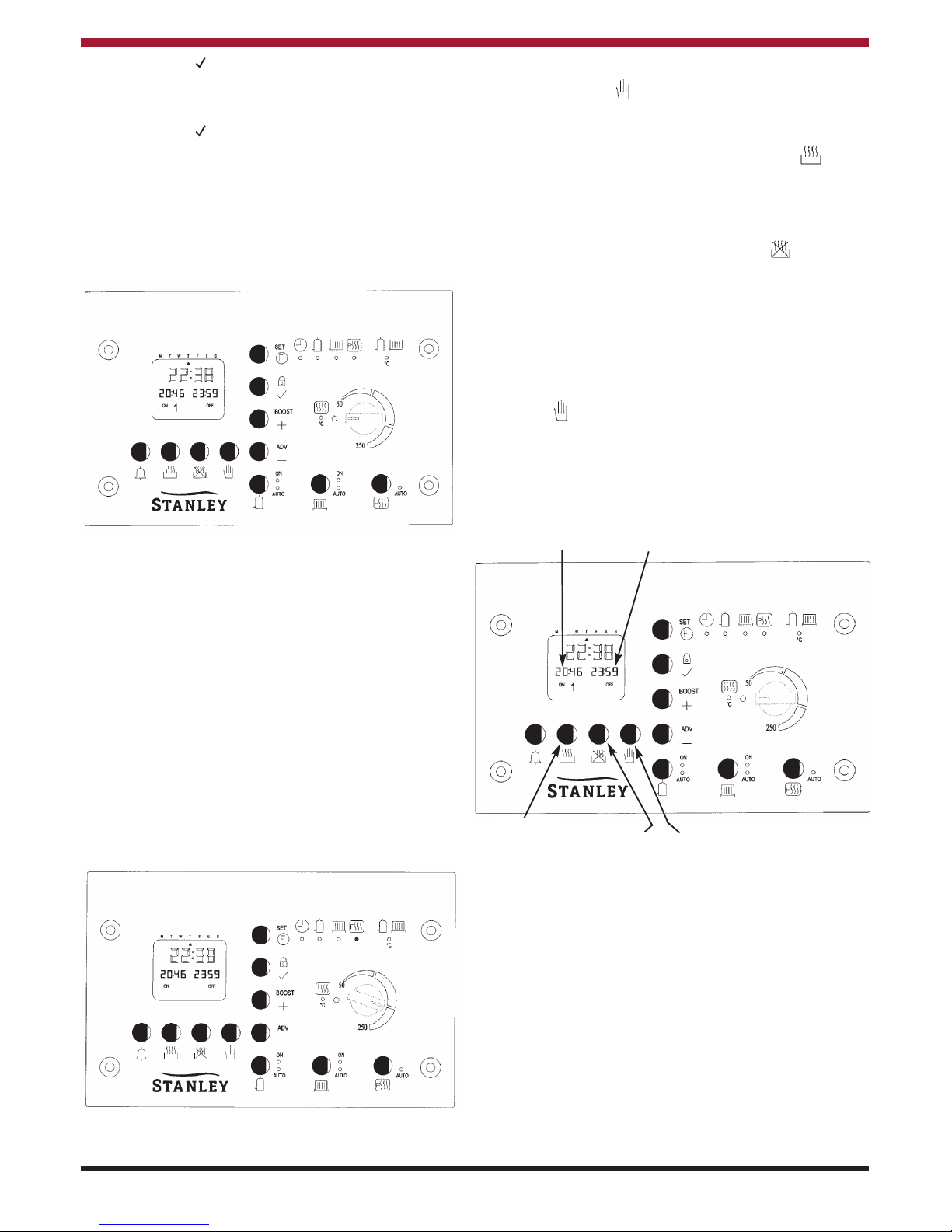

Code no 6 Flue thermistor over temperature

(Gas only)

Code no 8 Oven burner faulty

Code no 9 Boiler Excess Temperature

When an error occurs it can be reset by pressing the

“ ” button for 5 seconds, the code no. on the display

will disappear, if the error is still present the code no.

will reappear, it will be necessary to call the Stanley

service centre.

n the special case of a no. 9 code, this could be due

to all radiator valves being turned off. t is a

requirement that at least 1 radiator in zone 1 is

permanently on.

f Code 4 or 5 appear on the display screen prior to

the fault being cleared using the F button, it will

require the high limit swiches to be reset, to access

and reset the high limit switches take the following

steps:

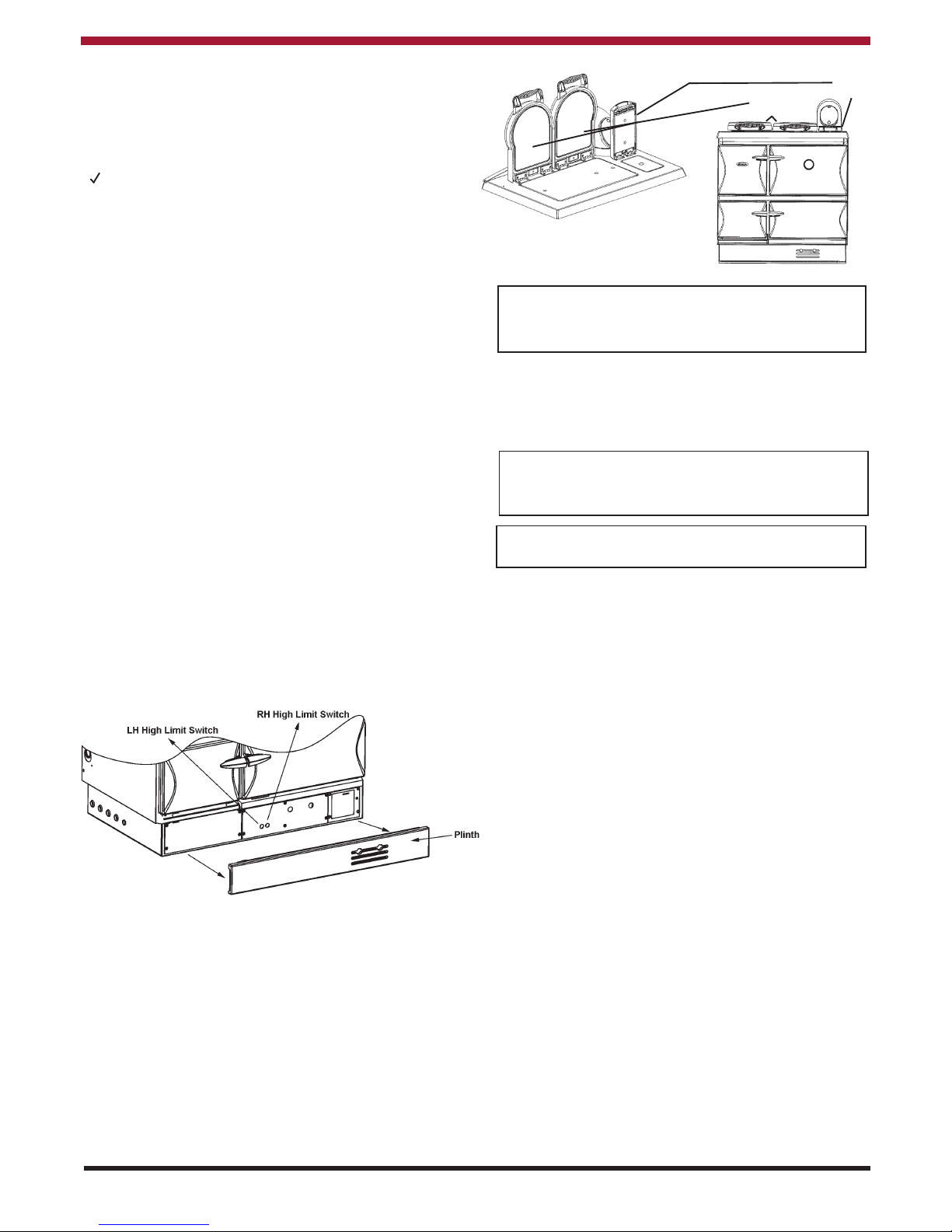

1. Remove plinth at base of cooker, the high limit

switches are located in the centre of the base

plate, see Fig.8.

2. Press the LH & RH buttons to reset the High Limit

reset switches, then press the F button for 5

seconds to clear the fault on the display screen.

However, if the high limit does not reset it may be

due to the appliance being excessively hot, wait until

the appliance has cooled and press the high limit

switches again, if they do not reset when appliance

is cool, please contact your local service engineer.

Fig 8

H T PLATE INSULATING C VERS

The insulating covers retain most of the heat that

would otherwise be radiated into the kitchen. They

also retain the heat in the hot plates so that rapid

heating of cooking utensils will occur when one or

both of them are lifted for cooking purposes.

Hotplate

Covers

Simmer

Plate

Cover

Fig.9 Fig.9a

C KING UTENSILS

For best cooking results and economy of operation

use heavy based, flat bottomed utensils.

IMP RTANT: WHEN HOTPLATE S NOT N USE

ENSURE THAT HOTPLATE COVERS ARE N A

DOWN POS T ON.

IMP RTANT: DO NOT USE M S-SHAPED PANS

WH CH MAY BE UNSU TABLE. DO NOT USE

ROUND BASED WOKS.

IMP RTANT: WE DO NOT RECOMMEND DEEP

FAT FRY NG ON TH S APPL ANCE.

CLEANING

IMP RTANT: BE CAREFUL F THE H T

APPLIANCE.

General cleaning must be carried out when the

cooker is cool.

Stanley cookers are finished in a high gloss vitreous

enamel. To keep the enamel in the best condition

observe the following tips:

1. Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.2.

f milk, fruit juice or anything containing acid is

spilt on the hob or down the cooker, be sure to

wipe it immediately or the vitreous enamel may

be permanently discoloured. Jam and

preservatives containing sugar can permanently

damage the vitreous enamel.

3. Keep a damp cloth to hand while cooking, to

wipe up any spills as they occur, so they do not

harden and become more difficult to remove

later.

4. f spills do become baked on, a cream cleanser

can be used. For stubborn deposits a soap

impregnated pad can be carefully used on the

vitreous enamel.

8