Sivu 9 / 18

7. OPERATING THE ROAD GRADER

Before operating the road grader, make sure:

-the road grader is installed correctly

-all locking pins are in place

-hydraulic hoses are connected right and properly

-hoses are intact

-there are no oil leaks

-all functions are working properly

-learn to operate the road grader in a closed area before actually using the device

7.1. Operating instructions

1. Make sure that the attachment and the base machine are compatible in terms of mechanical solutions,

hydraulics and electricity

2. The road grader is attached to the towing hook on the base machine. Engage the parking brake. Attach the

road grader to the base machine.

3. Turn off the base machine and make sure the parking brake is applied.

4. Make sure there is no pressure in the base machine hydraulic system. When connecting, always make sure the

hydraulic connectors are clean and the hoses are intact.

5. Check carefully the attachment’s, the base machine’s and the fitting’s trajectory for collision. Make sure that the

hydraulic hoses and attachments have enough space. If needed change places of the hoses in the base

machine.

6. Stay alert for any abnormal behavior and oil leaks also during driving.

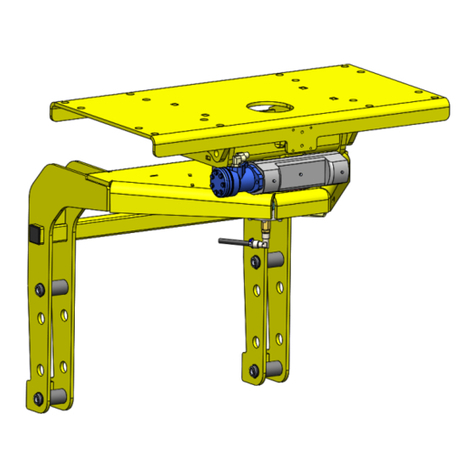

7.2. Grading adjustmets

Grader is equipped with a remote controller, which allows to control all actions with one 2-way section valve. Controller,

it’s fastener and power socket are added to the base machine.

Operating the controller:

-Attach electricity from the base machine with a 3-pin power socket.

-Turn the controller on with a green START-button (must be done every time the power supply stops).

-Operate controllers’ buttons simultaneously with the base machine’s directional valve.

-When transferring the grader turn off the controller with a red STOP-button.

-The warning light of the controller lights up 100 hours before the batteries are empty.

-If there is an error in controller, recode it.

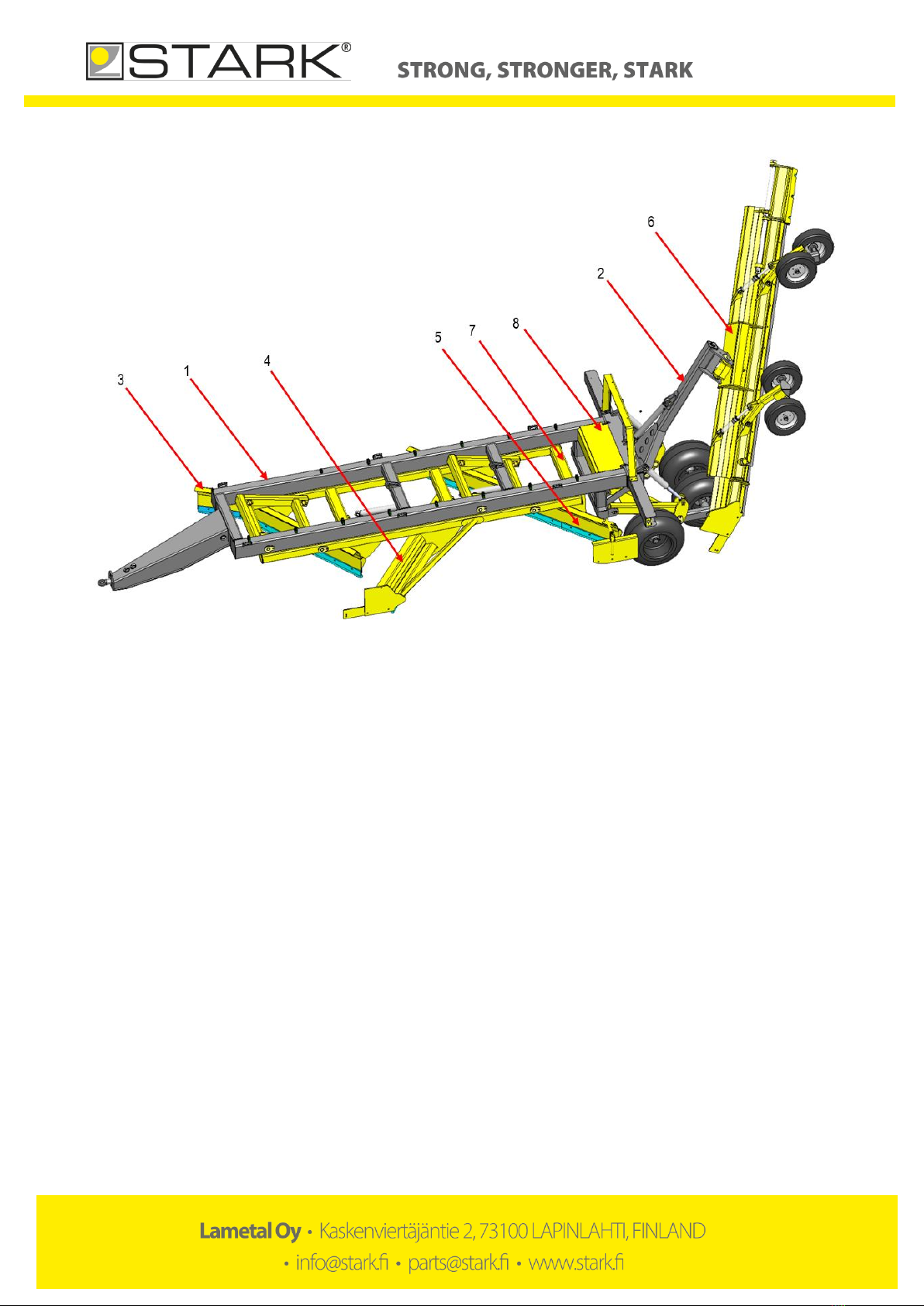

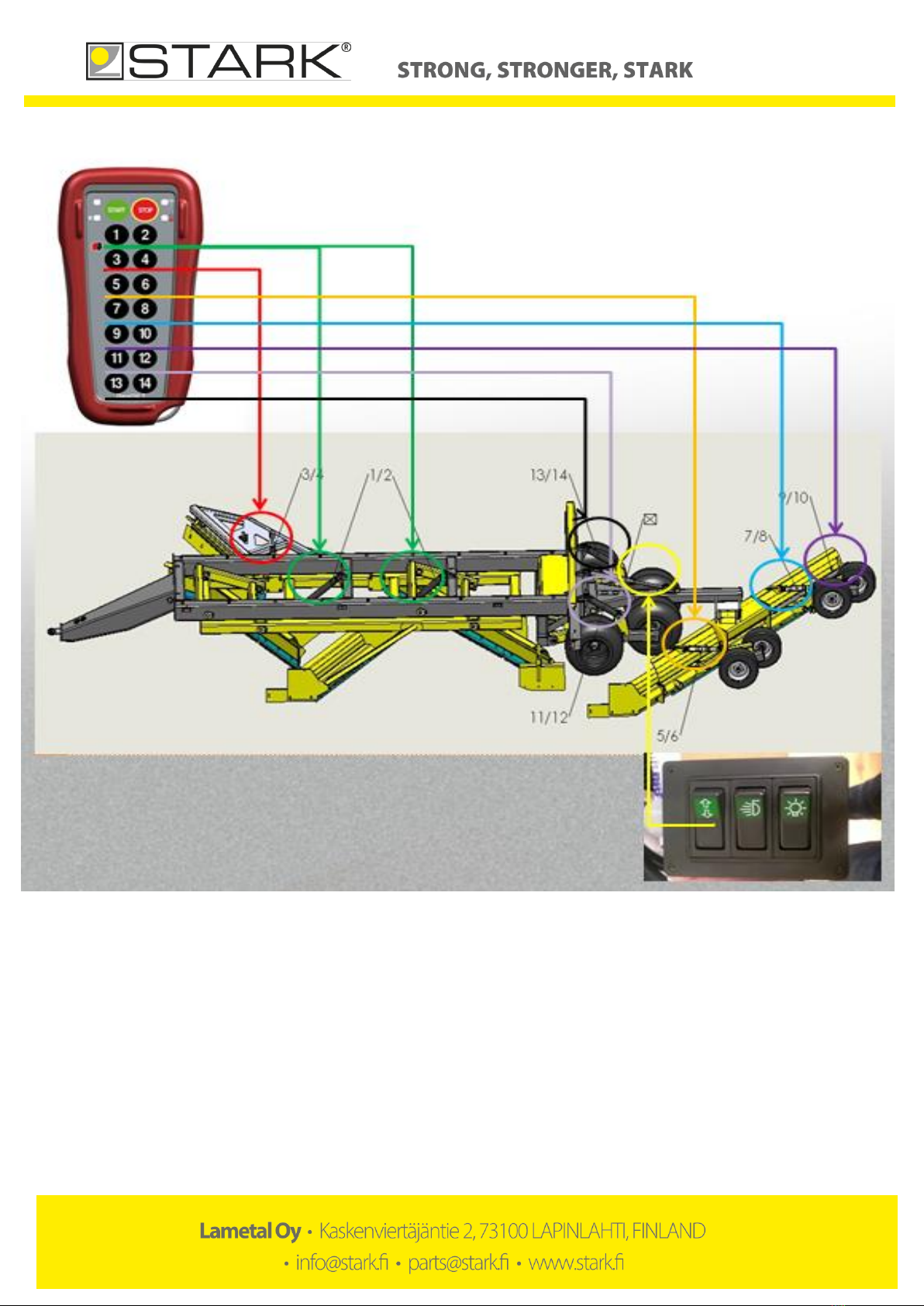

Functions of the controller (picture 3):

-Main blades of the grader lift/descent with buttons 1 and 2. When transferring the road grader keep main

blades all the way up.

-Main blades’tilt can be adjusted with buttons 13/14 and 11/12. Use slope pointer to check the slope of the

grader.

-Windrow blade lifts/descents with arrow buttons of controller box. When transferring the road grader keep

windrow spreader all the way up.

-Windrow blade’s tilt can be adjusted with buttons 5/6 and 7/8. Windrow’s height depends on the depth of the

grading. If there is sand coming out of windrow blade, it is too close to the road. Windrow spreader is adjusted

correctly when rocks come out of windrow blade and transferred material spreads evenly on the road.

-Width of the windrow blade can be adjusted with buttons 9 and 10.

-If grader is equipped with side blade, it can be adjusted with buttons 3 and 4. When transferring the road

grader keep side blades all the way up.