Operating Instructions

IS1 PROFIBUS 3.00 E - Technical alterations reserved - 3

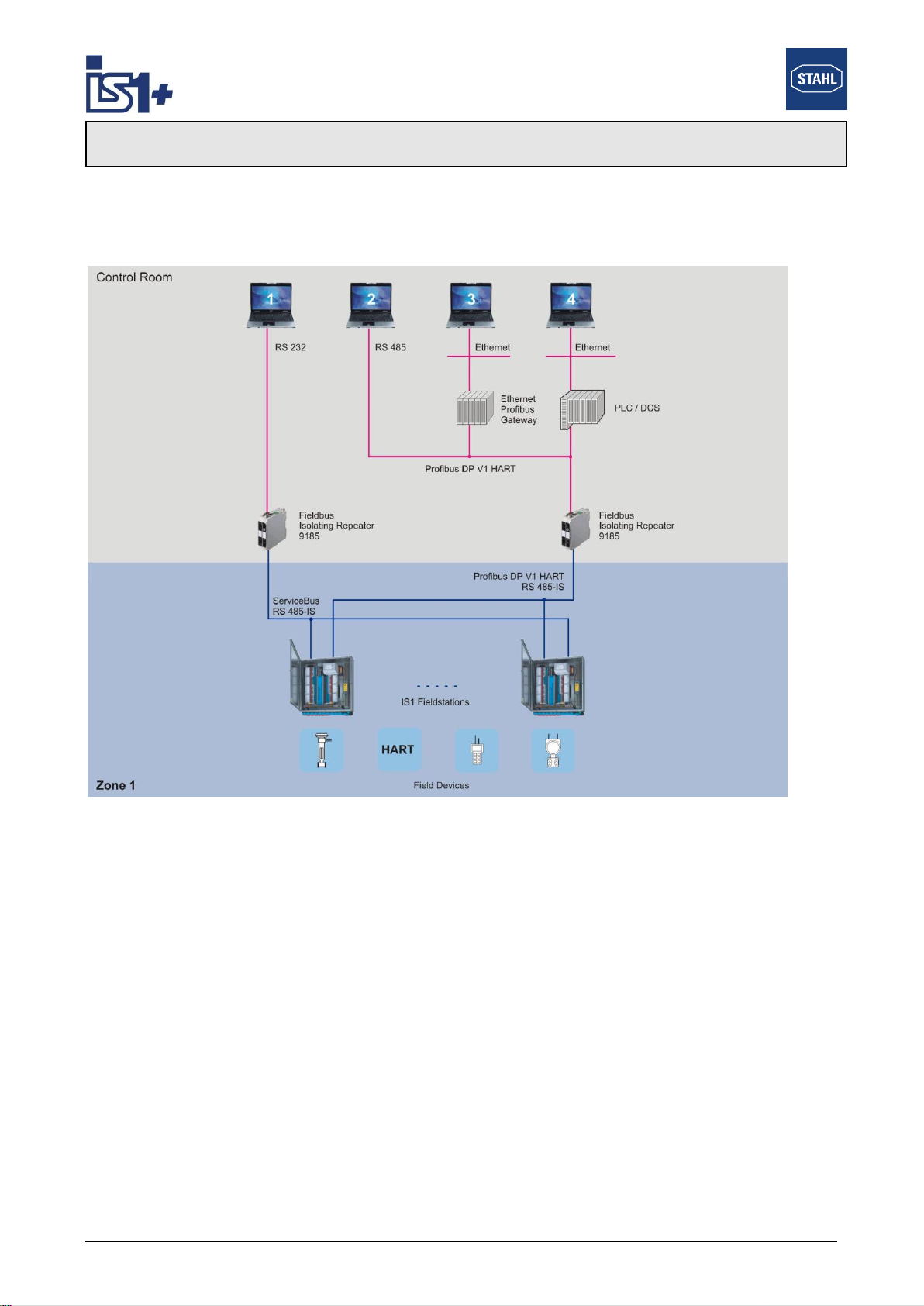

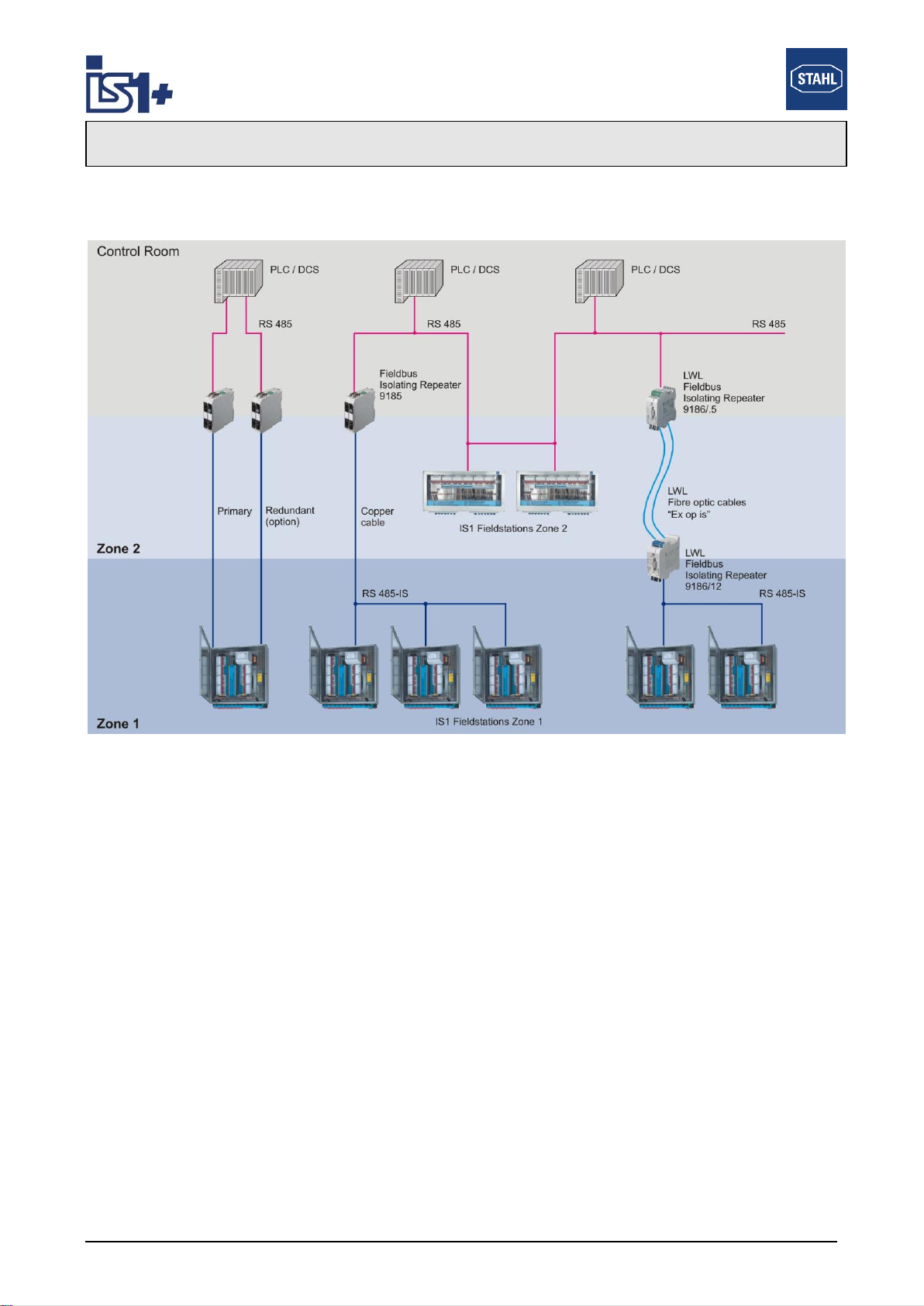

PROFIBUS DP interface for IS1+

Bit coding of IO-Module parameters ...................................................................................... 53

3.2.4.1 AIM / AIMH / AUMH............................................................................................................ 53

3.2.4.2 UMH 9469.......................................................................................................................... 54

3.2.4.3 TIMR 9480........................................................................................................................ 55

3.2.4.4 TIM mV 9481 ..................................................................................................................... 56

3.2.4.5 TIM 9482............................................................................................................................ 57

3.2.4.6 DIM (9470/3x in compatible mode).................................................................................... 58

3.2.4.7 DIOM 9470/3x, 9471/35, 9472/35 (IS1+) ...................................................................... 59

3.2.4.8 AOM / AOMH 9466............................................................................................................ 60

3.2.4.9 DOM.................................................................................................................................... 61

3.3 Data word structure of the I/O modules.............................................................................................. 62

Analog modules...................................................................................................................... 62

3.3.1.1 AIM, AIMH (9460/..., 9461/..., 9468/…, 9469/…) ............................................................ 62

3.3.1.2 TIM (9480/... , 9481/..., 9482/…) ..................................................................................... 65

3.3.1.3 AOM 0 –20 mA (9465/... , 9466/..., 9468/..)................................................................... 68

DIM, DIM+CF, DIOM (9470/.. 9471/.. 9472/..)................................................................ 70

DOM (9475/.., 9477/.., 9478/..) ............................................................................................. 76

3.4 Signal behavior in case of errors........................................................................................................ 77

Behavior of the input signals in case of errors ....................................................................... 77

Behavior of the output signals in case of errors..................................................................... 78

3.5 HART variables................................................................................................................................... 79

Module selection in GSE file / IS1 DTM / IS Wizard .............................................................. 79

Data format............................................................................................................................. 80

Selection of the HART variables ............................................................................................ 80

3.6 Diagnosis data.................................................................................................................................... 81

Standard diagnosis information in PROFIBUS DP ................................................................ 83

Identifier related diagnosis of the IS1+ modules.................................................................... 84

Device related diagnosis IS1+ Fieldstation (DPV0) .............................................................. 85

CPU Status (DPV1)................................................................................................................ 88

Module Status (DPV1)............................................................................................................ 90

Redundancy Status (DPV1)................................................................................................... 90

IO-Module Status (DPV1)....................................................................................................... 91

Channel-related diagnosis...................................................................................................... 93

3.7 Group alarm / field station status........................................................................................................ 95

Control register CPU .............................................................................................................. 95

Status register CPU................................................................................................................ 95

3.8 LED and LCD displays CPM 9440 ..................................................................................................... 96

3.9 LED displays CPU 9442..................................................................................................................... 96

3.10 DPV1 records ..................................................................................................................................... 97

3.11 I&M Function (DPV1).......................................................................................................................... 98

3.12 Online behavior of the IS1+ field station........................................................................................... 100

Parameter change................................................................................................................ 100

Configuration change. .......................................................................................................... 100

4Ethernet Interface 9442 CPU.......................................................................................................... 101

4.1 Ethernet Network Topology.............................................................................................................. 101

4.2 IP Address setting............................................................................................................................. 101

4.3 IS1+ Detect....................................................................................................................................... 101

4.4 Web Server....................................................................................................................................... 102

5IS1+ APL Driver library for PCS7.................................................................................................... 104

6List of abbreviations: ....................................................................................................................... 105

7Release Notes:................................................................................................................................ 106

8Support address.............................................................................................................................. 107

9Appendix A: GSD File Rev. vs. CPM 9440 Firmware Rev............................................................. 108