Avdel 07900-09080 User manual

0

0

20

40 60

80

100

1

2

34

5

6

7

lbf/in

2

bar

CALIBRATIONdue

07900-09080

Instruction Manual

Original instruction

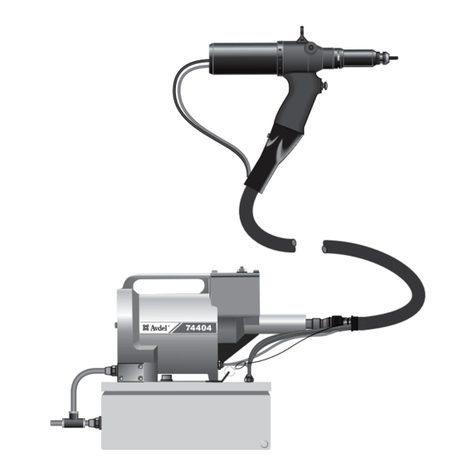

Broach Load Test Power Tool

07900-09080

Speed Fastening Applications

3

Contents

Safety Rules 4

Tool Specifications 5

Intent of Use 5

Putting into Service

Air Supply 6

Loading the Tool 6

Cursor 6

Nose Equipment 6

Operating Procedure 7

Air Pressure Graph vs Broach Load 8

Mandrel Life Table 9

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

Warranty

Avdel UK Limited installation tools carry a 12 month warranty against defects caused

by faulty materials or workmanship, the warranty period commencing from the date of

delivery confirmed by invoice or delivery note.

The warranty applies to the user/purchaser when sold through an authorised outlet,

and only when used for the intended purpose. The warranty is invalidated if the

installation tool is not serviced, maintained and operated according to the instructions

contained in the Instruction and Service Manuals.

In the event of a defect or failure, and at its sole discretion, Avdel UK Limited

undertakes only to repair or replace faulty components.

4

Safety Rules

1Do not use outside the design intent.

2Do not use equipment with this tool/machine other than that recommended and supplied by Avdel UK Limited.

3Any modification undertaken by the customer to the tool/machine or any equipment supplied by Avdel UK Limited or their

representatives, shall be the customer’s entire responsibility. Avdel UK Limited will be pleased to advise upon any proposed

modification.

4The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and

function by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel UK

Limited procedures. Do not dismantle this tool/machine without prior reference to the maintenance instructions. Please contact

Avdel UK Limited with your training requirements.

5The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the U.K. the “Health

and Safety at Work etc. Act 1974” applies. Any question regarding the correct operation of the tool/machine and operator safety

should be directed to Avdel UK Limited.

6The precautions to be observed when using this tool/machine must be explained by the customer to all operators.

7Always disconnect the airline from the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

8Do not operate a tool/machine that is directed towards any person(s).

9Always adopt a firm footing or a stable position before operating the tool/machine.

10 Ensure that vent holes do not become blocked or covered.

11 Do not operate the tool if it is not fitted with a complete nose assembly or swivel head unless specifically instructed otherwise.

12 When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against

fastener ejection, should a fastener be placed ‘in air’. We recommend wearing gloves if there are sharp edges or corners on the

application.

13 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool which should

be kept dry and clean for best possible grip.

14 When carrying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent start up.

15 The combination of fastener, mandrel, hole size and sheet thickness shall be in accordance with specifications set by Avdel UK

Limited.

16 The cylinder of the tool must be free to move without risk of hitting or trapping the operator.

This instruction manual must be read with particular attention to the following safety rules, by any person

operating this tool.

IMPORTANT

While a small amount of wear and marking will naturally occur through normal and correct use of mandrels,

they must be regularly examined for excessive wear and marking, with particular attention to the head

diameter, the tail jaw gripping area of the shank or heavy pitting of the shank and any mandrel distortion.

Mandrels which fail during use could forcibly exit the tool. It is the customer's responsibility to ensure that

mandrels are replaced before any excessive levels or wear and always before the maximum recommended

number of placings. Contact your Avdel UK Limited representative who will let you know what that figure is by

measuring the broach load of your application with a calibrated test tool. These tools can also be purchased

under Part Number 07900-09080, supplied with all necessary information for testing in this manual.

Intent of Use

Specification

5

Air Pressure Maximum 7 bar

Free Air Volume Required @ 5.5 bar 1.72 litres

Noise Level Less than 70 dB(A)

Weight Without nose equipment 3.0 kg

Vibration Less than 2.5 m/s2

This particular test tool is to be used solely with Avdel®speed fasteners supplied by Avdel®. The precise list of fasteners appears in

the mandrel life table page 9. The tool is supplied without any nose equipment as it is fundamental that this tool is used fitted with the

exact same nose equipment as that used on the placing tool you have selected to place your fasteners. Tools can be purchased under

part number 07900-09080 or you may contact your local Avdel representative to test your application.

The test tool can be used to define the ideal combination of tool/nose equipment/fastener for your application and in any case MUST

be used prior to the actual placing tool in order to define the broach load exerted on the mandrel when placing a fastener in the

application. IT IS ESSENTIAL TO ESTABLISH THE BROACH LOAD TO PREVENT OVER-USAGE OF MANDRELS AND RISK BREAKAGE

AND INJURY.

The intensity of the broach load will vary with the level of interference between the diameters of the fastener, of the mandrel head and

of the hole in the application as well as with the thickness of the application. SPEED FASTENING DEMANDS RIGOROUS OBSERVATION

OF RECOMMENDATIONS laid down in fastener technical data sheets and in the selection process of nose equipment laid down in

instruction manuals.

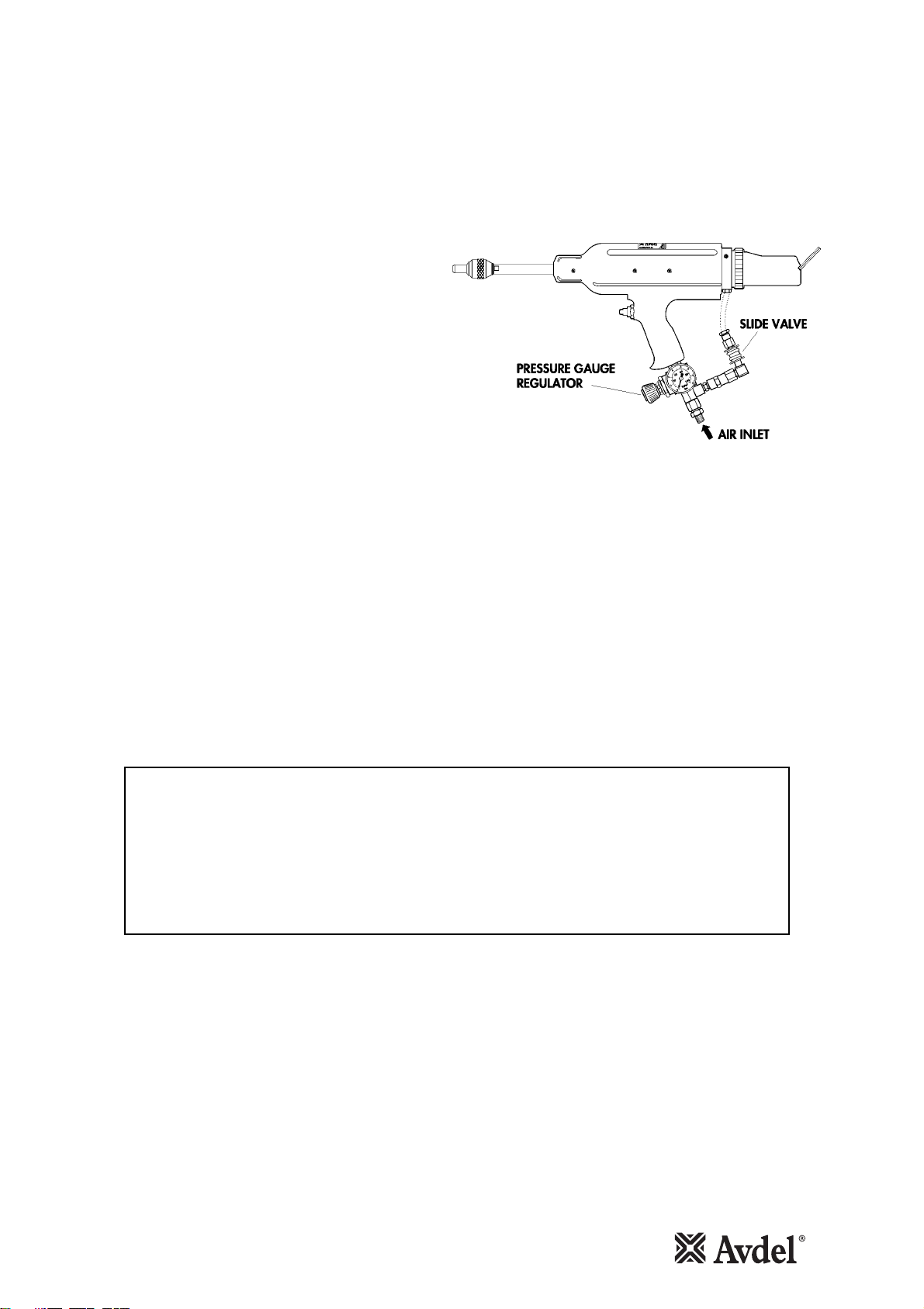

When putting the test tool into operation, its gauge will display the air pressure at which a particular fastener will place in a specific

application with defined nose equipment.

The graph on page 8, will allow you to convert that air pressure (bars) into a broach load (Newtons) which in turn can be

translated, using the table page 9, into a maximum safe number of placings for that series of fasteners with the exact

same nose equipment you will use with your placing tool AND in random samples of your actual application.

Air Supply

Loading the Tool

Cursor

Nose Equipment

Putting into Service

6

This tool operates with compressed air at a maximum pressure of 7 bar. We recommend that you temporarily make use of the air

supply set up for your actual placing tool with precautions as described in the instruction manual for your placing tool.

IMPORTANT

It is essential that the correct nose equipment is fitted to the tool to ensure both effective placing of the

fastener and SAFE operation of the tool.

IMPORTANT

It is essential to check that the cursor orientation before attempting to operate the tool.

The procedure for loading the tool with fasteners and for fitting the nose equipment to the tool are integral. Refer to the instruction

manual for your specific placing tool EXCEPT FOR 1.6MM (1/16”) AVLUG®WHICH SHOULD BE LOADED ONE AT A TIME PER TEST AS

THE TEST TOOL CANNOT EXACTLY EMULATE THE 07176 PLACING TOOL USED FOR PLACING THIS FASTENER.

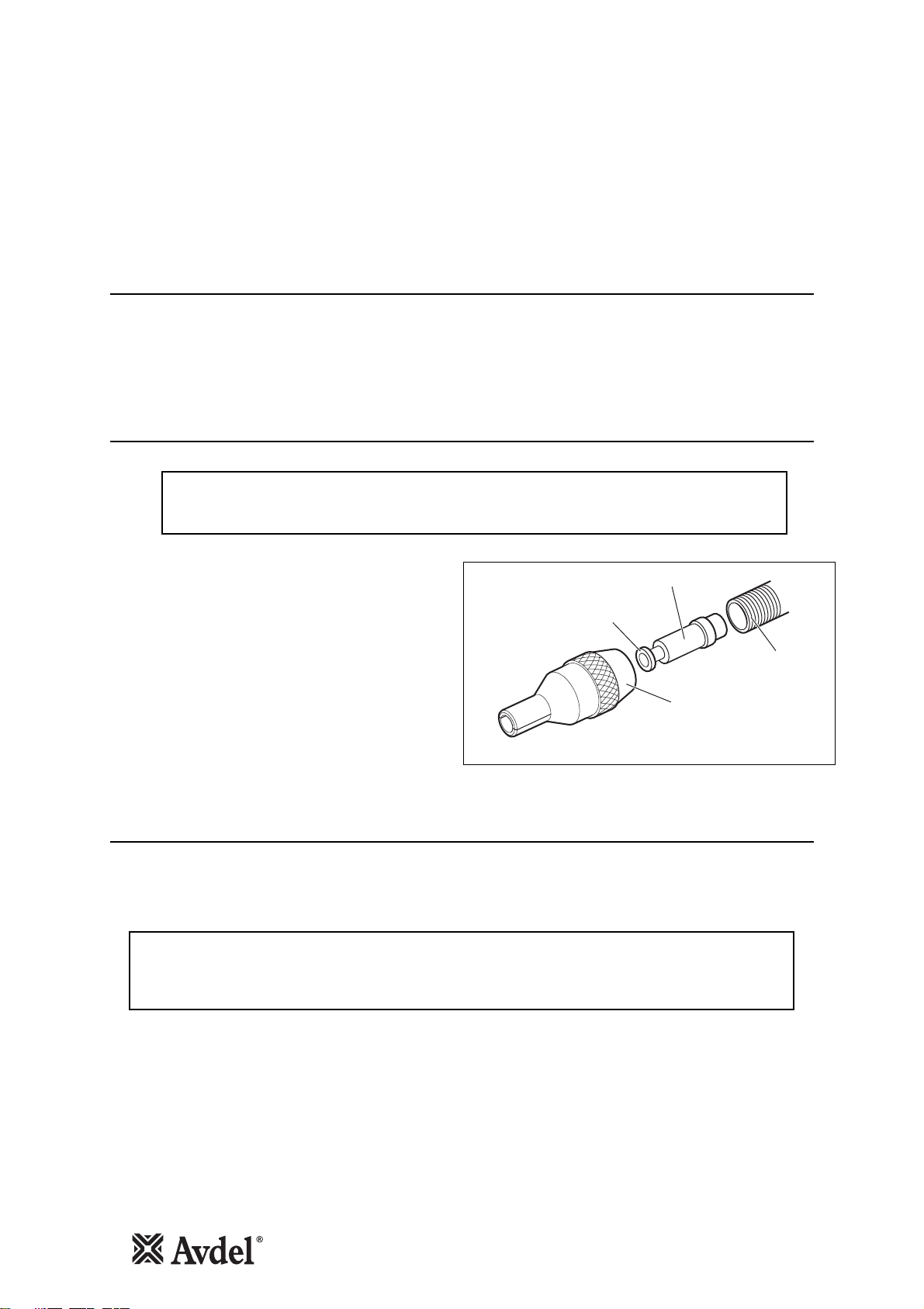

To avoid complete dismantling of the tool check the orientation

of the cursor before fitting the nose equipment to the tool. If

fitted incorrectly, the cursor will not allow feeding of the

fasteners. When fitted the correct way round, the cursor will

easily slide out of the barrel when a mandrel is pushed into its

centre then pulled back. To reverse the orientation of the

cursor, refer to the instruction manual for your particular

placing tool. The sprung loaded, slightly concave, end of the

cursor should point towards the front of the tool as shown

right.

NOSE

JAWS

TOOL

BARREL

CURSOR

SPRING

LOADED END

Fit the same mandrel, follower spring and nose jaws as you intend to fit on the tool which you have selected to place your fasteners

following the ‘tool loading’ instructions in the manual for that tool.

7

Operating Procedure

Putting into Service

IMPORTANT

The test tool MUST be returned to Avdel UK Limited at minimum every 6 months for re-calibration.

A new manual with an updated air pressure versus broach load graph will be supplied in English and in the

official language of your country if EC regulations apply.

NO MAINTENANCE WHATSOEVER MAY BE CARRIED OUT ON THIS TOOL BY ANYONE OTHER THAN

SPECIFICALLY TRAINED AND DESIGNATED AVDEL PERSONNEL. FOLLOWING MAINTENANCE, THE TOOL

MUST BE RE-CALIBRATED PRIOR TO FURTHER USE.

READ THE SAFETY INSTRUCTIONS page 4 carefully.

•Connect the test tool to the air supply.

•Set the gauge on the test tool to zero actuating the

trigger to ensure a true reading.

•Fit the exact same nose equipment to the test tool as

you intend to use on the tool you will be using to place

the fasteners in your application and as recommended in

the instruction manual for your specific tool. Note that

when testing 1/16” Avlug®fasteners NO POD must be

used. A single fastener must be fed at a time. To fit the

nose equipment, follow the ‘Loading the tool’ procedure

in the instruction manual for your placing tool.

•Switch on tail jaws by operating slider valve.

•Offer the protruding fastener into the application applying

a little pressure to ensure that the fastener head rests

against the application (This is crucial to obtain a true

reading).

•Hold the trigger in and SLOWLY raise the air supply pressure until the fastener places. Keeping the trigger held, read the air

pressure off the gauge before releasing the trigger.

•The mandrel is pulled through the fastener which is formed into the application.

•Remove the application. The next fastener will automatically be presented through the front nose jaws, ready for placing.

•The highest of at least 10 readings should be used.

•As the test tool was calibrated, the graph on page 8 will convert the air pressure reading in bars into a broach load in newtons.

TO CONVERT THE BROACH LOAD INTO A MAXIMUM NUMBER OF FASTENER PLACINGS PER MANDREL

•Locate your broach load reading on the scale at the top of the table on page 9 and on the left-hand side, find the line with your

fastener (name and size).

•The maximum recommended number of fastener placings with one mandrel will be shown where they intersect. THIS NUMBER OF

PLACINGS MUST NOT BE EXCEEDED. In case of doubt contact Avdel Fastening Systems for advice.

8

Air Pressure Graph vs Broach Load

9

Mandrel Life Table

MAXIMUM NUMBER OF FASTENER PLACINGS PER MANDREL MAX. LOAD AT

Fastener Tool Broach Load (lbf / N) 5000 PLACINGS

(for which the 100 / 110 / 120 / 130 / 140 / 150 / 160 / 170 / 180 / 190 / 200 / 225 / 250 / 275 / 300 / 325 / 350 / 375 / 400 / 450 / 500 / 550 / 600 / 650 / 700 / 750 / 800 / 850 / 900 /

mandrel is used) 445 489 538 582 627 672 717 762 806 851 896 1008 1120 1232 1344 1456 1568 1680 1792 2016 2240 2464 2688 2912 3136 3360 3584 3808 4032 lbsf N

1/16 Avlug 26000 20000 13000 XXXXXX XXXXXXXXXXX X XX X X X X X X X 127565

3/32 Briv 45700 36300 32500 28800 25100 23400 16000 10200 X XXXXXXXXXXX X XX X X XXXXX177787

2.8mm Rivscrew 50000 30500 25100 20900 16200 14600 13200 10400 8710 7240 6110 XXXXXXXXX X XX X X XXXXX214952

3mm Rivscrew 50000 30500 25100 20900 16200 14600 13200 10400 8710 7240 6110 XXXXXXXXX X XX X X XXXXX214952

2.5mm Avtronic 50000 50000 50000 49000 38900 35100 32400 29500 26600 23700 20400 11200 XXXXXXXX X XX X X X XXXX2411072

# 3/32 Avlug 50000 50000 50000 50000 43200 37200 33900 31600 28800 26300 23200 14500 XXXXXXXX X XX X X X XXXX2441085

3/32 Avlug 50000 50000 50000 50000 50000 40300 35900 33300 30900 28200 25700 18000 6920 XXXXXXX X XX X X X XXXX2581148

3/32 Chobert 50000 42600 33500 28200 23400 20400 17400 15000 12900 10800 9300 6400 XXXXXXXX X XX X X X XXXX2421077

3/32 Grovit 50000 42600 33500 28200 23400 20400 17400 15000 12900 10800 9300 6400 XXXXXXXX X XX X X XXXXX2421077

2.5mm Avsert 50000 42600 33500 28200 23400 20400 17400 15000 12900 10800 9300 6400 XXXXXXXX X XX X X XXXXX2421077

4-40 UNC Avsert 50000 42600 33500 28200 23400 20400 17400 15000 12900 10800 9300 6400 XXXXXXXX X XX X X XXXXX2421077

1/8 Avlug --50000 50000 50000 50000 48400 39800 35900 34500 30900 25700 19100 10800 XXXXXX X XX X X X XXXX2911294

2.8mm Avtronic 50000 50000 50000 50000 50000 50000 50000 44200 38500 35500 33100 27900 21900 14600 XXXXXX XXX X X X X X X X 2951312

1/8 Chobert --50000 50000 41700 35100 29500 26000 22600 20200 18000 12200 9660 7080 5250 XXXXX X XX X X X X X X X 3051357

1/8 Grovit --

50000 50000 41700 35100 29500 26000 22600 20200 18000 12200 9660 7080 5250 XXXXX X XX X X X X X X X 3051357

3mm Avsert ----41700 35100 29500 26000 22600 20200 18000 12200 9660 7080 5250 XXXXX X X X X X X XXXX3051357

6-32 UNC Avsert ----41700 35100 29500 26000 22600 20200 18000 12200 9660 7080 5250 XXXXX X X X X X X XXXX3051357

1/8 Briv ----50000 50000 50000 50000 50000 44200 38500 33100 28200 22900 16800 8510 XXXX X X X X X X XXXX3381504

1/8 Briv (St.Steel) ---------

50000 50000 41000 34600 30500 26000 20900 15700 8900 XXXXXXXXXXXX3901735

3.5mm Rivscrew ----50000 50000 50000 50000 34700 30200 26600 20400 15800 12200 9550 7410 5820 X X X X X X X X X X X X X 362 1610

5/32 Briv -----------32400 25100 20200 16400 13200 10700 8710 7000 X X X X X X X X X X X 443 1971

4.0mm Rivscrew -------

50000 50000 50000 44200 32400 25100 20200 16400 13200 10700 8710 7000 X X X X X X X X X X X 443 1971

4.8mm Rivscrew -------50000 50000 50000 44200 32400 25100 20200 16400 13200 10700 8710 7000 X X X X X X X X X X X 443 1971

5/32 Chobert ----------

48400 35100 26600 21900 17600 14500 11700 9660 7760 5190 X X X X X X X X X X 456 2028

5/32 Grovit ----------48400 35100 26600 21900 17600 14500 11700 9660 7760 5190 X X X X X X X X X X 456 2028

5/32 Briv (St.Steel) ----------------

25100 22400 18600 13600 10500 7590 5620 XXXXXXX6222767

3/16 Briv --------------50000 50000 47900 38500 32700 24300 19700 15500 12200 9660 7500 6100 X X X X 784 3488

3/16 Chobert --------------

50000 50000 47900 38500 32700 24300 19700 15500 12200 9660 7500 6100 X X X X 784 3488

3/16 Grovit --------------50000 50000 47900 38500 32700 24300 19700 15500 12200 9660 7500 6100 X X X X 784 3488

3/16 Briv (St.Steel) -------------------

35900 27500 22600 18400 15000 12200 10500 8700 7000 5500 X 922 4101

6mm Briv ------------------50000 35900 27500 22600 18400 15000 12200 10500 8700 7000 5500 X 922 4101

1/4 Chobert ------------------

50000 35900 27500 22600 18400 15000 12200 10500 8700 7000 5500 X 922 4101

TO CONVERT THE BROACH LOAD INTO A MAXIMUM OF FASTENERS PLACINGS PER MANDREL

•

•

•

Locate your broach load reading on the scale at the top of the table and on the left-hand side, find the line with your fastener (name & size).

The maximum recommended number of fastener placings with one mandrel will be shown where they intersect. THIS NUMBER OF PLACINGS MUST NOT BE EXCEEDED.

In case of doubt contact Avdel UK Limited

Where the achieved broach load is in between two values on the scale at the top of the table, use the higher table value to determine the mandrel life

Note

•

•

•

# Denotes using long mandrel

3/16 Briv, 6mm Briv & 1/4 Chobert - At higher broach loads, tool air pressure may need to be Circa 90PSI

Any application which results in a broach load in excess of that stated for a mandrel life of 5000 rivet placings

(Refer to right hand column of table) should be referred to Avdel UK Limited.

XBroach Load is too high - If close to the lowest number of placings, contact Avdel UK Limited for advice

Never use mandrels to place more than 50000 placings or more than the highest number shown

-

10

Notes

Declaration of Conformity

We, Avdel UK Limited, Watchmead Industrial Estate, Welwyn Garden City, Herts, AL7 1LY

declare under our sole responsibility that the product:

Model: Broach Load Test Power Tool

Serial No. ................................................

to which this declaration relates is in conformity with the following standards:

EN ISO 12100 - parts 1 & 2

BS EN ISO 8662 - part 6 BS EN ISO 11202

BS EN ISO 3744 BS EN 982

ISO EN 792 part 13 - 2000 BS EN 983

following the provisions of the Machine Directive 2006/42/EC

This box contains a power tool which is in

conformity with Machines Directive

2006/42/EC. The ‘Declaration of Conformity’

is contained within.

Date of issue

A. Seewraj - Product Engineering Manager - Automation Tools

Since 1 936 2010Since 1922

www.avdel-global.com

www.infastech.com

02.2011 • © 2010 Infastech

Autosert®(equipment), Avbolt ®, Avdel®, Avdelmate®, Avdel TX2000®, Avdelok®, Avex®, Avibulb®, Avinox®, Avinut™, Avlug

®, Avmatic®, Avplas®,

Avseal®, Avsert®, Avtainer®, Avtronic®, Briv®, Bulbex®, Chobert®, Eurosert®, Fastriv®, Finsert®, Genesis®, Grovit®, Hemlok®, Hexsert®, Holding

your world together®, Hydra®, Interlock®, Klamp-Tite®, Klamptite KTR®, Kvex®, Maxlok®, Monobolt®, Monobulb®, Neobolt®, Nutsert®, Nutsert

SQ®, Portariv®, Rivmatic®, Rivscrew®, Speed Fastening®, Squaresert®, Stavex®, Supersert®, Thin Sheet Nutsert®, Titan®, T-Lok®, TLR®, TSN®,

TX2000®, Versa-Nut®, Viking®and Viking360®are trademarks of Avdel UK Limited. Infastech™ and Our Technology, Your Success™ are

trademarks of Infastech Intellectual Properties Pte Ltd. The names and logos of other companies mentioned herein may be trademarks

of their respective owners. This document is for informational purposes only. Infastech makes no warranties, expressed or implied, in this

document. Data shown is subject to change without prior notice as a result of continuous product development and improvement policy.

Your local Avdel representative is at your disposal should you need to confirm latest information.

AUSTRALIA

Infastech (Australia) Pty Ltd.

891 Wellington Road

Rowville

Victoria 3178

Tel: +61 3 9765 6400

Fax: +61 3 9765 6445

info@infastech.com.au

CANADA

Avdel Canada Limited

1030 Lorimar Drive

Mississauga

Ontario L5S 1R8

Tel: +1 905 364 0664

Fax: +1 905 364 0678

infoA[email protected]

CHINA

Infastech (China) Ltd.

RM1708, 17/F., NanyangPlaza,

57 HungTo Rd., Kwun Tong

HongKong

Tel: +852 2950 0631

Fax: +852 2950 0022

infochina@infastech.com

FRANCE

Avdel France S.A.S.

33 bis, rue des Ardennes

BP4

75921 Paris Cedex 19

Tel: +33 (0) 1 4040 8000

Fax: +33 (0) 1 4208 2450

AvdelF[email protected]

GERMANY

Avdel Deutschland GmbH

Klusriede 24

30851 Langenhagen

Tel: +49 (0) 511 7288 0

Fax: +49 (0) 511 7288 133

AvdelDeutschland@infastech.com

INDIA

Infastech Fastening Technologies

India Private Limited

Plot No OZ-14, Hi Tech SEZ,

SIPCOT Industrial Growth Center,

Oragadam, Sriperumbudur Taluk,

Kanchipuram District,

602105 Tamilnadu

Tel: +91 44 4711 8001

Fax: +91 44 4711 8009

info-in@infastech.com

ITALY

Avdel Italia S.r.l.

Viale Lombardia 51/53

20047 Brugherio (MI)

Tel: +39 039 289911

Fax: +39 039 2873079

vendite@infastech.com

JAPAN

Infastech Kabushiki Kaisha

Center Minami SKY,

3-1 Chigasaki-Chuo, Tsuzuki-ku,

Yokohama-city,

Kanagawa Prefecture

Japan 224-0032

Tel: +81 45 947 1200

Fax: +81 45 947 1205

info@infastech.co.jp

MALAYSIA

Infastech (Malaysia) Sdn Bhd

Lot 63, Persiaran Bunga Tanjung1,

SenawangIndustrial Park

70400 Seremban

Negeri Sembilan

Tel:

+606 676 7168

Fax: +606 676 7101

info-m[email protected]

SINGAPORE

Infastech (Singapore) Pte Ltd.

31 Kaki Bukit Road 3

#05-03/06 Techlink

Singapore, 417818

Tel: +65 6372 5653

Fax: +65 6744 5643

info-sg@infastech.com

SOUTH KOREA

Infastech (Korea) Ltd.

212-4, Suyang-Ri,

Silchon-Eup, Kwangju-City,

Kyunggi-Do, Korea, 464-874

Tel: +82 31 798 6340

Fax: +82 31 798 6342

info@infastech.co.kr

SPAIN

Avdel Spain S.A.

C/ Puerto de la Morcuera, 14

Poligono Industrial Prado Overa

Ctra. de Toledo, km 7,8

28919 Leganés (Madrid)

Tel: +34 91 3416767

Fax: +34 91 3416740

ventas@infastech.com

TAIWAN

Infastech/Tri-Star Limited

No 269-7, BaodongRd,

Guanmiao Township,

71841 Tainan County,

Taiwan, R.O.C

Tel:

+886 6 596 5798 (ext 201)

Fax: +886 6 596 5758

info-tw@infastech.com

UNITED KINGDOM

Avdel UK Limited

Pacific House

2 Swiftfields

Watchmead Industrial Estate

Welwyn Garden City

Hertfordshire AL7 1LY

Tel: +44 (0) 1707 292000

Fax: +44 (0) 1707 292199

enquiries@infastech.com

USA

Avdel USA LLC

614 NC Highway 200 South

Stanfield, North Carolina 28163

Tel: +1 704 888 7100

Fax: +1 704 888 0258

infoA[email protected]

Manual No. Issue Change Note No. Date

AA 03/008 06-02-03

AB 03/338 06-10-03

AC 07/176 24-05-07

AD 11/082 31/03/11

07900-00683

Table of contents

Other Avdel Power Tools manuals

Avdel

Avdel T40 User manual

Avdel

Avdel 74201 User manual

Avdel

Avdel 74101 User manual

Avdel

Avdel 7241 User manual

Avdel

Avdel 7385 User manual

Avdel

Avdel 7287 User manual

Avdel

Avdel Genesis nG3 User manual

Avdel

Avdel Genesis 7537 User manual

Avdel

Avdel Genesis G1 71204 User manual

Avdel

Avdel Genesis G2LB User manual