203729

Rev. E, 11/20/18

© 2018, THE STANLEY WORKS. ALL RIGHTS RESERVED. 1 of 18

Stanley Access Technologies

Quick-Reference Guide TABLE OF CONTENTS

1. PURPOSE...................................................................................................................................................... 2

1.1 Discussion.................................................................................................................................................... 2

1.2 Applicability................................................................................................................................................ 2

2. PREREQUISITES......................................................................................................................................... 3

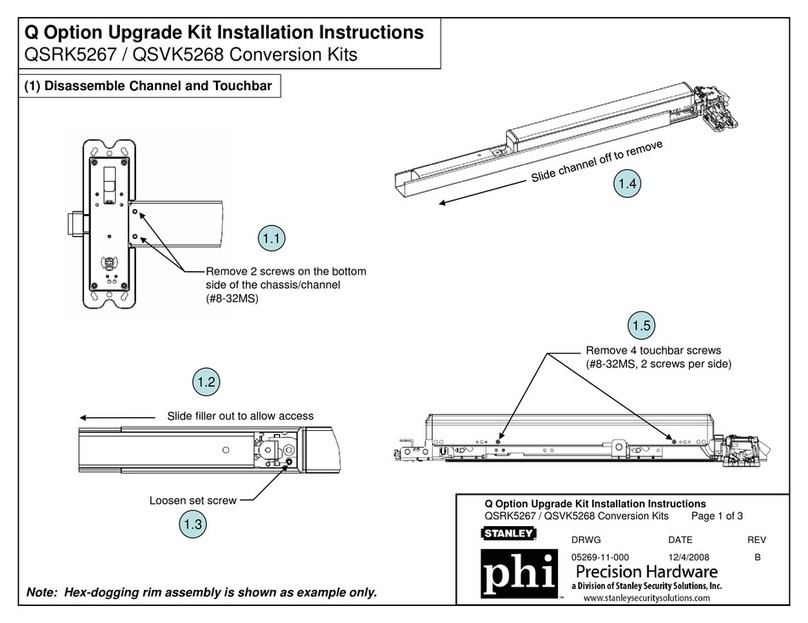

3. INSTALLATION INSTRUCTIONS ............................................................................................................ 4

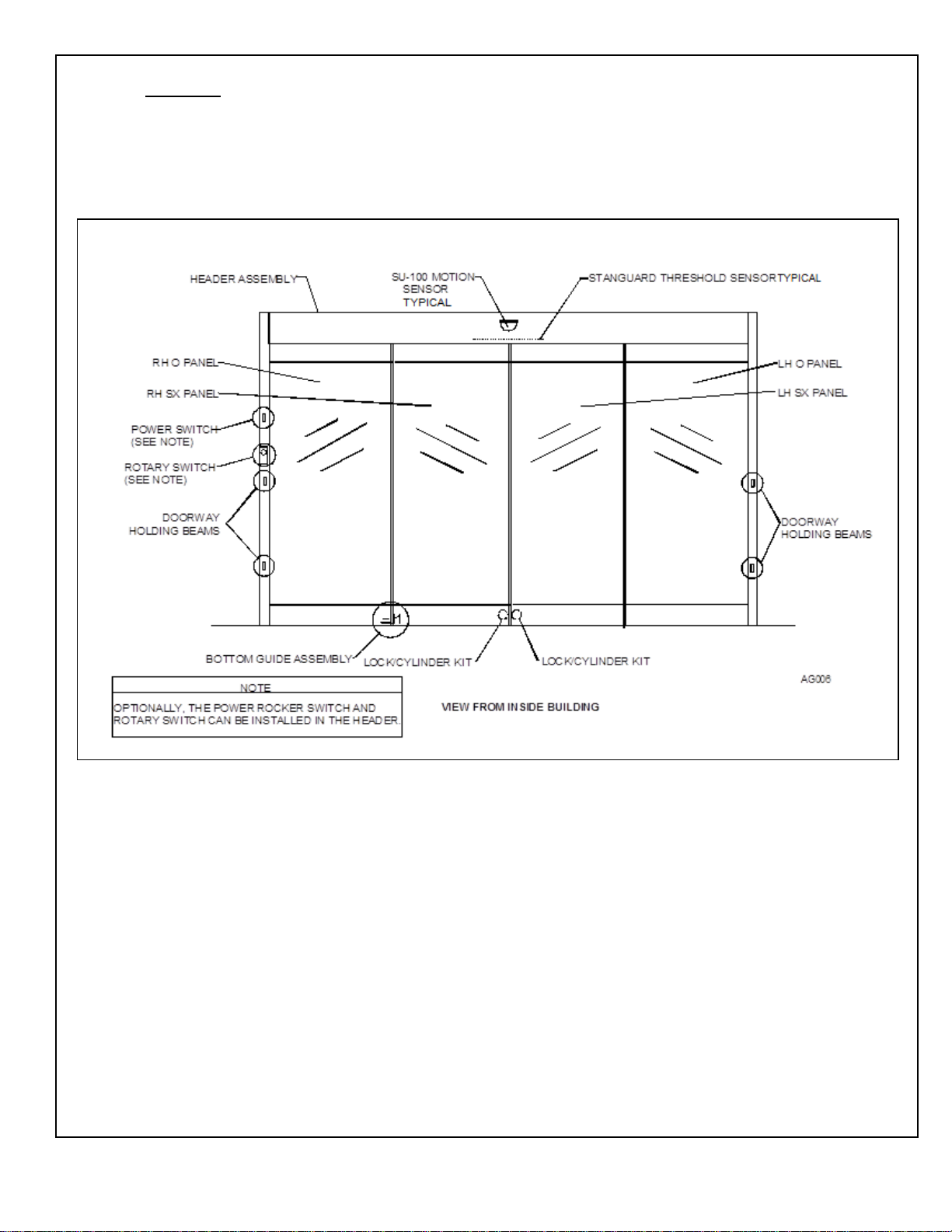

3.1 Installing the Header and Jambs..................................................................................................................4

3.2 Installing the Top and Bottom Rails onto the Glass Panel .......................................................................... 4

3.3 Installing the O-Panel Breakout Switch ......................................................................................................5

3.4 Installing the Lag Bolts................................................................................................................................ 6

3.5 Installing the O-Panel(s).............................................................................................................................. 6

3.6 Installing the SX Panel(s)............................................................................................................................ 7

3.7 Installing the Weatherstripping.................................................................................................................... 9

3.8 Adjusting the SX Panels............................................................................................................................ 10

3.9 Adjusting Belt Tension.............................................................................................................................. 11

3.10 Adjusting the Full-Open Bumper Stops ..................................................................................................12

3.11 Adjusting the SX Panel Emergency Egress Breakout Detents................................................................12

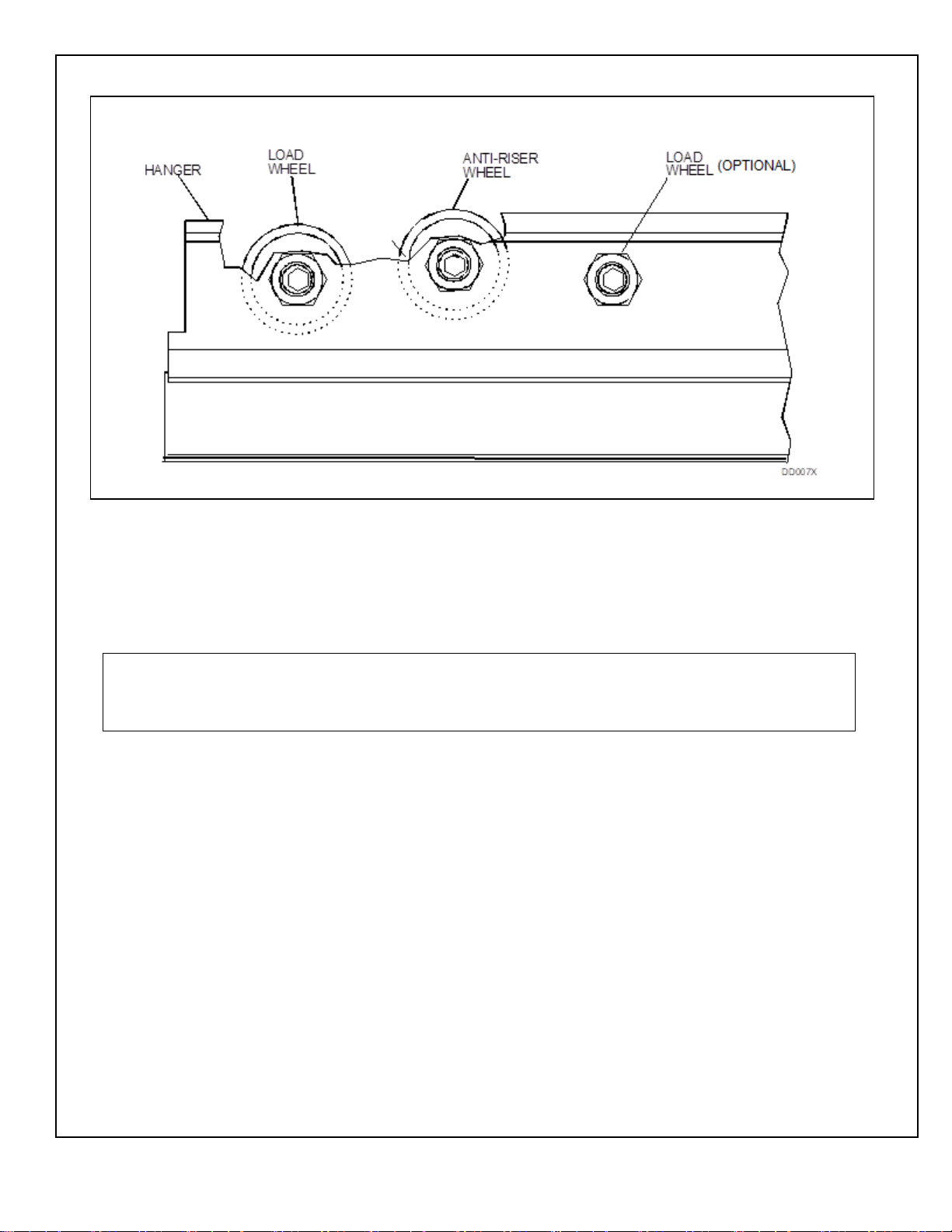

3.12 Adjusting the SX Panel Sag..................................................................................................................... 14

3.13 Wiring the Doorway Holding Beams...................................................................................................... 14

3.14 Installing the SU-100 Motion Sensors..................................................................................................... 15

3.15 Closing Out.............................................................................................................................................. 15

3.16 Replacement Parts ................................................................................................................................... 15

Attachments

Attachment 1, Documents, Definitions, Special Tools, Equipment, Materials, and Consumables ....................16

Attachment 2, Glass Panel Specifications........................................................................................................... 17

Attachment 3, Replacement Parts....................................................................................................................... 18