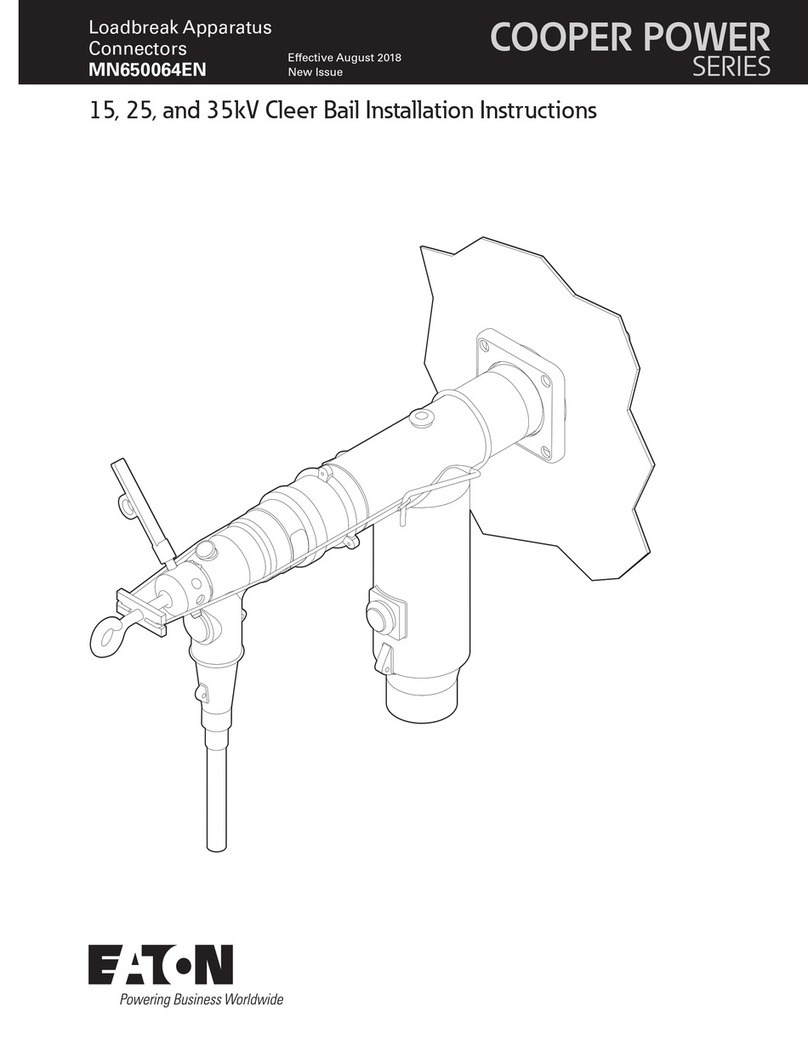

Stahlwille MANOSKOP 721 Quick User manual

Instructions for use

EN

MANOSKOP®721, 730 Quick

Status: 07/2016

Contents

Technical description....................................................................................................................................3

All models...........................................................................................................................................................3

Standard MANOSKOP®721/5 Quick, 721/15 Quick, 721/20 Quick and 721QR/20 Quick ...............................4

Standard MANOSKOP®721/30 Quick ..............................................................................................................4

Service MANOSKOP®730/5 to 730/65 Quick ...................................................................................................4

Technical Data....................................................................................................................................................4

MANOSKOP®721 Quick..........................................................................................................................4

MANOSKOP®730 Quick..........................................................................................................................5

Safety instructions ........................................................................................................................................6

Intended Purpose ...............................................................................................................................................6

Structural features of the information on dangers..............................................................................................6

Structural features of notices regarding material and environmental damage...................................................6

Correct torque settings ......................................................................................................................................7

Operation........................................................................................................................................................7

Selecting the inserts and insert tools..................................................................................................................8

Attaching insert tools ..........................................................................................................................................8

721/5, 721/15, 721/20, 721QR/20 Quick..................................................................................................8

721/30 Quick ............................................................................................................................................9

Attaching insert tools —730/5 to 730/65 Quick.................................................................................................9

Removing insert tools.......................................................................................................................................10

730/5 to 730/65 Quick............................................................................................................................10

Setting the torque level.....................................................................................................................................10

Controlled counter clockwise tightening...........................................................................................................11

Uncontrolled loosening of nuts & bolts ............................................................................................................11

Using the torque wrench...................................................................................................................................12

Maintenance.................................................................................................................................................13

Checking the accuracy of the cut-out value .....................................................................................................13

Adjusting for deviations in cut-out value...........................................................................................................15

Cleaning .......................................................................................................................................................16

Accessories..................................................................................................................................................17

For all models...................................................................................................................................................17

For STAHLWILLE Service MANOSKOP®730 Quick.......................................................................................17

Services............................................................................................................................................................17

Disposal........................................................................................................................................................17

Technical description

3

Technical description

No

Explanation

1

MANOSKOP®

2

Sliding scale

3

Magnifying glass

4

Pressure plate

5

Ratchet adapter

All models

MANOSKOP®721 and 730 Quick are adjustable

torque wrenches with a cut-out, tactile and audible

cut-out signals.

These torque wrenches have a safety cut-out

mechanism.

The wrench is set to cut-out at a certain torque

level by setting the required value on the force-

free sliding scale.

The setting slide has an automatic setting fail-safe

mechanism.

The measuring element is a flexible rod. The

flexible rod is not pretensioned and is only under

tension during the tightening process until the

wrench cuts out.

After use, it does not need to be reset to the

lowest value.

As soon as the torque wrench is released, it is

ready for the next job.

The 2-component grip, which is ergonomically

designed, ensures pleasant and safe handling.

The right grip position is indicated by optical and

tactile signals.

These wrenches will only tighten in one direction.

Counterclockwise tightening is possible thanks to

an insert tool which is rotated by 180°. Exception:

The MANOSKOP®721/5 Quick, 721/15 Quick

and 721/20 Quick cannot be used for counter

clockwise tightening. Counterclockwise tightening

is possible with the MANOSKOP®®721/30 Quick

by means of a square drive which is pushed

through.

By means of the QuickRelease function, insert

tools can be changed quickly.

If necessary, these torque wrenches can be

readjusted without dismantling.

Technical description

4

Maximum permissible deviation of the set value

from the absolute value at cut-out is ± 4 %.

MANOSKOP®721 Quick and 730 Quick comply

with DIN EN ISO 6789, Type II, Class A.

Each MANOSKOP®has a serial number and is

delivered with a works calibration certificate in

accordance with the above stated

DIN EN ISO 6789.

Standard MANOSKOP®721/5 Quick,

721/15 Quick, 721/20 Quick and

721QR/20 Quick ...

... have a permanent, switchable ratchet with a

permanent square drive (sizes are shown in the

Technical Specifications). Controlled counter

clockwise tightening is not possible.

Standard MANOSKOP®721/30 Quick

...

... has a permanent, switchable ratchet with a push-

through 12,5 (1/2'') square drive.

Service MANOSKOP®730/5 to

730/65 Quick ...

... can be fitted with various insert tools. For this

purpose, the head of the wrench has a recessed

square drive at the face (sizes are shown in the

Technical Specifications) with a double-sided

locating hole and insertion groove. The insert tools

can be attached in the „normal“ position or rotated

through 180°. Controlled counter clockwise

tightening is also possible.

Technical Data

MANOSKOP®721 Quick

721/5

721/15

721/20

721QR/20

721/30

range

[N‧m]

[ft‧lb]

6–50

5–36

30–150

25–110

40–200

30–150

40–200

30–150

60–300

50–220

square drive shaft

fixed [mm]

usable from both sides [mm]

10 (3/8“)

–

12,5 (1/2“)

–

12,5 (1/2“)

–

12,5 (1/2“)

–

–

12,5 (1/2“)

Length 1) [mm]

338

415

483

483

530

functional length LF[mm]

293

387

418

418

486

weight [g]

915

1310

1490

1250

1710

1) length to centre of square drive

Technical description

5

MANOSKOP®730 Quick

730/5

730a/5

730/10

730a/10

730/12

730a/12

range

[N‧m]

[ft‧lb]

[in‧lb]

6–50

5–36

–

6–50

–

50–440

20–100

15–72,5

–

20–100

–

180–880

25–130

20–95

–

25–130

–

225–1150

insertable square drive [mm]

9×12

9×12

9×12

9×12

14×18

14×18

Length [mm]

315

315

370

370

410

410

functional length LF[mm]

288

288

343

343

390

390

standard extension SF[mm]

17,5

17,5

17,5

17,5

25

25

weight [g]

805

805

965

965

1100

1100

730/20

730a/20

730/40

730/65

730/II/65

range

[N‧m]

[ft‧lb]

[in‧lb]

40–200

30–145

–

40–200

–

350–1750

80–400

60–300

–

130–650

100–480

–

130–650

100–480

–

insertable square drive [mm]

14×18

14×18

14×18

14×18

22×28

Length [mm]

455

455

590

875

897

functional length LF[mm]

435

435

570

855

907

standard extension SF[mm]

25

25

25

25

55

weight [g]

1250

1250

1880

3280

3280

Safety instructions

6

Safety instructions

Intended Purpose

MANOSKOP®721 and 730 Quick have been

designed for controlled tightening of screw joints in

a workshop environment. In order to loosen a nut or

bolt during the normal tightening process, the

MANOSKOP®can also be used in the opposite

direction. MANOSKOP®721 and 730 Quick may

only be used for these purposes. To do so, the

correct attachments must be used with the torque

wrench.

The „intended purpose“ includes full adherence to

the information contained in this instruction booklet,

in particular the safety instructions and technical

tolerance limits.

The buyer is required to ensure that all users

comply with these instructions.

Any use beyond the use described here is in breach

of the intended purpose.

The buyer and user are responsible for any damage

or injury resulting from non-adherence to these

instructions.

MANOSKOP®721 and 730 Quick have not been

designed for tightening of screw joints under

series production conditions. This might lead to

inaccurate readings as a result of inadvertent

operation of the sliding scale.

The MANOSKOP®may not be used for

uncontrolled loosening of nuts & bolts —for

example rusty joints. This may cause damage to

the torque wrench.

Therefore, avoid overloading the product by more

than 25%.

The MANOSKOP®may not be used as a

hammer. This will lead to injury and damage.

Structural features of the information on

dangers

CAUTION

Notices containing the word CAUTION

warn of a hazardous situation which

may lead to slight or moderate injuries.

Structural features of notices regarding

material and environmental damage

ATTENTION!

These notices warn of a situation

which leads to material or

environmental damage.

Operation

7

Correct torque settings ...

... can be lifesaving in some applications. For this

reason, please note the following points:

CAUTION

Impermissible deviation from the

triggering accuracy leads to a risk of

injury.

Make sure that the triggering

accuracy is checked at the

prescribed intervals and is adjusted if

required.

If not specified by internal regulations of the

operator (e. g. test equipment monitoring according

to ISO 9000 ff), we recommend an inspection

according to DIN EN ISO 6789, i.e. after approx.

5000 cut-outs or after 12 months, whichever occurs

first. The period (12 months) starts with the initial

commissioning.

If an inspection shows that there is excessive

deviation, the torque wrench will have to be

readjusted (see page 15).

Operation

MANOSKOP®721 and 730 Quick are measuring

instruments and must therefore be treated with

care. Avoid subjecting the tool to physical knocks,

chemicals or excessive temperatures beyond the

limits given in these instructions.

Please note that extremes of climate (cold, heat,

humidity) may affect measuring accuracy.

Avoid overloading the tool by more than 25 % of the

maximum permissible load in the direction of

tightening or in the opposite direction. The

MANOSKOP®may be damaged. After such an

overload, the readings may be inaccurate in such a

way that the user does not notice.

Operation

8

Selecting the inserts and insert tools

CAUTION

Faulty or incorrect plug-in tools lead to

a risk of injury.

Exclusively use plug-in tools from

STAHLWILLE.

Make sure that the permissible load

capability of the plug-in tool exceeds

the capacity of the torque wrench.

Only manufacture special tools in

consultation with STAHLWILLE.

CAUTION

Unsecured plug-in tools lead to a risk

of injury.

Make sure that plug-in tools are

always secured against pulling out

by engaging the retaining pin.

Remember that the tool has to be of the correct

type and the right size for the screw or bolt.

Attaching insert tools

721/5, 721/15, 721/20, 721QR/20 Quick

For controlled clockwise tightening, switch the

ratchet to „R” or, for uncontrolled loosening of

joints, to „L”.

Slide the insert over the square drive of the

ratchet until it locates.

Operation

9

721/30 Quick

Check that the square drive is fitted to the right

side of the torque wrench.

If not, push the square drive out through the upper

side to the right side.

For controlled tightening, switch the ratchet to „R”

or, for uncontrolled loosening of joints, to „L”.

Slide the insert over the square drive until it

locates.

Attaching insert tools —730/5 to

730/65 Quick

Insert the insert tool into the internal square drive

on the face of the head of the wrench. The spring-

loaded locking pin of the insert tool will be

pressed down by the insertion groove.

Slide the insert tool in until it comes to the

endstop. Ensure the locking pin locates in the

hole.

Check to see that the insert tool is properly

attached.

To tighten counter clockwise, turn the insert tool

through 180° before attaching to the torque

wrench.

Operation

10

If you are using a ratchet insert tool, set this to the

desired direction by turning the control knob.

Removing insert tools

730/5 to 730/65 Quick

If the tool was attached in the „normal“ position,

press the release button on the underside of the

head of the wrench.

If the tool was attached to the torque wrench

rotated through 180°. Insert a fine punch into the

locating hole in the head of the wrench. Use the

punch to depress the locking pin.

Extract the insert tool.

Setting the torque level

The torque level at which the wrench cuts out is set

by moving the scale against the fixed mark. Always

approach the desired torque setting from a lower

value. Intermediate settings between two marks on

the scale can be estimated.

In order to be able to set the scale, the setting fail-

safe mechanism has to be operated first. Once the

setting fail-safe mechanism is released, the value

set is automatically locked.

Proceed as follows:

Hold down the pressure plate at the grip end to

release the setting lock.

Slide the scale to a torque level lower than the

desired cut-out value.

Slide the scale to the desired cut-out value. The

integrated magnifying glass helps you to position

the scale precisely.

Operation

11

Release the pressure plate again.

The set value is now safely locked.

Check the set value once again. If the set value is

wrong, repeat the process.

Controlled counter clockwise tightening

Due to reasons of accuracy, the torque wrenches

only function in one direction. This is identified by

an arrow and the word "CLICK".

Controlled counter clockwise tightening is possible

by turning the MANOSKOP®over. Exceptions: The

MANOSKOP®721/5, 721/15 and 721/20 Quick

cannot be used for counter clockwise tightening.

Counterclockwise tightening is possible with the

MANOSKOP®721/30 Quick by means of a square

drive which is pushed through.

For controlled counter clockwise tightening using

the MANOSKOP®721/30 Quick in the turned over

position, the square drive must first be pushed

through to the upper side. For controlled counter

clockwise tightening using the MANOSKOP®730/5

to 730/65 Quick, the insert tool has to be rotated

through 180°. Ratchet insert tools also need

switching to „L“ (CCW) for the correct tightening

direction.

Uncontrolled loosening of nuts & bolts

...

... opposite to the tightening direction is possible.

The cut-out mechanism is not placed under load

during this process.

ATTENTION!

Exceeding the limit torque leads to the

risk of the torque wrench becoming

damaged.

Make sure that a limit torque of

approx. 125 % of the maximum scale

value is not exceeded.

Do not loosen any tightly rusted bolts

using the torque wrench.

Operation

12

Using the torque wrench

CAUTION

An incorrect trigger value leads to a

risk of injury.

Make sure that the correct trigger

value is set.

CAUTION

Unsecured plug-in tools lead to a risk

of injury.

Make sure that plug-in tools are

always secured against pulling out

by engaging the retaining pin.

CAUTION

Slipping tools lead to a risk of injury.

Make sure that the tool cannot slip

off the workpiece.

Actuate the MANOSKOP®via the handle only. Grip

the handle centrally. Tighten at a tangent to the

slewing radius and at an angle to the tightening

axis.

Pull steadily and without any interruption,

particularly during the final phase, until you feel a

jerk and hear a click. The torque level set on the

scale has now been reached.

ATTENTION!

Incorrect use of the torque wrench

leads to the risk of material damage.

Under no circumstances continue

tightening the screw connection after

the torque wrench has cut-out.

As soon as the torque wrench has cut out, it is

ready for the next job.

Maintenance

13

Maintenance

The internal mechanisms of the torque wrench are

subject to normal wear and tear under operating

conditions. For this reason, the accuracy of the cut-

out should be checked at regular intervals.

If not specified by internal regulations of the

operator (e. g. test equipment monitoring according

to ISO 9000 ff), we recommend an inspection

according to DIN EN ISO 6789, i.e. after approx.

5000 cut-outs or after 12 months, whichever occurs

first. The period (12 months) starts with the initial

commissioning.

If inspection shows that there is a deviation, the

torque wrench must be adjusted.

The inspection and adjustment must be carried out

in accordance with DIN EN ISO 6789.

Checking the accuracy of the cut-out

value

To check the torque, a torque tester with the right

capacity is required which has an accuracy of ±1 %

of the displayed value or better.

If you have access to such a tester, you may

inspect the MANOSKOP®yourself. Suitable torque

testers are available from STAHLWILLE. It is also

possible for STAHLWILLE to test the MANOSKOP®

for you.

To carry out the test, proceed as follows:

Set the torque wrench to the highest scale

reading.

Operate the torque wrench five times ensuring it

cuts out properly each time.

Important note on the accuracy of the readings:

ATTENTION!

Incorrect use of the torque wrench

leads to the risk of material damage.

Under no circumstances continue

tightening the screw connection after

the torque wrench has cut-out.

In the following example a MANOSKOP®

730/10 Quick is used.

Set the torque wrench to 20 % of the maximum

scale reading.

Use this setting to perform five measurements on

the torque tester.

Use the following formula to make sure that the

values displayed by the torque tester do not

deviate by more than ±4 %.

A=deviation in %

W1=value set on the Manoskop

W2=tester measured value

Maintenance

14

Set the torque wrench to 60 % of the maximum

scale reading.

Use this setting to perform five measurements on

the torque tester.

Use the following formula to make sure that the

values displayed by the torque tester do not

deviate by more than ±4 %.

A=deviation in %

W1=value set on the Manoskop

W2=tester measured value

Set the torque wrench to the highest scale

reading.

Use this setting to perform five measurements on

the torque tester.

Use the following formula to make sure that the

values displayed by the torque tester do not

deviate by more than ±4 %.

A=deviation in %

W1=value set on the Manoskop

W2=tester measured value

If the tests show that there are deviations greater

than the permitted amounts, the wrench will require

readjusting.

Maintenance

15

Adjusting for deviations in cut-out value

You may return your torque wrench to

STAHLWILLE for adjustment. You will then receive

the tool back with a new works calibration

certificate.

You may adjust the torque wrench yourself. In this

case, however, STAHLWILLE‘s accuracy guarantee

is void.

A torque tester of sufficient capacity and accuracy is

required for making readjustments.

For readjustment, each MANOSKOP®is equipped

with two internal adjuster screws.

These are accessible with an Allen key, size 2 mm,

through two holes in the housing.

The screw which is closest to the end of the handle

is primarily for adjusting the lower end of the scale

range.

The screw which is closest to the head is primarily

for adjusting the upper end of the scale range.

Each screw has a minor effect on the adjusting

range of the other screw.

To protect the mechanisms from dirt and moisture,

these two holes are plugged.

To adjust the wrench, you will need the torque

tester and an Allen key, size 2 mm.

Cleaning

16

Proceed as follows:

Remove the two plugs using a sharp object.

Retain the plugs for later use.

To adjust the lower end of the range, insert the

Allen key in the hole nearer to the handle.

To adjust the lower end of the range, insert the

Allen key in the other hole.

Turn the Allen key with great care and very

slowly. Turning in a clockwise direction increases

the cut-out torque level, turning in the other

direction decreases it. The screws will lock in any

position.

Once you have made an adjustment using one

screw, check the effect by testing the cut-out

value on the torque tester.

Repeat the adjustment of one or both screws and

the testing process until the deviation has been

compensated.

Finally, do a thorough test again. Proceed as

described under „Checking the accuracy of the

cut-out value“.

If you cannot achieve adequate correspondence

between the triggering values and the set values in

this way, the triggering mechanism is probably

defective.

Consult STAHLWILLE if this occurs.

Replace the plugs as appropriate to protect the

cut-out mechanism against dirt and damp.

Replacement plugs are available from

STAHLWILLE.

Cleaning

Clean the MANOSKOP®only with white Spirit.

Other chemical substances may damage the plastic

components.

Accessories

17

Accessories

For all models

Inserts for square drives for all usual screw head

types and sizes.

For STAHLWILLE Service

MANOSKOP®730 Quick

Insert tools

ratchet insert tools

square insert tools

open-jaw insert tools

ring insert tools

Open ring insert tools

Torx®insert tools

Bit-holder insert tools

For inspection and readjustment purposes

Mechanical torque testers

Electronic torque testers

Services

repairs

testing and readjusting (incl. accuracy guarantee

and new works calibration certificate)

Training courses

Service portal: service.stahlwille.de

Disposal

When the tool finally has to be disposed of, please

observe your local environmental protection laws.

The handle is made of PPC.

STAHLWILLE Eduard Wille GmbH & Co. KG ‧ Lindenallee 27 ‧ 42349 Wuppertal ‧ Germany

Other manuals for MANOSKOP 721 Quick

1

This manual suits for next models

17

Table of contents

Other Stahlwille Power Tools manuals

Stahlwille

Stahlwille MANOSKOP 714 User manual

Stahlwille

Stahlwille MANOSKOP 730D How to use

Stahlwille

Stahlwille Standard Manoskop 720 Nf/80 Parts list manual

Stahlwille

Stahlwille Manoskop 721/5 User manual

Stahlwille

Stahlwille MANOSKOP 714 User manual

Stahlwille

Stahlwille MANOSKOP 721 Quick User manual

Stahlwille

Stahlwille Manoskop 71/80 User manual

Stahlwille

Stahlwille Standard Manoskop 720 Nf/80 User manual

Stahlwille

Stahlwille 701 User manual

Stahlwille

Stahlwille MANOSKOP 730a/10 Quick User manual