Stardex INJECTION EXPLORER User manual

INJECTION EXPLORER

STARDEX™ 0501

1. Security information

Read the instructions carefully before using Stardex 0501 (the device).

The device must be connected only to AC 220V with cable from the delivery kit.

Getting of electrical charges on the equipment is strictly prohibited!

Getting liquids inside the device is strictly prohibited!

Device body is constructed to protect its components from mechanical impact while

operating. Avoid body and front panel damage, do not drop the device and do not put

heavy objects on the top of it.

In case of defect (smoke, sparks, specific smell) immediately unplug it and send to the

service center.

All cables from the delivery kit must be supplied with standard plugs and do not have

mechanical damage.

The device does not contain self repairable parts inside. It is strictly prohibited to open the

device.

Keep and use the device in the areas inaccessible to children and pets.

The device is designed to work with Common Rail system. The user must understand

structure and working principle of injection systems.

Incorrect use of the device may cause the damage of the device or user’s injury.

2. Technical requirements and operation directions

Dimensions 230 mm х290 mm х60mm

AC power supply 220V 50Hz

Power consumption 50 W

Operating temperature from -100Сto + 500С

Relative humidity no more than 90% at 250С

Injection sensor

connector

Universal cable

connector

Power supply

connector

3. General Description

STARDEX 0501 is a highly professional universal device for the relative exploration of the

injection characteristics in Common Rail diesel systems and UIS. The device allows making

high precise measurements and registers the delay time of injection (the difference in time

between the moment of getting the electric pulse to the injector and the beginning of

injection) with output parameters on the colored touch screen display in digital and

graphical form. The results of measurements are saved in the device memory that allows

making a comparative analysis of the characteristics of all injectors mounted on the engine,

and making the necessary adjustments.

4. Switching on/off the device, connectors

1) Connect power supply unit connector to the appropriate connector of the device and

plug it in AC 220 V 50 Hz outlet.

2) Connect universal cable to the appropriate connector and connect it to the signal

wires of the injector using the appropriate cap.

3) Install the injection sensor into the appropriate adapter and install it into the fuel line

as close as possible to the nozzle (the best solution is to install the adapter with

injection sensor directly to the nozzle) and connect injection sensor into the

appropriate connector of the device.

4) To switch off the device unplug the power supply unit from the AC outlet.

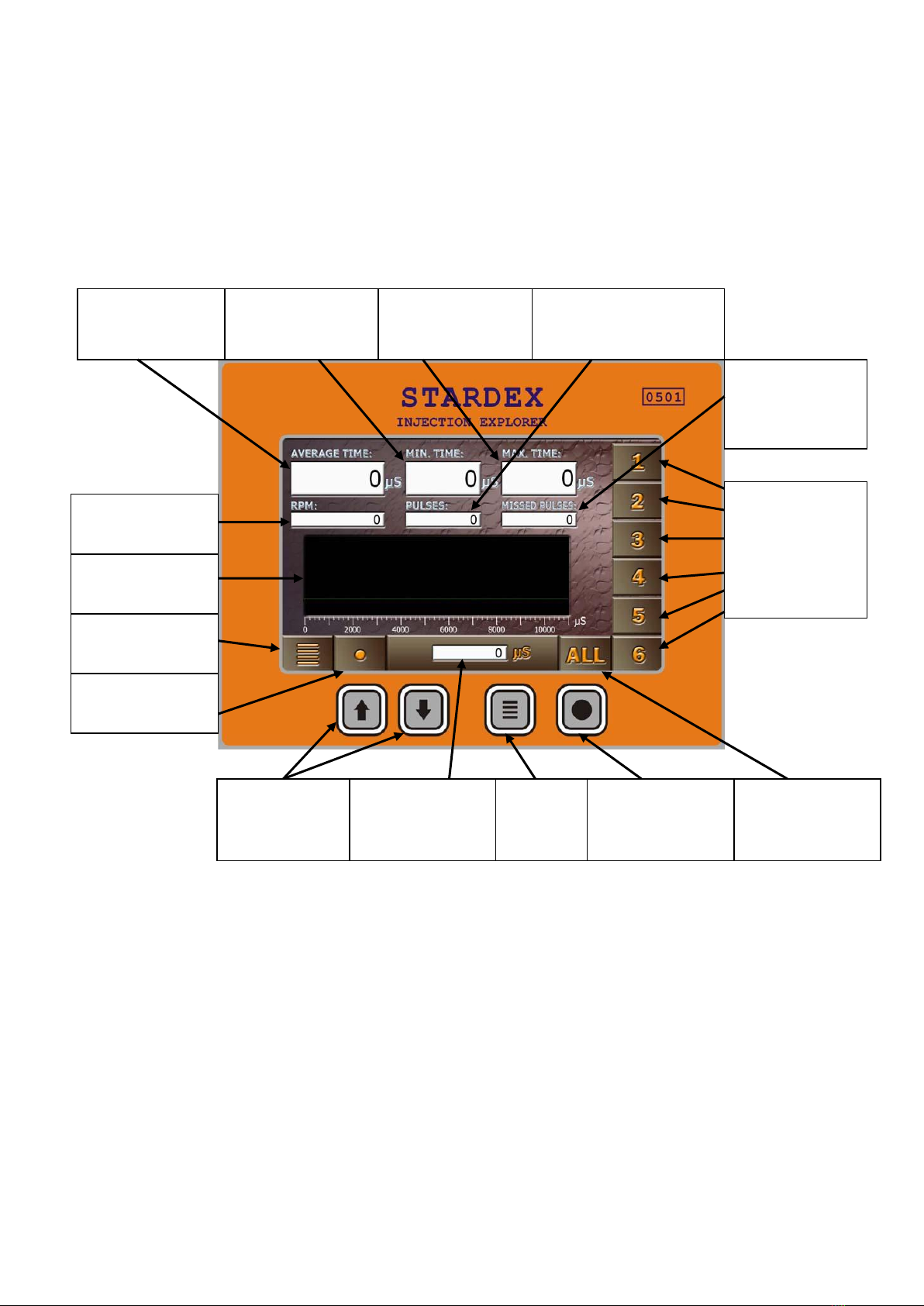

Average delay

time

Minimal delay

time

Maximal delay

time

Accomplished

injection counter

Missed

injection

counter

RPM

Injection

diagram

Navigation

buttons

“Menu”

button

“Reset” button

Interactive

button “Menu”

Interactive

button “Reset”

Interactive

button “All”

Interactive

buttons of

injectors

selection

Delay time on

the graph

5. Interface description and control buttons

Main window

RPM - the number of injections per minute, equal to the revolutions of the CamBox shaft, if

UIS is tested.

Average delay time –average parameter of injection delay time.

Minimal delay time –minimal registered injection delay time.

Maximal delay time –maximal registered injection delay time.

Accomplished injection counter –the number of signals to the injector after which the

injection from the nozzle was registered by the injection sensor.

Missed injection counter –the number of signals to the injector after which the injection

from the nozzle was not registered.

Injection diagram –graphic representation of the injection process registered by injection

sensor. The graph is updated when you click on the Reset button or touch the graph image

area on the screen.

Delay time on the graph –delay time of injection for a particular graph displayed on the

screen.

Reset button –resets all the parameters to the origin and the previous results are not

saved.

Menu button –switches on the device menu. Also the Menu button takes you back to the

main window of the device from the menu or exit from the submenu to the menu with

saving all the made changes.

Navigation buttons –are used for navigation in the menu and also to move between

different results of injectors testing or to display a comparative exploration of all tested

injectors on the screen.

Interactive buttons of injector selection –numbered interactive buttons according to the

order of testing the injectors. They are also used to switch between the results of injectors

testing. Exploration results of each injector are saved in the memory until the device is

unplugged.

Interactive button “All”–opens the statistics window for all tested injectors.

Interactive buttons “Menu” and “Reset” mean the same as “Menu” and “Reset” buttons

on the front panel.

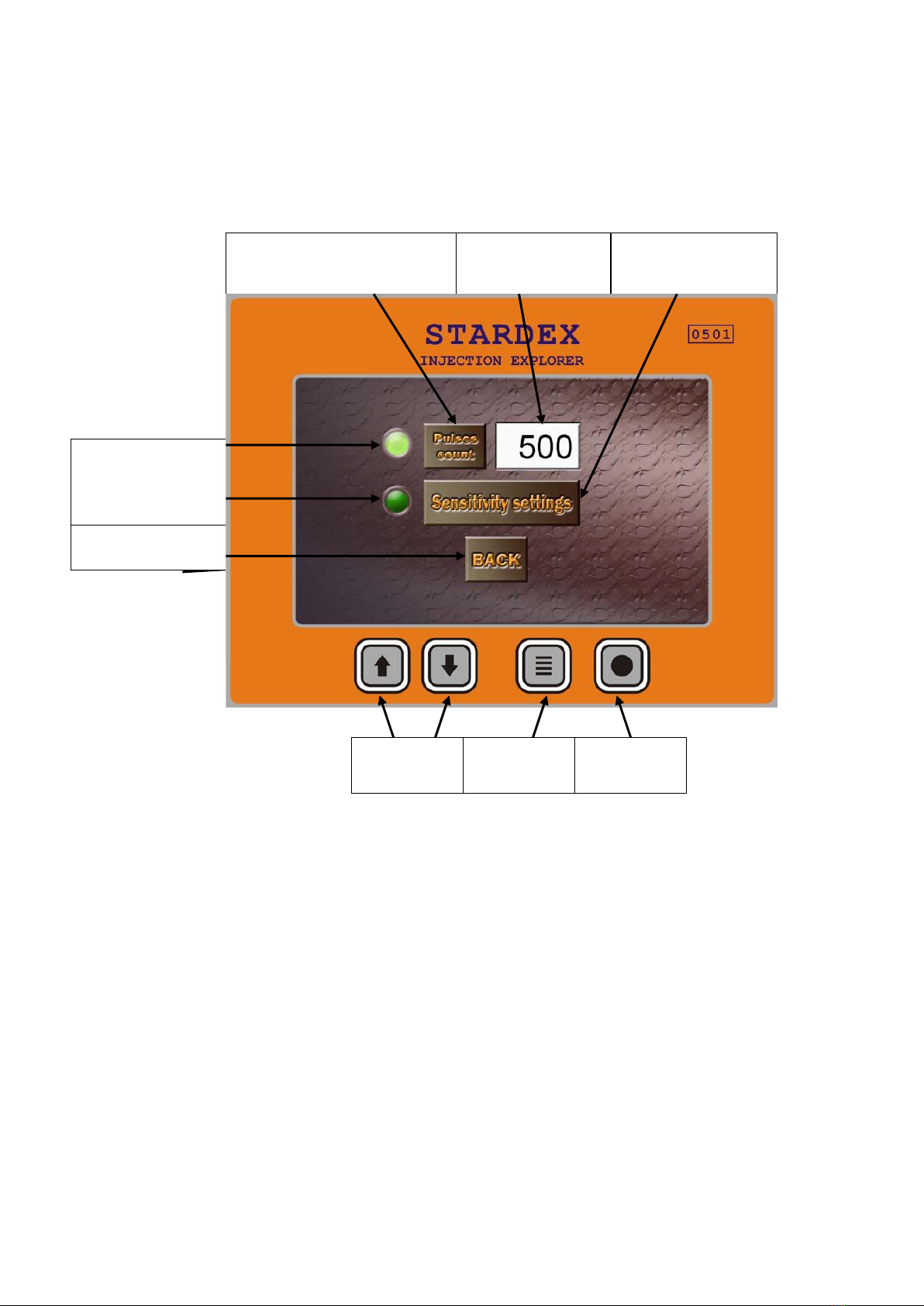

Menu window

Pulses count button –pulses counter changes the number of measurements values

(500, 1000, 2000)

Number of measurements –the number of accomplished injections after which delay

time counting will be finished.

Markers of keyboard control –are used for backlight of the selected menu item.

Navigation buttons –are used for selection of menu items.

Exit button –exits to the main window with saving all the made changes.

Enter button –is used for activation of the selected menu item.

Sensitivity settings button –opens the window of sensitivity settings.

Pulses count button

Number of

measurements

Markers of

keyboard control

Sensitivity settings

button

Exit button

Navigation

buttons

Exit button

Enter

button

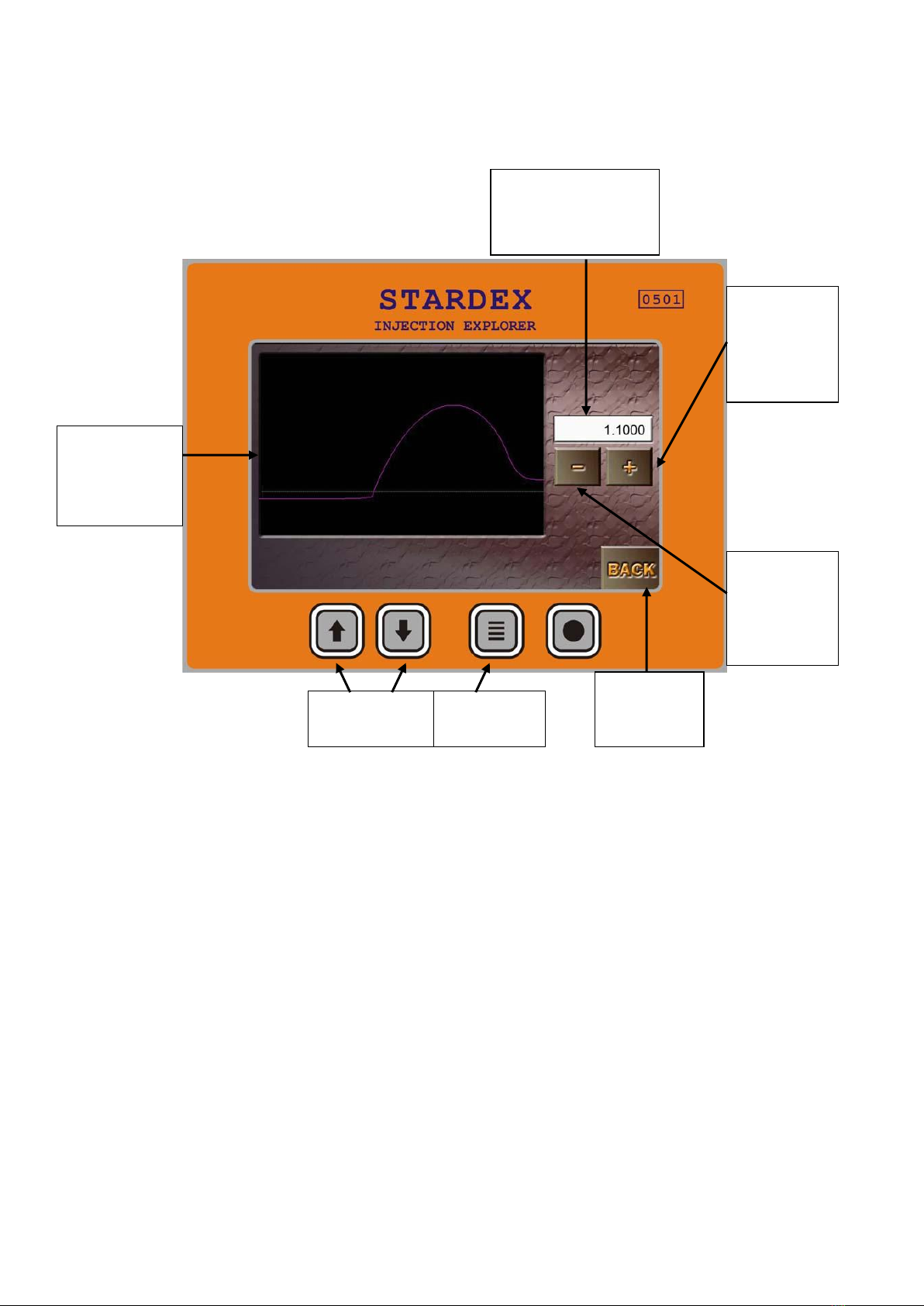

Sensitivity

settings

gragh

Sensitivity

threshold

Decrease

sensitivity

threshold

button

Increase

sensitivity

threshold

button

Exit button

Navigation

buttons

Exit button

Sensitivity settings window

Sensitivity threshold –with the increase of sensitivity threshold the sensor receptivity

to the small fuel supply decreases and vice versa. It is recommended to change the

sensitivity threshold only in case of delay time measurements of very small or very large

fuel delivery modes.

Sensitivity settings graph –the curve on the graph schematically shows the level of

injection sensor signal and the horizontal line shows the threshold of sensitivity.

Injection is fixed at the point where the injection sensor signal crosses the threshold of

sensitivity. It is recommended to set the sensitivity threshold in such a way that it will

cross the curve of injection sensor level as low as possible (watch example). The curve of

sensor signal injection level corresponds to the curve of the last injection measured in

the main window.

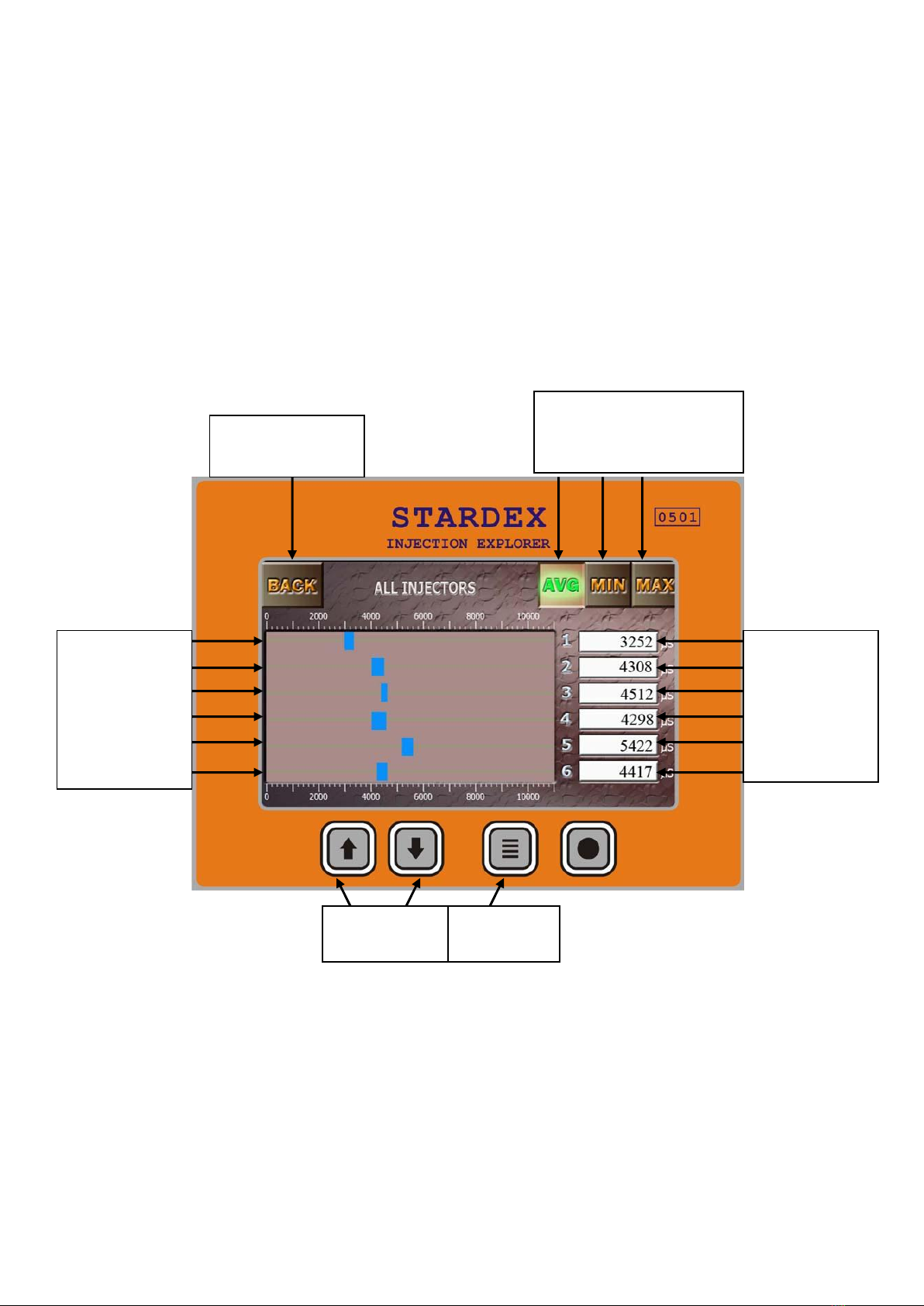

Numeral

values of

injection delay

Type selection buttons of

the injection delay

Values

diagrams of

injection delay

for each

injector

Exit button

Navigation

buttons

Exit button

Decrease sensitivity threshold button –decreases the sensitivity threshold of injection

sensor.

Increase sensitivity threshold button –increases the sensitivity threshold of injection

sensor.

Navigation buttons –change the sensitivity threshold (more\less).

Exit button –saves all changes made in the sensitivity settings window and exits to the

menu window.

Statistics window for all tested injectors

Numeral values of injection delay –numeral displaying of injection delay for a particular

injector.

Type selection buttons of the injection delay–AVG, MIN, MAX buttons change the type of

the displayed parameters in the area of numeral values of injection delay (average, minimal

and maximal).

Values diagrams of injection delay for each injector –graphic display of all delay time

values for all tested injectors.

Navigation buttons –changes the type of displaying values of injection delay AVG, MIN,

MAX (average, minimal and maximal).

Exit button –exits to the main menu.

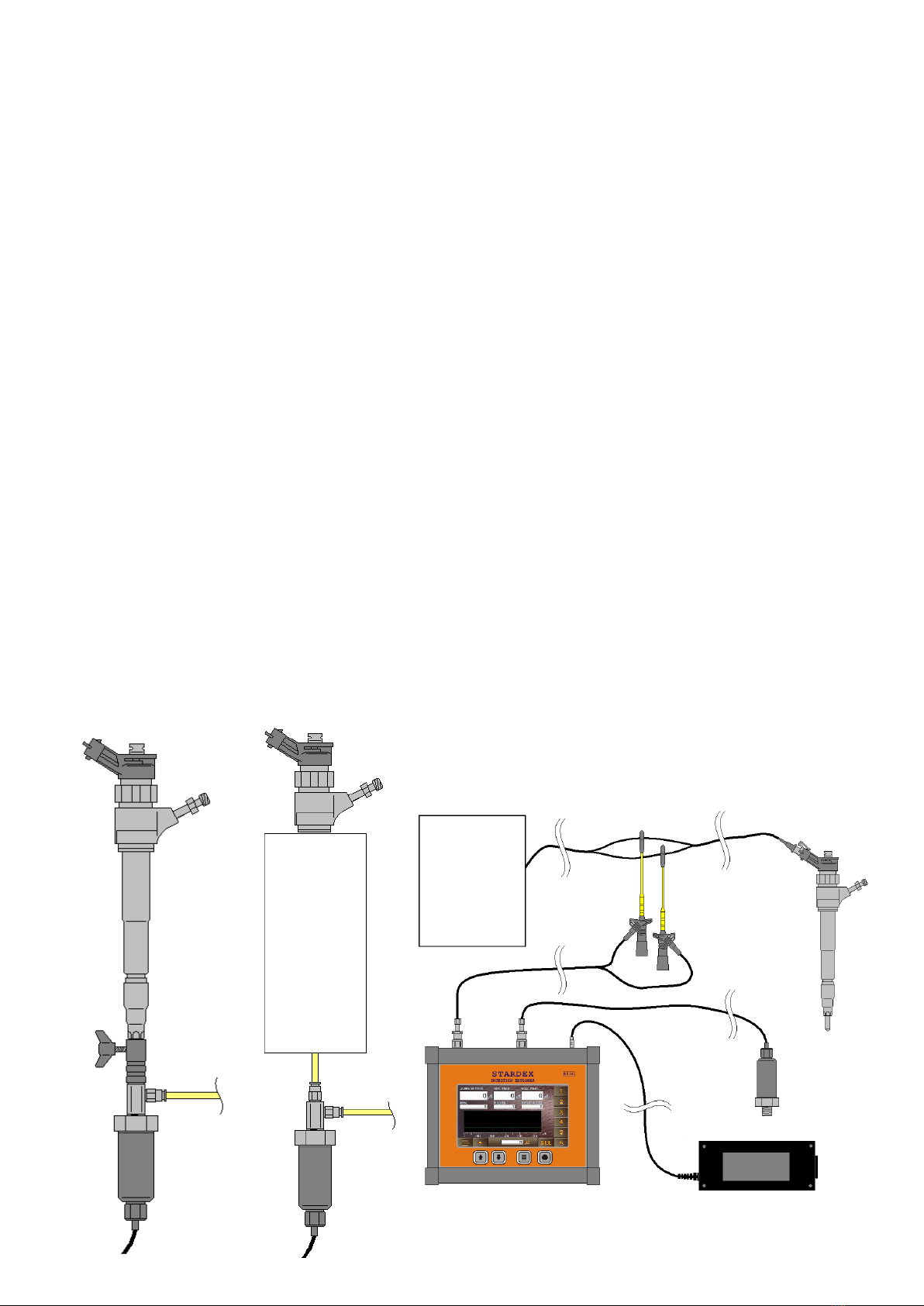

6. Installation on the test bench and the beginning of work.

Switch on the device. Install injection sensor into the adaptor. Install this adaptor directly

on the nozzle of the injector or in the fuel line as close as possible to the nozzle. Connect

the universal cable of the device to signal wires of the injector using universal adapter or

probe so that the signal from the pulse simulator to the injectors comes both on the

injector and on the device. Start the injector testing on the test bench. Wait about a minute

to fill the fuel line. To start the injection delay measurement, choose the number of injector

and press the button “Reset”. When the accomplished injection counter reaches the

number of measurements indicated in the menu window, the counting of all parameters

will be stopped and the results will be saved (it is possible to re-view the results of injectors

testing by clicking the button with the number of required injector in the main window or

open the statistics window for all the tested injectors).

Connection pattern.

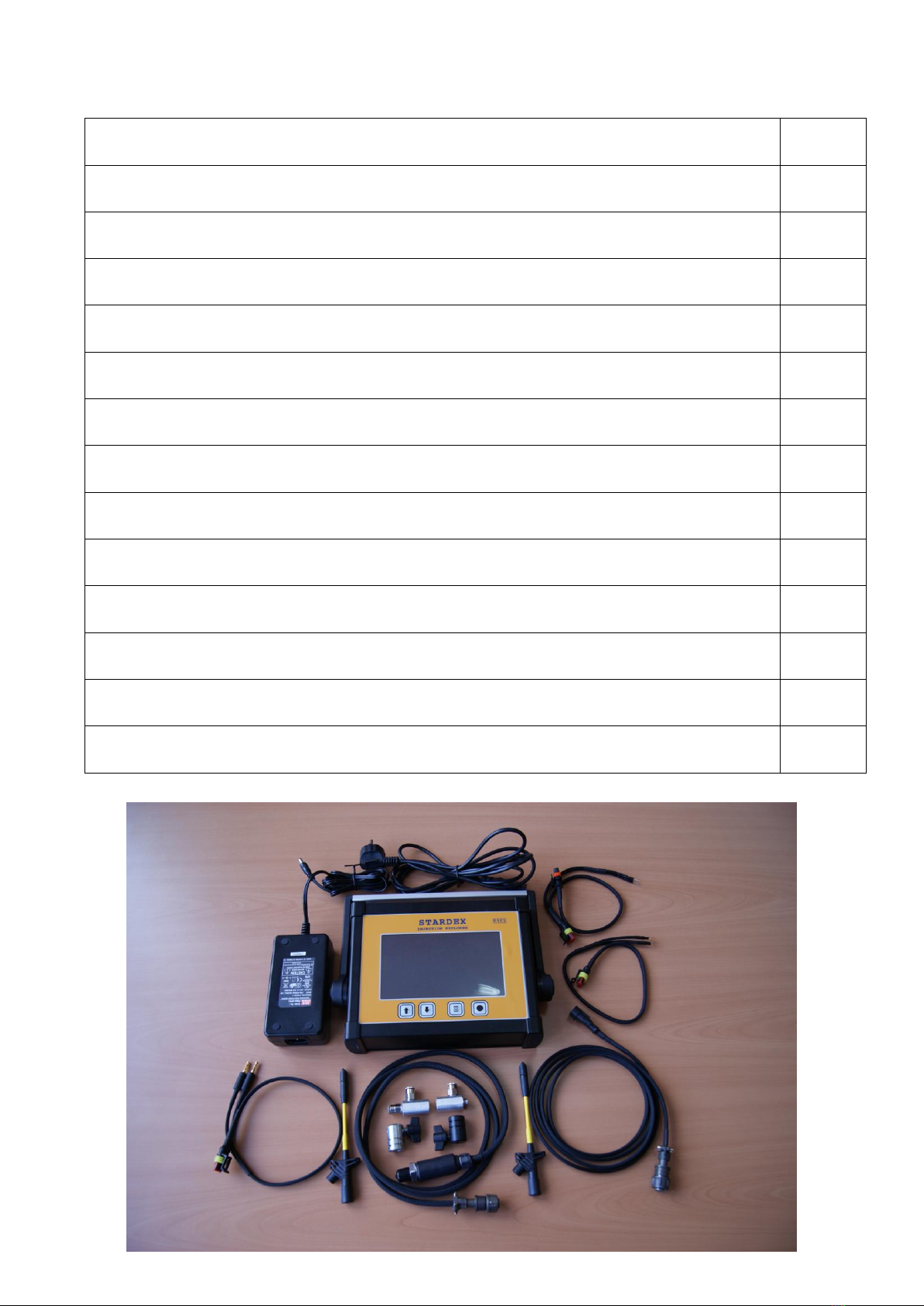

7. Delivery kit

Stardex 0501

1 pc.

Power unit

1 pc.

Power cable

1 pc.

Universal cable

1 pc.

Universal cable adaptor # 1

1 pc.

Universal cable adaptor # 2

1 pc.

Universal cable adaptor # 3

1 pc.

Probes for getting the signal from injector cables

2 pc.

Injection sensor

1 pc.

Fuel disperser d 7 mm

1 pc.

Fuel disperser d 9 mm

1 pc.

Adaptor #1

1 pc.

Adaptor #2

1 pc.

Technical description

1 pc.

8. Warranty and technical support.

The equipment has 2 year warranty. The manufacturer is not responsible for the damage

due to violation of the operation terms, misuse including unskillful or mistaken personnel

actions and if there are traces of mechanical impact.

9. Package.

The product is packed into bubble wrap and carton box.

Manufactured by:

STARDEX OY

PULTTITIE 2

00880 HELSINKI

FINLAND

www.stardex.fi

This manual suits for next models

1

Table of contents