3

Document No: CMM.2000.106 Rev: 1

Version : 22.034

Section 1: INSTALLATION

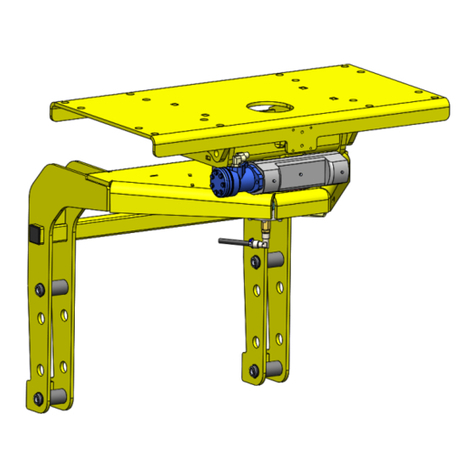

Section 1.1: Installation of Horizontal Hinged Closure

NOTE: The lifting eye on the door is the preferred method of moving the closure, but should it be

moved by hand, the handle on the door should be used. DO PULL THE CLOSURE WITH THE LATCH

HANDLE. The latch is not designed to withstand the weight of the closure, as it is a hand operated

safety mechanism to prevent the closure from being opened when the PAV is engaged.

Installation Instructions:

• Ensure the closure is level during the installation process

• Properly align the hub with the mating pipe

• Position the hinge vertically to permit easy opening and closing of the door

Section 1.2: Attachment of the Closure

NOTE: All welding should be performed by qualified welders in accordance with qualified procedures

such as ASME, API, ANSI, etc. These codes require that the welder and the weld procedure be

previously qualified. To avoid hub warpage, complete all nozzle and attachment welds prior to

closure installation.

Standard Hub Materials:

•Non ASME or door only: 2” thru 14” - ASTM A694 Grade F52

•Non ASME or door only: 16” thru 30” - ASTM A694 Grade F65

•Full ASME Code Stamped (door and hub): SA 350 LF2

The above are our standard hub materials, however other material yield strengths may be provided

based on customer requirements. It is important to always refer to material test reports (MTRs) to

determine weld procedure for actual materials being welded.

IMPORTANT: A bleeder valve and a pressure gauge must be installed on the vessel the closure is

welded to. An operator must be able to bleed the pipeline/vessel and determine when there is zero

(0) psig within the pipeline/vessel.