Installation Manual ET-/MT-xx8 Application and location

Page 6 of 91 R. STAHL HMI Systems GmbH / IM_ET_MT-xx8_en_V_01_01_02.docx / 11.03.2020

1 Application and location

The ET-/MT-xx8 devices, device platform SHARK (SERIES 400 / 500 and 600) are specially

designed for the Oil and Gas Industry. They can be mounted at Rig floors (fixed or mobile), drillers

/ crane cabins as well as wireline mounting and tankfarms. Suiteable for usage in hazardous

areas zone 1, 21, 2 and 22 (depending of device type), this devices are ideally for a large numbers

of applications.

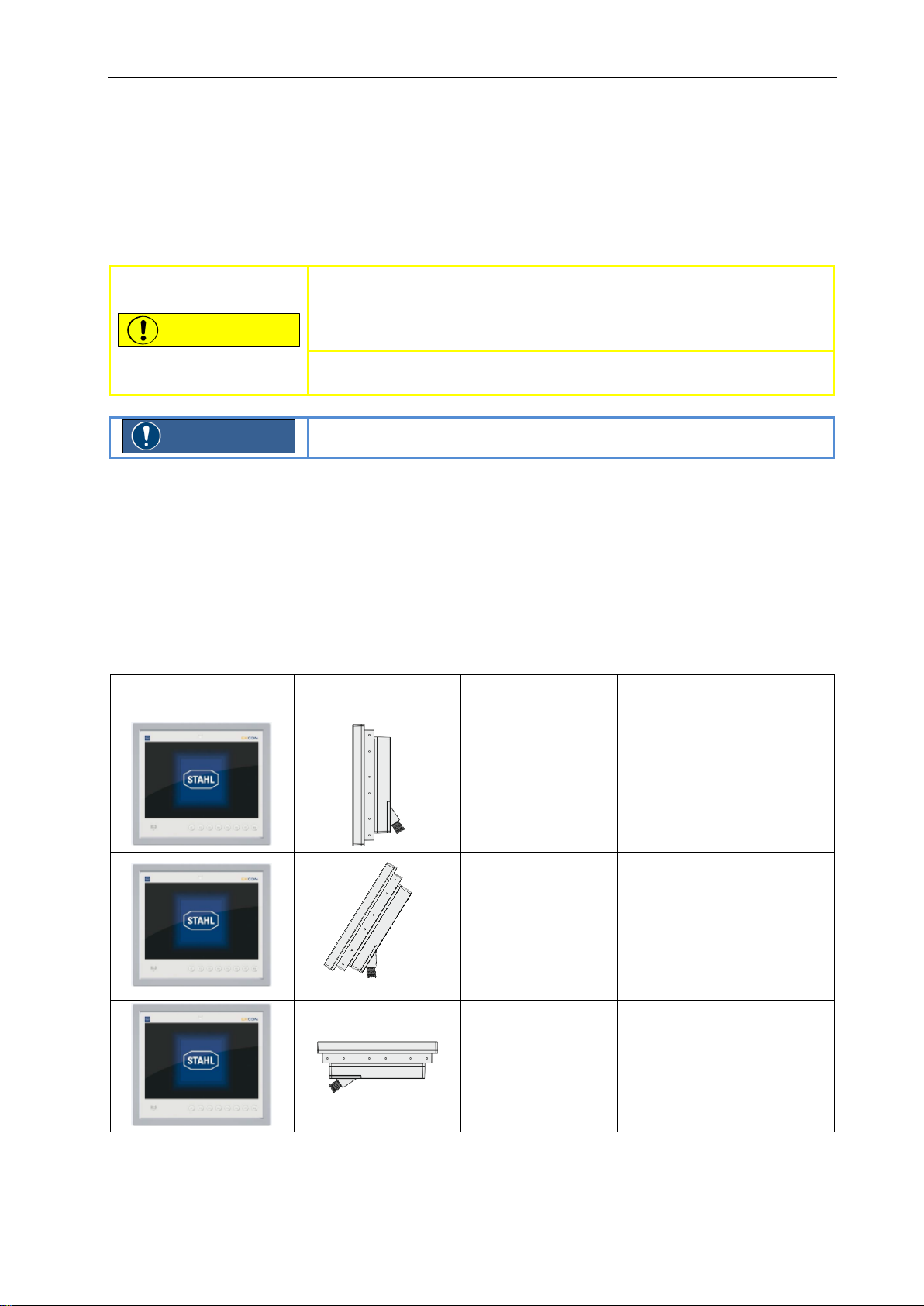

2 General notes

If not otherwise specified, all information, descriptions and

illustrations apply in the same way to devices x38 and x98 as well as

versions "Standard" and "Top Connect", even if the illustrations only

show one version !

3 Warnings

3.1 Touch operation

Incorrect / phantom operation:

Incorrect operation of the touch screen may result in accidental functions and errors. The

operating device will then be unable to implement these, may implement these incorrectly or in a

way not intended!

- Do not realise safety-relevant functions via the touch screen !

- Avoid accidental multi-touches !

- Do not touch the touch screen across a large area !

- Use a touch pen only for the capacitive touch screen !

- Before operating the device, thoroughly acquaint yourself with the multi-touch functions of

the operating system and the application !

- Switch off the device for cleaning and maintenance !

Conductive liquids on the touch screen can result in incorrect or phantom operations. This applies

in particular to salt water.

- Avoid contamination of the touch screen surface with salt water.

Protect the device bevor rain, snow and splash water, because large quantity of stand or floating

water can disturb the operation and can cause in unwanted cursor movements.

This protection can be done with a sun roof or any other covered construction. Strong wind, salt

water and rain had to be considered in this thoughts offshore.

Damage of the touch screen:

Only touch the touch screen with your fingers or a appropriate touch pen.

- Avoid contacts with pointed or sharp objects, this can damage the touch screen and lead

to a significant reduction in service life or even total failure of the touch screen !