8

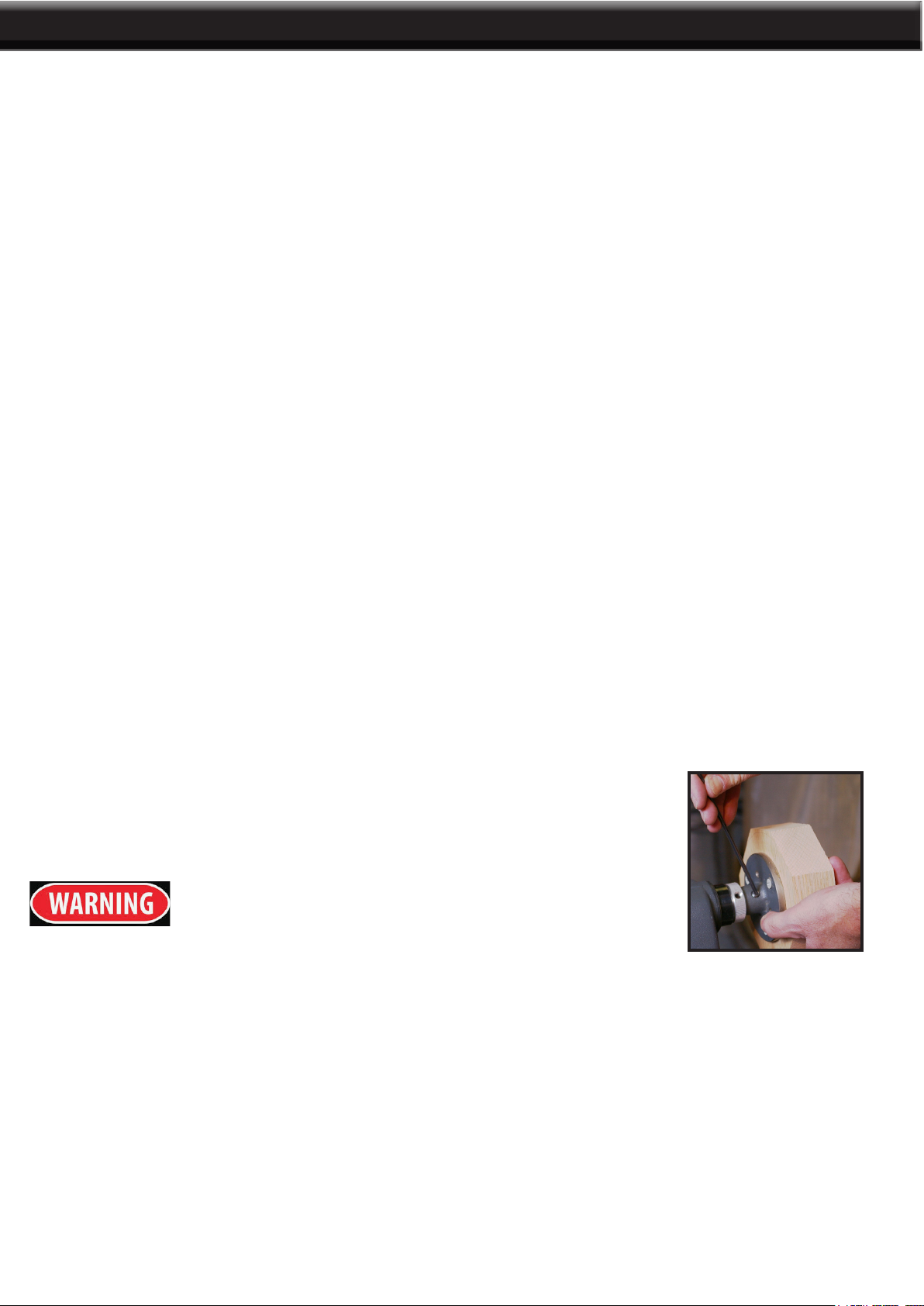

The tool is nearly always used to make nished cute, to cut vees and beads and to square shoulders.

It produces the best nish that can be obtained without a chisel. To avoid dulling, it should be used very

little for scraping. For nish cutting, the skew is held with the cutting edge considerably in advance of the

handle, bevel side down. Keeping the skew well over the work, pull it back until the edge begins to cut,

then swing the handle into position to advance the cut. Both the toe and heel of the skew can be used for

taking light cuts. To avoid burning the tip of the tool, do not penetrate the wood too deeply without cutting

clearances.

USING A SKEW

A shoulder can be the side of a square portion left in the work piece, the side of a turned section, or the

end of the work piece. Most shoulders are perpendicular to the work axis but a shoulder can be at any

angle.

CUTTING A SHOULDER

First, mark the position of the shoulder with a pencil held to the revolving work piece. Then make sizing

cut via the parting tool, placing the cut about 1/16” outside the shoulder position. Cut to within 1/8” of the

depth desired for the area outside the shoulder position. Cut to within 1/8” of the depth desired for the area

outside the shoulder. If the shoulder is shallow, the toe of the skew can be used to make a sizing cut. Do

not go in than 1/8” with the skew unless wider vees are cut to provide clearance for the tool.

Use the gouge to remove any waste stock outside of the shoulder. Smooth the section up to within 1/8”

of the shoulder unless it is more than 1” high, it is best done with the 1/2” skew. First, use the toe of the

skew to remove the shavings from the side of the shoulder down to the nished size. Hold the skew so

the bottom edge of the bevel next to the shoulder will be nearly parallel to the side of the shoulder. Make

sure this is with the cutting edge turned away at the top so that only the extreme toe will do the cutting.

If the cutting edge is at against the shoulder the chisel will run. Start with the handle low and then raise

it to advance the toe into the work. Cut down to nished diameter of the outside area, then clean out the

corner by advancing the heel of the skew into along the surface the outside area. Tilt the cutting edge with

the handle raised up so that only the extreme heel does the cutting if the shoulder is at the end of the work

called “squaring the end”. In this case, reduce the outer portion to a diameter about 1/4” larger than the

tool center diameter, saw off the waste stock later.

Use a pencil mark to indicate edges, then rough it out to within about 1/8” of the desired nish surface

by scraping with the gouge or round nose chisel. If the cove is to wide, sizing cuts can be made to plot

the roughing out. Once it is roughed out, the cove can be nished in two cuts; one from each side to the

bottom center.

CUTTING COVES

At the start of either cut, gouge is held with the handle high and the two sides of the blade held between

the thumb and forenger of the tool rest handle, just above the bevel. Position the ngers ready to roll the

blade into the cove. Hold the blade so that the bevel is at a 90 degree angle to the work axis, with the point

touching the pencil line and pointed into work axis.

From this start, depress the point slightly to start the cut, then continue to move the point down in an arc

toward the bottom center cove. At the same time, roll the chisel uniformly so that at the end of the cut, it

will be at at the bottom of the cove. The object is to keep the extreme point of the gouge doing the cutting

from start to nish. Reverse movements to cut the opposite side.

OPERATION AND ADJUSTMENTS