p/n 2M-Z19504 Owners Manual DW, DWN Drawer Warmer Series

7

OPERATION

Heating Options

1. Moist heat with Humitrol Rack:

a. MOIST operation prevents food from drying out as heat is

applied to the warming chamber.

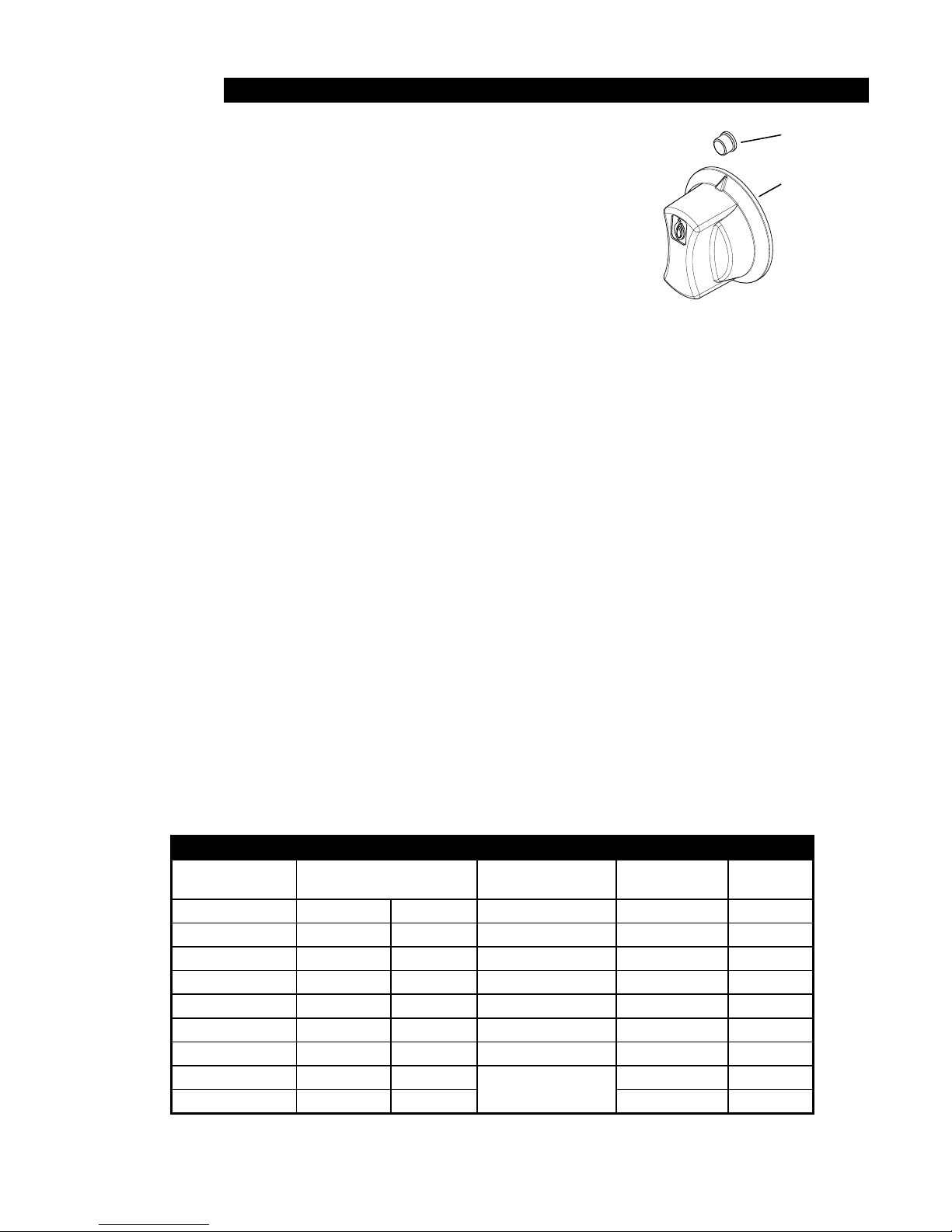

b. To set for MOIST operation, remove the Humitrol Rack

from bottom of drawer insert pan and carefully pour

approximately 2 quarts of water (½” depth) into the pan.

Reinstall rack.

c. When the drawer is closed, the Humitrol Rack allows

water vapor to rise through the stored product in the

drawer. The Humitrol Rack also decreases the sloshing effect of the water in the pan

when the drawer is opened.

d. Place the food directly on the rack. The rack is designed to support the food off of the

steam vents, where water droplets may form.

e. Check the water level in the pan periodically, and add water when necessary.

f. Set the front air vent between fully closed and half-open. Actual setting will depend upon

the type and amount of product stored in the drawer, the temperature setting, and the

frequency with which the drawer is opened.

2. Moist heat with pans:

a. This Star warmer is designed to accommodate any combination of standard-size, steam

table pans.

b. Place a small amount of water in drawer pan. Place the steam table pans in the drawer

pan.

c. Check the water level in the pan periodically, and add water when necessary.

3. Dry heat:

a. For some applications, you may want to store previously prepared foods in a dry-heat

environment. To do so, place the food directly into the empty (i.e. no water) drawer pan.

Exposed surfaces can be hot to the touch and may cause burns.

NOTE:

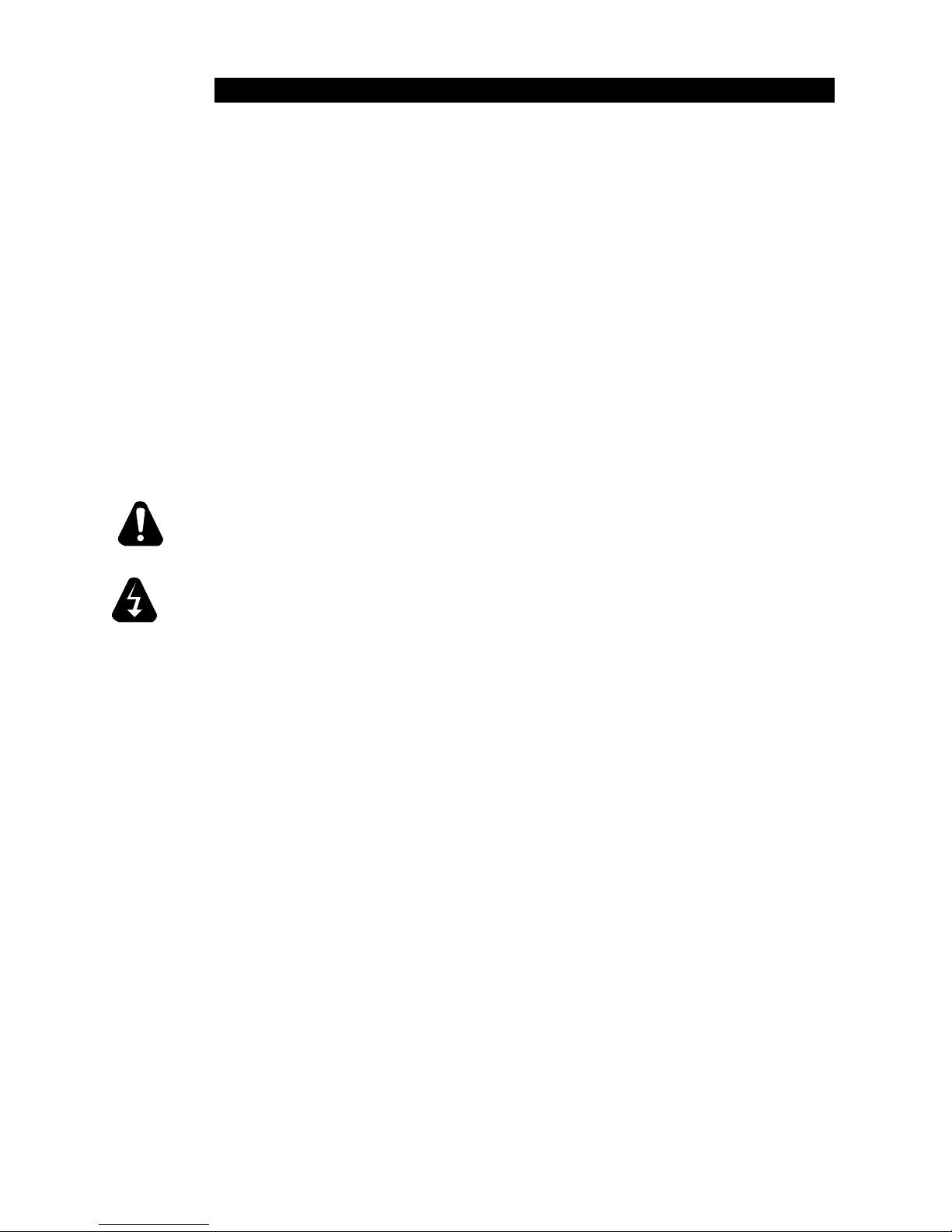

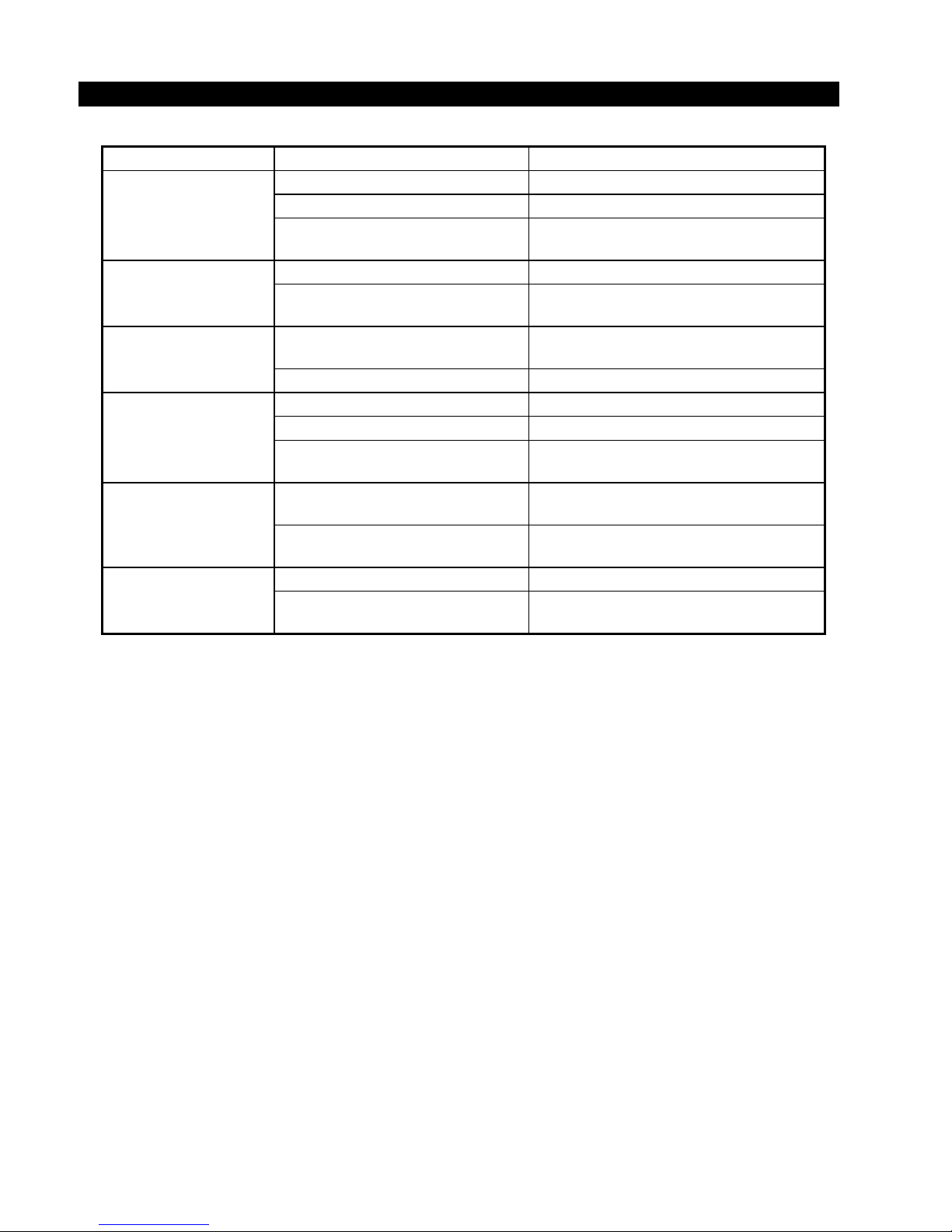

The chart below is intended as a guide ONLY. Your own experience with this appliance, type

of foods and method of operation will enable you to determine the temperature control and air

vent settings best suited to your operation.

HEATING

INDICATOR

THERMOSTATIC

TEMPERATURE

CONTROL

IL2930

OPERATING CHART FOR DRAWER WARMERS

PRODUCT TYPE RECOMMENDED

STORAGE TEMP. TYPE OF HEAT CONTROL

SETTINGS

AIR VENT

SETTINGS

Hard Rolls 160-185ºF 71-85°C Dry 7-8 Full Open

Soft Rolls 150-175ºF 65-79°C Moist 6-7 Open - ½

Vegetables 175-185ºF 79-85°C Moist 7-8 Open - ½

Meats 165-185ºF 74-85°C Dry 6-8 Full Open

Fish 165-185ºF 74-85°C Moist 6-8 Closed

Casseroles 150-175ºF 65-79°C Dry 6-7 Full Open

Pies, Desserts 160-185ºF 65-85°C Dry 6-7 Full Open

Taco Shells 150-170ºF 65-76°C DO NOT put water

in the pan.

4-6 Full Open

Corn Chips 150-170ºF 65-76°C 4-6 Full Open