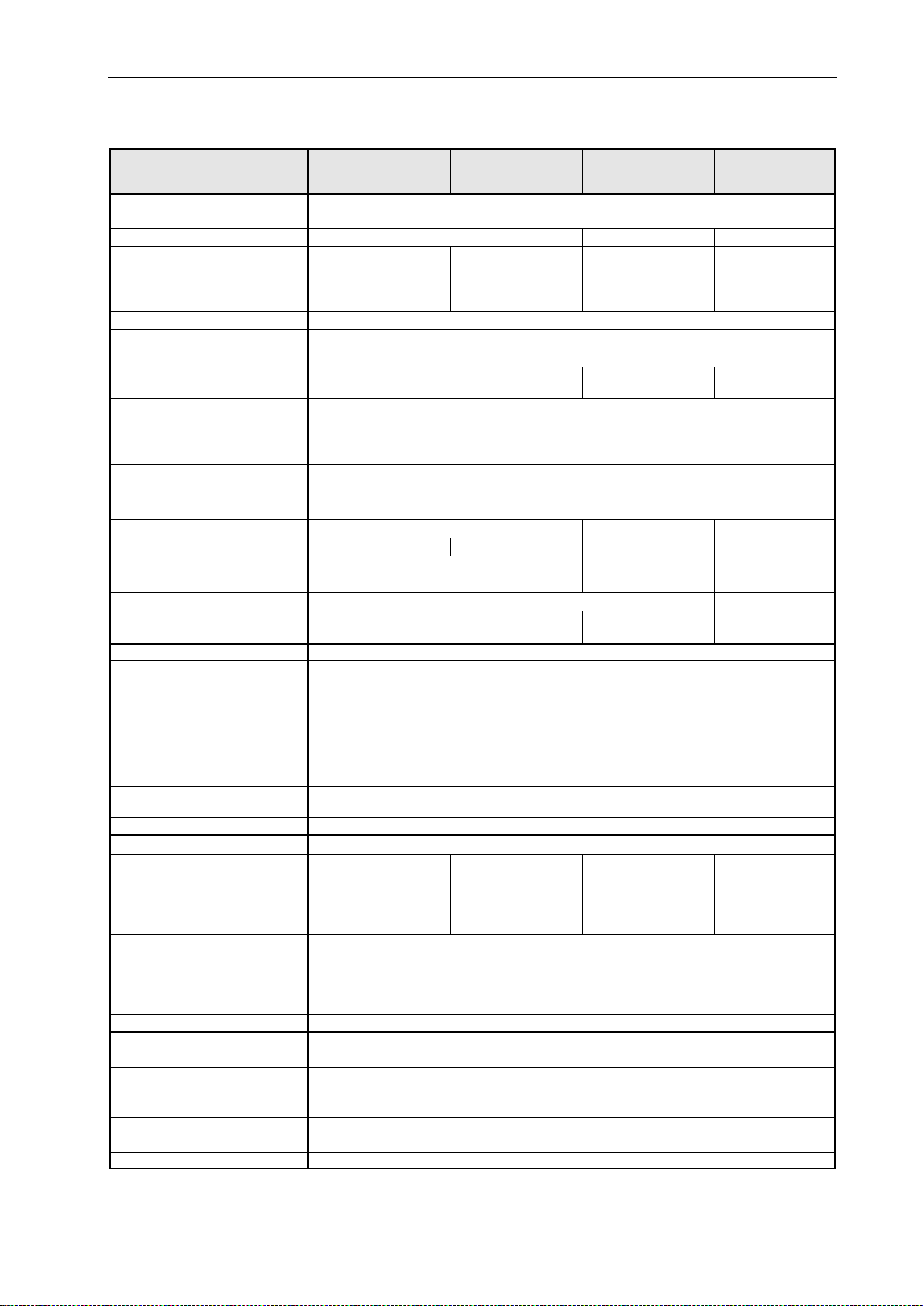

2.4 MT-3x6-A-* (SERIES 300 Operator Interfaces)

The MT-3x6-A-* operator interfaces have been designed for the visualisation of medium-sized

automation tasks, operation as built-in device and tankfarm application in hazardous areas. The

Eagle operating stations have been designed to run with a proprietary operating system, making

them highly secure against external manipulation.

Users operate the device via the membrane keyboard integrated into the front plate and via the

LCD display with touch screen.

Communication with control and automation systems runs via the serial interfaces (RS-232

RS-422/485, Ethernet) connected in the "e"-area at the back of the devices. Various peripheral

devices, such as barcode scanners, card readers, USB sticks and WLAN / Bluetooth modules

can be connected via USB interfaces or optional fitted modules.

With a wealth of functions, these HMI devices provide optimum visualization. Their active

communication concept in combination with integrated functionality reduce the automation

system workload.

2.5 MT-4x6-A-* (SERIES 400 Panel PC)

The MT-4x6-A-* devices are robust Panel PC´s for hazardous areas. With their pre-installed

Windows operating system they are ready to run straight away.

As a standard, all Panel PC´s are equipped with a touch screen and several interfaces and are

based on the powerful Atom technology, making them the most powerful devices on the market.

2.6 MT-5x6-A-* (SERIES 500 Thin Clients)

The MT-5x6-A-* devices of the 500 SERIES can be integrated into modern networks as Thin

Clients or with a KVM box via KVM-over-IP, thus providing ideal and flexible access options with

central data administration.

The MT-5x6-A-* device, which is used for operation and visualization, is located in the

hazardous area, whereas the PC that is operated is located in the safe area. Each ERP / MES

network can be accessed from each Thin Client via the IP address.

The Thin Client system supports both modern technologies such as DVI and USB and older

technologies such as VGA and PS/2.

2.7 Overview hardware revision MT-xx6