Stahlwille Standard Manoskop 720 Nf/80 Parts list manual

25

STAHLWILLE

Torque Wrenches

Standard Manoskop®

720 Nf/80

721 Nf/80

721 Nf/100

Service Manoskop®

730/80

Technical

description

All models

Manoskop®720 Nf/80, 721 Nf/80,

721 Nf/100 and 730/80 are adjustable

torque wrenches with a cut-out, tactile

and audible cut-out signals.

•These torque wrenches have a

safety cut-out mechanism.

•The wrench is set to cut-out at a

certain torque level by setting the

required value on the N m/ft.lb scale

using a force-free knob.

•The setting knob has an automatic

setting fail-safe mechanism.

Content

Technical description . . . . . . . . . . . 25

Technical specifications . . . . . . . . . 27

ãImportant safety instructions . . . 28

Operation . . . . . . . . . . . . . . . . . . . . 30

Maintenance. . . . . . . . . . . . . . . . . . 39

Cleaning the Manoskop®........43

Accessories . . . . . . . . . . . . . . . . . . 44

Disposal . . . . . . . . . . . . . . . . . . . . . 44

26

•The measuring element is a flexible

rod. The flexible rod is not

pretensioned so it is only under

tension from the start to the end of

the actual tightening operation until

the wrench cuts out.

•As soon as the torque wrench is

released, it is ready for the next job.

•These wrenches will only tighten in

one direction. To use the Manoskop®

wrench for loosening, turn it over.

•If necessary, these torque wrenches

can be readjusted without

dismantling.

Maximum permissible deviation of the

set value from the absolute value at cut-

out is ± 4 %.

Manoskop®720 Nf/80, 721 Nf/80,

721 Nf/100 and 730/80 comply with

DIN EN ISO 6789, Type II, Class A.

Every Manoskop®has a unique serial

number and is supplied with a works

calibration certificate.

STAHLWILLE Standard

Manoskop®720 Nf/80 ...

... has a permanent, fixed head with an

exchangeable 20 (3/4'') square drive.

STAHLWILLE Standard

Manoskop®721 Nf/80 ...

... has a permanent, non-switchable

ratchet with an exchangeable 20 (3/4'')

square drive.

STAHLWILLE Standard

Manoskop®721 Nf/100 ...

... has a permanent, non-switchable

ratchet with an exchangeable 20 (3/4'')

square drive.

27

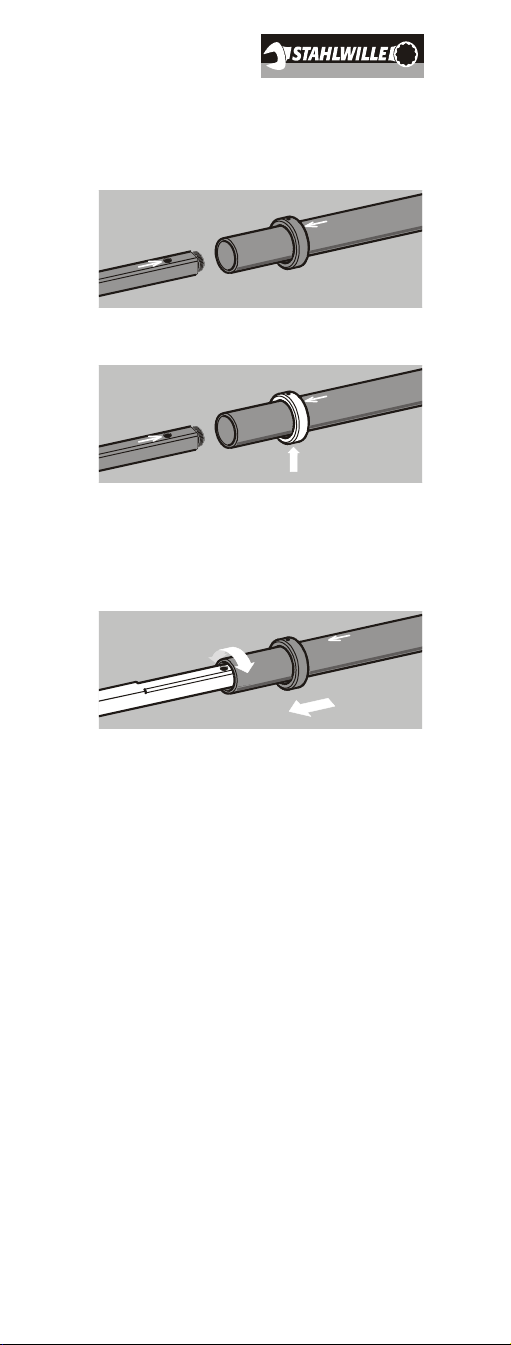

The wrench consists of a basic wrench

and a grip tube. The grip tube is placed

over the end of the basic wrench where it

locks in place by means of a locking pin

that locates in a hole. The locking pin is

attached to the grip tube by a spring-

loaded ring. To attach or remove the grip

tube (e.g. for setting), press the ring

against the wall of the tube which will

extract the locking pin. The locking

position is marked with an arrow.

STAHLWILLE Service

Manoskop®730/80 ...

... can be fitted with various shell tools.

For this purpose, the head of the wrench

has an external 24.5x28 square drive

pointing forwards with a spring-loaded

locking pin on the underside. The shell

tools can be attached in the „normal“

position or rotated through 180°.

Technical

specifications

alength to centre of square drive

bwith grip tube attached

Manoskop®720 and 721

720 Nf/80 721 Nf/80 721 Nf/100

Torque range [N m]

[ft.lb]

160–800

120–600

160–800

120–600

200–1000

150–725

Exchangeable square

drive [mm]

fixed

20 (3/4'')

ratchet

20 (3/4'')

ratchet

20 (3/4'')

Length Åa [mm] 1.013 1.013 1.466

b

Weight [g] 6.135 6.770 7.570

b

Manoskop®730

Torque range

shell square

drive

[mm]

Length Weight

Model

[N m] [ft.lb] [mm] [g]

730/80 160–800 120–600 24,5 x 28 970 4.960

28

Intended Purpose

Manoskop®720 Nf/80, 721 Nf/80,

721 Nf/100 und 730/80 have been

designed for controlled tightening of

screw joints. They may only be used for

this purpose. To do so, the correct

attachments must be used with the

torque wrench.

Manoskop®721 Nf/100 may only be

used with the grip tube in position.

Otherwise the readings will not be

accurate.

The „intended purpose“ includes full

adherence to the information contained

in this instruction booklet, in particular the

safety instructions and technical

tolerance limits. The buyer is required to

ensure that all users comply with these

instructions.

Any use beyond the use described here

is in breach of the intended purpose.

The buyer and user are responsible for

any damage or injury resulting from non-

adherence to these instructions.

•Manoskop®720 Nf/80, 721 Nf/80,

721 Nf/100 und 730/80 have not

been designed for tightening of

screw joints under series production

conditions. This might lead to

inaccurate readings as a result of

excessive wear in the switching

mechanism.

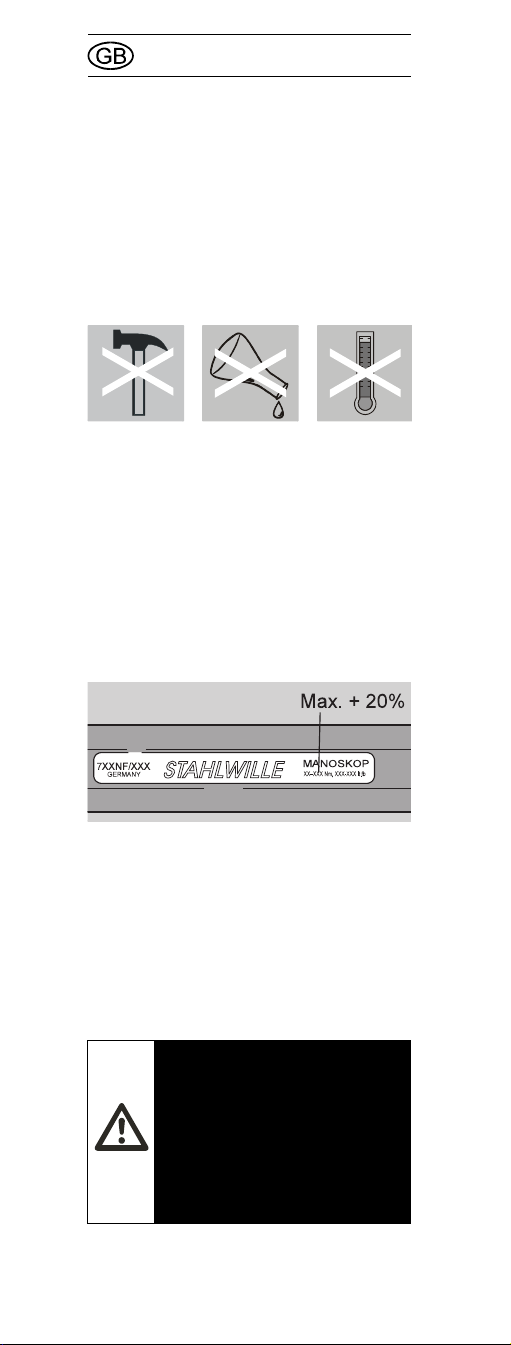

•The Manoskop®may not be used as

ahammer. This will lead to injury and

damage.

ãImportant

safety

instructions

29

•Manoskop®720 Nf/80, 721 Nf/80,

721 Nf/100 und 730/80 may not be

used in the direction opposite to their

intended direction or for uncontrolled

loosening of nuts & bolts – e.g. rusty

joints. This may cause damage to the

torque wrench.

Correct torque settings ...

... can be lifesaving in some applications.

For this reason, please note the following

points:

Unless otherwise indicated in the user's

internal regulations (e.g. test equipment

inspection to ISO 9000 et seq), an

inspection must take place after approx.

5000 operations or every 12 months,

whichever is the shorter. The time frame

(12 months) starts with the first usage.

If an inspection shows that there is

excessive deviation, the torque wrench

will have to be readjusted (see page 41).

Additional important safety

points ...

... may apply depending on the

application. These are found in the

appropriate sections marked with danger

symbols ã.

ãCAUTION!

In order to ensure the

cut-out is working

accurately, it should be

checked at regular

intervals.

30

Operation

Manoskop®720 Nf/80, 721 Nf/80,

721 Nf/100 und 730/80 are measuring

instruments and must be treated with

utmost care. Avoid subjecting the tool to

physical knocks, chemicals or excessive

temperatures beyond the limits given in

these instructions.

Please note that extremes of climate

(cold, heat, humidity) may affect

measuring accuracy.

Avoid overloading the tool by more than

20 % of the maximum permissible load in

the direction of tightening, as otherwise

the Manoskop®may be damaged. After

such an overload, the readings may be

inaccurate in such a way that the user

does not notice.

Avoid loading the tool against the

direction of tightening, as otherwise the

Manoskop®may be damaged.

Use the grip tube –

Manoskop®721 Nf/100

ãCAUTION!

Manoskop®721 Nf/100

may only be used with

the grip tube in position.

Otherwise the readings

will not be accurate.

31

Attaching the grip tube

1. Align the arrows on the Manoskop®

and the grip tube with each other.

2. Press the ring up.

3. Slide the grip tube over the

Manoskop®,until the locking pin

locates. If necessary, rotate the grip

tube slightly back and fore.

4. Check to see that the grip tube is well

located and the pin is in position.

32

Removing the grip tube

1. Press the ring up.

2. Remove the grip tube.

Selecting the inserts and

shell tools

ãCAUTION!

Ensure you have enough

space and can remove

the tube from the

Manoskop®safely

without losing your

balance.

ãCAUTION!

When using inserts on

torque wrenches with a

square drive, ensure

they have been

manufactured to comply

with standards and are

the correct shape and

size for the nut or bolt to

be tightened.

STAHLWILLE inserts

guarantee the

connection will be a

good fit and that the

drive profile will fit

exactly.

33

ãCAUTION!

Please use only shell

tools made by

STAHLWILLE. These

guarantee the correct

lever length, fit

accurately in all

situations and are

designed to have

sufficient strength.

ãCAUTION!

Ensure the maximum

permissible load of the

insert or shell tool used

is not exceeded. This

might be lower than the

maximum cut-out torque

of the torque wrench.

ãCAUTION!

Use of home-made

special tools may be

dangerous. If you need

to manufacture your

own tools, please

contact STAHLWILLE

first.

When using shell tools,

ensure that the locking

pin has located

correctly. Otherwise,

there is a danger of

injury or damage.

ãDANGER!

When using shell tools,

ensure that the locking

pin has located

correctly. Otherwise,

there is a danger of

injury or damage.

34

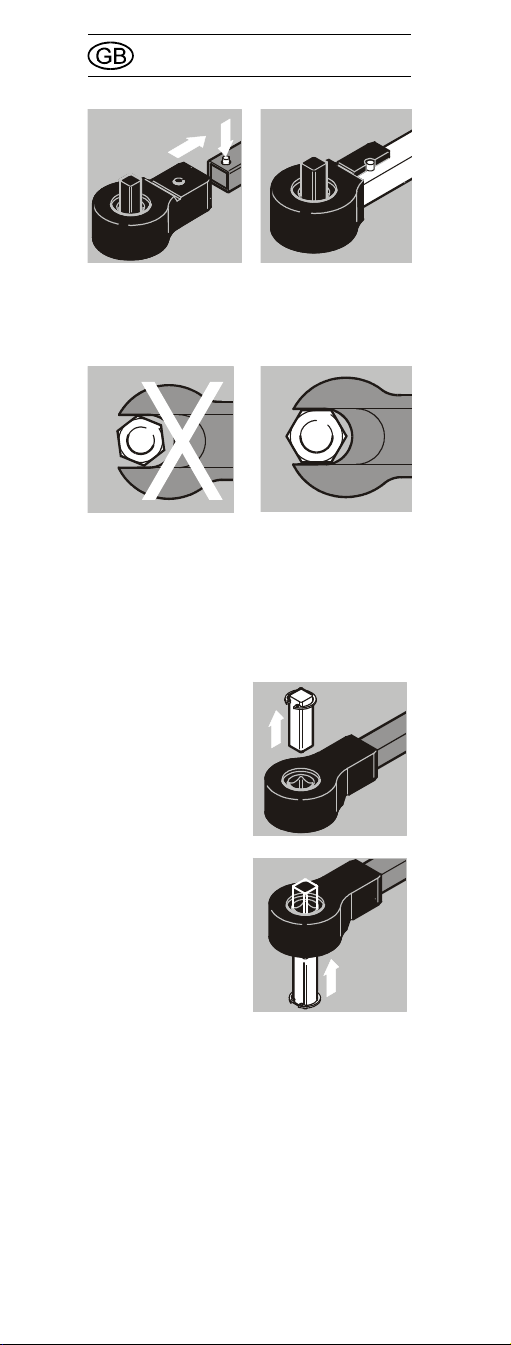

Remember that the tool has to be of the

correct type and size for the screw or

bolt.

Attaching insert tools

720 Nf/80, 721 Nf/80 und 721 Nf/100

1. Check that the square drive is fitted

to the right side of the torque wrench.

2. If not, push it

through to the

other side.

3. Then push it

back into the

head from the

other side.

4. Slide the insert over the square drive

until it locates.

35

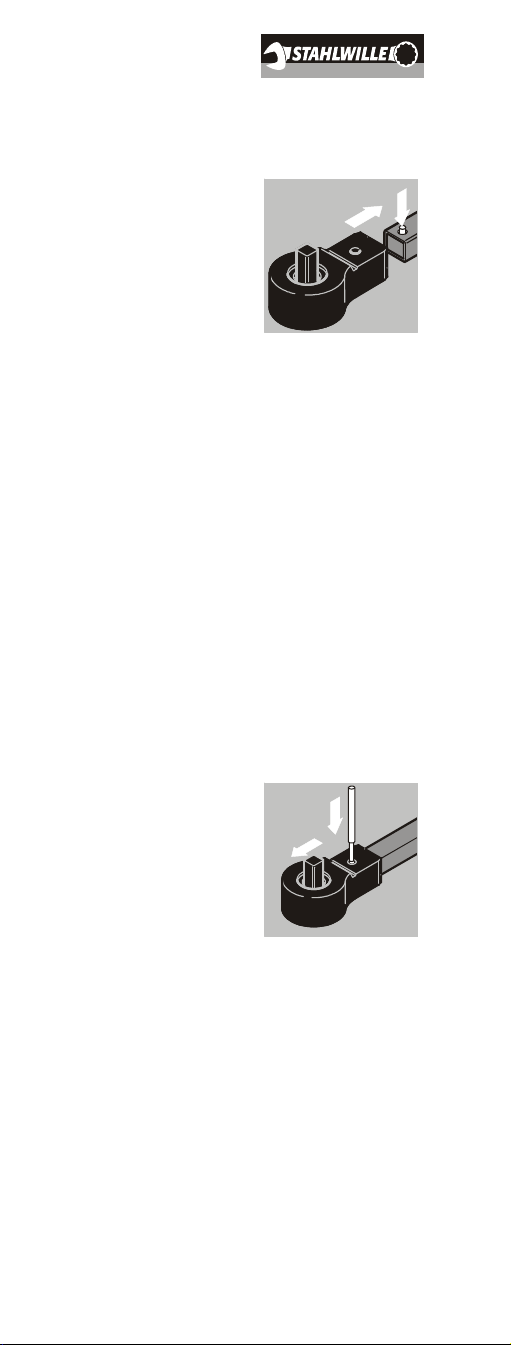

Attaching shell tools –

only 730/80

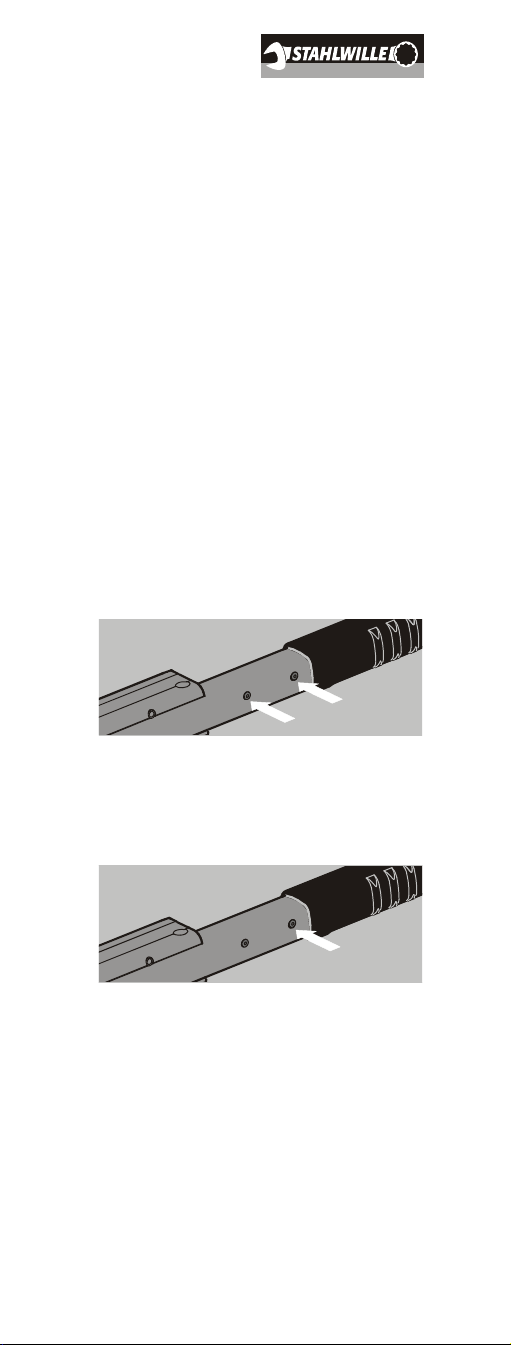

1. Press down the

spring-loaded

locking pin on

the shaft by

hand.

2. Slide the shell tool over the shaft of

the head of the wrench. Now press

down the shell tool until it comes to

the endstop. Ensure the locking pin

locates in the hole.

3. Check to see that the shell tool is

properly attached.

4. To tighten counter clockwise, turn the

shell tool through 180° before

attaching to the torque wrench.

Exception: If you are using a ratchet

adapter, attach as „normal“ to the

torque wrench and reposition the

square drive (see page 34).

Removing shell tools –

730/80

1. Insert a fine

punch into the

locating hole of

the shell tool

from outside.

Use the punch

to depress the

locking pin.

2. Now remove the shell tool.

Setting the desired torque

The torque level at which the wrench cuts

out is set by moving the scale against the

fixed mark. To do so, turn the smooth

running self-locking knob. Always

approach the desired torque setting from

alower value.

Intermediate settings between two marks

on the scale can be estimated.

36

Proceed as follows:

1. With the 721 Nf/100 it is necessary

to remove the grip tube first (see

page 32). This does not apply to

other models.

2. Turn the knob

clockwise until

the scale shows

avalue lower

than the desired

cut-off value.

3. Then turn the knob counter

clockwise, until the mark for the

desired cut-off value is in the middle

of the scale window.

4. Check the value again. If the setting

is wrong, return to 2.

Controlled counter

clockwise tightening

For reasons of accuracy, these torque

wrenches have been designed to work in

only one direction. The direction is

marked with an arrow.

Controlled counter clockwise tightening

is possible by turning the Manoskop®

over.

For controlled counter clockwise

tightening using the Manoskop®

720 Nf/80, 721 Nf/80 und 721 Nf/100 in

the turned over position, the square drive

must first be pushed through to the upper

side and refitted from the underside

(see page 34).

37

For controlled counter clockwise

tightening using the Manoskop®730/80,

the shell tools have to be rotated through

180°. Exception: If you are using a

ratchet adapter, attach it to the

Manoskop®in the "normal" manner.

Then push the square drive out through

the upper side and reinsert it from the

underside (see page 34).

Uncontrolled loosening of

nuts & bolts ...

..., for example during a tightening

operation, is possible if the Manoskop®is

turned over.

ãCAUTION!

Never exceed a limit of

120 % of the maximum

scale reading. Do not

use the tool for

loosening rusty nuts

and bolts. This may

cause damage to the

torque wrench. After

such an overload, the

readings may be

inaccurate in such a way

that the user does not

notice.

38

Using the torque wrench

Only apply force to the Manoskop®via its

handle. Hold the handle in the middle.

Apply force at a tangent to the swivel

radius and at right angles to the axis of

the nut or bolt.

Pull steadily and without any interruption,

particularly during the final phase, until

you feel a jerk and hear a click. The

torque level set on the scale has now

been reached.

ãDANGER!

Caution! Before you use

the tool, check that the

cut-off value has been

set correctly and that

the insert or shell tool is

correctly fitted.

Manoskop®721 Nf/100

may only be used with

the grip tube in position.

Ensure the locking pin

has correctly located.

Apply the wrench in

such a way that the tool

cannot slip off the head

of the nut or bolt.

Otherwise, there is a

danger of injury or

damage.

39

As soon as the torque wrench has cut

out, it is ready for the next job.

Maintenance

The internal mechanisms of the torque

wrench are subject to normal wear and

tear under operating conditions. For this

reason, the accuracy of the cut-out

should be checked at regular intervals.

Unless otherwise indicated in the user's

internal regulations (e.g. test equipment

inspection to ISO 9000 et seq), an

inspection must take place after approx.

5000 operations or every 12 months,

whichever is the shorter. The time frame

(12 months) starts with the first usage.

If inspection shows that there is a

deviation, the torque wrench must be

adjusted.

The inspection and adjustment must be

carried out in accordance with

DIN EN ISO 6789.

Checking the accuracy of

the cut-off value

Atorque tester of sufficient capacity and

accuracy is required for the inspection.

If you have access to such a tester, you

may inspect the Manoskop®yourself.

Suitable torque testers are available from

STAHLWILLE. It is also possible for

STAHLWILLE to test the Manoskop®for

you.

ãCAUTION!

Important! Once the

wrench has cut out,

never apply more

pressure! You should

therefore not pull too

fast in case you cannot

stop the motion quickly

enough when you hear

the click.

40

To carry out the test, proceed as follows:

1. Set the torque wrench to the highest

scale reading.

2. Operate the torque wrench five times

ensuring it cuts out properly each

time.

3. Set the torque wrench to 20 % of the

maximum scale reading.

4. Operate the torque wrench five times

on the torque tester. Check to see

that the readings shown on the

torque tester are not more than

4.15 % greater and not more than

3.85 % smaller than the value set on

the torque wrench.

5. Set the torque wrench to 60 % of the

maximum scale reading.

6. Operate the torque wrench five times

on the torque tester. Check to see

that the readings shown on the

torque tester are not more than

4.15 % greater and not more than

3.85 % smaller than the value set on

the torque wrench.

7. Set the torque wrench to the highest

scale reading.

8. At this setting, operate the torque

wrench five times on the torque

tester. Check to see that the readings

shown on the torque tester are not

more than 4.15 % greater and not

more than 3.85 % smaller than the

value set on the torque wrench.

ãCAUTION!

Important note on the

accuracy of the

readings: Once the

wrench has cut out,

never apply more

pressure! You should

therefore not pull too

fast in case you cannot

stop the motion quickly

enough when you hear

the click.

41

If the tests show that there are deviations

greater than the permitted amounts, the

wrench will require readjusting.

Adjusting for deviations in

cut-off value

You may return your torque wrench to

STAHLWILLE for adjustment. You will

then receive the tool back with a new

works calibration certificate.

You may adjust the torque wrench

yourself. In this case, however,

STAHLWILLE's accuracy guarantee is

void.

Atorque tester of sufficient capacity and

accuracy is required for the inspection.

Every Manoskop®has two adjusting

screws inside for readjustment purposes.

These are accessible with an Allen key,

size 2 mm, through two holes in the

housing.

The screw which is closest to the plastic

handle is primarily for adjusting the lower

end of the scale range.

The screw which is closest to the head is

primarily for adjusting the upper end of

the scale range.

42

Each screw has a minor effect on the

adjusting range of the other screw.

To protect the mechanisms from dirt,

these two holes are plugged.

To adjust the wrench, you will need the

torque tester and an Allen key, size

2 mm. Proceed as follows:

1. Remove the two plugs using a sharp

object. Retain the plugs for later use.

2. To adjust the lower end of the range,

insert the Allen key in the hole nearer

to the handle. To adjust the lower

end of the range, insert the Allen key

in the other hole.

3. Turn the Allen key with great care

and very slowly. Turning in a

clockwise direction increases the cut-

out torque level, turning in the other

direction decreases it. The screws

will lock in any position.

4. Once you have made an adjustment

using one screw, check the effect by

testing the cut-off value on the torque

tester.

5. Repeat the adjustment of one or both

screws and the testing process until

the deviation has been

compensated.

43

6. Finally, do a thorough test again.

Proceed as described under see

„Checking the accuracy of the cut-off

value“ on page 39.

7. Refit the plugs to protect the cut-out

mechanism from dirt and damp.

Replacement plugs are available

from STAHLWILLE.

Cleaning the

Manoskop®

ãCAUTION!

If you cannot

compensate for the

deviation within the

prescribed tolerances

using the method

described here, it is

likely that the cut-out

mechanism is damaged.

Such defects can only

be repaired if the torque

wrench is dismantled.

Contact STAHLWILLE in

such cases.

ãCAUTION!

Please use only white

spirit. Other chemical

substances may damage

the plastic components.

44

Accessories

For all models

•Inserts for square drives for all usual

screw head types and sizes.

For STAHLWILLE Standard

Manoskop®730/80

•Sockets

•ratchet adapters

•square shell tools

•open-jaw shell tools

•ring shell tools

For inspection and readjustment

purposes

•Electronic torque testers

Services

•repairs

•testing and readjusting (incl.

accuracy guarantee and new works

calibration certificate)

Disposal

When the tool finally has to be disposed

of, please observe your local

environmental protection laws. The

handle is made of soft PVC.

Other manuals for Standard Manoskop 720 Nf/80

1

This manual suits for next models

3

Table of contents

Other Stahlwille Power Tools manuals

Stahlwille

Stahlwille MANOSKOP 721 Quick User manual

Stahlwille

Stahlwille Standard Manoskop 720 Nf/80 User manual

Stahlwille

Stahlwille Manoskop 71/80 User manual

Stahlwille

Stahlwille MANOSKOP 714 User manual

Stahlwille

Stahlwille 701 User manual

Stahlwille

Stahlwille MANOSKOP 721 Quick User manual

Stahlwille

Stahlwille MANOSKOP 714 User manual

Stahlwille

Stahlwille Manoskop 721/5 User manual

Stahlwille

Stahlwille 701 User manual

Stahlwille

Stahlwille MANOSKOP 730a/10 Quick User manual